Claron Hydraulic Seals Ltd

Claron Hydraulic Seals Ltd manufactures a comprehensive range of high quality sealing products within the UK, marketed under the Polyseal® trade name.

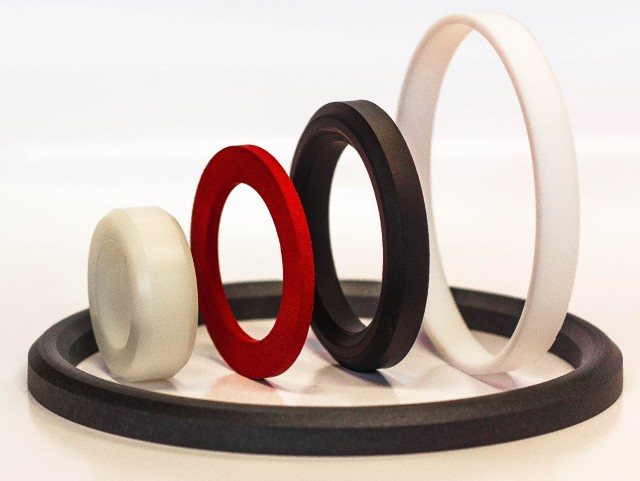

The range encompasses the latest modern designs including One-piece Piston Seals, Polyurethane Piston and Rod Seals, Wiper Seals. Bearing Rings and Back-up Rings. In fact most products and designs you are likely to find anywhere, in both modern and the more traditional hydraulic systems.

The product ranges meet European, American, and Asian housing standards and are manufactured in materials including Rubber/Fabric, Polyurethane, various PTFE compounds and many other high performance plastics.

Our commitment to providing quality products is reflected in our rigorous Quality Control Systems which are approved to ISO 9001:2008 giving full traceability of all our products.

Claron also provides a supporting range of customer related services including the supply of Seal Kits packaged to meet the requirements of both production and after market sales.

-

Quality Managment System

28 January 2020After our last audit in March Claron Hydraulic Services have now obtained the certification for BSI ISO 9001:2015 Quality Management Systems

Thanks to the dedication of all staff and the continued enhancement and updating of the existing quality systems, Claron will be able to better serve the requirements of all its existing and new customers into the future.

Our Quality Certificate can be downloaded here FM 22558 -

LED Lighting

28 January 2020Following on from the installation of Solar panels the company has made further significant investment in LED lighting. The continued drive to reduce the energy consumption of the production facilities in Paignton has seen the installation of an intelligent LED lighting system.

The system was designed to further improve the lighting conditions in the production facilities whilst still reducing the overall energy consumption. The new install consists of Intelligent LED light units which replace sodium hi-bay units. This is forecast to lower the annual Claron lighting bill by 70%.Intelligent Lights

Eluma is a high performance lighting technology which on average provides 74% energy savings. Each LED light unit has it's own PIR and can detect area occupation to either maintain or turn off the light source as required. Each unit is fully programable for sensitivity, brightness and duration. -

Clean Energy: Solar Power Install

28 January 2020In a drive to help reduce the carbon footprint and energy consumption of the production facilities at the site in Paignton, Devon. Claron has invested in a Solar Photovoltaic system.

The purpose designed system by Devon Eco Energy has been installed to make better use of the available roof space with the latest high specification renewable energy solution.

The new system consists of 144 Solarworld AG Sunmodules and two Power One Auroua 3 phase inverters giving a total generating capacity of 36Kw. This will help lower the Claron carbon footprint by 42tonnes of CO² a year.Cutting Edge

Designed with an East West configuration this system will give a better energy pattern through the day to align with production rather than just peak power at midday. Intuition energy monitoring has also been installed to record the generation and manufacturing usage patterns throughout the day. This monitoring solution will also help in the on going work to reduce the energy bills in the future. -

New Product: Specialised Flange Seal Outperforms O-Rings in SAE J518 Flanges

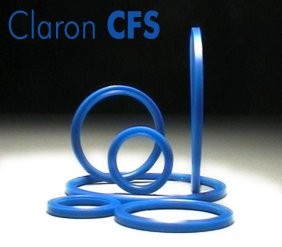

28 January 2020Specialised seals to suit SAE J518 Flanges have now been introduced by Claron Hydraulic Seals Ltd.

Called style CFS, the seals are manufactured from a high performance grade of Polyurethane which has been developed specifically for arduous sealing applications. The material provides excellent resistance to gap extrusion and compression set over a wide temperature range of -40°C to +110°C at up to 400 Bar.The SAE J518 standard was introduced by the American Society of Automotive Engineers to cover hydraulic flanged tube, pipe, and hose connections, including four-bolt split flange types used in the design and maintenance of self-propelled vehicles for use on land, sea, air or in space. The SAE J518 flanges, which have been designed to avoid the use of threaded connections, also have a wide range of general hydraulic applications and are being used on earth moving machines, and power steering systems manufactured around the world.

Unlike common O-Rings, Claron CFS style seals are specifically designed to fit the SAE J518 location groove. With their rectangular cross section and point contact sealing lips, they are formed and sized to accurately locate within the machined housing.

Their design provides superior performance to both O-Rings and rubber flange seals, while eliminating the 'pumping effect' which is common to close fitting O-Rings.The seals are available in six standard SAE J518 sizes from 0.500" to 2.000", together with two metric sizes of 33.5x26.3 and 45x36.2

Contact Claron for further information on CFS style seals.

-

New Production Facilities Opened

28 January 2020The huge increase in demand for Clarons highly successful range of PTFE products has led to a major expansion of the production facilities at the specialist site in Paignton, Devon.

The purpose designed building has been commssioned to meet this increase in demand as well as to enhance existing production capabilities and the quality of service for which Claron are renowned.

The new building has also allowed a major re-structuring of the existing production areas for a more co-ordinated approach to the three key areas of production thereby improving output across all the product ranges.

This major expansion has also provided further facilities for the continued growth of the company into high technology fields.High Technology

The purpose built structure provides the strictly controlled environment so fundamental for the production of high quality components by using the latest technology for heating, lighting and ventilation.A very strict control of the working environment is necessary for the accurate manufacture of P.T.F.E. components. This requirement was provided for by the installation of 3 split-system Heat-Pump air conditioner units, together with ventilating and circulatory fans, and so provides the means of maintaining a specific temperature to very close tolerances throughout the summer and winter months.

The lighting system is based upon high level sodium units which react to the outside available light so taking account of environmental requirements and also maintaing good fixed level of interior light.

All production equipment is serviced with power and compressed air etc. through service channels to maximise the floor and air space.

The new factory building almost doubles the previously available production area and gives Claron the means for expansion into the new Millennium and beyond through t