BeaconMedaes

Company Overview

BeaconMedæs is a Global leader in medical gas pipeline (MGPS) turnkey solutions. With services including preventative maintenance contracts, equipment servicing, installation and commissioning, site surveys and design services to HTM02-01 standards.

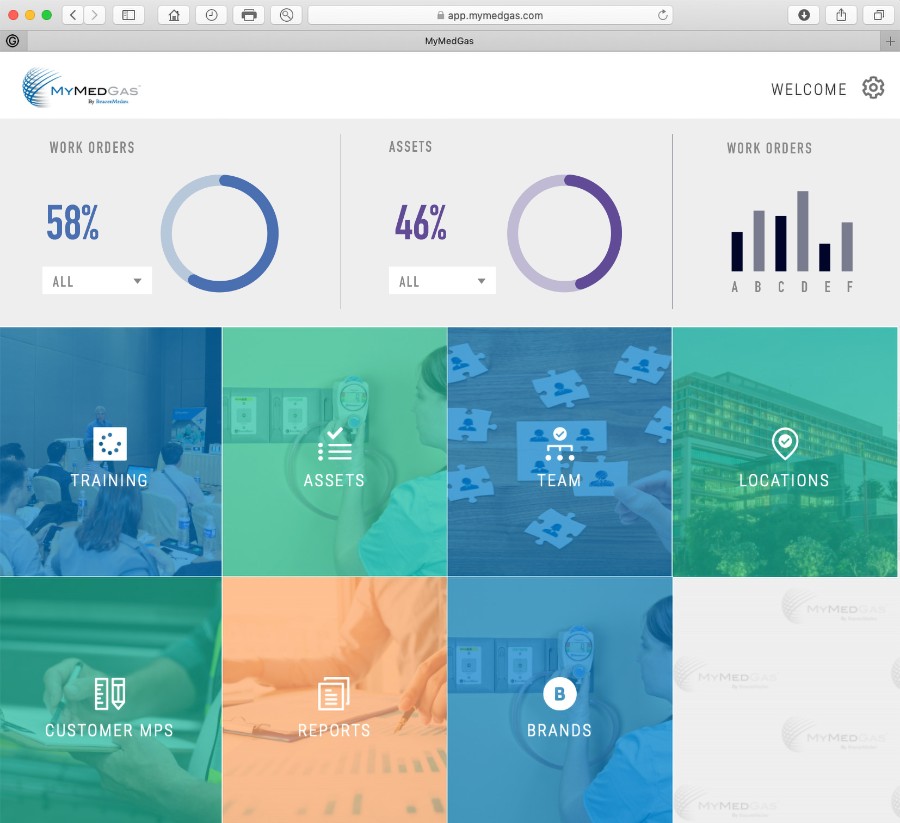

MyMedGas by BeaconMedaes is a new way to manage your medical gas pipeline system (MGPS). It provides one central digital location from which everything relating to the MGPS can be easily overseen and managed, with data accessed at any time and from and place.

Our installation team offer unrivalled experience and expertise with our products. With pre qualification through such quality bodies as Safecontractor, CHAS and Constructionline you can be sure we take Health and Safety and quality service seriously. BeaconMedæs has a proven track record of delivering projects on time, from major acute facilities to small extensions and refurbishments, so whatever the size of the job we can help you out. Following installation, we can provide verification, testing and commissioning, preventative maintenance contracts and emergency repair services.

Medical gas service and support is central to everything we offer our customers, and we maintain the UK’s largest service force dedicated exclusively to medical gas systems. We provide full mainland coverage and emergency 24 hour call-out so day or night, 24-7 we have your medical gas systems covered.

Our products are UK manufactured and CE marked to the medical devices directive including medical air plant, medical vacuum plant, AGSS, gas manifolds, GEM terminal units, medical gas alarms, valves as well as architectural products such as area zone service units, pendants and bedhead trunking to HTM02-01 standards.

Whatever services you require your medical gas system is safe in our hands.

Please contact us today for any works relating to your medical gas system and we will arrange for one of our regional sales engineers to visit site.

-

MedGasScan - a new on-site inspection service offered by BeaconMedaes

15 February 2023MedGasScan is a new on-site inspection service offered by BeaconMedaes, the medical gas pipeline specialists. Our qualified team can undertake a full inspection of your medical gas pipeline system, to identify and measure gas leaks on the pipeline itself, or the associated equipment.

To identify gas, it’s necessary to use specific tools. Our camera is designed to detect ultrasonic signals produced by the loss of gases such as oxygen, nitrous oxide, entonox or medical air, which are typically not audible by the human ear. Leakages can be often be found on components joints within source equipment such as manifold control systems and air plant or control valves which can be “blanked” off and hidden in ceiling voids. As well as worn out terminal units, hoses and flow meters connected to the patient equipment. The camera works at distance or through protective windows on products such as area valve service units (AVSU’s).

-

BeaconMedaes Award from IHEEM 2022

15 February 2023BeaconMedaes were awarded 2nd place in the 2022 Healthcare Supplier of the Year awards, achieving Highly Commended status. Presented by IHEEM the Institute of Healthcare Engineering and Estate Management - the team enjoyed a fantastic evening alongside fellow colleagues and professionals in the healthcare market.

-

BeaconMedaes & Medclair - Partnering to Reduce Anaesthetic Gas Emissions & Help Hospitals Reach Net Zero

15 February 2023BeaconMedaes and Medclair have announced an exciting new partnership that will totally change the way hospitals manage nitrous oxide (N2O). BeaconMedaes is proud to be the sole UK supplier of Medclair’s unique Central Destruction Unit (CDU). The low-energy unit provides sustainable gas cleaning of exhaled nitrous oxide, eliminating it by more than 99% by causing it to decompose rapidly into nitrogen and oxygen, the main components in air. This means the surrounding environment is made safer for staff and patients without any reduction in the level of pain relief provided.

Andy Tudor, BeaconMedaes Marketing and Communications Manager – UK and Ireland, says: “This new and innovative product from Medclair sits perfectly in our portfolio of products and services. The CDU is installed downstream of our active Anaesthetic Gas Scavenge plant, enabling us to offer a complete system from the Terminal Unit through to the exhausting of the gas. We can provide the system design (revit 3D), installation and commissioning of the system. Post installation, we can provide a service contract for the necessary inspection and maintenance of the equipment and system. We are excited to work with Medclair and offer this solution to the UK healthcare market and help support the NHS drive for net zero emissions.”

-

BeaconMedaes launches new AGSS Anaesthetic Gas Scavenging System

15 February 2023The BeaconMedaes CE marked product range is now available and stocked in our distribution and customer centre at Markham Vale, Derbyshire. BIM models are available to assist with plant room layout drawings and will enable the MGPS to be co-oordinated alongside other services.

The Anaesthetic Gas Scavenging System (AGSS) is an active system which extracts and disposes of waste anaesthetic gas mixtures from operating theatres and any other areas fitted with nitrous oxide terminal units such as maternity departments. The removal at source thus eliminates the possible long-term health hazards to exposed medical personnel.

-

BeaconMedaes launches BIM models for Medical Gas Pipeline products

15 February 2023BeaconMedaes, part of the Atlas Copco Group, launches detailed BIM level 2 models and 3D design services for improved planning and coordination of Medical Gas Pipeline Systems.

The BeaconMedaes CE marked product range is now available in BIM format. These models are available on request and will enable MGPS to be coordinated alongside other services.

Not only can we provide designs of medical gas pipelines to HTM02-01 guidelines, our experienced in-house design support team can also provide detailed 3D drawings and schematics showing detailed sizes, equipment and locations. This simplifies the onsite installation work and can be easily adjusted by our in-house design support team to produce detailed and accurate as fitted layout drawings once installation has been completed.

Once completed, all design and layout drawings can be uploaded and stored on our secure asset management and compliance portal, MyMedGas. On this portal, which provides a central location for storing medical gas pipeline records, these drawings can be accessed by the hospital at any time

-

BeaconMedaes Won The Award for Best in Show of The USA Partnership Pavilion

1 February 2019Yesterday BeaconMedaes won the award for best in show of the USA partnership pavilion. Today will be our last day at Arab Health 2019. Come see our prize-winning booth and find out how we maintain our name as one of the world’s largest medical gas service providers. See you at stand H1.F59.

-

BeaconMedæs introduces a new medical vacuum filter assembly for medical gas pipeline systems

1 February 2019July 2018, Rock Hill, SC, USA – BeaconMedaes, Part of the Atlas Copco Group, introduces the MV Medical Vacuum Filter Assembly for medical gas pipeline systems. The new bacterial filter assemblies are designed to protect the vacuum system, the workers who maintain the equipment, and the surrounding environment. The NFPA 99 standard, 2018 edition now requires the addition of bacteriologic filtration at the medical vacuum plant. To meet these new compliance requirements, BeaconMedaes has launched the MV Filter Assembly for medical vacuum, to be installed at the inlet of the vacuum system for removal of any liquids, solids or bacterial contaminations. The new MV Filter Assemblies utilize a single point connection design featuring interconnecting piping, isolation valves, and a rugged frame that allows for seamless plug and play installation. The modular design allows for quick disassembly to accommodate any hospital or healthcare facility door entrances. With the complexity of installation reduced dramatically as the piping and valves are pre-fitted and assembled at the factory, overall installation costs are reduced. With flanged connections between the filters, valves, and piping, the single point connection design also means there is no risk of leakage. All MV Filter Assemblies are leak tested before leaving the factory. The MV Filters incorporate filter elements of the highest quality. The elements are made from pleated glass fiber media which captures particulates, bacteria and liquid aerosols, removing contamination that could damage the vacuum pump and release harmful contaminants into the downstream air. The MV Filters are independent third party tested and fully compliant to HEPA filter efficiency rating. In addition, these vacuum filter assemblies have endured stringent earthquake testing to receive the OSHPD seismic pre-certification, proving they are resistant to the most severe earthquake conditions. With the filter certification and the assembly rating, our MV Filter Assemblies provide you with peace of mind. The MV Filter Assemblies range in system capacity from 45 scfm to 630 scfm. All filters in each assembly are capable of individual isolation, and all system capacities shown with one filter in reserve. “At BeaconMedaes we understand the importance of the customer’s lifetime value management. Our MV Medical Vacuum Filter Assemblies offer best-in-class performance, minimal service downtime, ease of installation and low maintenance costs,“ said Abhijeet Jain, Global Product Manager for Medical Vacuum. “When it relates to compliance and design specifications, we maintain strict standards and thus all our filter elements are third party tested and certified. Additionally, our filter assemblies are seismic certified too, we recognize the added value to offer all these certifications as part of our standard product features. Our MV Medical Vacuum Filter Assemblies are an ideal solution for hospitals and healthcare facilities of any size.”

-

BeaconMedæs introduces new ISO Standard Area Valve Box for medical gas pipeline systems

1 February 2019BeaconMedæs introduces new ISO Standard Area Valve Box for medical gas pipeline systems August 2018, Rock Hill, SC, USA – BeaconMedaes, Part of the Atlas Copco Group, pleased to launch a new Area Valve Box for medical gas pipeline systems The ISO Area Valve Box has been designed in accordance to the ISO 7396-1 standard where all clinical areas must be individually monitored per guidelines. The purpose of the unit is to provide fast access to the pipeline distribution system in case of a fire or emergency malfunctions as well as monitor individual and central systems within hospitals. The Area Valve Box supplies both an inlet and outlet connection. Additionally, the Area Valve Box allows the hospital and maintenance staff to physically isolate sections of the pipeline during downstream system repairs or maintenance situations. The BeaconMedaes ISO Area Valve Box embodies a simplified design with modern components. The components include a robust powder coated metal case designed for rugged durability. The unit is easy to install and can be mounted wall recessed or surface mounted. Also included is a valve assembly, which consists of a copper 22 mm outlet tube and inlet tube with an InLine Shut-off valve for trouble-free operation. The valve assembly has a transition block which houses a pressure gage for easy pressure reading, an emergency and maintenance inlet, as well as the pressure and vacuum switches. Likewise, the physical isolation device allows for valve isolation when the inline shut-off valve is in service yielding the back feeding of gas through the emergency and maintenance inlet. The units are intended to be installed downstream of line pressure regulators. When used for emergency situations, the device must be incorporated in the emergency management plan of the healthcare facility. To offer this level of added security, the Area Valve Box comes with electronic pressure sensors which provide highly precise measurement values and activate a visual alarm in the event of abnormal pressure changes. The built-in alarm is a LCD display with 16 inputs for up to 8 gases. When not in alarm mode, the display message reads “Status of System is OK”. Alternatively, the alarm can be programmed with a different message up to 16 characters and two lines. If an alarm condition would occur a message will appear, a red LED light will flash, and a ringtone will be activated. Fully compliant to ISO 7396-1, the Area Valve Box pressure switches continuously monitor the network pressure. The optical and acoustic alarm functions immediately indicate any malfunction situation and pressures are displayed independent of the power supply via the analog pressure gauges.

-

BeaconMedaes launches new range of high-efficient medical compressors for HTM market

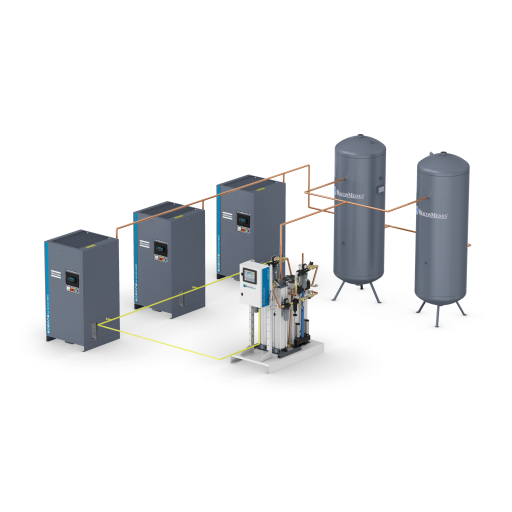

1 March 2017BeaconMedaes, part of the Atlas Copco Group, launches a new range of high-efficient ultra-compact medical compressors for use in HTM-compliant Medical Air Plants.

When first launched in 2013, the GA VSD+ brought a game-changing revolution in the compressor industry with its extremely high efficiency and innovative vertical design. This technology is from now on available in a variant for use in HTM-compliant medical air plants.

The GA VSD+ MED is at heart an oil-injected screw compressor. However the novel concept of the GA VSD+ consists of a new drive train, where the classic induction motor has been replaced by a unique permanent magnet motor. Due to the high rotation speeds that can be achieved by this motor, there is no longer a need for a gear case. Combining that with the high efficiency of the in-house developed motor, the variable speed concept allows tremendous energy savings – in classic applications, up to 50% in comparison with a traditional fix speed compressor. “In medical applications, where demand for air varies moment to moment as patient treatments proceed, even greater savings may be possible,” says Mark Allen, Vice President Marketing.

On top of that, the drive train assembly is aligned vertically, leading to an even more thrilling 55% saving in footprint. In hospitals, the latter is a sought-after feature where floor space is often limited and at a premium.

The GA VSD+ MED comes with specific safety features to meet and exceed the HTM standards. Apart from modified software with automatic restart after voltage failure, the unit incorporates an amp meter, main switch and a temperature sensor to monitor the outlet temperature. The machine provides failure to go on load alarming, confirming that pressure is effectively building when the start command has been sent to the unit.

The new range stretches from 7 to 37kW and is now available through BeaconMedaes as part of their medical air plant range.

For more information, please contact: Kurt De Smet, Product Manager - Phone: +32 (0)3 870 2869, E-mail:kurt.de.smet@be.atlascopco.com

-

BeaconMedæs launches its new Lifeline® MCS Medical Manifold

1 March 2017BeaconMedæs, part of the Atlas Copco Group, launches its new Automatic Changeover Medical Manifold for increased patient safety.

In line with our ability to stay at the forefront of medical technology, BeaconMedæs has developed the Lifeline® MCS Manifold to better meet the needs of our customers.

With an aim to minimise the risk of low pressure even in a peak demand, BeaconMedaes is probably one of the only companies in the United Kingdom that uses two stage regulators in their manifolds. This results in a leading high flow capacity of 1,750 lpm at 4 bar stable pressure over the entire flow range. Additionally, two stage regulation extends the operational life of the system significantly. BeaconMedaes always uses halogen free high pressure regulators which reduces the risks of self-ignition and emission of toxic gases.

To increase control over medical gas consumption, our new Lifeline® MCS Manifold includes a colour graphical display with a precise pressure indication. Visualisation of the remaining gas volume in cylinders and average flow consumption will give you full control over your medical gas installation.

Thanks to its digital control panel and two stage regulators the manifold has low changeover pressure that saves you up to 270,000 litres of valued gas annually1. This will be considered of great value when looking at the total cost of ownership.

To reduce cost and time of installation of a new BeaconMedaes manifold we integrated and preinstalled many components, such as a test point (medical gas terminal unit) and a pre-piped exhaust. We also reduced the width of the complete control system by 30%, offering more freedom during installation and saving premium space. Additionally a wall mounting bracket is now supplied – so installation of the manifold can be done by a single person.

In short, the new BeaconMedaes Lifeline® manifold is not only reliable, innovative and efficient system, but it also allows you to keep costs under your control.

For more information, please contact: Alexander Losev, Product Manager - Phone:+32 (0)3 401 94 85, E-mail: alexander.losev@be.atlascopco.com