LMK Thermosafe Ltd

LMK Thermosafe are the world leader in design and manufacture of Industrial Induction Drum and Base Heaters, plus Flexible Heating Jackets for Totes, IBCs, Barrels, containers and pipes of many sizes.

Our products have been supplied to over 70 countries since 1985 and used by major companies including Unilever, GlaxoSmithKlein, Astra Zeneca, Huntsman, Bayer, Rhodia, Castrol, Dunlop, BP, Procter & Gamble, Roche, Rentokil & Exxon.

LMK Theromsafe has always sought to develop innovative solutions for our customers’ needs and continues to invest in new product initiatives where these help our global partners meet technical challenges heating materials or surfaces.

If you have any questions or would like more information, please don't hesitate to contact us.

LMK is fully BS EN ISO 9001(2000) certified

-

Curing Composites, Resins & Laminates

4 August 2022The marine and aeronautical industries use fibre reinforced resins, laminates and gelcoats in many applications where durability, finish and quality go hand in hand. Our flexible heating jackets have been utilised for surface curing during product assembly and where any post-production work results in the need for re-finishing.

Applications vary from insurance quality repairs to luxury yachts, through surface curing of wind turbine blades during manufacture and re- finishing of blade tips during maintenance.

Composite structures assembled in the construction of commercial and military aircraft often require surface heating. The high density insulation used throughout our products ensures a very evenly distributed heat is delivered, and the flexibility of the jacket permits uneven surface to be thoroughly cured. Sensors can be embedded where necessary for logging.

We manufacture custom sizes and shapes, so with your drawings, images and temperature requirements we would be pleased to work out a solution and pricing without obligation.

-

Outdoor Instrumentation Winterisation in Cold Climates; A practical alternative to Trace Heating

3 May 2022Inteliheat NA has partnered with local engineers to successfully deliver a number of custom designed hazardous area certified heating jacket solutions in Canada. A frequent requirement has been for solutions to the problems posed by hazardous area instrumentation certifications with a low temperature limit of minus 20°C when outdoor ambient can fall to -40°C in winter. Not only does this create a safety certification issue, it also often means that liquid crystal displays on the devices cease to operate.

In the past, a partial solution may have been to fit semi-rigid certified trace heating cable around the items, adding separate insulation blankets. However, the cable could not be applied across the lcd’s, and a specialist installation engineer was essential to ensure correct configuration. Should any subsequent maintenance be required on the item, the heating cable would need to be removed and replaced, adding greatly to the expense of any service work undertaken.

Inteliheat offer de-mountable heating jackets made to measure, combining effective insulation and heating to C1D2, C1Z1 and other hazardous area standards. Removable flaps for local inspection of information displays, waterproof covers, adjustable pull-cords, Velcro & D-Ring style fixings can all be accommodated. A Universal Instrument Heating Jacket System is available for standard sizes of equipment to speed up the design & procurement cycle and reduce capital costs.

Systems have been supplied for several Gas Analyzer systems with HMI displays at the Shell Scotford site in Ft. Saskatchewan, operating over winter to maintain 20°C ±2°C with -40°C ambient and 40mph wind speeds. Shell’s Project Manager stated “The Inteliheat product performed so well that I had no hesitation in purchasing additional units for upcoming winter programs”. Larger custom solutions have been provided to other petrochemical plants in Canada for protection of pipeline pumps and motors.

Inteliheat (NA) LLC is a wholly owned subsidiary of LMK Thermosafe Ltd, a global leader in the supply of drum and container heating equipment used in potentially explosive atmospheres. All heaters are manufactured and designed to the strictest of quality and world wide safety standards in our state of the art ISO 9001: 2015 certified automated facilities near Cambridge, England.

To discuss your Instrumentation Winterization solutions, contact LMK Thermosafe today.

T: +44 (0)1440 707141

E: sales@drumheating.com -

Fast and Safe Melting of Waxes and Solids

8 April 2022William Ransom & Son plc has been developing and manufacturing natural botanical extracts and liquid pharmaceuticals for over 150 years. From traditional beginnings as a supplier of extracts of locally grown plants and herbs to the pharmaceutical trade, Ransom has grown into an internationally renowned botanical extract specialist and a major supplier of consumer health care brands.

Electrical safety concerns associated with metal clad radiant element drum heaters prompted the installation of THERMOSAFE® fully encapsulated and ATEX safety certified Induction Heaters for use with 205 litre drums of solid lanolin. Their Plant Manager stated: “Reliable, safe and consistent melting has been achieved since we installed the Induction Heaters. We are very pleased with the results achieved.”

The THERMOSAFE® Induction Drum Heater is certified by SIRA for use in potentially explosive atmospheres, both to ATEX and IECEx international standard, and is IP66 rated, so can be hosed down even whilst in use. The induction coil is totally enclosed within a chemically resistant GRP moulding for maximum protection and safety. LMK Thermosafe Ltd manufacture a wide range of drum and container heating products used in process industries worldwide, including flexible heating jackets in a variety of sizes, materials, power levels and voltages. Standard ranges are available from stock from 20 to 210 litre capacity, plus 1000 litre IBC containers and totes.

Many compounds in the pharmaceutical and health care industries include a proportion of petroleum jelly (commonly known in one form by product name “Vaseline”). This is usually supplied in solid form to user companies in steel drums. Most grades are very poor absorbers of heat, so it can take a substantial time using traditional radiant heating devices or steam ovens for the drum’s content to be sufficiently liquid for pumping or dispensing.

Too much localised heat (such as provided by silicone band heaters) can easily burn or damage the material characteristics, but operational factors usually demand a rapid melt time. The THERMOSAFE® Induction Drum Heater has proved ideal for this purpose, especially when combined with LMK’s adjustable power controller. Power delivery can be perfectly matched to optimum heat absorption rate so that, for example, a complete melt is achieved through safe, unattended, overnight heating.

Wilmar Wilson Meier and Company Ltd, of Dublin have been very successfully using the THERMOSAFE® Induction Heater for petroleum jelly processing for a number of years. The Operations Director commented “We simply set the drum and heater up at the end of the day, and by the following morning, the petroleum jelly is ready to use. It’s an ideal solution, very reliable

and completely safe”.

For more information about safe, efficient Drum Heating solutions contact LMK Thermosafe today.

T: +44 (0)1440 707141

E: sales@drumheating.com -

Palm & Soft Oil Processing

8 April 2022No hot spots, No flames, No heating elements, and No fire risk

Founded in 1983, Anglia Oils are now a significant supplier of palm and soft oils in the UK market. Investments at their edible oils refinery at King George Dock, Hull, has not only dramatically increased capacity and flexibility in production, but has taken Anglia into completely new markets.

In their bakery products business, Thermosafe induction heaters are used to heat drums of lecithin, an additive used in the manufacture of a specialist butter type cooking oil. The lecithin needs to be carefully heated to a per-selected temperature for optimum viscosity, and it must then be introduced to the final mix at accurately controlled flow rates.

Eratic or inaccurate heating could have devastating effects on the additive as well as on the final product itself.The Thermosafe heater is ideally suited for this task. The heater is placed in position over the drum, and because it operates on the induction principle, the heater itself always remains cooler than the drum.

There are no hot spots, no flames, no heating elements, and no fire risk. These are all vital safety features much appreciated by employers and employees alike.

The Thermosafe process is also safer for the product. Its heating effect is uniform, infinitely controllable, and will not degrade the contents of the drum through overheating.

Anglia employ an effective method of ensuring the accuracy of the mixing rate. The Thermosafe heater and the drum containing the lecithin are mounted on a load cell which guarantees accurate flow measurement, far more efficiently than the usual flow meter device. The load cell is in turn linked to a microprocessor control unit which enables Anglia to accurately pre-set temperature levels and flow rates.

Thermosafe Induction heaters are the only drum heaters available certified for use in explosive atmospheres (Zones 1 & 2), and IP66 enclosure protection allows for hosing down and use outside.

Contact us today to find out how LMK Thermosafe can help improve your Oil Processing application.

T: +44 (0)1440 707141

E: sales@drumheating.com -

Do you know the real cost of Band Heaters?

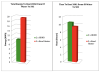

8 April 2022• In under 6 months the total operating cost of an HHND jacket is less than a typical high power band heater

• HHND Heating jackets use almost half the energy for similar performance

• Operators are safe to touch an HHND, but could be burnt by a band heater

HHND – The Band Heater Alternative

We are pleased to announce our new “HHND” Flexible Heating Jacket for applications requiring high-performance, low-cost solutions. The jacket is for general industrial use where price is a critical part of the decision.

Designed for standard 200 litre drums, this heating jacket delivers 750 watts of power. Excellent performance in the heating of liquids and melting of some solids has been shown at a price point normally associated with energy hungry silicone band heaters. Due to the high-grade, high-density insulation incorporated as standard, the outer jacket surfaces can be touched safely without protective equipment.

A single HHND heating jacket may be used for heating liquids and melting some solids. Two or three heating jackets combined, will increase the heating rate and allow the most difficult solids to be melted.

This product is specifically marketed for distribution via our worldwide sales partners holding local inventory, and will only be sold in batch quantities of 10 or more. Each jacket will be wrapped for individual resale, with its own operating instructions.

DOES A “LOW COST” BAND HEATER DELIVER BETTER VALUE FOR MONEY THAN AN INSULATED HEATING JACKET?

Our HHND band heater replacement has been rigorously tested and compared with typical silicone band heaters to scientifically analyse performance, energy usage and operating costs.

In a standard test environment, a full 200L drum of water was heated from 20C to 50C using two of each heater type, logging power consumption and content temperatures.

The results clearly showed that although a band heater is marginally quicker to heat the entire contents to 50C, the total energy required is almost double our HHND insulated jacket.

For more information about cost effective Band Heater alternatives, contact LMK Thermosafe.

-

Jet Fuel heated by THERMOSAFE®

8 April 2022Introducing a completely new aircraft into commercial or military service requires extensive certification testing before customer deliveries can begin. The Sikorsky S-92 is an advanced transport helicopter that incorporates the latest design safety features such as flaw tolerance, bird strike capability, turbine burst containment and benchmark crashworthiness.

As part of the performance flight tests for FAA certification, Sikorsky needed to safely pre-heat JP-8 jet fuel in standard 55 US gallon drums, to 136°F (58°C), and deliver it to the aircraft’s tank through an approved ground fuel pump with filtration. The drums needed to be vented, so fuel vapour with a flash point of only around 100°F is present, and the potential fire risk very high.

Sikorsky approached LMK for a solution as the THERMOSAFE® Induction Drum Heater does not use traditional radiant heating elements. The heater always stays cooler than the drum, with the steel drum wall being heated by the induction effect. Thus its key safe use criteria is the auto-ignition temperature of the hazardous vapour. JP-8 is a kerosene type fuel with an auto-ignition temperature well above the safety rating of 170°C (T3) given to the THERMOSAFE® under its European ATEX and International IECEx approvals for hazardous area use.

The drum wall and fuel temperatures were separately monitored for the duration of the tests, conducted at Sikorsky’s Florida facilities, and the results logged onto a laptop computer running analyses software. The project was very successfully completed well within the allotted time frame. Charles Greenberg, co-ordinator at Sikorsky commented “Safety has to be our number one priority, and LMK’s Induction Heater helped us resolve all the potential issues. Technical support from their UK headquarters during the crucial planning and preparation stages was excellent, and we were delighted with the results”.

Sikorsky is a subsidiary of United Technologies Corp (NYSE:UTX) of Hartford, Conn, USA, which provides a broad range of high-technology products and support services to the aerospace and building systems industries. LMK Thermosafe Ltd manufacture a wide range of drum and container heating products used in process industries world-wide, including the award winning THERMOSAFE® induction heater.

-

Helping to Heat Up the Food Processing Industry

8 April 2022New product development in any industry always brings new technical challenges and hurdles. The introduction of Alpen Cereal Bars was no different for leading British breakfast cereal manufacturer, Weetabix Limited. One problem was large containers of glucose-based solutions needed to be heated and kept at optimum temperature before blending with other ingredients as part of the manufacturing process.

Weetabix found a perfect solution with LMK’s dual circuit IBC2 Flexible Heating Jacket. Able to quickly raise temperatures of large volumes of liquids and efficiently retain heat, each jacket utilizes tough, water resistant nylon for the outer layer, and custom coated heat and chemical resistant materials for the inner layers, with high efficiency insulation inside to reduce heat-loss to a minimum.

LMK Thermosafe Ltd manufacture a wide range of drum and container heating products used in process industries world-wide, including flexible heating jackets in a variety of sizes, materials, power levels and voltages. A wide standard range is available from stock to fit 25, 50, 100 or 205 litre drums as well as 1000 litre IBC containers and totes.

Honey is one of the many foods that need to be heated to reduce viscosity. LMK Thermosafe Induction Drum heaters have provided the solution for honey processing applications around the world. The THERMOSAFE® Induction Heater causes the steel drum to be heated up directly rather than through radiant transfer, thus optimising temperature distribution across the drum surface for quick and easy Rim Liquefying. Only a matter of minutes of application is required before the entire contents can be emptied with little or no residue left in the drum.

Close temperature control can be achieved with the use of a power controller to avoid the development of high HMF content where longer term storage at higher temperatures is required.

Designed to heat up to steel 205 litre drums, the unit is simply placed over the drum; physical contact is not required. As there are no radiant elements, the heater remains substantially cooler than the drum being heated, enabling safe and unattended use, overnight if required. The induction coil cannot be damaged by accidental spillage, and personnel can work comfortably in close proximity. Complete access to the drum while heating enables pumps and stirrers to be easily employed. The Thermosafe is IP66 rated, so can be hosed down, even when operational, in complete safety.

For more informations about the THERMOSAFE® Induction Heater or Flexible Honey Heating Jackets, contact LMK Thermosafe today.

T: +44 (0)1440 707141

E: sales@drumheating.com -

Long term use of the THERMOSAFE® Industrial drum heater – still going strong after 27 years

5 April 2022The award winning THERMOSAFE® Industrial drum heater: A safe, efficient, fast, clean and maintenance free Industrial process heating solution with a seemingly unlimited life!

Our award-winning THERMOSAFE® Induction Heater has shown once again why, after 30 years of production, it is still the number one in the market.

One long-standing customer and regular user of the Type A THERMOSAFE® returned their unit to our UK factory for assessment after 27 years use. After a full set of tests we found it to be in perfect working order, still performing as new. We simply replaced the cable and gland before returning it for many more years’ service.Supremely safe and fast, our timeless induction heaters work by creating their own magnetic field which directly heats the steel wall of the drum. No radiant elements, no moving parts, just a permanent drum heater that you can rely on for a lifetime. Fully ATEX and IECEx certified for use in Zone 1 and 2 Hazardous Areas.

The original THERMOSAFE® Induction Drum Heater was developed and field tested in the early 1980’s primarily to solve the problem of heating polybutene synthetic resins, which are highly viscous at normal ambient temperatures, have a very low thermal conductivity and can be combustible under certain conditions.

Certification for the heater’s use in potentially explosive atmospheres was gained in 1986 and one of the very first batch to be commercially manufactured was supplied to Adshead Ratcliffe, after running field trials in conjunction with BP Chemicals using their “Hyvis” product. In the following years, the heaters have been sold to over 60 countries.

Adshead Ratcliffe continued to use their first heater in the manufacture of intumescent strips for sealing of glazing in commercial buildings, and as sales increased, the heater just kept on operating safely and efficiently, year by year by year.

When an additional heaters became necessary, alternatives were considered, but nothing could compare to the standards of reliability and durability set by the THERMOSAFE® so a second unit was purchased in 2015, almost 30 years after the original, followed by a third in 2018 and yet another in 2019.

China clay is used extensively in the production process, so the heaters must withstand the harsh environment created by these abrasive ingredients.

All four units are likely to be operational and trouble free for the next 30 years.

For more information about the Patented THERMOSAFE® or to discuss your Process Heating requirements, contact LMK Thermosafe today.

T: +44 (0)1440 707141

E: sales@drumheating.com -

Savings All Round

5 April 2022Comma Oil & Chemicals Ltd, of Gravesend, Kent, replaced their steam heated oven with induction drum heaters. They achieved tighter temperature control, faster throughputs, and energy costs were drastically reduced. Project payback was only 8 months.

The Company

Comma Oil blend and manufacture a wide range of oils and lubricants. They also produce a variety of car care products ranging from polishes and cleaners to anti-freeze. Link to: http://www.commaoil.co.uk/Original Process

Chemical additives, which are delivered and stored in 45 gallon drums, were loaded into a steam heated oven and left for up to 8 hours to achieve the correct temperature and viscosity prior to the difficult and often complex blending process.The drums had to be manhandled into the oven which was an unpleasant task, since the environment was hot noisy and dirty.

The steam oven could accommodate 8 drums, but this was rarely possible since the drums often required heating to different temperatures which meant the oven was frequently under-utilised.

The slow turnround meant that a large number of drums were kept in circulation which required valuable storage space and additional handling.

SEEBOARD Technical Services

The production limitations were discussed during a visit by Seeboard's Industrial Sales Engineer, who suggested that induction drum heaters could solve the problem.Following successful field trials arranged with the Industrial Energy Efficiency Centre, an initial order for 3 induction drum heaters was placed.

The heaters consist of a large induction coil encased in a glass reinforced polyester cylinder, which is placed over the drum. An AC supply induces an alternating current in the drum itself, generating heat uniformly through the drum surface.

Induction Drum Heaters

The induction drum heaters have enabled blending throughput to increase from 5 to 20 drums per day - and increase of 300%. Annual energy costs have reduced six fold, in spite of this increase in production.The heaters take as little as 2 hours to achieve consistent, even melts with no product degradation. The much greater control of temperature and viscosity produces a higher quality product.

To find out how your company can improve energy efficiency with THERMOSAFE® Induction Heaters contact LMK Thermosafe today.

T: +44 (0)1440 707141

E: sales@drumheating.com -

Process Heating in Agrochemical Bulk Production

5 April 2022LMK Thermosafe Ltd has built a strong global reputation for quality and high reliability, designing, and manufacturing hazardous area certified industrial heaters for over 30 years.

Herbicides, fungicides and insecticides are very closely controlled by all national and EU licencing authorities. There are serious health and safety implications for incorrect storage, use, or disposal. Ingredients may include pendimethalin, chlorpyrifos & surfactants.

Manufacturers in the global Agrochemicals Industry have purchased specialist heaters from LMK Thermosafe Ltd where process audits and safety dictate that the highest standards are maintained at all times during production and blending. Potentially explosive ingredients in steel drums need to be heated to very precise temperatures as fast as possible. The safety and repeatability of performance of our THERMOSAFE® Heaters are ideal for these tasks.

In some sectors, solvent free formulations have required new raw materials to be blended into the batch. These are often semi-solids delivered in 1000 litre IBC’s and require heating to over 40ºC to liquefy and agitate for consistency prior to pumping. The “Thermulate” IBC3 has been carefully designed and tested to meet the stringent needs of such processes.

A factory manager at one large plant stated:

“We have used Thermosafe drum heaters for over twelve years and know they will be safe and reliable. In recent years, their flexible heating jackets have proven to be equally reliable heating IBC’s of very viscous materials”

For more information or to discuss your Process Heating requirements, contact LMK Thermosafe today.

T: +44 (0)1440 707141

E: sales@drumheating.com -

Custom heating jackets cut time and cost from curing processes

1 April 2022Around the world, wind power is becoming an increasingly important part of energy production. As the industry advances, so do demands on manufacturers to produce larger turbines and thus longer blades.

Long blades produce greater power, but they also create difficult challenges for designers, manufacturers and maintenance staff. The component parts are usually manufactured from GRP composites in complex, aerodynamically-efficient shapes, and assembled in sections.

Post curing and re-working of molded parts during initial manufacture is often required. If the design requires components to be embedded in the blade, for example sensors or lightening conductors, then this will necessitate some post-mould re-working. Processes used to increase the durability of the blade's leading edge also usually require steady state heat curing.

Large, heavy blades are especially prone to being damaged in transit or during site installation, and repair and re-working will be required in such situations.

Furthermore, as they suffer wear during use, repair is more difficult than for smaller blades. Adhesives and composite materials often require heat to be applied at precise temperatures and uniformly across a surface, in order for to produce a high-quality result – requirements that are even harder to meet on site than in a purpose- built factory. The use of unsuitable, pieced-together on-site heating solutions is a mistake that can prove extremely costly. However, the cost of getting large blades back to a factory for rework after installation is usually prohibitive, especially as many wind farms are located offshore or in remote, mountainous areas.

The best solution to this common dilemma is to use custom flexible heating jackets, such as those designed and manufactured by LMK Thermosafe Ltd specifically to match individual blade profiles. Our quality control and design capacity gives unrivalled ability to build heater products to North American, European and Worldwide safety standards, and for harsh use both indoors and outdoors.

Since 2003 LMK Thermosafe's ability to design and produce top quality, precision heating jackets has won us an unparalleled international reputation, and a long list of world-class clients, including Sinopec, BASF, Vestas, Akzo Nobel, Johnson & Johnson, and many more.

All our products are designed and made at our high-tech automated factory in Haverhill, England. This allows us to have complete control over the development, manufacturing and quality control process. It also enables us to create heating jackets for complex shapes like turbine blade tips, to our customers’ exact specifications.

A superior quality heating element is machine-stitched into each jacket – its careful positioning plus the jacket's high density insulation work together to ensure that heat is distributed evenly and efficiently.

A range of power ratings and fixed or variable thermostat options (typically 40°C, 90°C, 160°C) are available to suit your exact temperature needs. Jackets can be created in a wide variety of shapes, and can be joined together to heat the most complex-shaped items. The jacket's own fully-adjustable straps ensure a perfect fit.

Contact LMK Thermosafe today to discuss your composite curing requirements, and we'll design a quality heating jacket solution that will save your business time and money.

T: +44 (0)1440 707141

E: sales@drumheating.com