F&R Products Ltd

Specialising in coil in tank systems ranging in size from 0.5kW up to 150kW, these units are used for a variety of applications. Additional features can include close temperature control and pure water systems. Bespoke designs available.

Agents for Hyfra Pedia range including oil/quench cooling.

-

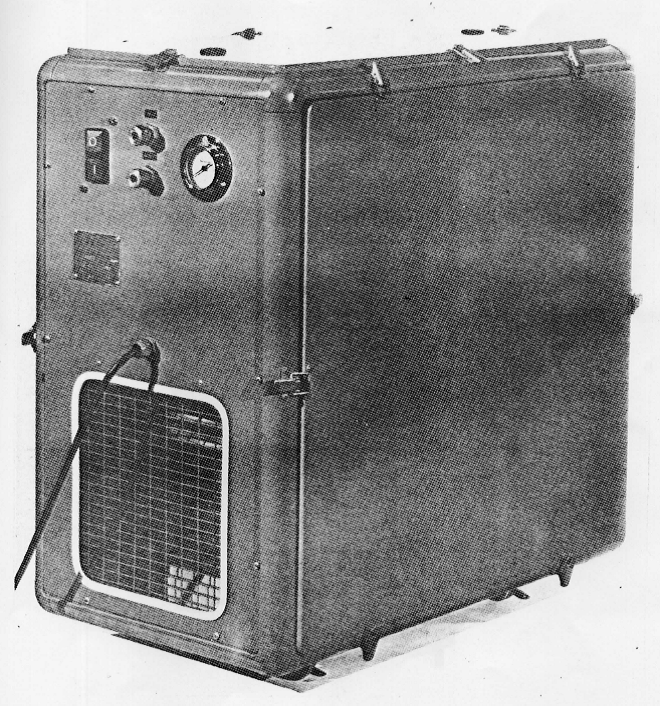

Water Chiller Sigma 16-Special

26 January 2024F&R Products would like to introduce Hyfra Pedia’s Sigma 16-S water chiller which is designed for either internal or external siting in dirty environments as includes special twin wide gap condensers and is readily available from F&R Products Ltd’s stock chillers.

As well as supplying brand new chillers, F&R Products Ltd also offers a wide range of refurbished Hyfra water, oil and emulsion chillers, including the Alpha, Chilly, eChilly, Gamma, Sigma, TRK and VWK models direct from stock.

In addition, as well as being Hyfra’s UK agents, F&R Products Ltd are both F Gas registered and REFCOM approved and are able to offer quick site attendance, authentic spares, plus annual/biannual service contracts for all water cooling equipment through our network of refrigeration engineers based throughout the UK and Ireland.

If this is of interest to you, or indeed, you have any need of our services or require additional information, please do not hesitate to contact us.

For further information contact F&R Products Ltd on 01823 663281 or sales@fandrproducts.co.uk.

-

Checking Industrial Chillers for Refrigerant Leaks

11 January 2024Checking industrial chillers for refrigerant leaks!

Refrigeration systems using ozone depleting refrigerants such as R407C, R410A, R134A etc. with a charge equivalent of 5 tonnes CO2 or more are legally required to be checked at least annually for leaks by a qualified person.

This inspection, together with a service of the equipment, has the added advantage of ensuring the condenser is clean and hence the unit is operating efficiently drawing the least amount of energy to achieve its full cooling capacity.

F&R Products Ltd are both F Gas registered and REFCOM approved so can assist you with this service.

For further information contact F&R Products Ltd on 01823 663281 or sales@fandrproducts.co.uk.

-

Water Chillers - Maximum Efficiency and Minimal Energy Costs

7 December 2022Maximum efficiency and minimal energy costs!

Following the recent exuberant increase of energy costs, we would like to take this opportunity to emphasise the importance of servicing your industrial chiller(s) regularly.

As you know, it is a legal requirement for refrigeration systems using ozone depleting refrigerants such as R407C, R410A, R134A etc. with a charge equivalent of 5 tonnes CO2 or more to be checked at least annually for leaks by a qualified person.

Whilst the engineer carries out this check, he can easily service the equipment, thus ensuring that the unit is operating as efficiently as possible and drawing the least amount of energy to achieve its full cooling capacity. As a result, it will undoubtedly have a positive impact on your electricity usage and cut costs accordingly.

F&R Products Ltd are both F Gas registered and REFCOM approved so can assist you with this service.

For further information contact F&R Products Ltd on 01823 663281 or sales@fandrproducts.co.uk.

-

Winter is on its way - time to check your water cooling equipment!

8 October 2021Winter is coming – check your water cooling systems!

As the first signs of winter are showing with the days getting shorter and the mornings colder, it is time to check the glycol levels in your water cooling systems.

To prevent unexpected downtime and unnecessary repair or even replacement costs, it is advised to check the glycol levels in your cooling equipment to prevent frost damage.

There are two main types of glycol; Ethylene and Propylene - Ethylene for systems associated with the industrial applications but note is highly toxic and Propylene for systems associated with the food industry.

Ideal concentration would be 25% to 30% thus preventing system from freezing in ambients down to minus 10°C to minus 16°C. Too much glycol will result in reduced cooling duty.

For further information contact F&R Products Ltd on 01823 663281 or sales@fandrproducts.co.uk.

-

F&R Products – working through COVID-19 pandemic (2)

8 January 2021F&R Products – working through COVID-19 pandemic (2)

Since the outbreak of the Coronavirus F&R Products has taken the necessary measures in order to secure the health and safety of our staff and clients and to help slow down the spread of COVID-19.

As we are entering a new lockdown and we previously suspended all non-urgent service work we were, and certainly are, still available to help our clients with their critical breakdown issues by either sending our engineers, all whilst ensuring social distancing and following health and safety regulations or providing assistance over the telephone or email. Where annual and biannual chiller services are required, we will approach these on a case-by-case basis.

We keep monitoring the government’s guidelines on a daily basis and will act accordingly.

For now we hope everyone stays healthy and safe during these difficult times.

Should you need any information about our products or services please do not hesitate to contact us.

01823 663281

-

RCU Water Chillers for Food Industry

8 November 2019F&R Products’ RCU range of water chillers are unique in their design in that they are able to chill tap water to 1°C without the addition of glycol, this being especially useful for cooling potable water for food applications.

The unique system of copper coils, immersed in an insulated tank, is able to support high or low volume water flows without the problems associated with other conventional evaporators such as plate, coaxial or tube in tube designs.

The standard evaporator material for the range is copper tube immersed into a GRP tank but other materials are available such as various grades of stainless steel suitable for food applications.

The design also offers a far greater degree of temperature stability than conventional chillers due to the large water volume acting as a thermal flywheel.

Other variants include the facility of a special coil size to fit within a customer’s existing tank.

Typical applications would be to cool the water prior to being mixed with flour in the manufacture of bread or pastries.

-

NEW! Hyfra Sigma FleXX Water Chillers

13 February 2019The new Sigma Flexx range of water chillers comply with EU regulation 2016/2281 which became law in January this year. The design provides flexibility and adaptability for many applications giving a competitive advantage to both manufacturers and end users of industrial water cooling equipment.

The Flexx range has six models with duties ranging from 3kW to 64kW offering low operating costs and environmental benefits (reduced refrigerant volumes). They have close temperature control (+/- 1°C) as standard and provide operational reliability. Energy efficiency is achieved through demand based operation via electronic speed control of both the refrigeration system and thermostatic expansion valve meaning power demand is only that which is necessary to complete the work to hand.

The range is suitable for wter, emulsion or oils with operating fluid temperatures ranging from minus 10°C up to +40°C working in ambients of up to +40°C.

For further information contact F&R Products Ltd on 01823 663281 or sales@fandrproducts.co.uk.

-

Winter is coming ? check your water cooling systems!

13 February 2019Winter is coming – check your water cooling systems!

As the first signs of winter shows itself with the days getting shorter and the mornings colder, it is time to check glycol levels in your water cooling systems.

To prevent that expensive repair or replacement invoice check NOW the glycol levels in your cooler to prevent frost damage.

There are two main types of glycol; Ethylene and Propylene. Ethylene for systems not associated with food industry and Propylene for systems that may be ingested.

Ideal concentration would be 25% to 30% thus preventing system from freezing in ambients down to minus 10°C to minus 16°C. Too much glycol will result in reduced cooling duty.

For further information contact F&R Products Ltd on 01823 663281 or sales@fandrproducts.co.uk

-

F&R Products Ltd Website

13 February 2019Some of you who follow our website will have noticed our website went missing for a few weeks! This was due to an attack from outside forces who believe it is fun to mess around with other peoples’ property.

We are now pleased to announce that due to the hard work and endeavours of our web host, Marmalade Designs, we are back on line.

Our website gives help and assistance to those who are unsure as to what form of equipment they require and how to calculate the size of equipment that is required.

If all else fails you can always call us on 01823 663281 and we will do our very best to help with your selection of the most suitable solution.

-

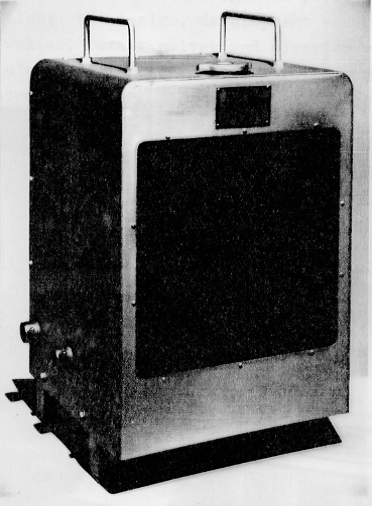

Reliability of F&R Products Ltd's Water Chillers

13 February 2019F&R Products Ltd, one of the oldest and most experienced manufacturers of industrial cooling systems in the UK, can trace the design and components in equipment manufactured by themselves, back to 1961.

The oldest known unit built by themselves still in use is an RCU5 built in June 1980 which cools a plastics moulding machine and is regularly serviced by F&R Products Ltd.

With the aid of these comprehensive records it has been possible to replicate designs and duties of equipment made by the company over its 55 years of existence. The company would be interested in hearing from anyone who has equipment manufactured by F&R that is older than this.

F&R Products Ltd manufacture, sell, service and repair all types of industrial water cooling equipment throughout the UK and Ireland, they are also agents for the Hyfra Pedia range of water chillers.

For further information contact F&R Products Ltd on 01823 663281 or sales@fandrproducts.co.uk