Curtiss-Wright Surface Technologies

Curtiss-Wright Surface Technologies (CWST) provides high quality surface treatments which will improve the life and performance of critical components through its global network of over 70 operating divisions and specialist onsite teams. Our surface treatments have been successfully used by OEM’s in major industries such as aerospace, automotive, oil & gas and power generation for many years.

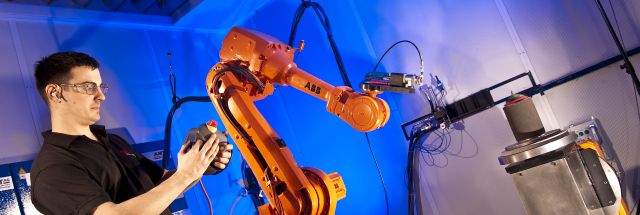

Metal Improvement Company (Newbury Division) offer quality metallurgical solutions to improve the performance of metal. With advanced technology, these improvements can be integrated into products when required and can dramatically enhance lifetimes improve fatigue strength, precision shaping, selective hardness and surface finish.

At Metal Improvement Company (Newbury Division), we deliver our innovative enhancements to our customers and help to create new state of the art products. We offer laser peening, peen forming, controlled shot peening, superfinishing and solid film lubricant coatings.

We are located in the UK with divisions in Evesham, Earby, Sunderland, Newbury, Derby, and Chester.

Keronite

Keronite’s PEO technology, part of Curtiss-Wright Surface Technologies, enhances the performance of light alloys and is utilized across various aerospace applications, ranging from large-cast structural components to geometrically-complex components. PEO-coated components are frequently used as a lightweight alternative to heavier metals, a strategy employed across the industry to improve aircraft fuel economy. Notably, aerospace manufacturers have extensively adopted this technology to combat corrosion, dry-sliding wear and as an eco-friendly alternative to toxic chromate conversion coatings see more here.

Fluregiene 200™

Curtiss-Wright Surface Technologies, Everlube® Coating Products have partnered with BioCote® to expand their fluoropolymer coating product range to create Fluregiene 200™: an antimicrobial coating that is ideally suited for many surfaces and environments.

Based on existing Everlube® coating technology, the new Fluregiene 200™ is a unique fluoropolymer coating that offers low friction, easy-clean properties combined with superb chemical and abrasion resistance. With a view to improving hygiene standards, Everlube® Coatings have integrated BioCote® antimicrobial technology to protect the coating from microbes such as bacteria, mould and fungi. Benefits of applying antimicrobial technology into the Fluregiene 200™ include:

Anti-fouling

- Low COF Surface coating (0.08 – 0.2 static)

- Corrosion resistance and excellent chemical resistance

- Excellent chip and abrasion resistance

- Reduces and prevents build-up of contaminates

- Excellent flexibility

- Dirt and debris less likely to attach to the surface

Microbial & bacteria growth inhibitor

- Using patented BioCote® antimicrobial technology against microbial growth

- Inhibits and reduces microbial growth on protected coating

- Protects treated surfaces against bad odours, staining and material degradation

Easy clean and reduced cleaning intervals

- Provides continual microbial reduction on coating

- High PTFE content allows easy wipe down and cleaning

- Provides more hygienic and cleanable surface than brushed or finished steels

Applicable to a wide range of parts and components such as door handles, elevator buttons, airport seating and gym equipment, the Fluregiene 200™ will be highly beneficial for these surfaces. BioCote® also has real-life data to support the application of this antimicrobial technology in environments such as health care, transport, education, public areas and much more.

For more information on Fluregiene 200™ and Everlube® Coating Products please contact our coatings team

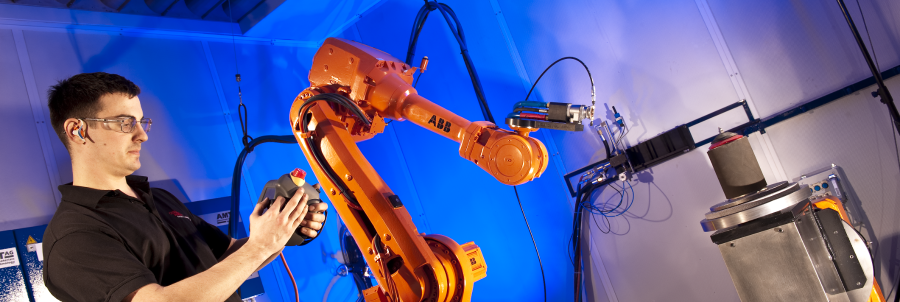

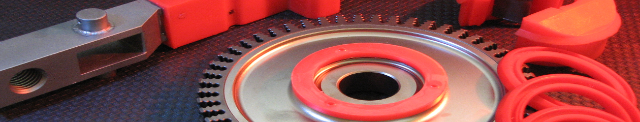

Controlled Shot Peening

We offer controlled shot peening as a cost-efficient and practical solution to reduce tensile stress.

Controlled shot peening reduces tensile stresses by applying loads from production processes such as machining, welding and grinding.

Shot Peen Forming

Our shot peen forming processes can be used and applied to structures like aircraft wing skins. They produce curvature that greatly improves effectiveness and lift.

Shot peen forming on aircraft structures can also correct distortion of components following production processing.

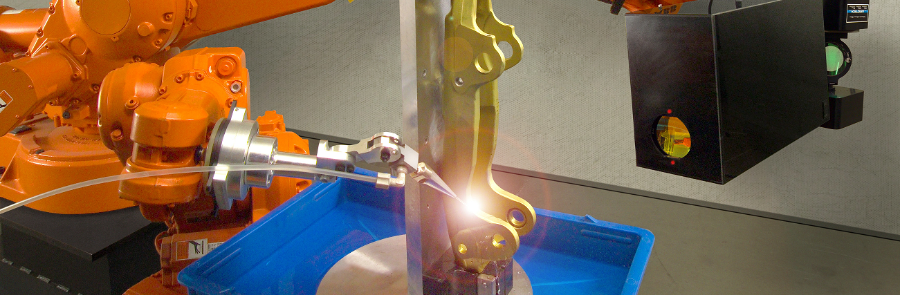

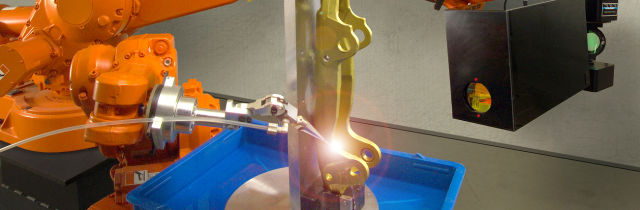

Laser Peening

The laser peening application induces a high precision compressive, residual stress into a specific point on a component.

Laser peening penetrates components up to 5 to 10 times deeper than any other traditional cold working technique or application.

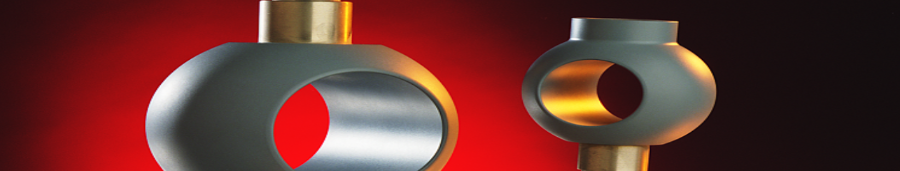

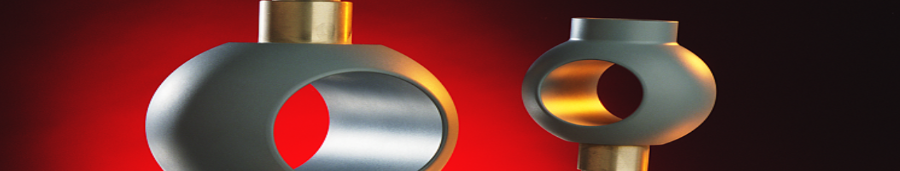

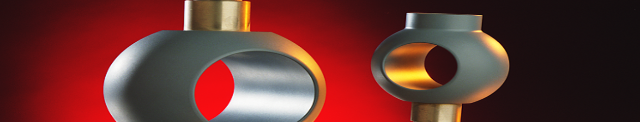

Isotropic Finishing (Superfinishing)

Isotropic finishing (superfinishing) is an exceptionally successful application to reduce micro-pitting, noise and oil temperature.

Isotropic finishing (superfinishing) can extend a component's life and seriously enhance its performance by eliminating surface asperities and improving lubricant retention.

Heat Treatment

We are heat treatment specialists and offer thermal processing to reduce stresses in fabricated metal component.

Our range of heat treatments controls the surface of components through hardness requirements to improve the overall strength and ductility of the component.

Wet Treatments (Anodising)

We provide a variety of wet treatments (anodising) techniques aimed at improving chemical and atmospheric corrosion defence.

Wet treatments (anodising) can enhance corrosive resistance and dramatically improve the application of adhesives and paint primer.

Engineered Coatings

Our engineered coatings are based upon our expertise and experience of successful component coatings.

Our engineered coatings enable us to use less expensive metals and enhance the durability and part wear life. Altogether this greatly reduces overall maintenance costs.

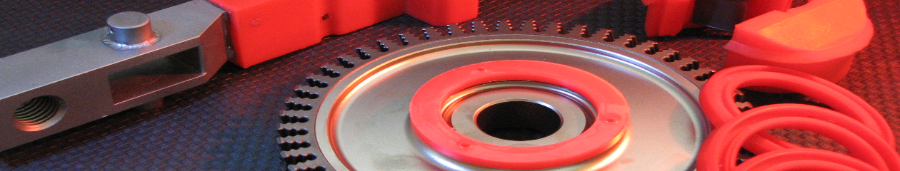

Protective Mouldings (Peenflex)

Our protective mouldings (Peenflex) are abrasive and damage resistant mouldings. Protective mouldings (Peenflex) are a cost-efficient answer to protecting component parts.

The parts are well protective through all manufacturing processes, including storage and despatch, moving and lifting.

Architectural Finishes (Peentex)

Architectural finishes (Peentex) are decorative textures applied to a finished structure. They are applied by shot peening.

Architectural finishes (Peentex) not only change the aesthetic of completed structures but also enhances metal components in a practical way too.

Find Us on Google

We can be found on Google.co.uk