Applications Engineering Ltd

Since opening for business in Uckfield, East Sussex in 1983, Applications Engineering Ltd has become synonymous with the supply of control and instrumentation products.

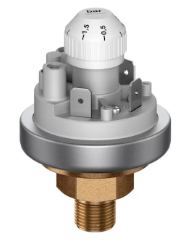

Our impressive array of items offered include; pressure switches, differential pressure switches, pressure transducers, pressure gauges, level switches, level sight indicators, flow switches, flow sensors, float switches, solenoid valves, temperature switches, temperature sensors and vacuum switches.

Product quality and service is of utmost important to us and we are proud to declare that our Management System has been approved to ISO 9001 status since March 2003 (currently certified to 9001:2015) and is approved and annually audited by ISOQAR. Without this, we wouldn’t have been able to supply into some of the worlds’ most prestigious manufacturers supplying the exacting needs of the military industry.

NEXT DAY DELIVERY is on offer for most products as we store a large volume of stock at our facility in Uckfield, East Sussex. Customers can also come and collect products from us, if need be.

-

When are Fire Sprinklers Required in Residential and Commercial Buildings?

11 August 2023Fire sprinklers play a crucial role in saving lives and protecting assets in residential and commercial buildings. Research conducted by the National Fire Chiefs Council (NFCC) suggests that fire sprinkler systems successfully control and extinguish fires in almost all residential and commercial cases.

The evidence of a fire sprinkler system’s effectiveness would seem apparent, yet the UK seems alarmingly behind other European countries when it comes to sufficient regulations and legislation around proper fire sprinkler installations.

Therefore, to clear up any confusion, this guide will outline the key rules to remember when it comes to installing fire sprinkler systems in both new and existing properties, both residential and commercial.

Fire Sprinkler Rules for Residential Buildings

Prior to 2020, statutory guidance in England stipulated that buildings over 30 metres tall (and that had been constructed since 2007) were only recommended to have an automatic fire sprinkler system installed.

It also stipulated that existing high-rise structures, such as apartment blocks, student accommodation, houses of multiple occupancy, boarding houses, care homes, and residential buildings where the floor level of the top storey is over 30 metres high, should have sprinkler valve systems retrofitted, especially if a fundamental change is made to the structure itself.

However, in May 2020, the Department for Levelling Up, Housing & Communities published amendments to the guidance, which essentially modified the minimum height requirements for buildings that need fire sprinklers. Now, all buildings with top storeys that sit more than 11 metres above ground level should have a fire protection sprinkler system installed throughout the premises.

As it stands, there is no mandatory requirement for existing buildings (built pre-2007) to have fire sprinklers fitted, despite the FPA’s vehemence to change this and implement more sufficient fire protection measures, especially in schools.

For existing residential buildings that are undergoing major renovation or structural restoration works, fire sprinklers will likely need to be retrofitted. However, extensions or minor cosmetic work may not require the need for this.

In residential applications, sprinkler systems should be fitted in accordance with regulations BS 9251 (or BS EN 12845 for flat blocks outside the scope of BS 9251).

In layman’s terms, as long as the building is at least 11 metres tall, you should seriously consider whether the existing fire protection sprinklers are sufficient and upgrade accordingly.

Fire Sprinkler Systems for Commercial Buildings

Under UK Building Regulations Part B, businesses spanning 20,000 square metres or more (which are uncompartmented) are legally obligated to install a fire sprinkler system. Suitable fire suppression systems including sprinklers must be installed in new commercial buildings like offices, shops, restaurants, factories, facilities, warehouses, and distribution centres (among others) or retrofitted in accordance with this legislation.

Many business owners express consideration for installing fire sprinklers even if they are not legally obliged to.

Any UK business that employs more than five people (or that is open to the public) must complete a fire risk assessment by law, and the assessment may recommend a business install a fire sprinkler system, even if there are no legal or regulatory grounds for doing so. Factors that influence the recommendations may be based on building size, layout, height, environment, existing fire protection controls, and occupancy levels. If a fire assessment shows that the building possesses a high fire risk, installing fire sprinklers may be recommended even if not mandated.

In summary, even if the guidance says that installing sprinklers isn’t mandatory after you complete your legally-required fire risk assessment, you are at liberty to do so.

By understanding when fire sprinkler systems are required and utilising high-quality components, you can ensure your building meets UK regulations and legislation. It’s highly recommended that you regularly evaluate your fire protection system needs and specifications to ensure you have adequate measures in place.

Using Quality Fire Sprinkler Equipment from Accredited Professionals

When installing or upgrading fire sprinkler systems, using reliable, specialised equipment that meets British and European standards is crucial.

As leaders in supplying tested and quality marked control valves, flow switches, pressure gauges, solenoid valves, temperature sensors, and more, Applications Engineering Ltd provides the certified equipment your residential or commercial project needs.

Partnering with experienced technicians and designers ensures your bespoke sprinkler system is compliant, efficient and effective in protecting your building and occupants when it matters most.

At Applications Engineering Ltd, we can turn product orders around swiftly (with next-day delivery) to ensure that your system receives the necessary vital components and parts to bring it to optimum working capacity.

We have significant stock in our East Sussex facility, and we would welcome direct collection if that’s more convenient for you. If you would like expert advice on how we can help you meet your control and instrumentation needs, please fill in our contact form or get in touch with us directly today.

-

Common Problems and Solutions for Fire Sprinkler Valves

11 August 2023Fire sprinkler systems are a crucial fire protection feature in many buildings throughout the UK. The valves in these systems play an important role in controlling water flow and ensuring adequate pressure is available when needed. Over time, issues can develop with fire sprinkler valves that prevent them from opening, closing or sealing properly.

This can lead to loss of pressure, leakage, or failure to activate when required. Being aware of the most common sprinkler valve problems and their solutions allows building owners to quickly identify and restore functionality. This helps avoid expensive repairs down the line and, most importantly, ensures the system is able to operate as designed in the event of a fire.

Proactive inspection and maintenance are key, so building owners can spot potential valve issues before they lead to system impairment. By understanding the solutions available, any problems can be effectively remedied.

Corrosion and mineral buildup

One of the most frequent issues that can occur with fire sprinkler valves is corrosion and mineral buildup. This problem arises when water sits stagnant inside the sprinkler system’s piping and valves. Over time, the water accumulates mineral deposits and corrosion builds up on the inner valve components.

The stagnant water lacks sufficient flow to flush away these deposits. As corrosion and minerals accumulate, they can prevent fire sprinkler valves from opening fully or sealing tightly. Valves suffering from corrosion may only partially open, obstructing the required water flow rates. Sealing can also become compromised, leading to leaks even when the valve is closed.

There are two main solutions to address corrosion and mineral buildup.

- Firstly, establishing a routine for regularly flushing the sprinkler valves and system helps clear out stagnant water and prevent substantial deposit accumulation.

- Secondly, coatings and linings can be applied to the interior of pipes and valves. This creates a protective barrier between the water and metal components.

With proper flushing and the use of anticorrosive coatings, corrosion and mineral buildup can be avoided. This ensures valves function as designed.

Frozen valves

Another frequent problem for fire sprinkler valves in the UK is freezing due to exposure to cold temperatures. This issue tends to occur more often with valves located in unheated areas of a building.

When water sitting inside pipes and valves is exposed to temperatures below freezing, it can turn to ice. This prevents the valves from opening and water from flowing through the system as intended. The expansion force of water turning solid can also damage valve components. Frozen valves are unable to activate the sprinkler system in the event of a fire.

There are a few key solutions to avoid frozen fire sprinkler valves.

- Insulating the valves and nearby piping helps maintain warmth.

- Maintaining minimum indoor temperatures in unheated spaces of at least 4°C can also prevent freezing.

- Adding glycol to the sprinkler system water lowers its freezing point. This makes the water less likely to freeze at typical UK winter temperatures.

Leaking valves

Leaking from fire sprinkler valves is another frequent problem encountered. This is usually caused by damage to internal valve components that are meant to provide a watertight seal. Specifically, leaking often occurs due to the deterioration of rubber gaskets or the breakdown of metal valve seats.

As these components wear out or become damaged, they are no longer able to seal the valve closed. This results in constant water leakage even when the valve is supposed to be shut off. Besides wasting water, leaking valves cause a loss of pressure in the system. This can impair the sprinkler system’s ability to deliver adequate water density to a fire.

The solution is to replace any damaged or worn-out internal gasket and valve seat components. This typically requires shutting off the system, disassembling the valve, inspecting and replacing any faulty rubber or metal sealing parts, and then reassembling the valve.

Jammed valves

A common issue that can impair fire sprinkler valves is becoming jammed and failing to open when required. This most often occurs due to a buildup of rust, mineral scale or debris that prevents the valve disc or plug from moving into the open position.

Over time, the water flowing through the valve can leave behind rust particles, mineral deposits, and other debris. This material builds up on the internal components of the valve, such as the valve disc and seat. Eventually enough accumulates to mechanically jam the valve parts and prevent the disc from lifting or sliding out of the closed position.

A jammed valve fails to allow water flow when the fire sprinkler system activates. The solution is to clean and lubricate the internal valve components to restore proper operation. This may involve disassembling the valve to access and clean the disc and seat. Any rust or scale is removed, and the parts are lubricated to prevent friction and sticking.

For all of your fire sprinkler valve system needs

Fire sprinkler valves are a critical component that can develop several common problems over time. Regular inspection, maintenance, and prompt repairs are key to preventing valve failure. Working with a specialist like Applications Engineering ensures your valves remain in optimal condition. For expert assessment of your fire protection valves or assistance with any necessary repairs, contact the knowledgeable team at Applications Engineering today.

-

Best Practices for Fire Sprinkler System Maintenance

11 August 2023As a business or commercial property owner, you have a responsibility to ensure the safety of anyone that passes through your premises. A crucial part of personal safety management is making sure your fire sprinkler system is properly maintained and functioning as intended.

Neglecting your fire sprinkler system could have serious consequences in the event of a fire, ranging from personal injury to structural damage and even collapse. Therefore, it’s prudent that you follow these recommendations to keep your fire sprinklers functioning and your fire safety systems in working order.

The Importance of Fire Sprinkler Maintenance

A properly maintained fire sprinkler system is critical for the safety of your building occupants and for preserving your property’s structural integrity. If unchecked, the following issues could arise.

Insufficient Fire Containment

When a fire breaks out, an active fire sprinkler system can extinguish or contain the flames before the fire department arrives, and even prevent the need for individuals to use a fire extinguisher. This can dramatically limit damage and prevent people from putting themselves in unnecessary danger, not to mention the prevention of injury or loss of life.

Poor Functionality

If your fire sprinkler system falls into disrepair or fails to function as it should, it may prove wholly ineffective in an emergency. Potentially, it could only partially activate, allowing a fire to spread more rapidly without proper containment. At worst, however, it could fail to spring into action, allowing the fire to spread at such a rapid pace that safety is more quickly compromised.

Fire Spreads More Quickly

As said above, the consequences of fire sprinkler system neglect can be catastrophic; building fires can potentially destroy entire structures and all of their contents. The costs associated with a severe fire like this go well beyond repairing the building or replacing the contents, not to mention the fact that business operations may be disrupted for an extended period.

By ensuring your fire system – including its valves, pumps, switches and fittings – is inspected, tested and maintained as recommended, you are investing in maximum fire protection and prevention. Taking some vital and straightforward steps in ensuring the integrity of your fire sprinkler systems is well worth the time, resources, and costs, particularly when you consider the possible financial repercussions that could burden you following an unchecked fire breaking out. You have an obligation to protect the property, assets, and people inside it, so your due diligence is imperative for preserving the stability of the building as well as life.

How to Check Whether Your Fire Sprinkler System is Working Correctly

Inspect and Test Components Regularly

At a minimum, you should have your fire sprinkler system inspected once a year by a certified fire safety technician.

They will check that all components like sprinkler heads, pipes, check and control valves, fire pressure switches, pumps and the control panel are in good working order. Any damaged or malfunctioning parts will be identified and either repaired on-site or put forward as a recommended remedial action for you to take. All defective, damaged, or broken parts should be replaced as soon as possible.

Maintain Proper Water Pressure and Flow

Your fire sprinkler system requires adequate water pressure and flow to operate effectively in an emergency. Water supply valves should always remain fully open and unobstructed, with pressure gauges performing to your system’s chosen specifications.

Test the water flow through the main drain valve annually to ensure it meets the minimum gallons per minute (GPM) requirement for your system size. If you cannot do this yourself, consider asking an accredited fire safety expert to run the water pressure test for you.

If water flow or pressure drops below the necessary levels, it indicates an issue like a blockage in the pipes that must be addressed immediately.

Inspect and Replace Sprinkler Heads

Fire sprinkler heads are the critical components that disperse water should a fire be detected. It’s worth inspecting your fire sprinklers for any signs of corrosion, obstruction, or damage, and ordering any replacement fire sprinkler heads if they are looking particularly worn.

Usually, however, sprinkler heads can function correctly for a good few years before succumbing to any damage, but depending on the product, some heads may need replacing sooner. For free advice about the longevity and durability of fire sprinkler heads, get in touch with Applications Engineering Ltd.

Test Emergency and Monitoring Systems

In addition to the fire system itself, any connected emergency or monitoring systems should be tested regularly. Ensure emergency pumps are regularly tested as per the manufacturers’ instructions. Monitoring systems should be checked every day to confirm they are still active and sending signals properly. A good recommendation is to check the system upon entry of the premises in the morning, and once more when exiting the property.

A professionally installed and properly maintained fire sprinkler system is the most effective way to protect your building and everyone inside from the devastating effects of a fire. By following these best practices for maintaining your fire sprinkler system, you can help ensure it will operate effectively in the event of an emergency and continue protecting your property and anyone inside for years to come.

Enterprise-Level Fire Protection Products Available

At Applications Engineering Ltd, we have been designing, supplying and installing high-quality fire sprinkler systems for over 20 years.

We specialise in producing and supplying parts for high-quality, professional fire sprinklers and safety systems, as well as intricate parts like solenoid valves and CPVC fittings. We are happy to provide advice on any concerns that you may have about any parts of your fire safety system.

Don’t leave the safety of lives and the structural integrity of your building to chance – contact us for a no-obligation chat with our certified and friendly team. We can ensure you have the most advanced, high-quality fire sprinkler system products and parts, so that your building is complying with all relevant fire protection guidelines and legislation, as well as preserving safety inside.

-

Fire Prevention Strategies for your Workplace

11 August 2023When it comes to workplace safety, one aspect that cannot be ignored is fire prevention. Fires in the workplace can lead to serious injuries, loss of property, and even loss of life. That’s why it is crucial for businesses to have a comprehensive fire prevention plan in place.

By implementing proper fire prevention strategies, businesses can protect their employees, their property, and their bottom line. In this blog post, we’ll take a look at some common fire hazards in the workplace, as well as fire prevention strategies and emergency response plans that can help keep your workplace safe.

Common fire hazards

It is unfortunately the case that fires can happen in any workplace, regardless of the industry or size of the business. However, some workplaces are more prone to fire hazards than others. The most common fire hazards in the workplace include flammable materials, electrical equipment, smoking, cooking equipment, and heating equipment.

Flammable materials such as chemicals and other substances that can easily ignite and fuel a fire should be properly stored and handled to prevent fires. Electrical equipment, including overloaded circuits, frayed cords, and malfunctioning equipment, can all lead to electrical fires. Regular inspection and maintenance of electrical equipment is essential to prevent these types of fires.

Smoking is still a leading cause of workplace fires. It’s important to establish designated smoking areas away from flammable materials and to provide proper receptacles for cigarette butts. Kitchens and break rooms with cooking equipment can also pose a fire hazard if proper precautions are not taken.

These areas should be equipped with fire extinguishers and proper ventilation to prevent fires. Space heaters, boilers, and other heating equipment can potentially cause problems. Proper use and maintenance of these types of equipment can help prevent fires from occurring.

When you understand these hazards, it makes it easier to have a fire prevention strategy in place.

Preventing workplace fires

Preventing workplace fires requires a combination of employee training, regular inspections, and the implementation of fire safety protocols. Here are some steps that businesses can take to prevent workplace fires:

- Conduct regular fire safety training – all employees should receive regular training on fire safety, including how to use fire extinguishers and how to evacuate the building in the event of a fire.

- Install and maintain smoke detectors – smoke detectors should be installed throughout the workplace and regularly maintained to ensure they are working properly.

- Implement proper storage procedures – it’s a good idea to store flammable materials in designated areas away from anything that could potentially ignite them.

- Properly maintain heating and electrical equipment – you should regularly inspect and arrange for the maintenance of heating and electrical equipment to help prevent fires caused by malfunctioning equipment.

- Have a smoking policy in place – if smoking is allowed on company property, designated smoking areas should be established.

Have the right equipment in place

Fire safety equipment is an essential component of any workplace fire safety plan. There are several types of equipment that can help prevent and mitigate the effects of workplace fires.

One of the most important pieces of fire safety equipment is fire extinguishers. Portable fire extinguishers can be used to extinguish small fires before they escalate. It’s important to have the right type of fire extinguisher for the specific type of fire.

Another important piece of equipment is smoke detectors. Smoke detectors should be installed throughout the workplace and regularly maintained to ensure they are working properly. Smoke detectors can help alert employees to the presence of a fire early on, giving them more time to evacuate the building safely.

Other types of fire safety equipment include fire sprinklers, fire hoses, and fire blankets.

At Applications Engineering, we provide specialist fire sprinkler system components. If you are interested in learning more please get in contact with our experienced team today. -

Common Myths about Fire Sprinklers

11 August 2023Fire sprinkler systems have been saving lives and protecting property across the UK for over 100 years. Yet, despite their proven track record of safety and success, some common myths still surround their use.

At Applications Engineering, we are specialists in providing fire sprinkler technologies and products, and we frequently hear concerns from clients and consumers that are unfounded. Our goal here is to address the biggest myths and provide factual information to dispel any doubts about including these life-saving systems.

Properly installed and maintained, fire sprinklers are the single most effective method for combating fires in their earliest stages, before severe damage can occur – whether that’s in a business setting or in your home. However, they remain subject to unfair stigmas related to appearance, effectiveness, accidental discharge, and cost – all of which we will counter with facts from leading fire safety organisations and independent reports.

Myth: Fire sprinklers damage property by releasing too much water

Fact: Modern fire sprinkler systems are individually heat-activated directly over the fire source, suppressing flames precisely where needed. They rarely deploy fully and typically extinguish fires before significant damage occurs.

It has been estimated that the average fire sprinkler system in the UK discharges just 283 litres of water – roughly 6 bathtubs full. Installed correctly, sprinklers contain up to 99% of fire damage to the room of origin.

Myth: Fire sprinklers activate accidentally or malfunction frequently

Fact: Fire sprinklers are strictly engineered safety mechanisms that rarely activate without cause. The likelihood of accidental discharge or malfunction from a properly installed and maintained system is virtually zero according to fire safety organisations.

The risk of unwanted sprinkler release in any given year is less than 1 in 16 million. This is an incredible safety standard. Strict regulations and guidelines require rigorous testing, inspections and certification to prevent failure.

Two conditions must be met to activate a single sprinkler head: heat at the sprinkler head must reach its rated temperature, and the sprinkler head must have direct exposure to a heat source. General room temperatures will not trigger the entire system. Excessive ambient heat is required and activates one sprinkler at a time.

Accidental pipe bursts can discharge water but do not constitute a system malfunction. They rarely activate sprinkler heads themselves. All piping and components are built to avoid rust, corrosion and withstand building collapse for utmost reliability.

Myth: Fire sprinklers damage the appearance and decor of homes and buildings

Fact: Modern fire sprinklers are intentionally designed to be unobtrusive and blend in with surroundings when not in use. Their visual impact is minimal to non-existent in most cases. Addressing concerns that fire sprinklers will ruin aesthetics is unwarranted given how discreet they actually are.

Fire sprinklers remain concealed within the ceiling until heat activates them. Only the sprinkler head is visible, which is intentionally designed to be as understated as possible. Sprinkler heads come in finishes like white, chrome, brass or can be painted to match ceilings. For those wanting to further obscure even dormant sprinkler heads, decorative cover plates provide an affordable option to seamlessly blend them into any interior design or ceiling.

The notion that sprinklers must be an eyesore is outdated and no longer valid given advancements focused on unobtrusive yet efficient systems for any application. Their visibility during normal operation is minimal to nil in most properties. A few small sprinkler heads sporadically placed in ceilings pose little aesthetic impact, especially compared to the destruction caused by fires they can suppress.

If you are interested in having a fire sprinkler system installed, Applications Engineering specialises in providing high quality parts. Please get in contact with our experienced team today if you would like to learn more.

-

Why Your Industrial Premises Needs A High-Quality Fire Sprinkler System

11 May 2023Fire sprinkler systems are an essential component of fire safety in industrial facilities. It might be the case that your premises house large amounts of hazardous materials and heavy machinery, making them particularly vulnerable to fires.

Not only can a fire cause significant damage to the facility and its equipment, but it can also put lives at risk. Fire sprinkler systems provide an important first line of defence against fires, helping to suppress them quickly and minimise any damage.

In this blog, we take a look at the importance of using high quality fire sprinkler systems in your industrial unit.

It’s the law

Perhaps the most crucial reason that your industrial premises needs a fire sprinkler system is that it may well be against the law not to have one. In the UK, fire sprinkler systems are a legal requirement for any business premises with over 20,000 square metres of space. This will clearly be the case for many industrial facilities.

However, even if your facilities are not legally mandated to have fire sprinkler systems in place, you might be interested in installing them anyway, as they have a huge range of benefits.

Respond quickly to fires

Fire spreads quickly – more quickly than you can imagine. You might assume that if you spot a fire, you can easy run to an alarm, set it off, and everything will be fine. But an unchecked fire can move rapidly.

One of the key benefits of fire sprinkler systems is their ability to detect and respond to fires quickly. Most systems use heat detectors to detect the presence of a fire and, once activated, the sprinklers will begin to release water to extinguish the flames.

The speed at which the sprinklers respond can make a significant difference in the outcome of a fire. The faster the fire is suppressed, the less damage it can cause and the less likely it is to spread.

Contain the problem

Another important benefit of fire sprinkler systems is their ability to contain fires. When a fire breaks out, it can quickly spread to other areas of the facility if it is not controlled. Fire sprinkler systems help to contain fires by releasing water on the flames and preventing them from spreading. This can help to limit the damage caused by a fire and reduce the potential cost to the business.

Some facilities worry about potential water damage. But this pales in comparison to the potential negatives of fire damage.

Protecting your most valuable asset

Of course, a vital element of fire sprinkler systems is their ability to save lives and protect people in the facility. When a fire breaks out, it can be difficult for people to evacuate the building quickly and safely.

Fire sprinkler systems can help to suppress the flames and create a safer environment for people to escape. Additionally, many systems also include alarms, which can alert everyone on the premises to the presence of a fire and help them to evacuate more quickly.

For insurance

Many insurance companies require industrial facilities to have fire sprinkler systems in order to be eligible for coverage. Additionally, many local and national fire safety codes require fire sprinkler systems in certain types of industrial facilities. It is important for facility managers to be aware of the laws and regulations that apply to their specific facility and to comply with them.

Installing a fire sprinkler system can be a significant investment for an industrial facility, but it is an investment that is well worth it. The cost of the system can be offset by the cost of damage that can be caused by a fire, not to mention the potential loss of life. Many fire sprinkler systems can be retrofitted to existing facilities, which can help to reduce the overall cost of installation.

If you are interested in having a fire sprinkler system installed it is vital to have the right parts. At Applications Engineering we supply high quality fire sprinkler valves and a range of other equipment used in these systems. Contact our team today to learn more.

-

The cost of fire: minimising damage to your business with fire safety measures

11 May 2023There can be no doubt that one of the most catastrophic events that any business can suffer is a fire. From direct costs associated with rebuilding and repairing damaged property to indirect costs like lost revenue and increased insurance premiums, the financial impact of a fire can be devastating for a business of any size.

Despite this, many businesses are still unprepared for the potential dangers of fire, failing to implement adequate fire safety measures that can help reduce the risk of a fire. In this article, we’ll explore the cost of fire, including the direct and indirect costs associated with fires, and examine the fire safety measures that can help minimise these costs.

By understanding the full cost of a fire to a business, you can take the necessary steps to protect your business and employees from the financial impact of a fire.

Suffering a fire is expensive

When a business suffers a fire it can result in a range of costs to the company. These can be broken down into direct costs and indirect costs:

Direct costs

- Repairing damaged property – the cost of repairing or rebuilding damaged property, including materials, labour, and construction costs, can be significant.

- Insurance claims – your insurance can help cover the cost of repairs, but the process of filing a claim and negotiating a settlement can be time-consuming and complicated.

- Equipment and inventory loss – fires can destroy equipment, products, and inventory, resulting in a significant financial loss for your business.

Indirect costs

- Lost revenue – suffering a fire will disrupt business operations. This will almost certainly result in lost revenue and reduced productivity. Depending on the severity of the fire, it can take weeks or even months for a business to fully recover.

- Increased insurance premiums – after a fire, insurance premiums can increase, adding an additional financial burden to a business.

- Reputational damage – suffering a fire can also damage your company’s reputation, making it more difficult for a business to attract customers and generate revenue in the future.

The safety measures you can put in place

Fortunately, there are a number of fire safety measures that your business can take to minimise the cost of a fire. These measures can include:

- Carrying out regular fire risk assessments – this is an essential step in identifying and addressing potential fire hazards. The process should include a thorough examination of the building, equipment, and processes to identify potential fire risks.

- Providing fire safety training – regular fire safety training for employees can help ensure that everyone knows how to respond in case of a fire and minimise the risk of fire-related accidents.

- Installing fire alarms – fire alarms can provide an early warning of a fire, allowing employees to evacuate the building and emergency services to respond quickly.

- Installing fire sprinkler systems – fire sprinkler systems can help control and contain a fire, reducing the extent of damage to the building and contents.

- Implementing emergency evacuation procedures – in the event of a fire, it is important for employees to know what to do and where to go. Implementing emergency evacuation procedures, including fire drills, can help ensure a safe and fast evacuation.

At Applications Engineering, we specialise in producing parts for high quality fire sprinkler systems. If you are interested in using our parts as a part of your fire safety measures, please get in contact with our experienced team today.

-

Signs Your Fire Sprinkler System Needs Repairing or Replacing

11 May 2023One of the biggest priorities for any commercial building owner is to ensure that efficient fire safety controls are put in place. Fire safety and fire prevention must always be taken into consideration, whether you use the building for your own purposes, or sub-let it to other businesses.

It’s your responsibility to ensure that your fire safety systems can not only protect your property and the people within it but do so in accordance with UK fire safety regulations (the Fire Safety Act 2021).

One crucial component in any fire safety risk assessment is to ensure that your fire sprinkler systems are working correctly. This guide will explore the important factors to consider when looking at your fire sprinkler system and how to tell whether it’s due for a repair or upgrade.

How to Tell Whether Your Fire Sprinkler Isn’t Working Properly

You can usually tell when a fire sprinkler isn’t working properly with a few overt warning signs.

- Corrosion – Some fire systems hold water which can lead to corrosion over time, and you’ll know it by seeing rust or discoloured water. Corroded water can eventually cause a system to fail.

- Leaks – Water leaks are never a good sign, and long-term water damage can be a costly affair, potentially leading to the growth of mould or mildew. Leaks from fire sprinkler equipment indicate that something inside is not containing water properly.

- Pipe or head damage – Sprinklers themselves are made up of intricate parts and small fittings, which, if misplaced or damaged, can cause the system to fail or perform insufficiently. The pipes or sprinkler heads may, over time, succumb to wear and tear or inadvertent damage during any renovation or construction work.

- Malfunctioning – Fire sprinkler systems are often integrated with a widespread fire alarm system. Depending on the system controls, you may be alerted to a faulty or defunct sprinkler which requires your attention.

Risks of Ignoring Faulty Sprinkler Systems

Considering the chances of a fire breaking out are highly unlikely in most office-based environments, you should not rest on your laurels and assume that the sprinklers will douse any and all flames should they spurt.

It’s vital to have a fully functioning and monitored fire protection system to keep you, your building tenants and your inventory safe at all times.

If you ignore your fire sprinkler system for too long, the results could be devastating. There could be any of the following issues:

- Substantial property damage to the building and potentially neighbouring structures;

- Structural issues caused by fire damage, resulting in falling materials;

- Excessive smoke inhalation;

- Insufficient containment of fire;

- Slippery surfaces caused by leaks, posing a hazard to inhabitants;

- Serious and catastrophic injuries or illnesses, including loss of life.

How to Ensure Your Fire Sprinkler System Works Correctly

The best way to prevent any of the above risks from materialising is to ensure that your fire sprinkler system is working correctly.

Some simple ways to check whether your fire system is functioning as it should include:

- Arranging a fire sprinkler inspection with a professional, accredited company. Regular inspections will help you understand any faults or malfunctioning parts easily and they can usually be repaired or replaced quickly.

- Regular maintenance on these sprinkler systems to ensure they are in good working order, including any replacement of parts or repairing any damage.

- Conduct ad-hoc fire risk assessments in accordance with fire safety regulations whenever a significant change occurs, such as whenever a leasing business acquires more floor space.

- Consider upgrading the fire safety sprinkler system to account for any new planned structural works, ensuring that it’s installed and working correctly once the building work is completed.

Need to Repair or Replace Your Fire Sprinkler System?

The decision to replace or repair your fire sprinkler system is never clear-cut, and you will get a more informative assessment from a local fire sprinkler maintenance company.

You can usually get an idea if you ask yourself the following questions:

- How old is my fire sprinkler system?

- When was the last time I had my fire sprinkler system serviced?

- What type of fire sprinkler system do I have?

- Does the existing fire system meet UK fire regulations?

- Is the existing system sufficient for the size and scale of my building?

- Are there any long-term cost savings I can make by upgrading my fire sprinkler system?

While the above questions can be good food for thought, your best bet is to consult a fire sprinkler contractor who will assess your current system and give you the most practical advice from there.

At Applications Engineering, we specialise in producing and supplying parts for high-quality, professional fire sprinkler systems, and we are happy to provide advice on any concerns that you may have about any parts of your fire safety system.

If you are interested in the availability of parts such as check valves, pressure control valves or CPVC fittings, as well as other switches and flowmeters, we’d be more than happy to help you. Contact us for a no-obligation chat with our friendly and experienced team.

-

Pressure Washing: 6 Satisfying Ways To Clean Your Home

8 December 2022Our homes gather a lot of dirt and it can sometimes feel like a full-time job just keeping on top of the chores. Unfortunately, it’s not always easy to weave some cleaning time into our busy lives and things get neglected.

Then the months go by and those dirty fixtures and fittings around the house become part of the furniture and you are blind to them. Typically, it’s only when you have someone important coming to visit that you notice how shabby your home is looking.

A simple spruce up isn’t going to cut it for the patio that has been abandoned for years and you have forgotten what the original colour of your garden furniture was. Fortunately, there is a quick fix, a very quick fix, in fact, and it’s the pressure washer.

These powerful streams of water can wash away years of neglect in a matter of minutes, meaning your in-laws will never even realise how dirty your home was before they announced they were coming, just a week ago.

Let’s take a look at six ways you can blast away the dirt around your home with a pressure washer.

Freshening up your patio

Patios can seem like a great idea when installed but they turn dangerous if they aren’t regularly cleaned. Garden patios are prone to growing slippery organisms like algae or lichen in the cracks. They come in on the wind and are very difficult to remove.

As you sweep the surface you are helping them spread even more and the only tool for the job is a powerful pressure washer. The jet from the washer completely removes the lichen and algae from your patio, helping to stay cleaner for longer.

Lawnmowers and garden tools

Gardening tools and equipment, like lawnmowers, are designed to get dirty. However, if you leave them to get too dirty, they stop functioning properly, making what can often already be a chore seem even more difficult.

Lawnmowers can get clogged with grass cuttings, making them harder to push across your lawn and potentially blocking your grass collection box. This could spread grass cuttings all over your lawn, forcing you to get the rake out and make a simple job last twice as long.

Or you could take a power washer to your lawnmower, free it of excess grass clippings and make mowing the lawn light work. Other garden tools like strimmers and hedge trimmers can also be given a new lease of life by removing stubborn dirt with a blast from a power washer.

Outdoor walls

Scaling a ladder precariously leant against your outer walls isn’t the best way to clean them. Instead, you can blast them with a power hose from the safety of the ground, and more effectively too. Say goodbye to ingrained dirt and make your house look shiny and new!

Pressure washers can be used to clean most types of outdoor walls but you may need to turn the pressure down for wood or rendered surfaces.

Outdoor furniture

Garden furniture is wonderful when the sun is shining and the barbeques are fired up but over the colder months, they become neglected. With little reason to sit on them, many people’s outdoor furniture can grow dirty and grubby over the winter.

Plastic, vinyl or wooden furniture can often look like it has never been cleaned, possibly because it hasn’t, but with a power washer in hand, it’s actually pretty fun. As the years go by, our garden furniture grows grubbier and grubbier but with a blast of a pressure washer, it can look pristine once again.

Driveways, paths and patios

Cleaning the driveway is one of the most popular reasons for buying a pressure washer in the first place, so it’s best to use it for its intended purpose. Our driveway is often the first impression visitors get of our homes but they can also be really tough to clean.

A wire broom and some cleaning products will do a decent job of clearing the dirt from your driveway but is decent really good enough? Pressure washers can take care of your driveway in no time thanks to the large, flat surface you are working on. Blasting away at the driveway is satisfying because you can see an immediate before and after while doing it.

Garage floors

Garage floors don’t get a lot of love from their owners. They are often littered with debris from shelves above and any dirt falling from your gardening tools. If you store your car in your garage, you may have some oil spills from your engine.

Other common garage floor spillages that can be taken care of using a pressure washer include rust, paint and even bird droppings. Fortunately, you don’t have to get your hands dirty as you can set your pressure washer to its maximum setting and blast it all away.

The JetCleaner system

At Applications Engineering we specialise in hose cleaning systems, ensuring any blockage is dealt with efficiently and effectively. Cleaning pipes and hoses using the JetCleaner system removes blockages using compressed air to send projectiles through pipes or hoses which remove debris as they travel.

If you haven’t touched your pressure washer for a while then there is a chance it could be clogged. Our JetCleaner system is a fast and effective method for internal hose and pipe cleaning. Thanks to the powerful guns, nozzles and projectiles, the JetCleaner system is ideal for all industrial needs from hydraulics to food and beverages.

We also make and design high-quality fire sprinkler valve systems and pressure switches. If you are interested in JetCleaner systems or would like to get in touch about fire sprinkler systems, get in touch with our experts.

-

The Everyday Uses For Pressure Switches

8 December 2022Pressure switches are a part of our lives, but many people might not even know they exist. They are vital pieces of equipment to ensure the things we rely on work, like smartphones, aeroplanes, irrigation systems and energy systems. But what are pressure switches and how are they implemented in our everyday objects?

What is a pressure switch?

A pressure switch, sometimes called a pressure sensor, provides electrical feedback on the rising or falling pressure within a chamber. When the pressure meets a predetermined level, the pressure switch will engage to relieve or build up the pressure.

Let’s take a look at where you can find pressure switches.

Well water pumps

Well water, or borehole, pumps are submersible pumps used for the spraying, pumping and irrigation of stored water from water butts. The pressure switch signals to the well pump whether to start or stop pumping depending on the pressure in the water system.

A bad well pressure pump can result in low water pressure or possibly no water at all coming from the system. Your well water pump pressure switch might also be failing if it continually cycles for no apparent reason.

Electronic gas compressors

In the energy sector, a gas compressor is an essential piece of equipment. They are used in the production of electricity and heat production plus hydrocarbon extraction. The correct gas pressure is vital for the transportation of gas through pipelines and the lifting of oil in gas-lift operations.

Pressure switches are important for keeping the pressure at a consistent level; too much and the gas could change phase into a liquid. Alternatively, this may be the desired effect, in which case it’s important to ensure that transformation can be completed.

In-cell charge control inside a battery

Battery charging is essential for renewable energy and without a pressure switch, there is a danger of overcharging. However, pressure switches built into a battery cell disconnect the charging current whenever the internal pressure reaches a certain limit.

This is essential for prolonging the life of a battery cell in things like cars and smartphones. Too much charging reduces the lifecycle and capacity of the battery while also corroding essential components.

Activating an alarm if aircraft cabin pressure drops

The pressure of an aircraft cabin must be maintained at the right level for the safety of everyone on board. If the air pressure is too low at high altitudes it means your body isn’t receiving enough oxygen, triggering confusion, sleepiness or hypoxia (a lack of oxygen).

Cabin pressure is maintained via an outflow valve which ensures the incoming air remains in the cabin and is released at the correct rate. The use of a pressure switch for activating an alarm if cabin pressure drops is essential for maintaining safety at all times. If pressure is lost, oxygen masks are deployed to ensure everyone is getting enough but this could not happen without a working pressure switch.

Pressure panels on sliding doors

Sliding doors work in several ways but some use pressure panels to detect when someone is trying to walk through them. Once the pressure panel senses a change, thanks to the added force of someone stepping on it, the sliding door is activated and it opens up.

Needless to say, if the pressure switch on a sliding door pressure panel isn’t working, the door won’t open. Instead, it will have to be manually opened, which isn’t always easy or possible. There is also a risk that unsuspecting people could walk into the door expecting it to open as normal.

Powering refrigeration units

High and low-pressure switches are used as protective devices for compressor and refrigeration circuits. Refrigerants work by bringing hot gas into a compressor where it is subjected to high pressures.

The high pressure forced upon the gas turns the vapour into a liquid that absorbs heat from the conversion process. This is then passed into a low-pressure environment which forces the refrigerant to cool back to liquid form.

That exchange of heat causes evaporation which places a cooling load into the refrigerator. Gas is once again absorbed by the refrigeration unit, starting the cycle over again. Ensuring the pressure is maintained through a switch at both high and low ends allows the refrigeration process to continue working effectively.

Our pressure switch products

Here at Applications Engineering, we supply a variety of pressure switches for use in a variety of industries. Our pressure switches can be used in a variety of different areas including oil, air, water, compressors and differentials.

We are also specialists in high-quality fire sprinkler valve systems that are fit for purpose in modern domestic and residential properties. We supply to a huge range of companies and businesses, so get in touch to discover which pressure switch is best suited to your needs.

-

What is a Vacuum Switch?

8 December 2022Here at Applications Engineering, we supply single and double throw vacuum switches to our customers. But what is a vacuum switch? Let’s take a deeper look at what vacuum switches do and where you can expect to find them.

What is a Vacuum Switch?

In a nutshell, a vacuum switch provides a switching contact function whenever a predetermined vacuum gas pressure level is reached. This may be to relieve pressure in a system or it may be engaged to increase the pressure. They are a common feature of the hydraulic, pneumatic and processing industries and essential for operations.

For fluidic and liquid processing systems, a vacuum switch is there to trigger a circuit in the event of a vacuum being compromised. Whenever these switches sense a change in the vacuum, they open or close an electrical circuit. Not only is this essential for functionality, it’s also important from a safety aspect to prevent pressure from building up too much.

These switches can be adapted to match specific thresholds, ensuring that whatever purpose you have for them, they will be fit for the job. Our vacuum switches come in two basic forms: single throw and double throw.

Poles and Throws: What’s the Difference?

Our single pole vacuum switches come in two variations: single or double throw. It’s important to understand the roles of each switch when buying a vacuum switch for your needs.

Poles

A single pole switch has just one input and one output, meaning it has just two statuses – either on or off. When wiring these switches, it’s possible to configure them either normally open or normally closed.

Double pole vacuum switches have two connections to two separate circuits. Essentially, they are two switches in one and can be either staggered or connected simultaneously.

Regular single pole switches can be found in everyday items like home appliances, light switches and alarms. Similarly, common double pole switches are used for things like medical applications or light and fan combinations.

Throws

While there can be double and single poles in vacuum switches, there can also be either single or double throws. A throw refers to how many positions a switch can activate.

Single throw switches close a circuit in one position while a double throw switch has the capability for closing a circuit in two positions. Double throw switches also have a neutral position where neither circuit is activated.

Where Vacuum Switches can be Found

One of the most common industries where you can find a vacuum pressure switch is hydraulics. Vacuums are important for hydraulics, so regulating the pressure build-up is critical for keeping hydraulic equipment working.

Hydraulics are typically used for moving parts of mechanical systems that lift, push or pull heavy objects. They use a pump that draws in liquid which creates a vacuum at the inlet. When the pressure is increased, fluid is forced into the inlet, moving the hydraulic equipment. Regulating the pressure and vacuum is essential to ensuring sudden pressure fluctuations don’t occur, which could collapse the entire hydraulic arm or lever.

You can expect to find hydraulics in places like car manufacturing plants, construction machines and amusement park rides. They are also useful for more simple things like office chairs. No matter where hydraulics are used, given the loads they are typically responsible for handling, they need to operate at the right pressure.

Other Applications Engineering Products

At Applications Engineering, our customers can rely on us for exceptional quality products. We are also happy to advise anyone who should need it about any of our products – our team members hold expert knowledge in all areas.

Vacuum switches are just some of the products we supply to our customers throughout the UK. We are also a leading supplier of pressure switches and pressure transducers

-

A Beginner’s Guide To Fire Sprinkler Systems

8 December 2022There’s no doubt that fire sprinklers save lives. They can put a fire out or keep it under control long enough to give the firefighters a real chance to save a building and its occupants.

Given that they are mostly automated systems, there has to be some secret to how they work, doesn’t there? We’re delving into the world of fire sprinkler systems to discuss the various types and how they function.

What are the different types of sprinkler systems?

On the face of things, all fire sprinkler systems may look the same but there are four main types that all serve slightly different purposes.

The four main sprinkler systems are:

- Deluge

- Dry pipe

- Wet pipe

- Pre-action

Deluge sprinkler systems are commonly found in buildings where there is a major fire risk, or where fire would be catastrophic; think warehouses and high-rise buildings. The nozzles in these systems are always open and are triggered by an alarm that brings on the deluge of water.

Dry pipe sprinkler systems are slower than most to engage and are typically used in unoccupied or unheated buildings where there is a higher risk of pipes freezing or bursting. Nitrogen or pressurised air is stored in the pipes, which then leaks out when engaged and causes water from a tank to be released through the sprinklers.

Wet pipe sprinklers are the most common type of fire defence system in residential buildings. They use pressurised cold water that is immediately released by the sprinkler heads when they detect a significant increase in temperature.

Pre-action sprinkler systems combine wet and dry pipe systems to protect areas that are vulnerable to water damage. Water is only brought into the pipes whenever a fire is detected to prevent too much water from releasing and damaging important materials in places like offices and shopping centres.

How do sprinklers work?

Fire sprinkler systems are typically installed in ceilings or sidewalls, and there is a good chance that you have seen them wherever you work. Although not uncommon for sprinkler systems to be installed in residential properties, they are most frequently found in commercial properties.

An effective fire sprinkler system makes use of a water supply that is piped through the walls into sprinkler heads, where the water is then distributed. Sprinklers rely on water being held under pressure in pipes throughout the building to release a downfall whenever a fire is detected.

They work automatically, which means there is no need to break the glass of a fire safety system for them to engage. Although it is commonly thought that they work by detecting smoke, many automatic sprinkler systems are engaged by heat.

Sprinkler head discharge

Sprinkler systems rely on the heads which are protruding from ceilings or walls to detect when there is a fire and to douse the flames with water. In the sprinkler head is a plug that is made of a material known as Wood’s metal. This is a metal that has a low melting point, so when the heat begins to rise from a fire it releases the pressure built up in the pipes and the water comes out.

There are different kinds of sprinkler heads depending on the building type and extinguishing needs. Regardless of the sprinkler system, the heads will house a trigger mechanism that opens whenever a certain threshold has been met.

Different types of sprinkler heads:

- Conventional heads discharge water downwards and some on the ceiling.

- Pendant spray heads aim water straight down and are used in buildings with high ceilings.

- Sidewall sprinklers are located high up on a wall and produce a wider arc of water than conventional heads.

What are the benefits of sprinkler systems?

Sprinkler systems are a great addition to any building to support fire safety but they are particularly useful in buildings like schools, hospitals, hotels, warehouses and many more.

Sprinklers in schools

Schools are important to their communities and besides the obvious safety benefits of fire protection, the ability to protect future generations is important. That vital community resource can grow and nourish young minds and the government has moved to ensure that new schools are installed with fire sprinklers.

Protecting vulnerable people

Fire sprinklers won’t always extinguish a blaze but they can temper or contain the flames long enough to let people evacuate. This is particularly apparent for someone with mobility issues and sprinklers in care homes or hospitals make evacuation that little bit easier.

Complicated buildings

Buildings like shopping centres pose a complicated problem for architects and safety officers. There are various systems in place like fire sprinklers, smoke detectors, emergency lighting and control centres that need to communicate with each other. Having a fire sprinkler system in place that works in tandem with other security measures ensures the safety of everyone who occupies these types of buildings.

Staying safe with fire sprinklers

Here at Applications Engineering, we provide vital fire sprinkler valve system products to ensure they are in perfect working order. We also offer flow, level and pressure switches to be used in conjunction with our fire sprinkler applications. For assistance with your fire sprinkler system or for any pressure switch enquiries, get in touch with a member of our team today.

-

How To Protect Your Fire Sprinkler System From Blockages

8 December 2022A fire sprinkler is a pretty fundamental line of defence, should your building go up in flames. Dousing the fire with many litres of water can keep it at bay in many cases, or even extinguish it entirely if fortune is on your side. However, they aren’t perfect systems and can sometimes be prone to blockages.

This obviously isn’t ideal as a blocked sprinkler won’t be doing its job properly, putting homes, businesses and people at greater risk. With that in mind, let’s look at the ways fire sprinkler systems can be protected from blockages.

Here at Applications Engineering we supply high-quality Fire Sprinkler Valve Systems that cover the requirements of modern domestic and residential properties.

Foreign bodies from the water

You might not think that the water you are using to sprinkle on fire needs to be clean but dirty water can pose a problem for fire sprinkler systems. Using water from poorly filtered sources, or even completely unfiltered, can cause a foreign body to enter the pipes and clog important valves or nozzles. Even fine materials such as sand and grit can become lodged eventually in a sprinkler system, reducing their effectiveness or possibly even clogging them entirely.

You must understand where the water for your sprinkler system is sourced and whether it is filtered or treated at any stage. Not checking the origins of the water could result in a clogged sprinkler system if regular checks and tests aren’t completed.

Biological growth

A by-product of using unfiltered or raw water is the biological material that may be living inside entering your fire sprinkler system. Small organisms may enter your sprinkler system in their larval state but grow larger once they are inside the pipes, filters or valves. This can impact the pressure as these organisms may grow to be obstructions.

In an ideal world, you will use filtered water that is treated with a chemical like chlorine but it’s not always possible, perhaps due to environmental and regulatory reasons. You may need to carry out some water treatment of your own to ensure the safety of your sprinkler system.

Ice shards

Fires can break out in many places, even where it’s cold. Although the temperature in most of the UK is relatively warm compared to other countries, it still regularly drops below freezing. That’s not ideal for a sprinkler system that relies on water running through it to smother and extinguish fire.

Ice may form when the temperature gets cold enough, causing blockages throughout the system. Any water exposed to the elements or that is formed as a result of condensation is at risk of forming a frosty blockage. It’s important to check your fire sprinkler system’s temperature resistance and adapt it accordingly.

Cold storage, for example, is commonly filled with flammable materials such as cardboard and requires extra attention from a fire safety perspective. For that reason, a dry fire sprinkler system is a great choice as it is not water-based and therefore won’t become clogged in freezing temperatures.

Limescale deposits

Depending on where you live in the UK, you might find your water is either crystal clear or cloudy and filled with limescale. If you live in a hard water area, take a look inside your kettle and discover how much limescale attaches itself to the filament. That same limescale inside a fire sprinkler system will have a similar impact on most metal components, from the pipes to the valves and nozzles.

This can reduce the pressure in the system, creating an imbalanced or ineffective stream of water. Pressure switches rely on water pressure to do all of the work for them. If that pressure is impacted by limescale deposits, the switch may not activate when it is supposed to.

A way to prevent this is to source your sprinkler water from non-potable reservoirs or an area with softer water. However, this may not always be possible so extra safety checks and replacing clogged parts should also be considered.

Corrosion

Perhaps one of the worst causes of fire sprinkler obstructions is corrosion or rusting. It is caused due to a chemical reaction between the metal of the sprinkler system and water, oxygen or both. Unfortunately, it’s not possible to avoid this, which is why it is such a common occurrence.

Typically, a small amount of corrosion won’t impact your fire sprinkler’s capabilities but when it begins to mount up it’s more likely to cause a problem. Rust is a common corrosion instigator but it’s not the only one.

Galvanic corrosion occurs when two metals, or more, are in contact through an electrical charge in water. Microorganisms like fungi or bacteria can cause biofilm on corroding material to react and become an obstruction over time.

Ways to avoid these types of corrosion include choosing a corrosion-resistant material for pipes, such as CPVC. It’s possible to remove the oxygen from your sprinkler system and replace it with nitrogen, which is a more resistant gas and is less likely to cause corrosion.

Fire sprinkler valve system products at Applications Engineering

A healthy fire sprinkler system allows for peace of mind for fire marshals and building managers. Our fire sprinkler valve system products range from flow, level and pressure switches to our innovative Dual Port Valves.

At Applications Engineering we provide temperature, pressure and vacuum switches alongside our fire sprinkler products. Please contact one of our experts today for assistance with all of your control and instrumentation product needs.

-

What Is A Priority Demand Valve?

8 December 2022Here at Applications Engineering, we provide a wide range of high-quality mechanical switches and sensors, catering for a variety of applications across many industries. Our range includes pressure switches, flow switches and sensors and fire sprinkler valve systems. Today, we would like to focus on priority demand valves and discuss why they are such an important element of a fire sprinkler system.

What does a priority demand valve do?

A priority demand valve is installed in a fire sprinkler system to restrict water flow in the event of a fire. It is an electrical valve that prevents water from flowing to your property during a fire, instead ensuring that all of the available water goes into the sprinkler system.

Fire sprinkler systems rely on pressure and flow from a water supply to safely and effectively control a blaze inside a property. This valve helps to protect the water supply to the fire sprinkler, rather than wasting it by distributing it to other areas of your property. Why would you need to take a shower, for instance, when there is a fire blazing in your home?

It’s better to concentrate the direction of water towards the emergency and switch it back to other areas of the property once that has been dealt with. We provide priority demand valves in two specifications, ½” – 2” and 2 ½” – 8” to accommodate pipe size and water flow.

How does a priority demand valve work?

During normal conditions, a priority demand valve sits in an open position, keeping the flow of water to your property at a consistent level. However, the moment your fire sprinkler system engages, the priority demand valve automatically closes. By closing itself, the priority demand valve isolates the supply to your property whenever your fire safety system has been activated by sprinklers, smoke alarms or power outages.

Priority demand valves come with either a solenoid valve or butterfly valve, depending on the requirements of your system. In situations where a property has a shared water supply, a priority demand valve ensures compliance with water supply regulations from the British Standard for Fire Sprinklers.

Typical properties identified in this regulation are:

- Individual dwellings such as houses and flats

- Houses of multiple occupancy

- Blocks of flats

- Dormitories

- Hostels

- Residential care homes

- Bed and breakfast accommodation

How do you know if you need a priority demand valve?

If your water supply is unable to provide an adequate water flow or pressure but your property fits into the above classification, a priority demand valve is required. A fire commissioning engineer is responsible for testing the water flow when commissioning a new fire sprinkler system. If the engineer deems your property needs it, a priority demand valve will be fitted into your property’s domestic water system just past the domestic stop tap.

Fire sprinkler systems with Applications Engineering

Your fire sprinkler system is an essential safety and emergency installation that you want to ensure is in full working order at all times. Here at Applications Engineering, we specialise in creating high-quality fire sprinkler valve systems for modern domestic and residential properties.

We have developed innovative, compact and easy-to-install valves for sprinklers that are of the highest quality and value for money. From dual port and ball valves to pump checks and pressure switches, we provide a comprehensive set of applications for all your fire sprinkler system needs.

If you would like to know more about any of our products, get in contact with a member of our expert team today and we will be more than happy to assist you.

-

How Do Pressure Switches Improve Safety?

8 December 2022Here at Applications Engineering, we specialise in the supply of high-quality mechanical switches and sensors for a wide variety of industries. Our focus in this blog will be on pressure switches, and how they are an essential piece of equipment for maintaining safety.

From industrial settings to domestic use, pressure switches help make the world a safer place. And given the importance of safety in dangerous workplaces, every piece of equipment that reduces risk is a good thing. But how do pressure switches improve safety?

What a pressure switch does

Let’s first quickly uncover what a pressure switch does. The function of a pressure switch is to deliver electrical feedback when a predetermined fluid pressure is reached. This could be either a rise or fall in pressure. Pressure switches respond to the change in fluid pressure, triggering them to either turn on or off. They act much in the same way as a light switch but the difference is they are triggered to switch rather than being manually turned on or off.

Where can you find pressure switches?

While many workplace safety features are signposted, pressure switches can go under the radar as a safety device. They are commonly found in industrial workplaces to sense when the pressure or vacuum has gone outside the predefined limit. In this situation, the pressure switch is likely to either shut off the power or raise an alarm for workers to be alerted to.

When pressure levels rise or fall beyond a set scope, they can damage equipment which in turn can put the people working nearby at risk, making a pressure switch an invaluable accident prevention measure. Pressure switches are also found in everyday locations, such as in office or apartment lifts, which operate under hydraulic pressure.

How pressure switches maintain safety

Pressure switches maintain safety by turning off or alerting people of a pressure change. For example, a furnace pressure switch can detect negative pressure during its start-up which then shuts the furnace down if there is low pressure. This could be due to a leak, and it should be investigated before the pressure is returned to working levels.

Air compressors are another example of why a pressure switch is an essential safety device. Using an electronic pressure switch, the motor is switched off on an air compressor when the desired threshold has been met. If this switch wasn’t in place, the tank could exceed a safe pressure level which can result in damaged components, or worse, an exploding tank.

In the case of a common lift in offices, shopping malls or residential flats, pressure switches constantly monitor the pressure levels in the hydraulic cylinder. This ensures that if the pressure drops too low, the lift’s power is cut and it won’t be operating at an unsafe pressure level which otherwise might cause it to hurtle towards the ground.

Considerations when choosing a pressure switch

Given their significant role in maintaining safety, you must choose the right pressure switch for the job. From selecting the right type of pressure switch to ensuring it is calibrated to measure the correct pressure levels, it is an important step in ensuring continued safety.

Here at Applications Engineering, we are perfectly placed to advise you on which pressure switch meets your needs. For simple monitoring systems, we offer single pole single throw switches, while for more complicated and advanced requirements we offer a range of single pole double throw switches.

Pressure switches at Applications Engineering

We are proud to supply high-quality pressure switches to a wide range of industries. Not only do we supply pressure switches, but we also provide fire sprinkler valve systems, level switches and flow sensors. If you would like to know more about which type of pressure switch you need or you have any queries about our other products, do not hesitate to get in contact.

-

Our Essential Fire Safety Checklist As Autumn Arrives

8 December 2022We have safely navigated our way through the long hot summer and as we enter September a new season is upon us. Evenings will be getting longer, the temperatures will drop and we will be seeking extra warmth from our clothes and our homes. While we heat our homes once more, the risk of fires increases, so let’s take a look at the most important fire safety checks you can do for autumn.

Check your heating system

There is a good chance your boiler and central heating system has seen little to no action over the summer months. With record high temperatures recorded across the country, the need for a radiator or fire has been minimal. Which means it’s essential that you check that everything in your heating system is in good working order before you start to heavily rely on it during winter.

Before the weather completely turns, switch your heating on and see how long it takes for the radiators to warm up. If they are slow or sluggish then they may need bleeding or there may be a fault with your temperature switches or sensors in your boiler. Ensure that your central heating is given a good test. If there are any irregularities, get your boiler serviced. Faulty heating systems are a fire hazard and must be dealt with immediately.

Good fireplace management

Perhaps you have moved to a new house complete with a fireplace and you are excited to try your fire starting skills. Maybe you are out of practice lighting and managing your fireplace – it’s important to refresh yourself on how to light and maintain a fire safely. From using a fireplace screen to avoid hot ash and sparks from flying around your home to never leaving a fire unattended, there are several essentials to bear in mind.

How you store your wood matters. Firstly, never store it any closer than five feet away from your fireplace to ensure that any sparks that do escape your screen do not ignite your firewood.

Secondly, ensure your firewood is dry as pockets of moisture in the wood can spark more regularly while wet wood also creates smoke which can be bad for your health. Even on cold days, ensure that you don’t overload your fire with excessive logs, as this may take hours to burn out which may tempt you to leave it unattended.

Test your fire and smoke alarms

In the event of a fire, your first line of defence is your fire sprinklers and alarm systems. These detect and alert you to changes in temperature or excessive smoke, allowing you to act fast and either extinguish the blaze or evacuate to safety. If they aren’t working properly, they may fail you when you need them the most, increasing the risk of a fire.

From protecting fire sprinkler systems against blockages to replacing the batteries in your smoke alarm, every check that you do increases the safety of your alarm system. Ensure that you have a working fire extinguisher in a place that is away from fire hazards to ensure accessibility in a time of need.

Create an evacuation plan

Whether you are at home or at work, it’s important that you understand the route you will take to escape a fire in the building. Ensure that escape routes are not obstructed and that everyone knows the most direct route to take. Knowledge and preparation are essential for fire safety in an emergency!

Improving fire safety with Applications Engineering

At Applications Engineering, we supply the highest quality fire sprinkler valve systems, from dual port valves to priority demand valves. We also supply a wide range of mechanical switches and sensors for applications across many industries. Our pressure switches and flow switches are from the best-known and reputable manufacturers. If you would like to know more about any of our products, contact an expert member of our team today.

-

How To Safeguard Your Fire Sprinkler System This Winter

8 December 2022Fire sprinkler systems play a critical role throughout winter as we rely more on heating systems than at any other time of the year. However, this can put them under extra stress and pressure as the risk of freezing increases and plummeting temperatures are a reason for concern.

So how can you maintain and protect your fire sprinkler system from freezing this winter? Let’s take a closer look!

Determine which type of sprinkler system you have