CP Cases Ltd

For over 50 years, CP Cases has been designing and manufacturing an extensive range of bespoke cases and 19” racks. Predominantly for Military, Industrial and Commercial applications.

With many years of expertise in the industry, we are confident we have the perfect formula. The innovation, durability and high-performance materials guarantee that CP Cases is the case provider of choice for mission-critical situations. Many of our products are accredited to MIL-STD-810, rated IP65 and carry NATO stock numbers.

Our West London HQ houses a range of in-house skills including rotomoulding plastics, Aluminium, laminating plywood, HPP, textiles, CNC foam machining, and label & screen printing. We feel at an advantage with everything under one roof; cutting down on lead time and bringing that bespoke attention to detail to our service from start to finish.

An extensive selection of options includes climate control (compressor and thermoelectric air conditioning units), EMC shielding; fire resistance, and anti-static capabilities. We are constantly developing and refining our product range, pioneering the most effective preventative solutions for weather resistance, water ingress, rough handling and severe impact.

-

Advantages of Custom-Made Equipment Cases

6 June 20235 Advantages of Custom-Made Cases for Equipment

When transporting any type of equipment, you want to ensure maximum protection so that it doesn’t get damaged. However, traditional cases can’t always offer this assurance due to the nuances of different types of equipment. This is where custom-made cases make all the difference. Expensive equipment can be kept safe with cases that are designed solely to protect your equipment against rough handling, extreme climates and anything else that comes its way.

5 advantages of custom-made cases for equipment

Custom-made equipment cases boast several advantages over standard cases thanks to the high-quality materials and customisable parts. Bespoke cases work flexibly around your essential equipment.

Designed to meet your specific equipment case needs

Any shape, size or quantity is catered for with custom-made cases. This means that your equipment will be guaranteed to be protected against all potential hazards. Whether you require a reinforced rugged case for rough handling or a cooling system to protect electronic equipment from overheating, custom cases listen to your specific needs and exacting requirements. You know your equipment and what it needs to be protected against, and a custom case can provide the perfect all-in-one solution.

Protects your high-value equipment

The main purpose of a case is to protect your expensive equipment, being able to ensure the full protection of valuable items offers the ultimate peace of mind. You need to be confident in relying on your equipment and a custom case ensures exactly that. Custom cases are made from robust materials such as polyethylene polymer to withstand impacts and the custom foam ensures a snug and secure fit.

Transports equipment easily

Lightweight polyethylene polymer makes lifting and transporting equipment much easier. Custom handles can ensure that cases can be safely transported without rough handling or accidental damage. Companies that regularly transport equipment can add wheels to cases to minimise the physical effort of moving heavy items. Additional fittings such as pressure valves can be another great option when transporting valuable equipment. The key to a great custom case is the expert behind it, who can offer advice on what works best for your equipment.

Saves on air freight costs

If you regularly ship equipment by air, custom cases can save a great deal of money. The extremely lightweight materials will significantly reduce air freight costs. On top of this, valuable equipment can get damaged when transported by air. Thankfully, custom cases use extremely durable materials to ensure that your equipment can withstand rough handling.

Excellent strength and durability

At CP Cases, our custom cases make protecting your equipment its priority. Using high-quality polyethylene polymer, custom cases are ruggedised, reliable and strong. The rotomoulding process ensures that edges and corners are reinforced, protecting equipment from any accidental damage. Custom foam inserts cushion equipment, absorbing any impact and preventing items from moving out of place during transportation. The main reason for commissioning a custom case is to keep your equipment safe, which is exactly why strength and durability are so important.

Custom-made case product options

Now that you know the countless advantages of custom cases, it’s worth understanding the different ways in which cases can be customised for your specific equipment needs. With so many product options available, it can be overwhelming, which is why at CP Cases we offer expert advice for each unique case.

Printing, labelling and branding

Making your equipment instantly recognisable in a busy warehouse or airport can save a lot of time and hassle. What’s more, our printing, labelling and branding can also help enforce a positive image of your company, boosting your recognition with clients and at events. Your unique branding represents your business and what better place for it than on the equipment cases you use on a daily basis? From silk screen printing to engraved labels and sewn-on badges — custom cases are truly an extension of your organisation.

Partitions and dividers

The purpose of a custom case is to fully support the use of your equipment and meet specific access needs. As a result, custom partitions and dividers can help you organise equipment and separate items to make your job easier. Using CAD tools, precise drawings can be translated into high-quality partitions and dividers that specifically work for your equipment, shielding valuable or volatile items from one another. Make the most out of your custom case by including partitions to ensure your equipment is safe and protected.

EMC/EMI shielding

EMI stands for electromagnetic interference which refers to the effect that a magnetic field can have on other devices nearby. When electricity flows into a conductor, this generates a magnetic field which can easily interfere with data signals. So, EMI shielding protects against this, ensuring that your equipment runs smoothly. If you have valuable specialist equipment that you need to rely on, you can fit your custom case with EMI shielding in which a metallic shield is placed around your equipment, absorbing any incoming signals. Not only should a case protect your equipment but enhance its performance.

External finishing

External finishing options on custom cases are designed to meet your exact requirements in both appearance and functionality. For example, aluminium cases can be produced in plain or rigidised aluminium with surface finishes from powder coating to anti-reflective finishes. These options can both work to boost durability whilst adhering to your brand aesthetic. The finishing touches to your custom case can add an extra layer of protection and practicality whilst giving a unique identity to your equipment.

Fittings and options

In order for custom cases to be truly fit for purpose they need to be customisable right down to the construction itself. Being able to access and transport your equipment in the most practical way possible is paramount at CP Cases. From adding wheels to make moving heavy equipment easier to pressure relief valves that ensure maximum protection, you can add additional fittings and options to optimise how you use and transport your equipment. Sophisticated locks can be added to boost security and handles to ensure safety when picking up heavy equipment.

A custom protective case is the ultimate bespoke solution to transporting your valuable equipment, keeping it safe and maximising its performance. We rely on our equipment in multiple high-pressure situations, so having a customisable case that works for your exacting requirements is the ideal companion.

-

How to Decide Which Transit Case is Right for You?

13 April 2023Transit cases are invaluable to the success of an organisation such as the Defence and Military or Medical industries. Transit cases are used by organisations to protect expensive, important or specialist products, tools or equipment. It is paramount that these goods arrive at destinations safely and intact to avoid any negative implications. This is why protective transit cases are invaluable in many industries. Whether it's storing or transporting technology, keeping expensive equipment safe is vital. Protective cases are designed to withstand severe impact and protect valuable contents to ensure the consistent high performance of equipment in all settings.

The Importance of Choosing the Right Transit Case

Due to the fragile and valuable nature of certain equipment, moving it around the world can become a major logistical challenge. In the event that high-value items become damaged beyond repair, it can result in increased costs or financial implications for the organisation. It can also result in decreased productivity due to the damaged or faulty equipment obstructing individuals from completing their job to their best ability. This is why choosing the right transit case for your organisation is a tough but crucial decision.

Every industry requires different protective transit cases to meet their product needs. At CP Cases, we supply a range of transit cases designed to last decades and withstand countless worldwide journeys thanks to their robust design. Every element within our cases are carefully selected to ensure the highest standard of protection for your tools or specialist equipment.

The Types of Transit Cases Available

RCZ Aluminium Cases & Containers

RCZ transit cases bring together the latest technologies in precision CNC metal forming to offer a comprehensive range of lightweight aluminium cases and containers in both standard and custom sizes. RCZ cases are designed to maximise the properties of flat stock 1.5mm thick high tensile aerospace-grade aluminium sheets. This is achieved by introducing innovative rimfold profiles that bring exceptional longitudinal strength and a patented pre-form corner design that significantly prevents impact damage to the corners when dropped with heavy loads. This transit case was designed with the defence industry in mind, with features such as climate protection, venting and EMC/EMI shielding.

Amazon Cases

Amazon cases were designed to meet the applications of the defence, marine, security, aerospace, oil and gas, satellite and telecommunications industries. This type of case has a unique patented design that offers a tough, lightweight, customisable system that can be tailored to an organisation's requirements and individual needs. Amazon Cases are highly resistant to impact and drop/shock, temperature extremes and vibration, as well as water and dust ingress. They can be modified to include features such as flame retardant, anti-static and low infrared reflectivity.

Custom Rotomoulded Cases

Custom rotomoulded cases are bespoke transit cases designed and manufactured specifically for a particular customer requirement. Rotomoulded cases offer exceptional strength-to-weight ratios and the plastic is resistant to temperature variations and solvents. CP Cases designers undertake extensive investigation and discussion to design a solution tailored to the organisation's needs. This type of transit case shares many of the same benefits of the Amazon Case range, such as resistance to impact, water resistance and dust ingress resistance.

Peli Cases and Injection Moulded Cases

Peli Cases are designed with the industrial, airline, military, broadcast and commercial industries in mind. This case provides all-weather protection and can be fitted with lightweight internally sculpted LD45 polyethylene closed cell foam to provide the perfect “nest” to ensure the secure protection of your equipment. The Peli Case is unbreakable, resistant to dents, scratches and corrosion and watertight up to nine metres.

Airship

The Airship case is a super lightweight protective case that offers significant weight saving against size and can achieve weight/volume ratios of better than 20kg/m3. This is a patented and bespoke solution that can be customised to suit an organisation's specific needs. The Airship case provides great strength to safeguard its contents through its outer rugged textile container and its polypropylene inner construction.

ProCase

The ProCase is a long lasting, rugged flight case solution to protect specialist or high-value equipment, such as musical instruments or surgical equipment. Using only the finest Finnish birch plywood and rigorous and bifurcated rivet construction, each ProCase flight case is glued, pinned and riveted with aluminium edges and steel knuckle corners to provide the ultimate protection. Similar to other transit cases, this product can be custom-built to meet the most intricate design requirements.

AluCurve

The AluCurve case is constructed without an edge corner to prevent seam splitting and add extra strength and exceptional resistance to drop damage. The AluCurve case contains features such as recessed catches and handles, a lid and body seals for ingress protection, a webbing lid and indents for stacking. The AluCurve can be customised to meet an organisation’s specific requirements, such as pad-lockable catches for extra heavy contents and easy manoeuvrability, low profile wheels, labelling and foam inserts for maximum protection.

AluWeld

The AluWeld case is designed to resist the most arduous of climatic and environmental conditions. This case is waterproof with seams and joints robotically welded to ensure the protection of its contents. AluWeld cases are used across a wide range of industries, including the defence, broadcast and medical industry.

Knowing the primary challenges you face in protecting your equipment or specialist products can make choosing a suitable transit case much easier. For example, if you require the highest level of protection from impact and water, the amazon case might be the best fit for you. Ensuring that expensive or valuable equipment is kept safe is paramount to organisations. At CP Cases, our protective transit cases are available to meet every challenge of rough handling and climatic or environmental hazard. Our transit cases are designed with practical, innovative features and optional extras such as partitions, foam cushioning or labelling to enhance protection and create a bespoke solution tailored to your specific needs.

-

What are the Benefits of Climate Control Systems in 19" Racks?

30 March 2023In today’s modern world, valuable electronic equipment is paramount to the success of organisations from defence and military to broadcasting, keeping expensive equipment safe is vital. Whether it’s storing or transporting technology, having equipment ready to deploy on demand is game-changing for multiple industries.

Electronic equipment is fragile and can be sensitive to extreme environments. This is why safe storage and protection are non-negotiable. Multiple industries may be required to transport electronic equipment in extreme temperatures that could damage the operational efficiency of equipment in critical situations. Climate control systems keep technology safe whilst maintaining the appropriate operating temperature, meaning equipment can be relied upon in all situations.

Protects sensitive equipment from extreme heat

Extreme heat is bad for electronic equipment and it can impact how well technology runs. For military, security, broadcasting, satellite, live performance and more, failure of electronic equipment in the field is simply not an option. During times of high pressure, equipment overheating absolutely must be avoided.

Climate control systems in 19-inch racks enhance the performance of equipment in any environment whether it’s during transportation or in an office. COOL Portable Air Conditioning offers temperature control that protects the sensitive components from heat which, as a result, maintains the optimum operating efficiency.

The air-conditioned server rack cools the equipment to reduce stress on the server’s current cooling system which minimises the likelihood of overheating damage.

Reduces the risk of condensation/mildew damaging products

Maintaining optimum temperature control is vital to prevent moisture from forming on electronic equipment. Moisture and technology don’t mix well and can lead to condensation or mildew forming which can destroy expensive electronics. The benefits of climate control systems are that they maintain a consistently cool temperature with regular air conditioning that doesn’t create an environment for dampness to survive.

When using technology in extreme conditions, from hot environments to high-pressure outdoor military climates, condensation can wreak havoc. This is why having a climate control system installed on 19-inch racks minimises the risk of equipment failure.

Improves the air quality for humans

The benefits of climate control systems can help humans too. Keeping the temperature-controlled and cool reduces dampness and moisture in the air. As a result, the air quality where technology is stored is much improved. This allows not only the technology to perform optimally but also the personnel working with it.

Having improved air quality in mission-critical situations can make a huge difference in the outcome which is why climate control systems are a must.

The overarching benefits of climate control for rack-mount equipment include improved technology reliability, reduced running costs, a longer working life of systems and safe transportation in extreme heat. Technology is crucial in many industries and when used in the military or broadcasting, the failure of electronics is not an option. This is why storing 19-inch racks with climate control systems is vital.

-

Types of Cases Available for the Defence and Security Industry

15 February 2023Defence and security industries require military cases that can combat rough handling, extreme climates, environmental hazards and unpredictable conditions. Lifesaving equipment requires the right casing which is why CP Cases offers a variety of different cases with IP ratings from IP54 to IP65.

Helmet cases

Helmets are vital pieces of defence equipment that can save lives. This is why it’s important that they are properly stored so as to protect them during transportation. Our helmet cases are specifically designed for helicopter pilot helmets which cost a great deal of money and so require the most premium cases. Made using AluWeld, these high-tensile aluminium cases offer maximum protection against environmental hazards.

Inside the case, we use engineered foam to cushion the helmet and the exterior has been swaged to increase stiffness by 25%. These lightweight cases are practical in design and effective in protecting military helmets.

Medical cases

Lifesaving medical supplies need to be transported safely, especially in military situations. CP Cases medical equipment cases provide tough water-resistant transportation for vital medical supplies. With a variety of customisation options, medical cases can be supplied with drawers to help organise and secure medical equipment.

Hygiene is paramount when transporting medical equipment which is why our cases are made from polyethylene which has zero fungal growth and is tested to MIL-STD-810F.

Rugged food containers

Military food containers need to be able to withstand extreme environments and rough handling. Food is fuel and a reliable container is a must for those working in defence and security. At CP Cases we have a range of rugged food containers made using food-grade polyethylene which is hygienic with no fungal growth and resistant to corrosion. Designed to hold standard gastronorm trays, rugged food containers can be washed in dishwashers without becoming distorted.

The six stainless steel catches seal in the heat, with a loss of no more than 11 C in over two hours. These rugged food containers are made for serving food in the most extreme conditions, being able to withstand a drop of 1000mm without leaking or sustaining damage.

Weapons cases

Transporting military weapons requires rugged cases that can protect expensive equipment from extreme climates and rough handling. Our military weapons cases are tailored to different applications depending on security size, weapon type and more.

The key to an effective weapon case is durability which is why CP Cases military cases are resistant to impact, extreme temperatures and water or dust. Nitrogen-blown polyethylene foam inserts eliminate the possibility of chemical contamination or corrosion, meaning weapons are kept safe and in pristine condition.

Amazon cases

Amazon cases are designed for military markets made for transit and storage of defence and security equipment. For maximum capacity storage and inter-stackable, amazon cases are the ultimate transportation for military equipment.

Made for air transport, amazon military flight cases are moulded from rugged polyethylene that can withstand rough treatment and extreme climates. UV stabilised, easily cleaned and corrosion resistant, these cases are ideal for transit and storage.

Extreme military environments require rugged cases to transport and store the highest grade of defence equipment. Having the right storage solutions will ensure that equipment lasts longer and performs at its best. At CP Cases, we have a variety of different custom cases for all defence and security uses.

-

The pros and cons of rotational moulding…

2 February 2023A deep dive into the rotomoulding manufacturing process and why we use this method for our Amazon range.

Rotational moulding is a manufacturing process involving the rotation and heating of plastic powder inside a mould. This is a common method in many industries including medical, energy & marine and defence to name a few.

Custom protective cases are amongst the products that rotomoulding is used to create, with many other commonly used products which emphasises the importance of this production method.

In this blog, we will be delving deeper into the pros and cons of rotational moulding, to better inform why we use this method for our flagship Amazon range of cases and racks.

The moulding process…

The moulding process is as simple as this:

- A hollow mould is filled with powdered plastic resin.

- The mould starts rotating bi-axially and is moved into an oven.

- The mould rotates as the resin melts and coats the walls of the mould.

- The mould is cooled until the resin stabilises into the chosen shape.

- The rotation is stopped, and the mould is opened to remove the finished piece.

This technology is mostly used for parts that need aligned wall thickness, high stability or even prestigious furnishes.

Pros…

There are a number of pros when using rotational moulding, from design versatility, reduction of environmental impact, recyclability, use of lighter materials, and meeting of demand.

Let’s dig a little deeper…

- Consistent wall thickness – with the rotation of the mould coating all walls evenly providing a sturdy base

- Long-lasting and flexible materials – Polyethylene is a strong material with many benefits. It protects against UV rays, is free from dust and is non-corrosive, meaning a more durable product.

- Low-cost tooling – rotational moulding tooling can be crafted for low-cost metals like aluminium due to the low operating pressures.

- Low environmental impact – during the cycle, no toxins or chemicals are released into the air. Unlike other processes, rotational moulding wastes very few materials and the plastic is 100% recyclable – really helping to reduce the carbon footprint.

- High strength, durability & stability – rotational moulding creates a solid piece with no need for welding, creating strength and thickness in the corners. The moulds are not exposed to external pressure, reducing the risk of any defects.

- Appearance – including a variety of size options, and a range of designs whiles accommodating surface finishes such as logos, writing, symbols & textures.

Cons…

As with any manufacturing process, rotational moulding also has its cons…

- High cost of raw materials – rotational moulding requires materials with high thermal stability requirements which in turn, creates a higher price tag as the cost of the essential additives and then grinding them into a fine powder is also added.

- Limited material options – mentioned above is the need for high thermal stability, with the ground additive to a fine powder for rotational moulding; meaning the material options are limited to poly-based resins.

- High cycle time – at only 8 rotations in a minute, rotational moulding can be a lot slower than other processes, sometimes taking up to 3 hours to complete 1 part.

Our Amazon range…

All of our Amazon cases & racks are produced using rotational moulding. Ideal for making tough, waterproof products and utilising a high-quality polymer that thickens at the edges and corners for extra strength and impact resistance.

Our Amazon range has brought rotomoulded containers to a new level for the 21st century by using decades of experience in case design and manufacturing. This results in a range of cases that are tougher, yet more spacious than any comparable product.

Contact us and we’ll help you find the best fit for your needs.

-

Which Protective Cases are Best for the Energy and Marine Industries?

9 December 2022The energy and marine industries use a lot of specialist equipment that needs to be transported and used in extreme environments and conditions. Protective cases are vital to avoid damage, delays and extra costs.

Why are protective cases important for energy & marine industries?

Protective cases are important for the energy and marine industries due to the hazardous and extreme environments equipment can be subject to in these sectors. Cases and bags for the marine and energy sectors need durable and innovative storage solutions to keep valuable equipment safe. Minimising damage to specialist equipment can help reduce project delays and costs caused by delays.

The best protective cases for marine/offshore use are completely waterproof to avoid damaging specialist equipment that may come into contact with water. In addition, cases and bags for the marine and energy sectors must protect equipment from potential damage during transit. The energy and marine industries involve a lot of logistics and equipment being transported worldwide; protective cases ensure that specialist equipment arrives safely and securely.

What case features are needed for these sectors?

Cases and bags for the marine and energy industries have specific case features that may require a bespoke solution. However, many cases and bags for use in these sectors share similar features.

For example, protective cases include specialist foams that can help increase efficiency by making it easier to identify and locate tools and parts. The specialist foam inserts can also be cut to the exact profile of equipment to avoid movement in the case and protect equipment from any drops or vibration. In addition, all cases and bags for the marine and energy industries must be waterproof and durable to avoid damage in transit and extreme environments.

Which protective cases are best for the energy and marine sectors?

Amazon cases

Amazon cases are designed to meet the requirements of many industries, including energy, marine, defence, telecommunications and security. Amazon protective cases are tough, lightweight and customisable to clients' needs.

They are made using a process called rotomoulding. Rotomoulding is a casting technique, but unlike most other plastics processes, no pressure is involved. As a result, rotomoulding is ideal for making tough, waterproof cases that use a high-quality polymer that thickens at the edges for extra strength and impact resistance. Amazon cases are one of the best protective cases for the energy sector, and marine/offshore sectors – and are ideal for any valuable equipment that needs to be transported or stored safely.

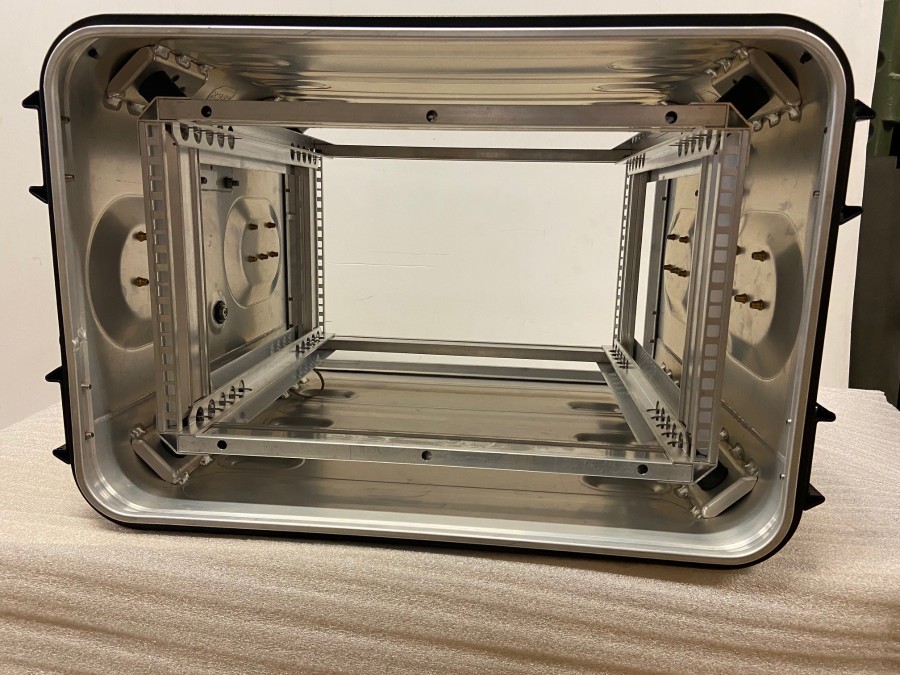

19-inch racks

19-inch racks are lightweight, strong and impact-resistant. They afford the energy and marine industries on-demand, fully deployable operational equipment. 19-inch racks meet the various and extreme transportation demands in the most hazardous environments, meaning safe storage and protection of fragile electronic equipment.

There are many different types of 19-inch racks, some of which perform better for different functions. For example, SatRack is favoured by communications companies due to its lightweight design, which allows the integration of satellite and electronic equipment within checked baggage limits.

Aluminium cases

Aluminium cases are tougher, lighter and more resilient than traditionally designed laminated wood cases, which means that aluminium cases protect equipment from even severe impacts. Aluminium cases are alternative, lightweight cases that can include a specialist foam design, which is tailor-made to protect contents during transit. Low-profile recessed wheels and a reinforced, retractable handle can be fitted for easy manoeuvrability when heavier contents are being transported.

In addition, aluminium cases can be personalised to match the user's needs. For example, indents can be created in the body of the case to fit a wide range of labels. Coloured corner domes can also be included to help identify each case.

Injection moulded Peli cases

An injection moulded Peli case is a case that provides an extremely high level of protection. Peli cases are strong and have high-impact, dust protection, chemical and IP67 water resistance. In addition, Peli cases provide excellent all-weather protection. They can also be fitted with lightweight, internally sculpted LD45 polyethylene, closed-cell foam that protects specialist equipment from movement and damage.

The energy and marine sectors need cases that protect valuable, specialist equipment from the elements, transport and extreme environments. There are many different types of protective casing for this industry: amazon cases, Peli cases and aluminium cases are just three of the best options.

Contact us and we’ll help you find the best equipment for your needs.

-

Custom-made Equipment Cases: What Options Are Available?

14 November 2022At CP Cases, we manufacture a range of cases using high-quality raw materials and customisable products. We have the flexibility to take standard designs and create bespoke solutions to meet our client's needs. Extensive research is undertaken to ensure we provide the very best protection for our customer's essential equipment.

Which product options are useful for equipment cases?

A large amount of our time is allocated to planning and designing our products to ensure that we’re producing the right products for our customers. At CP Cases, we have a wide range of product options available including printing, labelling and branding, partitions and more. We’re constantly developing and refining our product range – pioneering the most effective preventative solutions for weather resistance, water ingress, rough handling and severe impact.

Innovation is key in the production of our products. We strive to continuously innovate by adding new and improved features to our range that bring added value and increased performance to our cases. Our strong focus on attention to detail enables us to fully comprehend the client’s precise product requirements, informing our decision on the design process and giving us the opportunity to provide the right solution.

Custom partitions and dividers for equipment cases

To complement our extensive range of cases, we offer a bespoke partitioning and divider service. This feature is designed to segregate and protect valuable products and equipment. Partitions can be produced using computer-controlled equipment to meet your specific needs – from the segregation of rifles to the protection of intricate medical equipment. Precise drawings are translated into cut partitions which slot together to accurately house and protect your equipment. Partition systems are available for all our protective case types, including our plywood flight cases.

There are many great features in our custom partitions. They’re lightweight, space-saving and are made using hard-wearing material for maximum protection. Partitions and dividers are also interchangeable should your requirements change. These product features work to enable you to get the best value out of the product and accurately protect your equipment.

Printing, labelling and branding for custom-made cases

We offer our customers protective packaging that not only makes your equipment instantly recognisable but also reinforces a positive image of your company. Our printing, labelling and branding service is a low-cost yet effective method of getting high-value returns in presentation and recognition. Our clients can utilise a range of options including silk screen printing, engraved labels and sewn-on badges to personalise cases, racks or bags with their unique branding.

There are many appealing features in our printing, labelling and branding service. Labels can be applied to cases manufactured in laminated plywood, aluminium and plastics. If you require branding and labelling on bags or textile products, multicolour embroidery, screen printing or rubber labels can be utilised to create a brand image. Our team of experts will advise you on the most suitable material to brand your equipment to make it instantly identifiable.

External finishing options for cases

We have a wide variety of external finishing available for our cases. Our cases and 19-inch racks are available in a variety of construction materials, including aluminium rigidised aluminium, laminated plywood and plastics. Each material offers a wide range of finishes to match your exact requirements in terms of appearance and functionality.

There are numerous styles of external finishes to customise your cases and provide full protection for your equipment. Aluminium cases and racks produced in plain or rigidised aluminium can be coated with a range of surface finishes including: powder coating, wet painting and anti-reflective finishes. Plywood cases and racks are produced with the highest quality Finnish birch plywood and can be laminated with high-pressure laminate (HPE) in black, royal blue, dark green, mid grey or light grey. We ensure that there’s a variety of options available to our clients to customise their products to specific needs, along with providing excellent customer service.

Adding custom wheels, handles and locks

We offer a wide range of fittings and options for our cases, bags and 19-inch racks. From wheels and handles to locks and pressure values, our designers and engineers can advise you on the exact features required for your protective equipment. Our design engineers use their wealth of knowledge of materials and production processes to advise you on the most suitable fittings for your protective equipment, depending on the weight and size of your contents. For example, options for plywood flight cases include handles, catches, hinges, locks and wheels. Whereas pressure relief valves are more fitting for aluminium cases.

We offer fittings on our custom-designed bags such as Velcro or zip closures, label pouches, and swivel hooks. All of the fittings we offer are designed to provide the highest level of sophistication to protect your products.

At CP Cases, we endeavour to provide our clients with the highest quality service by taking standard designs and transforming them into new and bespoke solutions. Contact us today to discuss your requirements and our friendly team will be happy to help.

-

Which types of cases are best for transporting medical equipment?

25 October 2022When transporting medical equipment, it’s incredibly important that it’s securely stored in a case that protects the contents from potential damage. Any type of impact, from shock, vibrations or careless handling can have serious implications on vital medical equipment, so it’s fundamental that the type of case is considered to keep equipment safe and undamaged. Medical groups rely on having resistant and reusable cases for transit so CP Cases has used their expertise to help choose the best cases for transportation of medical products.

Aluminium cases

Aluminium cases are ideal for use in the medical industry as they are extremely strong and can protect contents under severe impact. These cases are manufactured in 2mm rigidised aluminium and are designed with indented corners and rounded edges for reinforced strength and safer handling. Aluminium cases can also be fitted with a specialised foam interior to add cushioning for more delicate contents.

CP Cases offers aluminium cases in two designs: AluCurve and AluWeld. There are differences between AluCurve and AluWeld, so it’s important to consider the type of equipment that will be stored before choosing which design to use. Highly valuable and breakable contents may be more secure in Alucurve cases as they have an incredibly high resistance to drop damage, whereas equipment that will be transported outside may be better suited for Aluweld, which is incredibly weather resistant.

Custom rotomoulded cases

Custom rotomoulded cases are another great option for the transportation of medical products and are designed specifically for customers’ needs. Cases are available in made-to-order sizes, so will be the exact dimensions needed for fitting the desired contents. Similar to aluminium cases, rotomoulded cases offer a great strength-to-weight ratio and can be fitted with foam inserts for additional protection. Rotomoulded cases are manufactured using polyethylene, which has high resistance to temperature changes and solvents. It’s also effortless to clean using steam or pressure washing and has zero fungal growth, making it easier to maintain hygiene standards – perfect for medical use.

These cases are suitable for any portable medical equipment needs and are ideal for renal patients looking for easier ways to transport vital medical equipment in a safe and convenient way. They also have a discrete design, having a suitcase-like shell, which may make it more comfortable for individuals to use on a day-to-day basis. The cases are relatively cheap, especially for lower production runs, so offer a more cost-effective option on small orders.

Custom-built bags

Custom-built bags provide protection and lightness for easy medical transportation.

They can be fitted with specially-engineered non-absorbent foam to hold delicate medical products in place (such as surgical instruments or orthopaedic joints). They are better suited to smaller medical tools that are needed on the go and can be designed for optimum functionality, such as being able to choose the type of fastener or adding on handy clasps and clips. Another benefit of the custom-built bag is that they can be manufactured with hard-wearing waterproof materials so are ideal for portable use, whether indoors or outdoors.

What are the advantages of custom-made medical cases?

There are many advantages of having custom-made medical cases, which is likely why 85% of CP Cases output to the medical industry are custom-made orders.

Having customised medical cases allows for a design that will suit a client's exact requirements. Having a tailor-made medical transportation solution means the level of protection works in harmony with the functionality and usability of the case. For example, customising a durable case to include wheels and extendable handles for smoother transportation. It also means increased protection for the medical equipment as interior protective cushioning can be fitted to hold the exact shape and size of the contents, reducing any internal movement during transportation. Additional drawers and trays can be added too to keep smaller, delicate pieces of equipment organised and secure.

Having a case to suit your exact requirements will make transporting medical equipment easier and more secure than opting for a standardised case design.

If you are interested in finding out more about medical cases, get in touch with CP Cases today.

-

What are the benefits of rugged textiles equipment cases?

26 September 2022Rugged textiles equipment cases can be used within many different industries and can be customised with features that make them fit for each individual user. They are designed to function as a protective and portable storage solution for valuable equipment and can be highly beneficial to keeping industrial equipment secure.

What features do rugged textiles cases contain?

Rugged textile cases and bags are manufactured using tough Cordura fabrics and other durable materials, yet are incredibly lightweight. They are available in different styles including the standard flapped or zipped bag, hand-held briefcases, or pull-along cases. Various useful elements can be incorporated into the case design, depending on how the bags are intended to be used. Typical cases include shoulder and hand grips and are padded to protect against dirt, rain and extreme temperatures. These features also make the bags more comfortable and convenient to handle.

Additional optional features include:

- Slings

- Clasps

- Clips

- Closures (including zips, poppers and Velcro - depending on personal preference)

- Dividers

How can rugged textiles cases be customised?

Rugged textile equipment cases can be completely customised from the initial consultation. Orders begin with a standard case template, but can be designed further to fit certain functionality needs. During early discussions, features can be requested and measurements are taken, as each case will be made specifically for the dimensions of future contents. Once the design stage begins, sketches and prototypes will be available throughout the process, up until the final product to ensure it’s meeting client criteria.

Case features (as mentioned above) are optional for individual client requirements, so clients can opt for velcro closure for easy use, or zipped for added security where best suited. If the bag needs to be transported often, clients may choose to add wheels or a telescopic handle for easier movement. Common features that are added to these cases include specialised foam interiors to cushion easily damaged goods. Impact resistance, anti-vibration, forced cooling, anti-fungal, and anti-static are all also important features that can be included in industry-specific designs.

Whilst practical, tough and lightweight, the aesthetic aspects of the cases are never overlooked and can also be customised to suit the brand. They are available in many different colours and the material can be embroidered with logos to maintain a client's image and reputation.

Which industries are rugged textile cases best suited for?

Rugged textile equipment cases are ideal for industries in which high-value equipment or tools are transported frequently. The cases are designed to protect items such as electronics, surgical instruments, and engineering tools, so can be utilised in various industries.

The broadcast industry can benefit heavily from rugged textile cases as they are perfect for storing cameras, and audio apparatus in a way that is secure but also easy to access when filming or catching live footage. Similarly, with hire companies working for live events, audio-visual equipment such as monitors or projectors will need tough, reusable cases to keep equipment safe whilst travelling between venues.

Another industry that rugged textile cases are well suited for is the military and defence. For professionals in this industry, keeping personal equipment at hand is vital, so these lightweight bags can be designed for comfortable and convenient use. They also need to be durable and withstand different environments, which is easily achievable with rugged textile cases with their tough exterior and environmental controlled features.

If you are interested in finding out more about rugged textiles cases, get in touch with CP Cases today.

-

What are the benefits of using server racks?

12 July 2022Every industry has valuable equipment that is fundamental to how their organisation performs, whether it be in the defence and military sector or in the broadcasting field. With this reliance on expensive equipment comes the need for suitable storage solutions and ways to ensure the protection of property. This is where server racks come in handy. Server racks can be used for many different purposes and are the ideal solution for keeping equipment safe and secure. There are numerous advantages of using server racks including them offering an improved level of security and neatly organising space. Here at CP Cases, we have decided to go that extra mile to offer customisable options for your server racks, designing them specifically so that they are more fitting and beneficial to your personal needs.

Customisable options

Having storage that is right for your specific requirements is crucial for effective work performance which is why CP Cases create personalised server rack designs for your individual needs. By investing in server racks that have been created to suit the requirements of your organisation, you are able to choose features that will benefit you the most, whilst feeling confident that your equipment is secure and well protected.

A popular customisation feature is the addition of climate control systems that can prevent overheating, keeping all electrical equipment cool and safe. This can be highly beneficial to organisations that operate in extreme weather conditions such as within the marine and energy industry, where there is demand for server racks that are capable of withstanding hazardous surroundings. This feature can also be highly beneficial for those working with medical equipment, as it is often likely that their contents need to be kept at an optimal temperature in order to remain effective.

The ability to customise our server racks means that whatever shape, size or weight of content that needs to be stored, there will be a suitable and effective solution for you. Along with additional features, the server rack can be customised with accessories including drawers or shelves. These can be useful for storing smaller pieces of equipment and having designated storage spaces for each item, will reduce the chances of misplacement and disorganisation.

Improving security

Keeping your equipment secure, and avoiding unauthorised access is critical, especially for organisations working with sensitive information. Our 19-inch server racks are available in many different styles and materials, to ensure your goods are kept protected at all times.

For optimal security, server racks can even be custom-fitted with system shielding’s which have become increasingly more important as more complex electrical devices face the challenge of malfunctioning if wrong interacting with external systems. To avoid this, CP Cases offers EMI shielding, which adds another layer of security. TEMPEST shielding prevents sensitive equipment from emanating electromagnetic radiation that may carry classified information, helping to prevent risks of data leaks. EMI shielding however can be incredibly useful when storing multiple devices, as it stops the transfer of energy between technology, thus reducing the chances of malfunction. Improving the safety of highly valuable equipment is one of the most advantageous aspects of our server racks.

Organising space

By choosing the right server rack for your unique needs, you will be able to optimise your space, giving more order and functionality to the workspace. With a storage solution that has been designed to fit your specific contents, there is no wasted space and equipment can remain snuggly fit, without the risk of moving around or getting misplaced. Many of our server racks, including the STRATORACK, are beneficially lightweight and stackable, meaning you can easily arrange your equipment upwards, optimising the floor space. In addition, the optional addition of integral wheels means your server rack can also be easily transported and no extra equipment is needed to assist with moving processes or future relocations. Along with the perk of having an aesthetically pleasing environment, server racks can also prevent injuries from falling equipment, and potential damage to expensive equipment.

Whatever the industry, using high-quality server racks can be incredibly beneficial and can change the way equipment is maintained and protected, whether that be from damage or from electrical interference.

Explore our case studies for more information about the benefits of using server racks.

-

AluCurve Vs. AluWeld: What's the difference?

22 June 2022Aluminium flight cases are an incredibly useful product complete with strength and style. These cases are able to withstand severe impact and protect valuable contents, whilst being lighter and more resistant than traditional designs. At CP Cases, we offer two varieties of aluminium flight cases with individual qualities that are beneficial to different purposes: AluCurve and AluWeld. Here we delve into the differences between AluCurve and AluWeld to discover the advantages of the designs.

What is AluCurve and AluWeld?

AluCurve flight cases are made from welded 2mm rigidised aluminium and are constructed without edge corner welds to prevent the risk of seam splitting. They are reinforced with durable pre-pressed corners which strengthens the edges of the cases and makes them extra resistant to high-impact drop damage. These AluCurve cases have also been thoughtfully created for practicality, including features such as recessed handles and indents for convenient stacking.

On the other hand, Aluweld flight cases have an incredibly tough design, yet are actually lighter than traditional laminated plywood cases and meet the strict US ATA300 Cat1 standard of a minimum 100 return air trips. Manufactured using high-tensile aluminium and having robotically-welded seams and joints, these cases are extremely reliable and can withstand even the most strenuous climates and weather conditions. The AluWeld case also has an ideal strength-to-weight ratio.

What are the benefits of AluCurve cases?

There are many advantages of using an AluCurve flight case which offers the perfect balance between style and protection.

The lack of corner welds means the cases are rounded so they are safer to handle and have a smoother finish. This doesn’t withdraw from the case's strength which is intensified by the pre-pressed corners. This feature means the case is able to endure the highest levels of drop damage.

Another advantage of the AluCurve case is its ability to be customised with colour-coded ‘smarties’ so that branding can be established, or for the convenience of being able to organise equipment into easy-to-identify colour-coordinated categories. This design is ideal for owners who are in need of a high protection and stylish case and are particularly popular within the broadcast industry.

What are the benefits of AluWeld cases?

The tough and made-to-last design of AluWeld also has many advantages. These flight cases are weatherproof to IP54, meaning they are ideal for withstanding intense and challenging environments. They have been specifically designed with interlocking lids and body seals that prevent external matter, such as rain and dirt, from infiltrating the contents of the case.

Along with this, AluWeld flight cases are custom manufactured to meet exact requirements. This means that features that are more fitting for individual needs, such as impact-resistant nylon corners, can be incorporated into the case design. Being completely customisable makes the AluWeld case perfect for a wide range of industries, including medical and defence.

Which industries are AluCurve and AluWeld cases used in?

Whilst both AluCurve and AluWeld cases can be advantageous to a variety of industries, their unique features make them more suitable for use in specific markets.

AluWeld cases’ ability to be customised makes them ideal for industries that require intricate designs, such as cases that can hold various sized or shaped equipment. For example, when used in the medical industry, it’s vital that medical supplies are transported safely. AluWeld cases can be manufactured with suitable indents and shelving to secure equipment and prevent spillages or movement when handled.

The lightweight design of AluWeld cases also makes them ideal for industries with heavy equipment or high levels of storage needs, such as the defence and broadcast industry. For example, AluWeld helmet cases are effective as the strength and weight ratio makes them ideal for carrying large quantities of equipment without becoming bulky or inconvenient.

AluCurve cases’ tough and durable design also makes them perfect for industries with high-value equipment. Broadcast media is a key industry that can make use of AluCurve cases, as electronic equipment is often expensive and takes up a lot of space. By keeping valuable equipment in AluCurve cases, it protects against breakages that could have a financial impact. Also, as the AluCurve cases are ideal for stacking, storing broadcasting equipment is more efficient and saves space.

Another industry that AluCurve cases are ideal for is the military, as the cases offer maximum protection and can sustain harsh environments. They are designed to combat the most difficult levels of rough handling that they are likely to be subjected to during military use.

If you are interested in finding out more about AluWeld and AluCurve cases, get in touch with CP Cases today.

-

How to choose the right server rack for your needs

19 April 2022In today’s market, there’s a wide range of different server racks available. Here at CP Cases, we’ve put together a helpful guide on how to choose the right server rack for your needs.

Which types of server racks are popular?

Perhaps you’re looking for a server rack that would suit the defence and security sectors, or maybe you’re after something designed for broadcast. Whatever your requirements are, we have a range of popular server racks here at CP Cases.

One of the most well-known server racks is our 19-inch Amazon Rack. These racks are ideal for defence, marine, security, aerospace, satellite and telecommunication industries. Due to the use of rotomoulding, these server racks are strong and resistant to drops, knocks and extreme temperatures. However, these racks don’t contain the thick wall cavity usually found in rotomoulded products, so there’s even more space.

Another popular type of server rack is our 19-inch SatRack. The lightweight yet robust design of this rack makes it perfect for transporting delicate electronic equipment. To ensure maximum protection, the frame contains stainless steel nuts and is suspended in a honeycombed, polypropylene outer shell.

How can server racks be customised?

As everyone has different needs for their server rack, it’s important that customisation options are available. As our speciality here at CP Cases, we offer a range of specialist solutions and custom features. Whether you’re looking for a small size change, or you’d like a specific custom-built server rack, our experts have all the necessary skills.

One popular customisation feature is the addition of climate control systems to prevent overheating. Our server racks can be fitted with built-in air cooling systems to help keep IT equipment cool and safe.

Furthermore, for optimal security, server racks can be custom-fitted with either EMI shielding. Using a custom level of TEMPEST shielding is the best way to protect sensitive equipment from being intercepted by compromising emanations. On the other hand, EMI shielding works by preventing any environmental interference, so you can have peace of mind that your equipment is safe from this potential problem.

Which heights and dimensions are available for server racks?

The standard width of a server rack is 19 inches, as this is the standard mounting width of most rack-mounted equipment. However, the heights and dimensions of our server racks can be easily customised to suit your preferences.

Each of our server racks are available in a range of standard sizes. For example, SatRacks can be designed in 3U, 4U or 5U versions, and ProRacks range from 4U to 34U. We also offer custom half racks for equipment that doesn’t require the full size.

Does the level of protection vary between different server racks?

All server racks host a variety of benefits that make them secure and safe. But different server racks do offer different forms of protection, making them ideal for their varied purposes.

For example, ERacks are designed for commercial and military sectors, meaning that they need protection against environmental forces. For this reason, ERacks have a folded rim design to protect the edges and create resistance to water or dust ingress. In addition, these products feature a 19-inch internal rackmount chassis for optimal protection against shocks, vibration and impact.

In comparison, ProRacks offer lightweight protection for broadcast or music industries. This product contains suspended racks which give more protection against vibration but also keep the product lightweight and transportable. Furthermore, these racks contain side stiffening plates to reinforce the edges and enhance rigidity.

-

The Art of Commercial Engineering…

11 March 2022In recent weeks we have gained a new member of the CP-team within the UK sales department; Fabien Vijenthiran has joined us from an engineering background, to support our UK sales with a more technical understanding of our product range. We feel that Fabien will bring a fresh perspective to our sales outreach and be able to tackle those technical questions on demand, whilst continuing our efforts to build on relationships new and old. Welcome to the team Fabien, our Graduate Commercial Design Engineer.

To understand more about what Fabien will bring to the team - a ‘commercial engineer’ or ‘pre-sales specialist’ brings credibility to the company, its products and to its solutions. ‘Pre-sale’ or ‘Commercial’ Engineers demonstrate the value of the product and its solutions while promoting advantages over competitors with the charisma of a sales team and the technical know-how of a design team. This, in turn, leads to constructive quality feedback from customers towards product development in a way that the design team can take on board.

With the industries, equipment and processes we work with, and a majority of the customers/ prospects that we deal with engineers (or at least with a procedural way of thinking), it makes good sense to have the front end of CP Cases technically savvy with an undercurrent of personability.

The top 5 rules of Commercial Engineering:

- ‘Commercial’ Engineers are a member of the sales team

- ‘Commercial’ Engineers are not a salesperson

- ‘Commercial’ Engineers must be business relevant

- ‘Commercial’ Engineers must be technically knowledgeable

- ‘Commercial’ Engineers know their audience(s)

It is good practice to remember these rules when thinking about the objectives of your role. It can be a bit of a transition from an engineering setting to a more sales heavy environment – the important thing to remember is the value of your technical skillset and how that can help draw in more sales.

Authenticity is a key contributor to a great commercial engineer. The person on the other end of the phone (or email) needs to have confidence in what you are saying. This will evidently grow with practice and a deep understanding of the companies’ products and solutions. It’s your job to make sure that the products and solutions you sell are relevant, effective, and the right fit for that particular customer (even more important as CP operates in different market spaces).

As the engineering side of the sales team, it’s your job to have the IDEA:

- Identify

- Design

- Evangelise

- Adjust

This means identifying the customers’ top requirements, understanding what environments it will be used in, the handling etc… so that the product design can emulate the solution for these requirements. Work closely with the design team to evangelise the product solution, and if need be, support with any adjustments that are needed to cater to the customers’ requirements.

Knowing your audience goes without saying; you have to be able to put yourself in the shoes of the prospect you are talking to, understand their challenges, their needs for the product and be able to liaise with them in a language they understand. This is a key skill for a ‘commercial engineer’ and boils down to doing your homework and being applicable. Ensure you’ve thoroughly researched your customer, their requirements, and their environment as much as possible.

This applies especially in customer meetings. Knowing their interests and pain points before walking into a meeting is important. As projects progress, customers provide more information, discover more challenges, so it is important to modify your information to accommodate this on the fly. Any technical conversation should be a fluid entity, ebbing and flowing with the customer's feedback.

Like any other art form, ‘commercial engineering’ must be practised. Study your company’s products deeply and understand how they can provide solutions to their customers. Presentation skills and personability are a must, whilst constantly working on enhancing your communication skills. It is good practice to build your own style of working that works best for you and presents natural and comfortable. The more fluent you become, the more values you can bring to your team, company and also customers.

-

The Importance of Sustainability in Business

23 February 2022As we begin a new year, a fresh start, with climate change talks still creating a buzz from the COP26 summit, and people’s desire to do better by the world really shining through. There is no better time for businesses to reflect on their activities over the past year. For a period of time that has brought so much uncertainty throughout, it can be a refreshing prospect to gather your thoughts and see how far your business has come; however big or small the steps may be.

CP Cases Ltd is celebrating its 50th anniversary this year which is a milestone achievement in itself. We are proud of what CP Cases has achieved in the past half-century, having worked hard to get to where it is today. This meant keeping up with the everchanging trends in the different industries that we supply to; keeping above the curve when it comes to our manufacturing processes, innovation of products and the most important (and prevalent) trends – our social values and sustainability goals.

Social values and sustainability goals are the encouraging end result of a business strategy and the motivating factors to achieving them. Working in the manufacturing industry comes with its challenges when setting the focus areas for being an actively sustainable business. However big or small, all goals are part of a robust strategy working towards sustaining our planet and its resources. At CP Cases, we have contributed significantly (especially in the past year) to become a more sustainable manufacturer. Keep reading to find out what steps we have taken.

THE IMPORTANCE OF SUSTAINABILITY

message that we are the first generation to see our effects on the plant but the last generation that can do something about it. Whether individually or through your business, there is an increased awareness on activities that will impact the planet.

Sustainability is becoming more of a focal point for companies across all industries with 62% of directors taking into consideration a sustainability strategy needed to be competitive in today’s markets. Another 22% predict this type of planning will be the future.

With this in mind, we took the entrepreneurial step to hold our own rotational moulding machine in-house for the manufacture of our range of Amazon Cases and Amazon Racks.

RECYCLING

Rotational Moulding is a manufacturing process used widely in the automotive industry to produce weight-efficient, immensely durable and recyclable plastic containers and is an integral part of CP Cases flagship product line, Amazon Cases and Racks.

As mentioned, our London HQ is home to our brand-new Rotational Moulding plant which enables us to increase capacity and reduce manufacturing waste, our Amazon Cases & Racks are 100% recyclable.

Although there are many thermoplastics available the most commonly used for rotational moulding is polyethylene. This is because it has good processing characteristics, is relatively inexpensive and has satisfactory engineering performance combined with resistance to environmental conditions. It can be coloured for corporate requirements (even mottled!) and can improve UV resistance. The polyethylene we use biodegrades naturally, albeit over a long period of time. Methods are available to make it more degradable under certain conditions.

Manufacturers often create high volumes of multiple manufacturing waste materials in fast-moving environments. We endeavour to recycle most of our used materials including aluminium, polyethylene, general waste, plywood and more.

Most companies will share the same sustainability goal of reducing their carbon footprint in any way they can. Over the years we have been working hard to bring the majority of our production and manufacturing in-house. We are also in the planning stages of installing solar panels on the roof of the factory for a greener and more sustainable power source for our office space and machinery. Small steps definitely can make the biggest difference and we as a company are supporting this as much as we can.

COMPANY SOCIAL VALUES

Along with helping the environment with steps towards sustainable manufacturing, in any business, it is important to have social values in place. These are essential in maintaining a healthy relationship between all employees, the company and society.

CP Cases have many processes in place, adapting to the times over the last 50-years. Being a factory, a lot of our values are centred around adhering to a safe working environment for all of our employees and visitors which is paramount.

We have an active ‘always on’ value that demonstrates action to support the health and wellbeing, including the physical and mental health of our employees. We provide equal opportunities for all of our staff and demonstrate action to identify and tackle inequality.

We promote interest in STEM (Science, Technology, Engineering and Mathematics) and are part of the KTP programme to encourage collaboration between businesses and universities within the UK – with our current KTP Associate helping to digitise our manufacturing processes.

We create opportunities within our surrounding areas by employing locally and continue to support our local supply chain to deliver lower cost and higher quality goods and services.

More recently all staff members have been taking lateral flow tests twice a week which we still follow and have continued mandatory face coverings and social distancing practises around the factory to keep our employees and any visitors safe.

SPEAK TO OUR TEAM ABOUT OUR RANGE OF PRODUCTS

We are honoured to be building on our foundations to create the company’s next phase of growth and evolution, keeping up with the changing environments and working towards a more sustainable way of working. Here is to the next 50!

At CP Cases we pride ourselves on meeting the exact needs of clients across a huge range of industries, and we’ve been developing and improving our products for over 50 years. Contact us today to talk about your requirements and our friendly team will be glad to hear from you.

-

What are the advantages of aluminium camera cases?

10 February 2022For those using and transporting highly valuable camera and broadcasting equipment, it‘s essential to have a protective case. If not, you leave your equipment vulnerable to getting broken. An aluminium camera case such as those stocked by CP Cases can help those who use this kind of equipment to feel far more confident that it is safe.

What are aluminium camera cases?

Aluminium camera cases are protective cases used to keep camera equipment safe and protected, particularly when in transit. For many photographers, filmmakers and broadcasters, the camera case is almost as important as the camera itself. It protects their valuable and expensive tools from damage, and allows them to undertake projects in lots of different locations without worrying about their cameras.

How are aluminium camera cases made?

The best aluminium camera cases are made by welding the metal rather than riveting it, which creates a much stronger structure without any weak points. They are often also designed to have rounded edges, in order to further increase the strength of the structure, and also to make them safer to handle. The custom foam inserts inside, which keep the case’s contents in place, are bespoke and made to fit the exact shape of the equipment you are trying to store, and are engineered by specialists to be resistant to shock, fire and more.

What are the advantages of aluminium camera cases?

Having been a material choice for building air and spacecraft components, as well as power lines, and many common household appliances, it is unsurprising that aluminium also works extremely well for making protective cases. These cases are precisely designed to be highly effective and functional. Here are some of the benefits of aluminium camera cases:

- Aluminium is strong and light, meaning that cases made of this metal can be extremely tough and difficult to damage, while also being light enough to carry and transport easily.

- Aluminium is also non-corrosive and resistant to extreme temperatures, meaning that aluminium camera cases can be used to protect camera equipment even in challenging conditions.

- These cases are extremely tough and trauma resistant, meaning that they are extremely difficult to dent or damage, and can act as a shield for the delicate items inside. They are also fully impermeable and waterproof.

- Inside an aluminium camera case is a custom foam insert, specifically designed for maximum protection, into which the contents of the case can be inserted in order to prevent it from falling about inside and getting damaged.

- All aluminium can be entirely recycled, reducing negative environmental impacts.

Why are aluminium camera cases useful in the broadcast industry?

The tough, climate resistant nature of aluminium means that an aluminium camera case can be used to transport filming and broadcasting equipment even when conditions are extremely harsh. This is very useful when broadcasters want to travel to remote locations where conditions are challenging, and means that their cameras are kept safe from water damage. This is clearly very important, since many parties within the broadcast industry work on an international basis, and need to be able to reach a huge variety of locations without concerns for the safety of their cameras and equipment.

The broadcast industry uses a lot of complex, delicate and unusual kinds of equipment, many of which will have been custom-made and be expensive and difficult to replace. It’s therefore extremely important to ensure that they are stored and protected carefully, especially when they are being transported across the world. The ability to have bespoke foam inserts created, which perfectly fit to the contours of the equipment, providing the most secure storage possible, is therefore extremely valuable. CP Cases’ range of aluminium camera cases and camera rain covers will keep your equipment protected at all times, even in challenging conditions.

-

What are server racks and what are they used for?

29 November 2021What are server racks?

Server racks are used to house and transport technical and IT equipment. The category of server racks covers a number of varied products. It includes open or partly open framed cabinets into which mountable servers can be inserted, perhaps as part of an office’s IT infrastructure. On the other hand, server racks can also be highly secure enclosed cases suitable for transporting advanced IT and technological equipment in remote or challenging environments.

What are the different types of server rack?

Server racks come in different sizes which are suitable for different kinds of equipment and uses, with the most common standard size being 19”. However, in many cases server racks are customisable. These bespoke racks are designed to fit the specific shape and measurements of the equipment they store, while still allowing for wire connections and airflow. An example of a bespoke modified server rack would be the modular format Aeroflex ERack developed for BAE Systems and the RAF by CP Cases.

Some server racks, called open framed racks, do not enclose the equipment on all sides and therefore provide flexibility and accessibility for cables. These are often found in secure server rooms. Locked or enclosed server racks have solid sides and can be locked to provide a higher level of security. They are generally more expensive, but they can be used in non-secure locations or for transporting important equipment. Rugged rack servers are the sturdiest kind of server storage, and are often manufactured to be shock absorbent and protective.

What are server racks used for?

Server racks are used for holding technological and electronic equipment, including for IT and telecommunications. For example, this could be routers, switches, hubs and servers which make up complex IT systems like those held in data centres. Server racks have become hugely necessary in recent years thanks to technological developments around the Internet of Things and the widespread use of cloud-based solutions.

However, there are also a range of more highly specialised uses, particularly for rugged rack servers. This can include for the defence, security, oil and gas and aerospace sectors, where server racks may be required for transporting equipment over long distances and may need to be suitable for use in challenging climates and environments. In many cases, this kind of usage may require custom products, like those developed by CP Cases to hold electronic and communications equipment for the Swedish armed forces.

It’s not only defence and security forces who require secure, protective and portable server racks. Products such as the 19” Prorack, which can be enclosed on all sides for security, are used to hold equipment for industries such as music and broadcasting. These products are highly suited for use in the context of concert tours, music festivals and television productions because they provide a high level of protection while remaining relatively lightweight, and are equally suitable for use outdoors and indoors.

What are the advantages of using server racks?

Many of the benefits of server racks are specific to the contexts in which they are used and the specific kind of rack. In a data centre environment, operators rely heavily on the use of server ranks in order to store lots of servers and IT equipment in one place. Being able to stack technologies one on top of the other in a server rack reduces the floor space needed to store IT equipment, and therefore provides a cheaper solution.

Some server racks are designed to provide high levels of protection for delicate equipment. For example an Amazon Rack can provide high resistance to shock and impact while protecting delicate satellite equipment.

Server racks are designed for the storage and usage of computing and electronic equipment so they allow space for wiring, and they often have built-in cooling functions in order to keep equipment in good working condition.

How to cool server racks

One of the greatest challenges when storing large amounts of IT equipment is preventing overheating. This is particularly a concern for companies and organisations who operate in locations with hot or unpredictable climates. It’s therefore important to ensure that server racks have strong climate control features.

While some server racks may have built-in cooling systems, in many cases it’s necessary to customise or use additional equipment in order to create or enhance these features. Luckily, there are climate control systems available which can be added to server racks or used in conjunction with them in order to keep equipment in good condition.

-

How do portable climate control systems work?

11 November 2021A portable climate control system is similar to a portable air conditioner. However, it's much easier to use and more reliable for people and machinery working in extreme conditions. A portable climate control system allows the user more flexibility and safety when working with sensitive equipment that could be damaged by heat, humidity or freezing.

What is climate control?

Climate control is a more sophisticated form of air conditioning that enables the temperature to be more accurately controlled. It uses sensors and a computer to allow for precise temperature management. A climate control system is typically more straightforward to use than air conditioning. It gives the user the ability to choose their desired temperature instead of having to adjust hot and cool air.