Screwtech Engineering

Screwtech Engineering is a UK based company manufacturing high quality Twin Extruder Components for the plastics, rubber and food industries.

We Specialise in

- Screw Elements

- Barrels and Liners

- Shafts & Tips

- Dies & Moulds

- Vent Port Stuffer

Located in the Royal Forest of Dean in a modern business park, Screwtech offer alternative pattern parts for co rotating Twin Screw Extruders, including many commonly used Screw Elements, Shafts, Barrels and Liners.

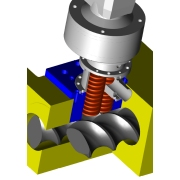

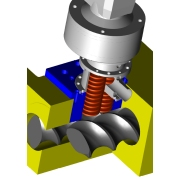

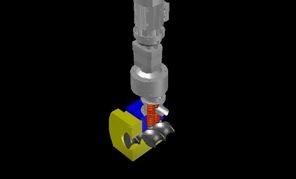

In addition the company has enjoyed great success for many well-known clients with its innovative 'Top Stuffer' which is a practical solution for venting problems when plastic is pushing its way up the Vent Port.

The company's specialist knowledge has been gained over many years. Screwtech works closely with its customers to offer advice, rapid response times and practical solutions to a wide range of problems

Vent Port Stuffer

- Self Wiping twin-screw design helps prevent material rising up the vent port

- Improve capacity - run at higher fill levels and maintain your product quality

- Minimise inconvenient and costly down time through vent port blockage

- Precision tolerances allow full vacuum to be drawn - removing moisture and volatiles

- Allows the screw configuration to be less critical

- Helps maximise use of available barrel length and vent port positions

- Increased extruder pressure improves porosity

- High quality stainless steel construction for demanding production environments

- Easy clean, two part vacuum chamber and separate seal housing

- Oil filled gearbox with water cooled jacket for long life expectancy at high temperature

- Various sizes to suit a wide range of twin-screw and single-screw extruders

- Proven design used by many leading compounding and profiling extrusion companies

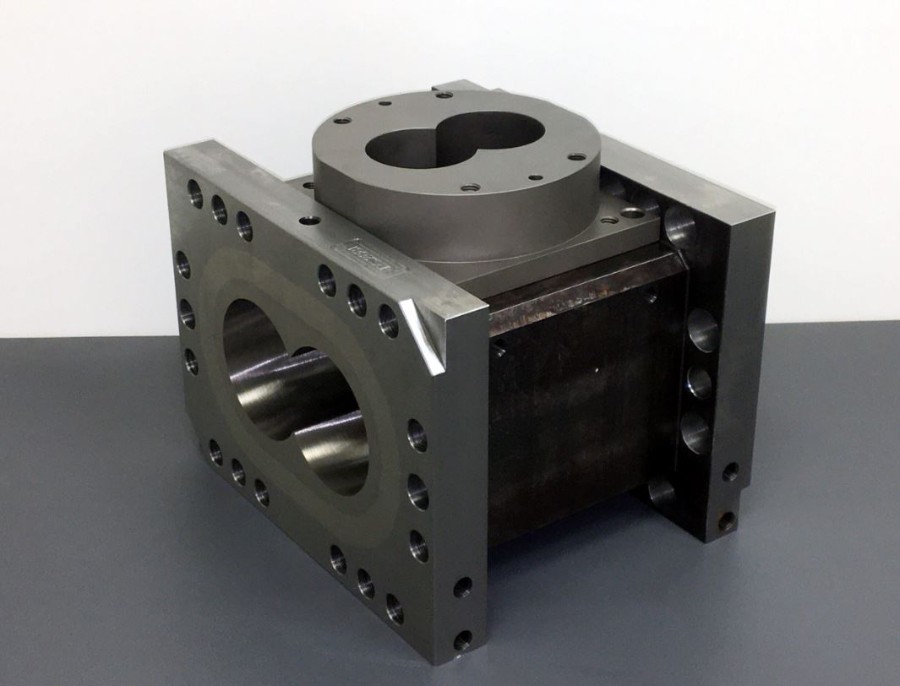

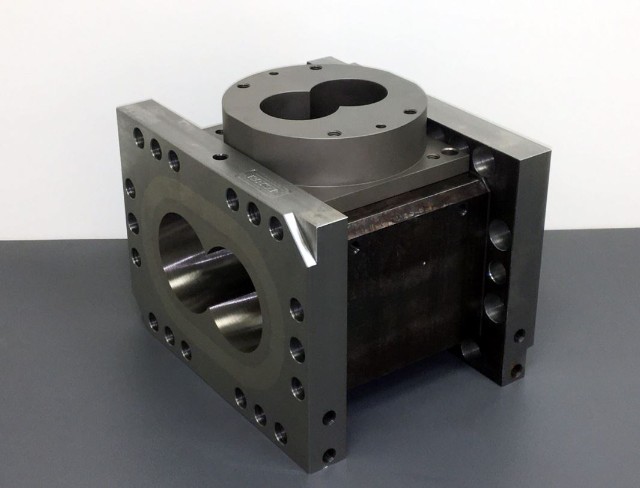

Barrels

Screwtech can provide a range of parallel barrels and liners up to 400mm in length (limitation of the spark erosion machinery). In addition Screwtech can manufacture bespoke parts and modifications should the need arise.

Liners

Screwtech can provide a range of parallel barrels and liners up to 400mm in length (limitation of the spark erosion machinery). In addition Screwtech can manufacture bespoke parts and modifications should the need arise.

Please contact Screwtech Engineering for more information on T: +44 (0) 1594 546577 or click here

Shafts

Screwtech can provide a variety of shafts & tips please enquire if you have a specific requirement.

- Round (Keyway’s)

- Hex

- Splined Ends

Tips

Screwtech can provide a variety of shafts & tips please enquire if you have a specific requirement.

- Round (Keyway’s)

- Hex

- Splined Ends

Dies and Moulds

Scretwech can manufacture various dies or moulds and use the latest 3D CAD modelling software. Please contact Screwtech Engineering for more information on T: +44 (0) 1594 546577 or click here

Corrosion Resistant Steels

All Screwtech parts are manufactured using only top quality wear and corrosion resistant steels that are designed to last as long or often longer than the original manufacturer's.

Nitriding, stainless steels and alloys or specially treated materials are all available depending on the customer's specific requirements for the plastic, paint and food industries.

Co-rotating twin screw elements

Co-rotating twin screw elements, shafts and barrels are available for a wide range of extruders. Screwtech manufactures a wide range of elements and specialises in Clextral and APV elements manufactured from alternative steels for corrosive and high wear applications.

Shaft Stripping Service

Screwtech offer a shaft stripping service to remove old and worn elements from the shaft and replace them with new. Whether you want a new configuration or simply don’t have the spare labour – Screwtech can help.

Anyone who has performed this task will know it can be laborious and time consuming. Occasionally ‘good’ elements can get broken during the removal process (which cannot be avoided) and the shaft stripping service is offered on this understanding.

Part Fitting Service

Screwtech engineers can visit your works to replace barrels, shafts and elements on site. Highly experienced engineers can provide help when your own resources are stretched or limited.

Machine Capability

- 4 Axis Wire Erosion

- CNC Thread Whirler

- Full Equipped Machine Shop

- Mills

- Lathes

- Surface Grinders

- Drills etc, etc

Screw Elements

All Screwtech elements are manufactured using only top quality wear and corrosion resistant steels.

Nitriding, stainless steels and alloys or specially treated materials are all available depending on the customers specific requirements.

Co-rotating twin screw elements for :

- APV

- Berstorff

- Betol

- Buhler

- Clextral

- Krauss Maffei

- Leistritz

- Maris

- Theysohn

- Werner and Pfleiderer