DW Plastics Ltd

We are specialist plastic extrusion manufacturers producing high-quality custom plastic extrusion profiles. As experienced and customer-orientated plastic extrusion manufacturers, we supply high volume plastic extrusions at competitive prices to a variety of customers across wide range of trade sectors.

We are plastic extrusion manufacturers and our well-equipped factory has a wide range of extrusion equipment, allowing for the manufacture of a great variety of plastic extrusion products for many industry sectors.

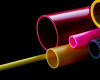

Our manufacturing facilities provide the flexibility to produce PVC extrusions in a variety of shapes, sizes and colours. Our extrusion lines can handle tubes up to 160mm in diameter and profiles up to 350mm wide.

-

Make UK Membership

12 April 2023Britain has a long history of manufacturing, and although this has declined over the years, it is still one of the world’s largest manufacturing nations.

D W Plastics is proud to be part of Britain’s manufacturing sector, supporting the local and UK economy.

We are pleased to have become members of Make UK, which is an organisation that helps to promote and support British manufacturing.

It campaigns and influences to get the best deal for manufacturing businesses. It also links companies and individuals for a common cause – creating an ideal environment for manufacturers to flourish and compete.

-

D W Plastics takes on additional premises

12 April 2023D W Plastics operates from facilities on the Terminus Road Industrial Estate, Chichester, West Sussex, close to the A27 and within walking distance of the train station.

This site has been the company’s home since 1997. It has recently taken on another adjacent unit, allowing it to continue implementing its expansion plans without moving. D W Plastics now occupies the whole factory on this conveniently located site.

The much-needed extra space has allowed the company to restructure the flow of its work processes and make space for additional storage and production facilities. In addition, it has alleviated the congested factory areas and provided additional production offices with more spacious rest areas and facilities for the staff.

These additional premises form a vital part of a sustainable expansion strategy, allowing the company to streamline its manufacturing and storage processes.

-

What is Plastic extrusion?

12 April 2023What is Plastic extrusion?

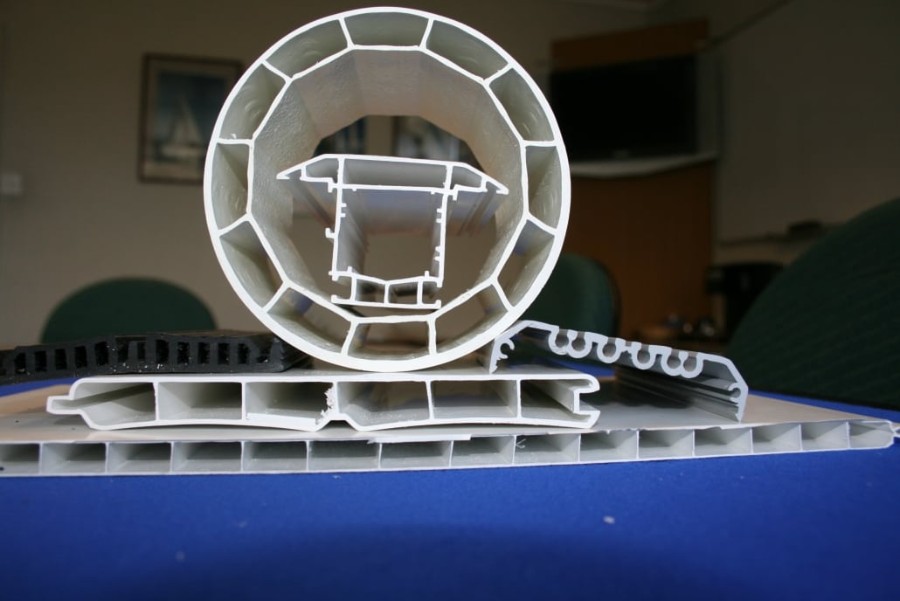

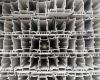

Thermoplastic extrusion is a high-volume production process where a plastic compound is melted at high temperatures and formed into continuous lengths of product. It is one of the most widely used manufacturing processes, along with injection moulding. Extrusion is suitable for two-dimensional product manufacturing, whereas injection moulding is suitable for three-dimensional. Extrusion products can be rigid, flexible, or a combination, covering many industry applications. Common plastic extrusion materials are Polyvinyl Chloride (PVC), Polyethylene (PE), Polypropylene (PP), but there are many other raw materials available in an extrusion grade. The extrusion process can also include co-extrusions with other materials, such as metal mesh or strips.

The extensive list of extrusion products includes pipes, tubes, roofing products, conduits, window and door profiles, fencing, planks, pipe covers, bags and sheets. Industries that use extrusions include construction, electronics, marine, automobile, horticultural, aeronautical, medical, geological, and architectural.The advantages of plastic extrusion:

- Profiles can be made with complex shapes and cross-sections

- Products can be produced in large volumes with minimal wastage

- The continuous, high-volume manufacturing process helps to keep costs low and speed up turnarounds

- It is versatile, as many different types of raw materials can be used, including recycled materials

- Additives can be used to improve the product properties, e.g. fire resistance, anti-fungal, and also to reduce static and friction.

D W Plastics only manufactures profile extrusions and does not make plastic sheets, films, coatings or wire insulation. Please get in touch for any plastic extrusion requirements.

-

Embracing Sustainability: The Pros and Cons of Plastic Extrusion Products Made from Recycled Materials

12 April 2023ADVANTAGES OF USING RECYCLED MATERIALS IN PLASTIC EXTRUSION PRODUCTS

Environmental Impact: Utilising recycled materials reduces the demand for new raw materials, thereby conserving natural resources and reducing energy consumption. Moreover, recycling plastic waste prevents it from ending up in landfills or polluting oceans and other ecosystems.

Cost-Effectiveness: Incorporating recycled materials in the manufacturing process can often result in cost savings, as the price of recycled plastics tends to be lower than that of virgin materials. These savings can be passed on to consumers in the form of lower product costs.

Enhanced Brand Image: By using recycled materials, businesses can demonstrate their commitment to sustainability and environmental stewardship. This can lead to an enhanced brand image, attracting eco-conscious customers and fostering long-term customer loyalty.

Compliance with Regulations: As governments worldwide continue to tighten regulations surrounding waste management and environmental responsibility, using recycled materials in plastic extrusion products can help businesses stay compliant and avoid potential penalties.

DISADVANTAGES OF USING RECYCLED MATERIALS IN PLASTIC EXTRUSION PRODUCTS

Quality Concerns: Recycled materials may contain impurities or have inconsistent properties, which can lead to variations in the finished product’s quality. If reprocessed materials are used to manufacture product there may be variations in colour/shade and shape of the profiles even if only a percentage mix is added to a virgin material. Using recycled material can also make the extrusion process difficult as it can cause variations in the profile’s size and shape which makes it impossible to keep within the specified tolerances. If the products need to look aesthetically pleasing, it is best not to use recycled material, but it may be possible to use a blend of material which may be acceptable.

Limited Material Availability: The supply of recycled plastics can sometimes be limited, depending on market demand and recycling infrastructure. This may result in supply chain disruptions or difficulties sourcing specific recycled materials. D W Plastics recycles most of its scrap material on site which is used in some products or sent away for further reprocessing. However, the quantities are not sufficient to be able to manufacture large volumes of product.

Higher Processing Costs: While the cost of recycled materials may be lower, the processing required to make them suitable for use in plastic extrusion products can be more complex and costly. This includes cleaning, sorting, and reprocessing the materials to meet the desired specifications.

Conclusion

At D W Plastics Ltd, we believe in striking a balance between environmental sustainability and product quality. While there are some disadvantages to using recycled materials in certain plastic extrusion products, the benefits often outweigh the drawbacks. By partnering with us, you can be confident in the quality and sustainability of the plastic extrusion products you purchase.

-

D W Plastics Joins Made in Britain

3 August 2022D W Plastics has become a member of Made in Britain. This initiative helps to promote and support the British market by linking companies with UK-based manufacturers.

As companies look to de-risk their supply chains and look for sources closer to home, there are many benefits of using a UK-based manufacturer, including:Shorter lead times

Products travel less distance, so arrive quicker, which can give a competitive advantage over competitors using overseas suppliers

Possibility of lower minimum order quantities

Smaller order quantities are more cost-effective, tie up less capital in purchases, no overstocking, and have more flexibility on stock

Reduced transport time, which is less harmful to the environment

Every company has to look to lowering its carbon footprint. For a UK company, sourcing products in Britain helps to lower its carbon footprint as transport time is reduced, and less fuel is used, consequently helping to relieve pressure on the environment.

Reduced transport costs

Transport costs are reduced due to shorter transport routes and smaller quantities.

High product quality, better quality control and product traceability

Local suppliers are more likely to work to certified quality standards that meet customer requirements, which also helps with product/material origin and traceability as this assures correct provenance. Quality issues can be dealt with more easily due to shorter lead times should replacement product be required.

Easier communication and flexibility, more control

Contacting and communicating with local suppliers is quicker and easier, especially when discussing technical issues relating to product manufacturing. Samples can be received next-day delivery. Face-to-face meetings are also simpler to arrange and more convenient.

Fewer supply chain risks

Using a UK manufacturer reduces the number of risk factors in your supply chain by eliminating threats such as supply and transport delays, long replacement lead times, and differing quality standards. This will help with business continuity and prevent catastrophic supply interruptions.

Supporting UK economy

Choosing UK suppliers supports the local and UK economy, which many are considering an important factor when selecting suppliers. We are finding that customers are willing to pay more for their products due to all the above advantages. D W Plastics is proud to be manufacturing and promoting British-made products.

-

Achievement Award

3 August 2022The D W Plastics’ team has again been awarded a certificate for good service and performance from one of our customers. It is always satisfying and encouraging to receive recognition for excellent performance and we are pleased to have been able to provide this service over the year. We have a strong track record in manufacturing high-quality extrusion products and our internal systems and processes of quality control give assurances that the level of service and quality will meet customer specifications and requirements. Through our own continuous improvement programme and regular customer contact, we strive to maintain high-quality standards and we pride ourselves in being able to go ‘above and beyond’ by being flexible and reacting quickly to all our customer’s requests.

-

Sponsorship for College Ladies’ Football Team

3 August 2022We are pleased to announce that D W Plastics will continue to sponsor Chichester College Ladies’ football team this season. After the restrictions during the last couple of years, the team will hopefully be able to enjoy a successful, uninterrupted season.

There has been a new influx of players for the current season, trials have been held, and the team has started training again. The team has also already played some matches and remains unbeaten.

Emma Alexandre, Head Coach, said, “The season has started really well. The girls have performed really well. We have won our opening three games. We are also sending five of our girls to England trials next week”.

Sue Burley, Managing Director, said, “We are pleased to be able to continue our sponsorship of the team’s kit this season, and we will be following their progress with interest. We wish them all good luck in their endeavours and every success, but most of all, we hope that they enjoy themselves.”

-

What are plastic extrusions used for?

3 August 2022D W Plastics Ltd is a thermo-plastics extrusion product manufacturer. We supply high-volume plastic extrusions across a wide range of trade sectors. There are many different applications for plastic extrusions. The most common are:

What are plastic extrusions used for? CONSTRUCTION

Apart from the obvious products, such as soffits, wall cladding, guttering, pipework, cable sheathing and insulation, plastic extrusions are used in construction for everything from the concrete foundations to the final interior finishing. Building products such as UPVC lintels, rainwater pipes, guttering, fascias, soffits, electrical conduits, cable protectors, window frames, pipe covers. UPVC is tough and resistant to chemicals, provides good electrical insulation, UV resistant, good impact resistance, good insulation properties, good UV resistance, good impact strength, good fire retardancy, good electrical insulation and damp proofing properties, and weight-saving, durable and therefore sustainable, which provide a positive environmental impact of construction projects. Learn more about plastic extrusion for construction and building projects AGRICULTURE, HORTICULTURE & HYDROPONICS

Using plastic products in agricultural land management and equipment is cost-effective and sustainable. For example, land drainage pipes, animal tagging, animal feeding, plant trays, irrigation troughs and pipes, irrigation, fencing, decking, agricultural equipment, edging products, gardening ties, plastic posts. Plastic is resistant to corrosion underground, is resilient, versatile, reliable, and durable. Learn more about plastic extrusion products for horticulture, agriculture & hydroponics. CONSUMER GOODS

Extruded plastic products have many different uses as parts of durable consumer goods, for example, fridge seals, electrical goods, convenience goods such as bottles and pots containing drinks, cleaning materials, to name but a few. HOUSEHOLD ITEMS

Furniture edge trims and furniture legs are often made with plastic extrusion profiles giving strength, easy maintenance, versatility and weight savings. AUTOMOTIVE

Wheel trims, cable covers, door seals, some interior and exterior trims. DRILLING & GROUNDWORKS

Clips and pipes for gas installations, plastic piping for water, clear sampling tubes, both underground and overground, on land and at sea. Learn more about plastic extrusion products for drilling and groundwork. TRANSPORT SECTOR

PVC extrusions for a variety of applications in the transport sector, including the rail and aeronautical industries, such as glazing seals, plastic sheaths for signalling, power and earthing cables, conduits & trunking for telecom and data cables, rigid PVC drainage pipes, barriers and fence posts. Learn more about PVC extrusions for transport sector. SAFETY & SECURITY PRODUCTS

Protective edge and corner strips, hygienic cladding profiles, fire blanket holders, and sealing strips, including fire-resistant seals. Learn more about plastic extrusions for safety & security products. RETAIL & DISPLAY

Open and covered label holders, ticket & shelf strips, price holders, corner frames for graphic display panels, channelling for display cases, gaskets & seals, poster hangers, clip-on edging, data strips, connector profiles.

Learn more about plastic extrusions for safety & security products. -

Channel Swim Relay – Successful

3 August 2022We congratulate our colleague and the team on their successful swim challenge. They managed to raise over £2,300 for the Marine Conservation Society. Here is a report on the swim:

Swimming the Channel as a relay is all about the team you do it with, it is a huge physical challenge but also very much a mental challenge. Not only is there the seasickness, but also the jellyfish, the huge ships, the cold water and the vast openness of the ocean which can freak you out (even if you don’t start worrying about how deep it is and what’s down there!).

Our team have been training for 2 years with the last few months of intensive sea swimming training. It takes this long, as you need to acclimatise yourself sufficiently to cold water swimming, so basically, swimming in just a swimsuit at least once a week, all winter in either the sea, river, or a lake.

You need a team who support each other not only through the swim but also through the training, as getting in to swim repeatedly when everybody around you is wrapped up in coats and woolly hats is no fun. In addition, there was the added challenge of keeping swim fit and staying mentally positive during multiple Covid-19 lockdowns and limited time in pool swim sessions.

Swim report

Chloe started us off from Dover in complete darkness, just lit by a torch shone on the beach from the boat at 01:18 am and the excitement was high. The water was rolling but nice conditions.

Carmen swam the second-night swim leg.

Unfortunately, by 03:00 am we got hit with seasickness first with Michelle and then Chloe.

Jane swam the 3.30 am sunrise swim, only to find no sunrise just a foggy soup, you couldn’t see anything at all except our boat.

Michelle got in for her first swim and thought the sickness would stop but it didn’t she continued to be sick whilst swimming.

We repeated our order of Chloe, Carmen, Jane, and Michelle for the next rotations of swims, which was when the Jellies decided to come out. Chloe and Carmen both repeatedly stung.

Jane got in for the third swim and was told by the pilot ‘you need to swim fast so we can make the Cap Gris- Nez’, the fastest crossing point. She was exhausted after her hour, but we were close enough in.

Michelle got into lovely flat water as we were out of the shipping lane, so pushed hard to ensure we got close enough inshore to miss the pull of the tide which if you get caught adds approx. 2 hours to the swim as it drags you up the French coast. While she swam the fog finally cleared and the team could see dolphins and a seal.

Chloe had to go in for the 4th swim still unwell but swam hard and pulled us into Wissant Bay, just above the Cap. Carmen took it home to the steps of the Sea Wall at Wissant.

We had glorious sunshine on the way home and finally, the sickness stopped so we could enjoy our achievements. We wanted 14-16 hrs and finished in 13.31 hours we are so very proud of each other, it was true teamwork.

-

What’s the difference between UPVC and PVC?

3 August 2022UPVC (Unplasticized Polyvinyl Chloride, PVCu) is a rigid material that can be used for thermoplastic extrusion and is supplied complexly clear or in a variety of colours and strengths. Unplasticised PVC is one of the stiffest polymers at ambient temperatures and is very durable. It is extremely versatile and can be used for UPVC profiles for internal and external applications, such as window frames, fence posts, trims, pipes, cores, cladding, and trunking.

PVC (Polyvinyl Chloride) has plasticizers added to make the product more flexible. Flexible PVC is a thermoplastic extrusion polymer used in a wide variety of plastic profiles. It can be very lightweight and is available in various softnesses, grades and a wide range of colours. It is very resilient and is compatible with many additives for colour, UV stabilization, and flame retardants. It is used for sleeves, gaskets trims and hosing, seals, handrails, decking products, wire, and cable insulation to name but a few.

-

Why recycle plastics?

3 August 2022Plastic products are a valuable resource and not waste. They should be collected, recycled and reused. Products can be rechipped, melted down and reprocessed into a practical material compound that can be used to make the same or other plastic products.

For example, milk, household detergent bottles, shampoo bottles can be made into new bottles, large and small containers, plastic planks, plastic furniture, playground equipment, recycling bins, T-shirts, fleece clothing, insulation for jackets and sleeping bags, carpeting and more. Plastic bottle caps can be recycled and used to make storage containers, reusable shopping bags, rope, garden tools, car batteries, and more bottle lids.

Plastics have a very good environmental profile:

- Less energy is used to produce it compared to other materials

- Only a very small percentage of the world’s oil production is used for the production of plastics

- Plastic products are durable and when they have completed their practical life cycle, they can either be recycled or incinerated to provide a source of energy

- By being lightweight plastics help to reduce fuel consumption in vehicles, whether in the transport of goods or the manufacture of cars, planes, trains.

- Plastic packaging reduces food waste and saves energy in transport, and is recyclable

- Plastic piping reduces leakages and therefore conserves water and saves energy processing and pumping water.

Plastic products have a huge role in sustainable construction providing excellent insulation properties and are cost-effective and provide durability. Replacing natural products with plastic products saves natural resources, e.g., helps to reduce deforestation.

Recycling plastics helps to:

- Minimise the amount of plastics sent to landfill sites

- Reduces the environmental impact of plastic-rich products

- Helps to conserve oil stocks

- Save energy as it uses less energy than producing new polymers

- Reduces the impact of plastic waste on the environment.

-

Reshoring UK Initiative

3 August 2022D W Plastics has joined the Reshoring UK initiative that has been established and backed by leading trade associations to help connect the manufacturing sector with accredited suppliers who can deliver required products and services. The initiative recognises the need for manufacturing to be ‘re-shored’ to the UK. The B2B web directory will assist OEMs in key industry sectors to link up with UK-based suppliers to fill the gaps in their supply chains.

Baroness Burt of Solihull, Patron of Reshoring UK, says ‘The development of the Reshoring initiative is to encourage engagement with our manufacturing supply chain and to recognise the strength, skills and innovation available to manufacturers in the UK’.

For further information visit the Reshoring UK website.

-

D W Plastics expand manufacturing capabilities

3 August 2022We are pleased to announce that we have expanded our manufacturing capabilities by taking over the plastic extrusion equipment and business from an injection moulding business based on the south coast.

The acquisition is part of our ongoing development and improvement plans to expand our manufacturing capabilities with the aim of providing customers with a wider range of services.

Sue Burley, Managing Director, D W Plastics says:

“Despite the current challenging economic conditions we are pleased to have been able to take this opportunity, which has been mutually beneficial to both companies.”

“It is part of D W Plastics’ on-going development and improvement plans to enable us to expand our manufacturing capabilities to provide all our customers with a wider range of services. We look forward to working with our new customers and co-operating closely with our new injection moulding partner.”

We have been building our reputation as the UK’s home for manufacturing high-quality, bespoke thermoplastic extrusion profiles since 1980. We now have 17 extrusion lines operating 24-hours a day.

Throughout our history, we have rapidly adapted to changes and challenges in the market place, keeping abreast of new developments within the plastic extrusion industry.

We manufacture a wide variety of products for customers in many industry sectors, including profiles for building, horticultural applications, sports and leisure, plumbing products, synthetic decking, safety, groundwork and DIY products.

Last year we joined forces with others nationwide to help create face shields components to help the fight against COVID-19. We deployed our small 3D-printer 24/7 to print components for the shields that were used in hospitals, hospices, care homes and schools during a national shortage in supplies.

Discover our full range of services and products. Alternatively, you can email us at info@dwplastics.co.uk or call us on 01243 774521.

From your first phone call, through to your finished product, our team is here to help you achieve the ideal outcome. Get in touch to discuss your requirements.

-

Christmas Jumper Day

3 August 2022This year’s Christmas Jumper Day was slightly different to previous years for obvious reasons, but it did not stop people getting into the spirit of things. We would like to thank all staff who joined in the fun and wore their special festive jumpers in support of Save the Children’s Christmas Jumper Day on Friday, 11th December. We noted that many jumpers were recycled from the previous year, which we see as very positive news!

Well done to all who took part and thank you for your donations. A total of £130 was raised online for this very good cause.

Save the Children is a charity which helps to ease the suffering of children across the world by helping them to recover from adversity, whether they are at risk due to conflict, natural disasters, or poverty. For further information visit their website: https://www.savethechildren.org.uk/.

-

Congratulations to Chichester College Football Academy!

3 August 2022Very well done to two of Chichester College Football Academy’s team members who have both received their first England College’s Caps. This is a great achievement and we wish academy players Gracie White and Nicole Robinson all the best and hope that there will be many more caps. D W Plastics is sponsoring the college’s female football team over the next few seasons. Unfortunately the team players had their season cut short like many other sports teams, but hopefully matches will be able to resume as normal next term. We will follow progress with interest.

-

PPE Donations for COVID-19 Effort

3 August 2022We are very pleased to report that the Solid Print 3D Covid19 Face Shield Group initiative donated 11,774 face shields to key health institutions around the UK over the past months. D W Plastics is proud to have been able to play a small part in this effort by donating a total of 258 headbands. However with many people doing as many parts as they could, it all adds up! Our small 3D-printer worked 24/7 to print components for the cause and we would like to again thank our local partners who also contributed by printing parts for us to deliver.

The assembled face shields were donated to hospitals, hospices, care homes and schools whilst there was a nationwide shortage in supply. We would like to think that they have made a huge difference by helping to keep key workers and their patients, clients and pupils safe. The scheme has now been closed as the supply of PPE equipment has now been restored, but we are ready to support any further efforts if required.

-

What do footballers do during lockdown?

3 August 2022Unfortunately, the Chichester College ladies’ football team sponsored by D W Plastics had their season cut short like many other sports teams. We were interested in how they were coping with the lack of games and being separated from their teammates. Click here to see what they have been up to during the lockdown period.

-

Continued Support for COVID-19 Effort

3 August 2022As the demand for face shields remains high, D W Plastics continues to 3D-print headbands for the assembly of protective equipment for key workers. Our small prototype printer has been working 24/7 to print components and we are delighted to be able to contribute towards the national effort to supply important PPE equipment. This week another 119 units have been couriered to the “Solid Solutions/Solid Print3D Covid19 Face Shield Group” initiative where they will be processed and sent on for assembly. The feedback has been very positive and we will continue to support the efforts for as long as possible.

-

Face Shield Components

3 August 2022Our first batch of headbands has been dispatched in our efforts to support the nationwide call for the manufacture of face shields for key workers.

The 3D-printed headbands have been sent to the “Solid Solutions/Solid Print3D Covid19 Face Shield Group” initiative where they will be processed and sent off for assembly.

Protective gloves, sanitizer and face masks were used during handling of the products at D W Plastics to ensure the safety of the recipients.

We would like to thank all our local partners who have contributed and sent in their 3D-printed parts for us to deliver.

D W Plastics will continue to support the efforts for as long as possible.

-

Supporting the COVID-19 effort

3 August 2022As well as continuing to supply our customers who are key essential suppliers to the government, NHS and pharmaceutical industry, we have joined the “Solid Solutions/ Solid Print3D Covid19 Face Shield Group” initiative to help with the supply of 3D-printed headbands for face masks. The parts will be printed in small batches and sent to a central hub in the Midlands where they will be sent off for sterilisation and assembly. We are pleased to be able to support the efforts as much as we can.

-

COVID-19 – UPDATE

3 August 2022During these uncertain times caused by the ongoing COVID-19 situation, we would just like to inform you that we have taken the decision to keep our operations open for as long as possible to continue to supply our customers, some of which are key essential suppliers to the NHS and pharmaceutical sectors.

The welfare of our workforce and the wider community is extremely important to us, so we have instigated additional measures to restrict potential exposure to and mitigate the spread of the virus. As many of our employees as possible are now working from home, and we are following Government advice and Public Health Guidelines with respect to safe working practices by increasing cleaning regimes within our facilities and implementing social distancing rules for our manufacturing operations.

We will constantly review the situation based on UK Government advice over the coming weeks and will keep you informed as things change.

-

Christmas Jumper Day

3 August 2022We would like to thank all staff who joined in the fun and donned their special festive jumpers in support of Save the Children’s Christmas Jumper Day on Friday, 13th December.

To add to the fun, prizes were handed out for the best jumpers! The photos show the prize-winning pullovers. Well done to all who took part and donated. A total of £113 was raised on the day for this very good cause.

Save the Children is a charity which helps to ease the suffering of children across the world by helping them to recover from adversity, whether they are at risk due to conflict, natural disasters, or poverty. For further information visit their website: https://www.savethechildren.org.uk/.

-

New Kit for Local College Football Team

3 August 2022We are delighted to announce that we are sponsoring Chichester College Women’s Football team. The partnership will start with immediate effect and will involve front of shirt sponsorship for all strips for three seasons.

Emma Alexandre, who coaches the team, approached the company during the summer after a very successful season which culminated in the team winning the AoC Sport National Championships in April 2018. The team were crowned National Champions after beating competition from eight other college sides (including elite category sides linked to the FA’s Women’s Super League) to claim victory. This was a great achievement for the college’s Female Football Academy, which is only in its second year.

The strip was unveiled earlier this week, and it has been warmly received by the team.

Captain Amber Howden, who is studying sport and exercise science, said: “We love the new kit and we are really grateful to D W Plastics for their support.”

“The kit is really fresh, it’s a new look for us and it makes us feel more professional. It brings us all together under the college colours.”

Matt Wright, Deputy Head of Learning for Sport at Chichester College, said: “The support from D W Plastics means a lot to the team and it is thanks to the hard work of Emma and Sue that this fantastic opportunity has come about.”

“It is great to work with local companies and for them to see value in our sports teams. Being able to buy new kit, in the college colours, is brilliant and it gives the team something to take pride in. We had a fantastic season last year, and hopefully, we’ll be able to celebrate more successes this season.”

Sue Burley, Managing Director said; “We are excited to be supporting the team and are looking forward to following their progress during the season. We hope that they can replicate their success of last season, but most of all that they enjoy themselves. I applaud the Academy’s commitment to promoting the sport to local youngsters to try to inspire them to engage in sport whether football or any other type of sport.” -

Hosting a MacMillan Coffee Morning

3 August 2022Thank you to all who took part and supported our efforts to raise money for MacMillan Cancer Support. It was a fun morning with staff, neighbours and other visitors popping into our offices for tea, coffee and cakes. A total of £111 was raised which has been sent off to help this very good cause.

To see how much has been raised by the Coffee Morning hosts across the country so far visit their website.