Applied Vibration Ltd

Since 1976, Applied Vibration Limited has been designing and manufacturing a range of vibrating feeders, conveyors, screens, tables and elevators for product handling applications. Applied Vibration Ltd designs machinery suitable for use in varied industrial sectors, such as Food Production, Pharmaceutical, Chemical, Glass Manufacture, Recycling and Waste Recovery, Hardware and Component Handling, Extractive (Minerals and Cement) and often other Special Applications on request.

Vibrating Feeders

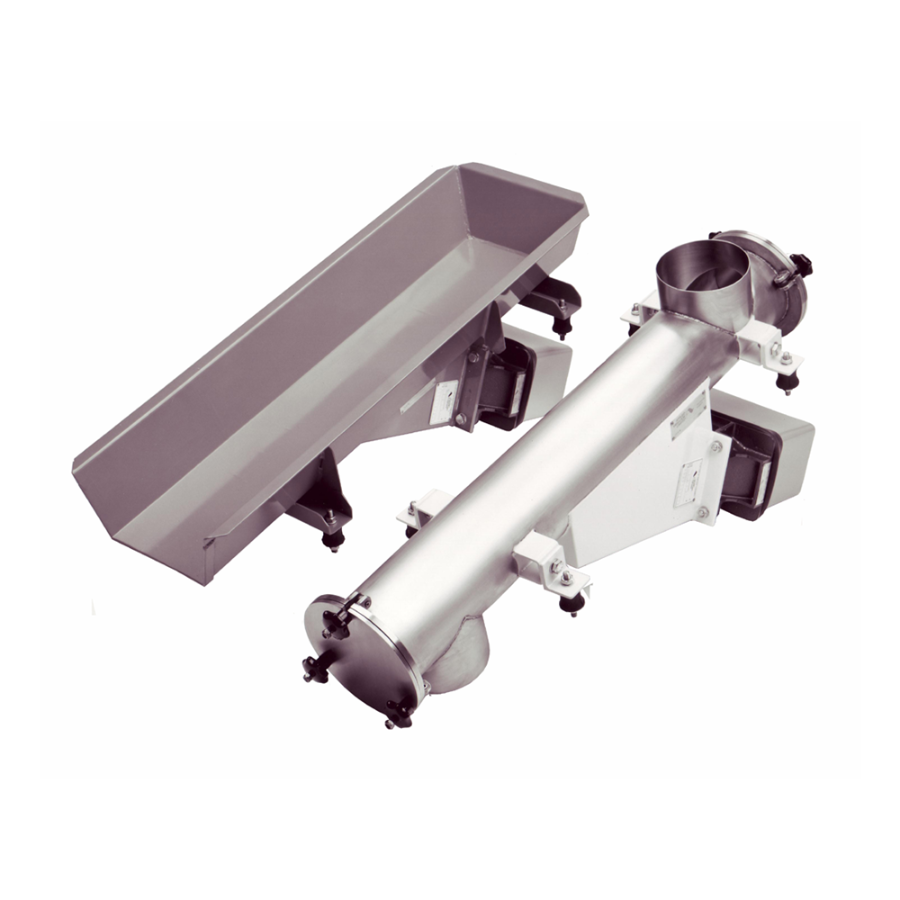

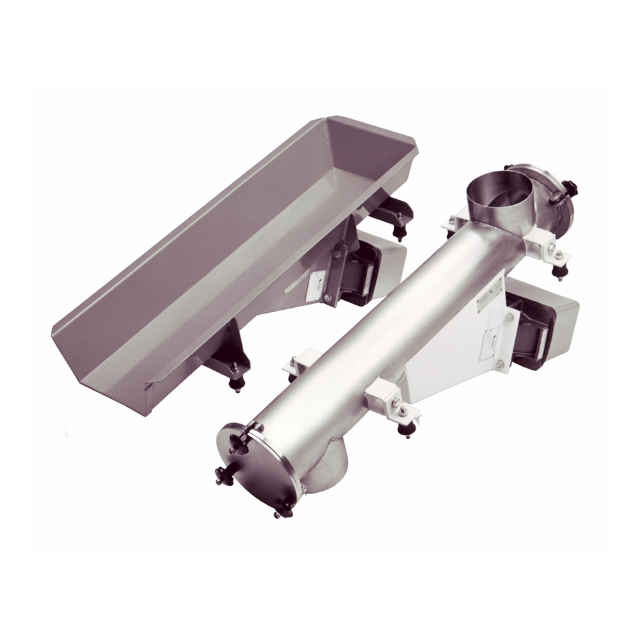

Vibrating feeders are used to discharge a controlled flow of material. Our Electromagnetic Drive Feeders are electromagnetically driven and have an instant stop/start function, making them perfect for weighing, packaging and many other feeding applications.

We design and manufacture a range of open trough, enclosed trough and tubular vibratory feeders, as well as hopper feeders for bulk quantities. Vibrating feeders can be used to transfer a product from one location to another, and to feed material into a container, silo or onto the next stage of a processing line.

Our feeders can be manufactured to high hygenic standards, making it suitable for the food and pharmaceutical industry, as well as for harsher applications such as recycling waste recovery.

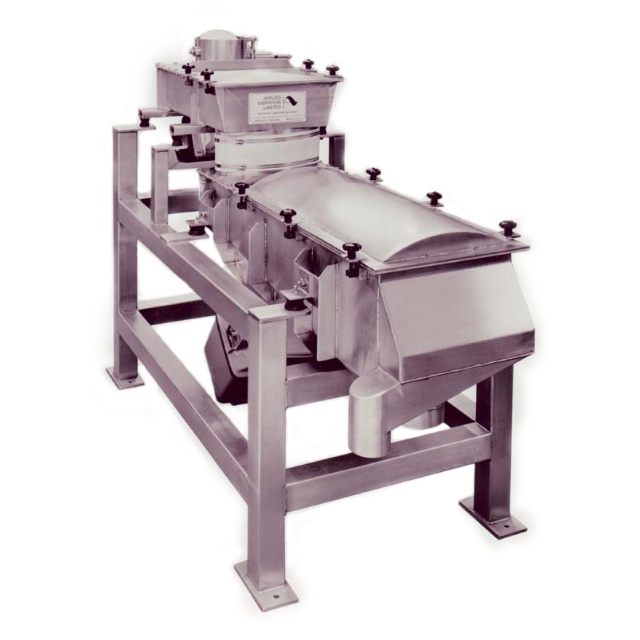

Vibrating Screens

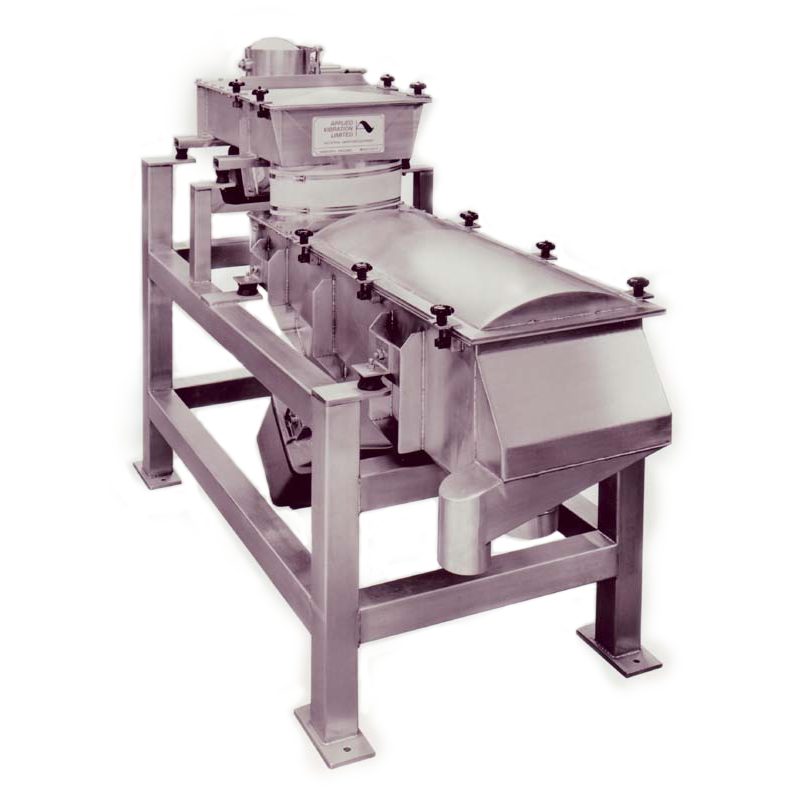

Vibrating screens are used mostly to separate products by size and are usually used for grading sized materials, removing dust and fines. Addition screening decks can also be added to separate a second size of particles, if the application requires so.

Oversize or agglomerated material and separating solids from liquids can also be removed by Applied Vibration separator screens. Though we have a wide range of standard vibratory screens, we also custom design and manufacture to particular specifications for many varied solutions - both in traditional industries as well as hygienic applications.

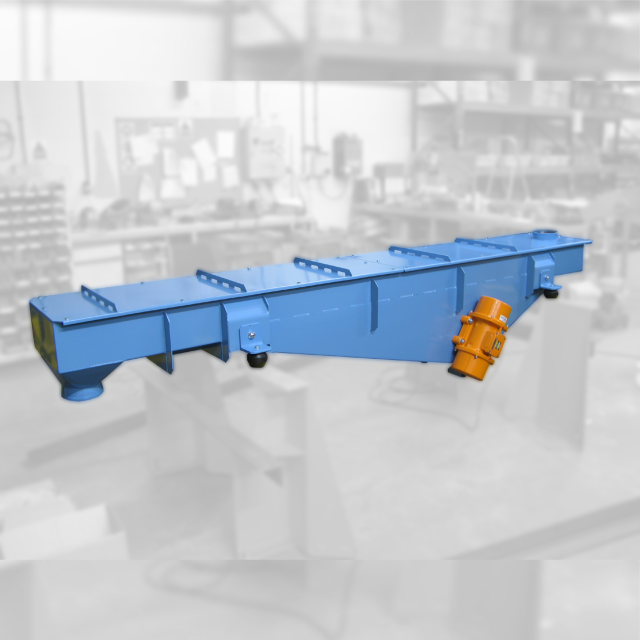

Vibrating Conveyors

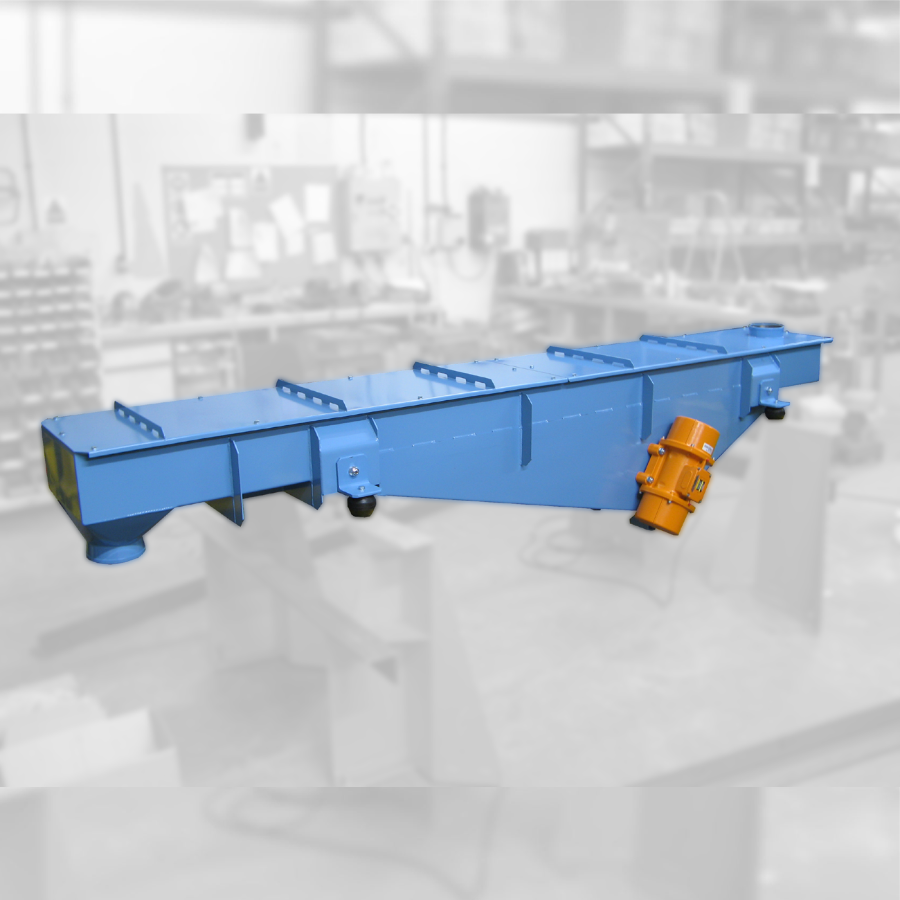

Providing high bulk material conveying rates, our twin motor drive conveyors can be of open, enclosed or tubular construction. Vibrating Conveyors are ideal for the bulk transport of product where throughput rates are fixed or require infrequent adjustment.

Heavy duty construction and abrasion resistant steel liner plates can be fitted for more arduous conveying tasks. Our twin motor drive conveyors can have throughput rates of typically up to 330 cubic metres per hour.

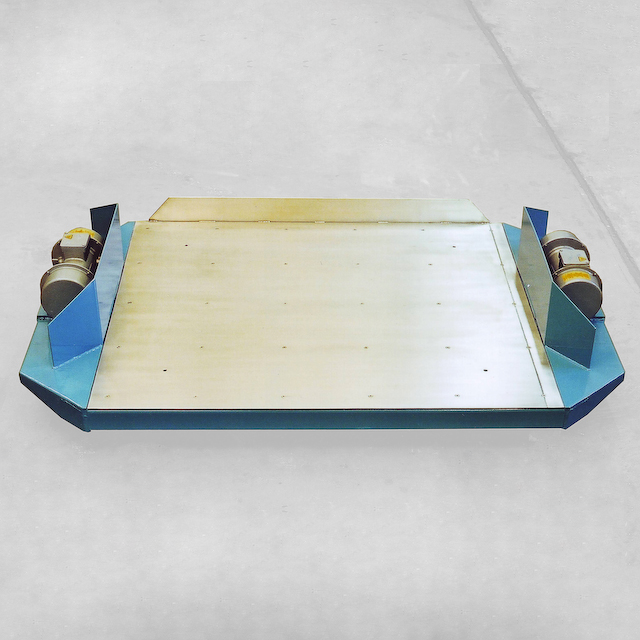

Vibrating Tables

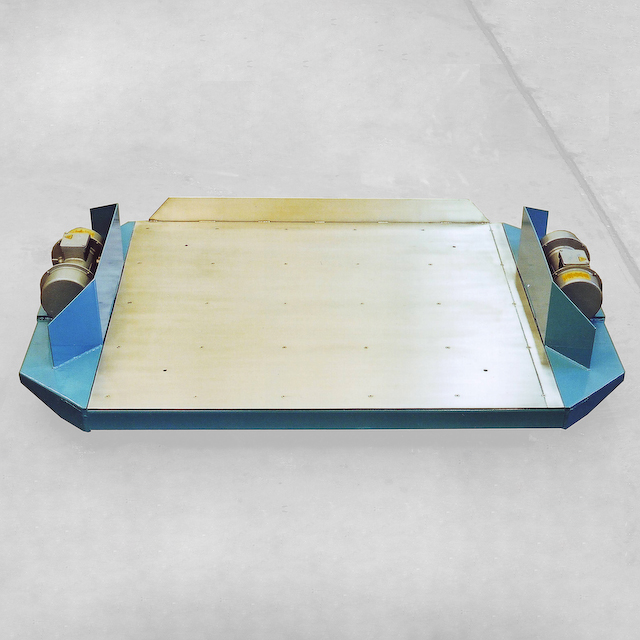

We can manufacture Vibrating Tables that are powered electromagnetically. They are predominantly used for the aeration, detachment and compaction of large amounts of material.

Compaction tables are often used in applications in the packaging industry where material is fed into sacks, bags and containers without creating too much volume. Vibratory tables are also often used in the construction industry, to compact cement and powdered building materials.

Screening Conveyor and Policing Screens

Screening and Policing Screens can be added as a secondary process to conveying material, as long as there is a reasonable difference in the size and volume of the fractions to be separated. For example the screening process may be to guard against occasional and unintentional oversize particles, or fines in the form of dust.

This type of screening frequently takes place both in process and often immediately prior to product packing and filling and ensures unwanted agglomerations of product are removed as well as any dust that has accumulated during upstream mechanical handling processes.

Loss In Weight Feeders

Electromagnetic drive feeders used when a rate of product feed needs to be accurately matched to a process or product stream and this can be controlled in a number of ways including level probes and interface signals. However we are often asked to produce equipment to provide more precise levels of feed for applications such as ingredient dosing and batching.

For this purpose we are able to mount bulk storage hoppers and electromagnetic drive vibrating feeders on weigh scale frames to provide accurate and feed rate adjustable doses of material on a loss in weight basis, making these an ideal solution for the controlled discharge and batching of products into processes and filling applications.

Vibrating Spiral Elevators

Applied Vibrating Spiral Elevators are used mostly for elevating duties where space is an issue. Vibrating elevators are also used in areas involving process cooling, heating and drying. Our vibratory spiral elevators can be supplied in heights that are over seven metres and can be fitted with bottom mounted or top mounted drives.

Product Transfer Systems

Applied Vibration can provide a solution for your Product Transfer Systems in the form of vibrating bin discharge units. They can be used to maintain the flow of products from bulk containers. To aid the product transfer systems, we provide dust tight docking assemblies when needed. They are used with vibrating feeders and conveyors to provides a complete solution.

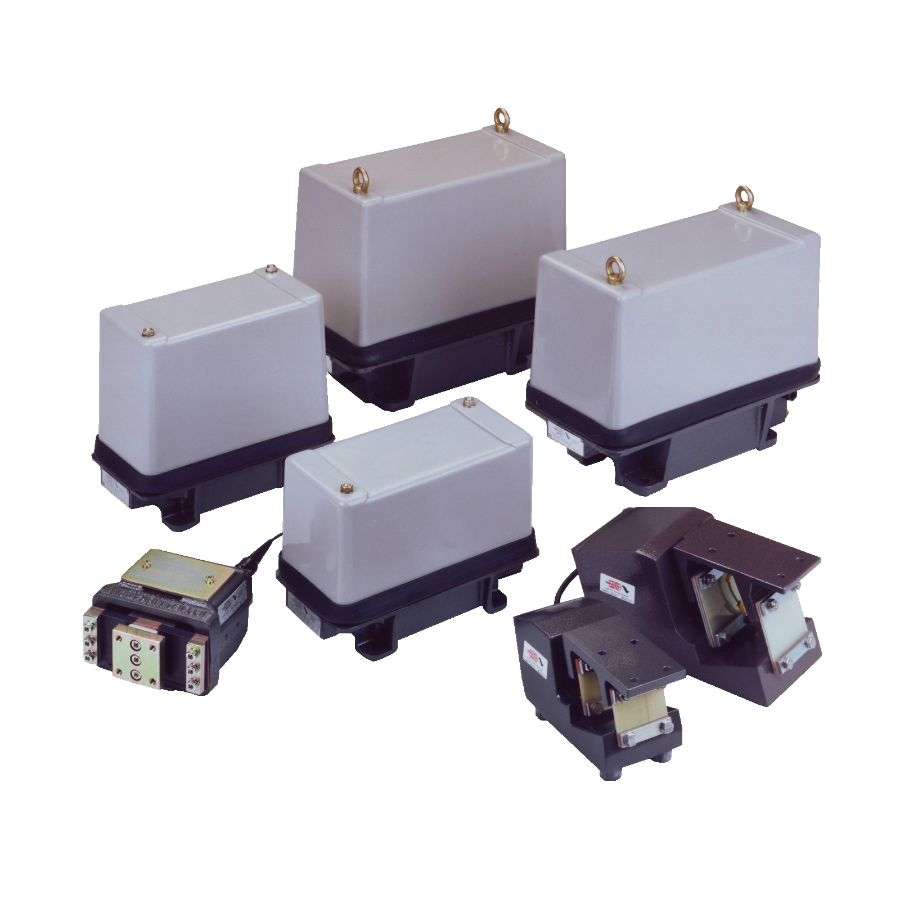

Drive Units

We manufacture four different types of drive units ideal for a range of applications. Our Drive Units include base mounted electromagnetic drive units and standard electromagnetic Drive Units that offer instantaneous stop/start flow, vibrator motors that are particularly suited for high capacity applications, and hopper vibrators that are designed to handle large quantities of product.