RSA Cutting Technologies Ltd

We supply sawing centres for single or multiple cuts, steel or stainless steel parts or non-ferrous metals. Our sawing centres are provided with short set-up times, easy operation, high precision and high economic efficiency. They can be smoothly integrated with all subsequent steps in processes such as deburring, chamfering, measuring, washing and stacking.

Sawing Machines Metal

From manual to semi-automatic to fully automatic circular sawing machines, you can find the right solution depending if you have single pieces to cut to large batches. Strong, back-lash free gear boxes ensure the best sawblade lifetimes and more precise cuts.

Deburring Machines

Sawing, punching and guillotining all produce sharp edges and laser cutting of sheet metal creates 90 degree edges leaving them sharp especially on stainless steel. Our tube deburring machines will deburr tube and section ends internally and externally in one operation and our sheet metal deburring machines leave smooth edges without any secondary burr in a single pass. Aluminium extrusion deburring machines will deburr the sawn ends without marking or scratching anodised or coated surface in a few seconds.

Technical Brushes

Technical Brushes from RSA are available for all industrial sectors from Engineering to Automotive, Marine through to Aerospace. Whatever your application may be we have the right brush or can develop it for you. We can supply in a full range of filaments from our special wire to diamond or high temperature abrasive nylon to give you high performance and longer lifetimes. We can also offer you full technical backup and advice from our UK specialist.

Tube Chamfering Machines

RASAFAS is the answer to the demands of product development in the automobile, aircraft, machine and aggregate industries and in many other high-tech areas.

RASAFAS does inside and outside chamfering of tubes as well as facing and outside chamfering of solid bars.Designed as a modular series, RASAFAS offers high output, highest possible precision and reliability as well as short conversion times.

Facing and interior and exterior chamfering are done in one work process, dry. Advantage of dry cutting: less cleaning. Collecting and removing swarf was also developed under this aspect. The swarf fall directly onto a conveyor and doesn't just drop randomly into the machine. The collection container is outside of the RASAFAS and is easily accessible for emptying.

All conventional tool holders such as the HSK-C-63 or SK40 can be used.

RASAFAS can be integrated into any existing production line and linked to any separator system.

Aluminium Extrusion Deburring Machines

Deburring tubes, bars, profiles and sheets after cutting is a must. But only the right system will provide low cost, reliable and immaculate deburring with the machine design and the high performance brushes being optimally adapted to the properties of the workpiece and the quality of the material.

RSA as the manufacturer of the machines and high performance brushes combines is the only company to combine both scopes. You the user benefit, as this complete system allows you to always have reproducible, perfect results.

Discover the advantages RSA deburring systems have to offer!

Wire Brushes

As system provider that produces deburring machines as well as brushes, RSA possesses the know-how for attuning the drive system. Because only the skilful attuning of the right extent speeds, drive concepts, work piece feeds on the one side and the alignment and dimensions of the high performance brushes on the other side result in the most profitable processing costs in the end.

Sheet Metal Deburring Machines

RASAMAX MONO was designed for deburring handy sized sheet metal with notches and contours. The machine's ergonomic shape ensure optimal working conditions. Sheets up to 6 mm thick can quickly and safely be rounded without forming a secondary burr.

RASAMAX MONO is suitable for deburring single pieces and small batches. The user simply guides the sheet along the rotating high performance brush for reliable burr and oxide layer removal. The piece is turned over to machine the top and bottom edge. The process takes just a few seconds. The machine's special design with extended brush drive allows even for very pointy notches to be deburred.

The sheet to be machined is manually guided along the rotating deburring brush using slight pressure. Yet all corners and angles are deburred without residue. The variable adjustment of the clearance between high performance brush and workpiece guide easily compensates the brush wear. Even deburring results are guaranteed throughout the entire service life. The brush can be changed in just a few steps.

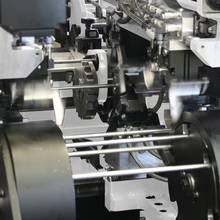

Tube Deburring Machines

Our RASAMAT products are ideal for single pieces and small batches. After just a short training period they are easy to operate, even by less skilled personnel.

The RASAMAT 2002 will handle asymmetrical profile shapes or short workpieces. Here the workpiece is fed through an aperture cover which can also be changed over within seconds.

Both modules combine maximum workplace safety with flexibility and ultra short set-up times. Depending on the size of the workpiece deburring takes only one to five seconds per endface. Even with small daily volumes the RASAMAT will cover its investment in less than twelve months.

RSA Cutting Technologies Ltd Overview

Enter details and RSA Cutting Technologies Ltd will contact you