James Technical Services Ltd

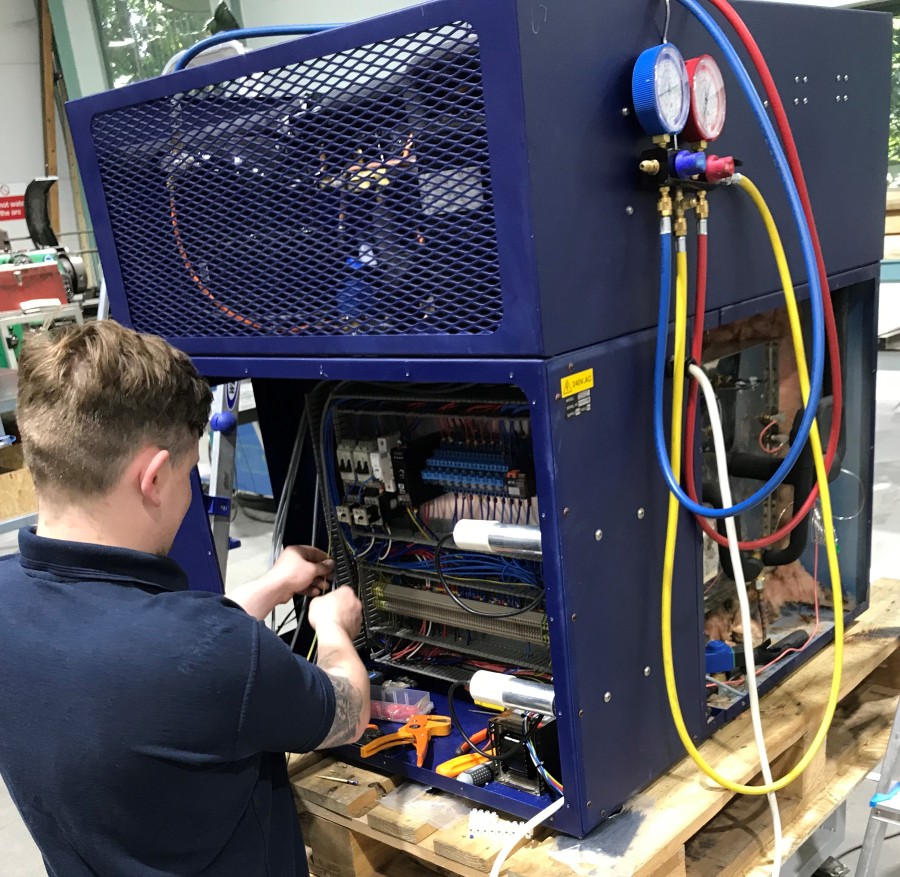

JTS is one of only a handful of independent UK companies currently manufacturing environmental test chambers. The compact nature of our company enables us to maintain a high degree of flexibility in our manufacturing processes, thus bespoke test chambers are one of our specialities.

JTS offer a wide range of competitively priced environmental test chambers. Our standard range of test chambers includes bench top and floor standing models, across temperatures ranging between -65°C and +150°C (from -80°C to +300°C for specific applications), and humidities between 10% and 98% RH.

JTS hold a stock of used test chambers and refurbished equipment which can provide an economic alternative to purchasing a new chamber, while for short term or irregular testing a selection of hire chambers are available.

-

Maximising Test Load Capacity

18 April 2023An issue faced by many customers is how to achieve the most test capacity without impacting on chamber performance. Putting the maximum test load in and still achieving even distribution and stability is a challenge when building bespoke equipment.

Airflow is key and having a good understanding of how a customer will load their product ensures the best results are achieved.

For one JTS customer who’s test cycle lasts several months, incorporating steady slow ramps and long dwells, humidity distribution is critical. For them the distribution accuracy is so paramount the chamber is regularly calibrated using the 9 point mapping system. One probe is placed in each corner just away for the chamber wall and one in the centre, the allowable tolerance in this scenario is 2% rh. During tests if the humidity fluctuates out of specification in any area of the chamber, the test is aborted.

Bespoke racking can help resolve distribution issues and the rack on this recent project was built to ensure good even air flow and ensure stability.

With a temperature range of -20°C to +80°C and a humidity range of 20 to 98% the chamber spends a lot of time testing at high temperature and high humidity, over 95%. These conditions are harsh, so the test frame was built of stainless steel and to enable easy product loading, sliding compartments were incorporated in the design.

Fully loaded this racking weighs around 600kg, so a reinforced chamber floor was essential.

Reliability of chambers that do long term testing is essential, down time causes testing backlogs and unwanted stress. Time spent understanding what is required of a chamber and how it is going to be used, ensures JTS get the design and build correct.

This in turn enables us to keep to our mission, to design and build robust, innovative solutions for our customers - something to rely on.

-

Independent Specialist UK Manufacturer

29 April 2020JTS Ltd is an independent specialist UK manufacturer, with design and build undertaken in-house by a team of skilled engineers and technicians. We believe in working closely with clients to ensure the best outcomes for individual test needs, whether the requirement is for standard or bespoke chambers, containerised systems, or walk-in room. As a small company backed by over 40 years of experience in test chamber manufacture, we have the flexibility to adapt to all new and developing test requirements.

As such, we are delighted to have been working on a project for KW Pressure Testing, part of KW Group, who provide testing services for the Oil & Gas Subsea, Oceanographic, Materials Science and Energy sectors. As part of their development of a dedicated test facility to provide high quality environmental and pressure testing service.

the KW Pressure Testing brief was for a multipurpose walk-in chamber to accommodate variable test loads and test specifications for their own clients. The conditions to be recreated require the chamber to operate at a temperature range of -70°C to +200°C, with test loads of up to 3000 kg, optionally loadable by crane. The chamber needed to be constructed with modular sections for ease of transport.

JTS engineers developed an adaptable, modular roof system to facilitate test loads that exceed 2m high, or that need to be loaded into the test chamber by overhead crane. With a test area of 2m wide x 3m deep x 2m high the chamber provides a test facility that is energy efficient and versatile, whilst enabling the wide range of test specifications that KW Pressure Testing offer to their clients.

Working closely with customers in this way ensures the best outcomes for individual test needs, whether the requirement is for standard or bespoke chambers, containerised systems, or walk-in rooms. With experience across a wide range of industries, and a varied client base, we are ready to help you achieve the best environmental test solutions for your products.

JTS also provides full after sales support, including operator training and ongoing technical support. We offer a variety of service and breakdown contracts, from a one-off visit to ensure compliance with current Fgas legislation, to full scheduled maintenance and unlimited breakdown cover. JTS will structure a contract to suit the needs of the customer.

Please contact us for more information on sales@jts-test-chambers.co.uk / 01874 711209 or visit our website jts-test-chambers.co.uk

-

Bespoke / Custom Testing Equipment

1 November 2019As a small company, we have the flexibility to develop tailored/custom testing equipment solutions for your individual test requirements. Our engineers will work with you on every stage of the process - from initial discussion as to the best way forward for you and your budget, through to quote, design, build and installation. You will always deal direct with experienced engineers, able to draw on cross-sector knowledge of different industries and processes

In the past, examples of our test chambers work include, but are not limited to:

- Cryogenic Storage

- Heat treatment plants

- Rain simulation

- Walk-in rooms

- High Temperature Ovens

- Dust Ingress and Sand Blast Chambers

- Vibration Ports

- Thermal shock testing

- Large Scale Refrigeration Plant Systems

- Altitude Test Chambers

- HARASS & HALT Testing

We will also work with you to meet special space or configuration requirements for your custom testing equipment, such and positioning of the refrigeration plant, alternative access such as lift-off lids for crane loading or reinforced floors for heavier loads.

A 1 year warranty is included. Service contracts to cover the test chamber after the warranty period expires are available on enquiry, and can be discussed with your order.

Talk through your requirements for environmental test chambers by getting in touch via our contact page or calling us on 01874 71120

-

About Us

31 October 2019JTS is an independent specialist manufacturing company, established in 1995 to design and build reliable, high-performing environmental test chambers, serving a wide variety of industries.

Operating from a modern purpose-built factory unit, we believe in working closely with clients from enquiry and quote to delivery and beyond, to ensure their chamber meets with their requirements.

Processes

Design and manufacture are undertaken in-house by our team of skilled engineers and technicians.

Our systems are designed to be highly reliable, adaptable and flexible over the lifetime of the chamber.

We are constantly improving and developing the way we work, and how we approach design, to keep pace with changing industry.

Ethos

We provide ongoing training for staff, to ensure compliance with evolving standards and regulations, as well as building and updating skills and personal professional development.

We are an equal opportunities employer, and believe it is possible to have a family flexible approach whilst maintaining high standards of manufacturing.

Made in Wales, our suppliers are British wherever possible.

Our Team!

Directors/owners

Glen James: Glen has been designing and building test chambers since 1978. He leads our team on design, quality control and technical development.

Susan James: Finances, strategy and growth, and people.

Director

Gillian Byrne: Gill is our Sales Engineer, and has been involved with JTS almost since inception.

Production/Design Manager

Dave Price

Office Administrator

Andrea Lewis

Technicians

Rhys Griffiths, David Latham, Andrew Davies and Oliver James are key to our manufacturing processes with mechanical, electrical, refrigeration and programming skills.

-

Container Conversions

31 October 2019Special Projects: test cells

JTS container conversions at CAPSE, Swansea University's Centre for Automotive and Power Systems Engineering.

A total of eight 30 ft shipping containers were converted into self-contained ‘test cells’ for temperature & humidity testing at CAPSE’s Pontypridd site. Battery testing can be highly volatile; to minimise risk in this case, JTS engineers designed an innovative CO2 cascade system, capable of achieving a range of +80 / -40c at high rates of temperature change. As an inert gas, CO2 has a major advantage in this application over alternative refrigerants which are either highly flammable, less efficient or have a far higher GWP (Global Warming Potential).

Contact us to discuss your own test requirements.