Curtiss-Wright Surface Technologies

Curtiss-Wright Surface Technologies (CWST) provides high quality surface treatments which will improve the life and performance of critical components through its global network of over 70 operating divisions and specialist onsite teams. Our surface treatments have been successfully used by OEM’s in major industries such as aerospace, automotive, oil & gas and power generation for many years.

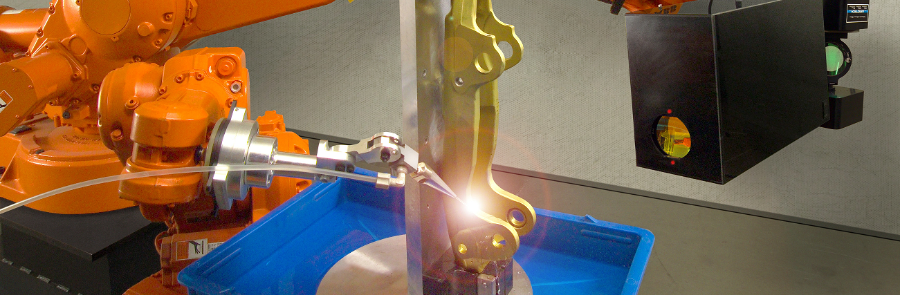

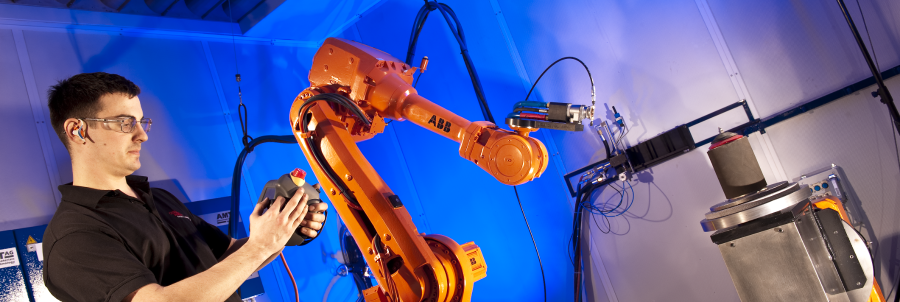

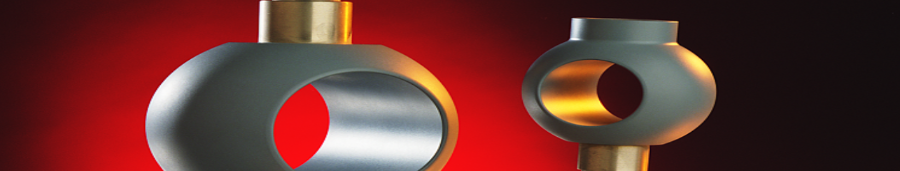

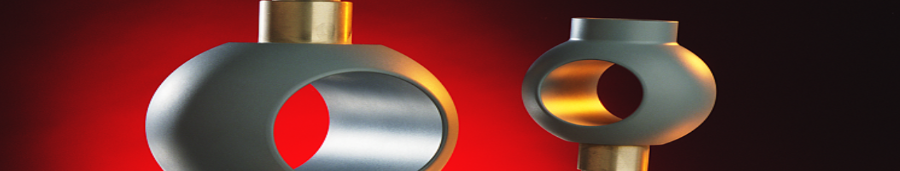

Metal Improvement Company (Newbury Division) offer quality metallurgical solutions to improve the performance of metal. With advanced technology, these improvements can be integrated into products when required and can dramatically enhance lifetimes improve fatigue strength, precision shaping, selective hardness and surface finish.

At Metal Improvement Company (Newbury Division), we deliver our innovative enhancements to our customers and help to create new state of the art products. We offer laser peening, peen forming, controlled shot peening, superfinishing and solid film lubricant coatings.

We are located in the UK with divisions in Evesham, Earby, Sunderland, Newbury, Derby, and Chester.

-

CURTISS-WRIGHT ACQUIRES KERONITE GROUP LTD

11 April 2024DAVIDSON, N.C.–(BUSINESS WIRE)– Curtiss-Wright Corporation (NYSE: CW) today announced that it has completed the acquisition of the stock of Keronite Group Limited (Keronite) for $35 million in cash. Keronite is a leading provider of Plasma Electrolytic Oxidation (PEO) surface treatment applications offering corrosion protection, wear resistance, thermal protection and electrical insulation for the defense, commercial aerospace and industrial vehicle markets, and also in semiconductor manufacturing.

Keronite is expected to generate sales of approximately $9 million in 2022 and is expected to be neutral to Curtiss-Wright’s adjusted diluted earnings per share in its first full year of ownership, excluding first year purchase accounting costs, and produce a strong free cash flow conversion rate of approximately 100%. The acquired business will operate within Curtiss-Wright’s Aerospace & Industrial segment.

“The acquisition of Keronite increases the breadth of our surface treatment services portfolio with unique and complementary coatings technologies recognized for their critical performance in severe service environments,” said Lynn M. Bamford, Chair and CEO of Curtiss-Wright Corporation. “The combination of this business with Curtiss-Wright’s long-standing customer relationships and global sales channels provides strong alignment to the strategic priorities as highlighted at our 2021 investor day and is expected to yield significant opportunities for long-term profitable growth.”

Keronite’s PEO surface treatment process utilizes a bath-based method of producing ceramic layers on light alloys such as aluminum, magnesium and titanium to enhance their inherent performance characteristics. As the surface is oxidized, it incorporates an electrolyte thereby giving the coating specialized characteristics that are tailored to the specific application. Through Keronite’s process, lightweight metals are afforded the wear and performance properties of high-weight materials such as carbide or steel in a more environmentally-friendly manner, and are well-suited to support demanding applications such as aerospace or electric vehicle programs.

Keronite, which was founded in 2000 and employs nearly 45 people, is based in Cambridge, UK, and also maintains operations in Greenwood, Indiana.

About Curtiss-Wright Corporation

Curtiss-Wright Corporation (NYSE:CW) is a global integrated business that provides highly engineered products, solutions and services mainly to Aerospace & Defense markets, as well as critical technologies in demanding Commercial Power, Process and Industrial markets. We leverage a workforce of 8,000 highly skilled employees who develop, design and build what we believe are the best engineered solutions to the markets we serve. Building on the heritage of Glenn Curtiss and the Wright brothers, Curtiss-Wright has a long tradition of providing innovative solutions through trusted customer relationships.

This press release contains forward-looking statements made pursuant to the Safe Harbor provisions of the Private Securities Litigation Reform Act of 1995 that are based on management’s beliefs and assumptions. Such statements, including statements relating to Curtiss-Wright Corporation’s expectations for the future opportunities associated with the acquisition, the success of transferring Keronite’s technology throughout our existing world-wide network, and the success of the Company integrating Keronite into its Aerospace & Industrial segment are not considered historical facts and are considered forward-looking statements under the federal securities laws. Such forward-looking statements are subject to certain risks and uncertainties that could cause actual results to differ materially from those expressed or implied. Readers are cautioned not to place undue reliance on these forward-looking statements, which speak only as of the date hereof. Such risks and uncertainties include, but are not limited to: a reduction in anticipated orders; an economic downturn; changes in competitive marketplace and/or customer requirements; a change in US government spending; an inability to perform customer contracts at anticipated cost levels; and other factors that generally affect the business of aerospace, defense contracting, marine, electronics and industrial companies. Please refer to the Company’s current SEC filings under the Securities Exchange Act of 1934, as amended, for further information.

-

CURTISS-WRIGHT ANNOUNCES RIBBON CUTTING CEREMONY OF ITS NEW SURFACE TECHNOLOGIES FACILITY IN BEKESCSABA, HUNGARY

5 September 2023PARAMUS, NJ – August 29, 2023 – Curtiss-Wright’s Surface Technologies Division, a leading global provider of highly engineered surface treatments and analytical services, announces the ribbon cutting ceremony of its first Hungarian location in Bekescsaba, Hungary. This facility is a strategic partnership with Linamar Hungary Zrt, a premier EV gearbox manufacturer for electric vehicles, and will provide on-site shot peening services, while also providing a platform to support the entire Eastern European market. David Rivellini, Senior Vice President and General Manager, Curtiss-Wright Surface Technologies Division, says “We are delighted to have been asked by Linamar to provide a solution to support their shot peening needs. Shot peening extends the lifetime performance for high torque applications, which is critical to the electric vehicle market. Not only will this new facility allow us to provide quick turn times for Linamar, thereby saving them time and money, but will also allow us the opportunity to support additional shot peening needs in the growing Hungarian aerospace market as well as the Eastern European market.”

To learn more about Curtiss-Wright Surface Technologies, please visit: www.cwst.com

About Curtiss-Wright Corporation

Curtiss-Wright Corporation (NYSE:CW) is a global integrated business that provides highly engineered products, solutions and services mainly to Aerospace & Defense markets, as well as critical technologies in demanding Commercial Power, Process and Industrial markets. We leverage a workforce of approximately 8,400 highly skilled employees who develop, design and build what we believe are the best engineered solutions to the markets we serve. Building on the heritage of Glenn Curtiss and the Wright brothers, Curtiss-Wright has a long tradition of providing innovative solutions through trusted customer relationships. For more information, visit www.curtisswright.com.

-

Curtiss-Wright’s Keronite Business Secures Nadcap Approval Certification

21 June 2023PARAMUS, NJ – June 16, 2023 – Curtiss-Wright Surface Technologies Division today announced that its Keronite business, a world leader in plasma electrolytic oxidation (PEO) applications including a pioneering surface treatment that uniquely enhances the performance of light alloys, has successfully secured Nadcap accreditation for Chemical Processing at its Greenwood, IN facility. Nadcap (National Aerospace and Defense Contractors Accreditation Program) is the aerospace industry’s global accreditation program designed to recognize special processors that integrate and maintain stringent Quality System and process control standards. Pursuit of Nadcap accreditation demonstrates an organization’s desire to mitigate customer risk and promote product safety. Keronite joins more than 45 other Curtiss-Wright Surface Technologies Business Units that are Nadcap accredited. Commenting on the approval, David Rivellini, Senior Vice President and General Manager, Curtiss-Wright Surface Technologies Division, noted: “We're incredibly proud to earn Nadcap accreditation for Chemical Processing. This approval is a testament to our unwavering commitment to quality, our continuous improvement of manufacturing standards, our innovative processes, and the development of new technology.” Keronite’s PEO technology enhances the performance of light alloys and is utilized across various aerospace applications, ranging from large-cast structural components to geometricallycomplex components. PEO-coated components are frequently used as a lightweight alternative to heavier metals, a strategy employed across the industry to improve aircraft fuel economy. Notably, aerospace manufacturers have extensively adopted this technology to combat corrosion, dry-sliding wear and as an eco-friendly alternative to toxic chromate conversion coatings. Rivellini concluded, “Curtiss-Wright is committed to delivering the best possible technologies and breakthrough applications, while providing our customers an opportunity to utilize unique surface treatment applications offering corrosion protection, wear resistance, and other properties, such as thermal and electrical insulation. This recognition underscores the quality of our processes within the industry, while also creating more opportunities to expand our footprint in the aerospace sector.” In November 2022, Keronite was acquired by Curtiss-Wright Corporation. The business is now a part of Curtiss-Wright Surface Technologies, within its Engineered Coatings Business Unit, empowering aerospace manufacturers worldwide to benefit from a comprehensive range of solutions for an extensive array of applications.

To learn more about PEO, or understand how it could bolster the performance of light alloys in your designs, reach out to our team of experts or read our flagship white paper, ‘What is Plasma Electrolytic Oxidation?’ to discover more about this revolutionary technology: https://blog.keronite.com/what-is-plasma-electrolytic-oxidation To learn more about Keronite, please visit: www.keronite.com To learn more about Curtiss-Wright Surface Technologies, please visit: www.cwst.com About Curtiss-Wright Corporation Curtiss-Wright Corporation (NYSE:CW) is a global integrated business that provides highly engineered products, solutions and services mainly to Aerospace & Defense markets, as well as critical technologies in demanding Commercial Power, Process and Industrial markets. We leverage a workforce of 8,100 highly skilled employees who develop, design and build what we believe are the best engineered solutions to the markets we serve. Building on the heritage of Glenn Curtiss and the Wright brothers, Curtiss-Wright has a long tradition of providing innovative solutions through trusted customer relationships. For more information, visit www.curtisswright.com

-

New Brochures

18 August 2022We have added some new brochures to our website. Please click on the link and take a look. Controlled Surface Treatments Downloads | CWST

-

MedTec Ireland

18 August 2022CWST will be exhibiting at Medtec Ireland on the 21st- 22nd September. Our stand number is 77. Pop along and say Hello.

-

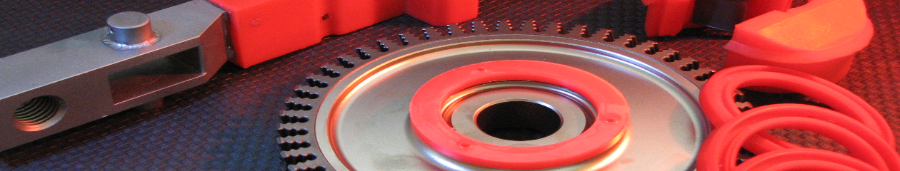

Introducing Fluregiene 200™

21 June 2022Curtiss-Wright Surface Technologies, Everlube® Coating Products have partnered with BioCote® to expand their fluoropolymer coating product range to create Fluregiene 200™: an antimicrobial coating that is ideally suited for many surfaces and environments.

Based on existing Everlube® coating technology, the new Fluregiene 200™ is a unique fluoropolymer coating that offers low friction, easy-clean properties combined with superb chemical and abrasion resistance. With a view to improving hygiene standards, Everlube® Coatings have integrated BioCote® antimicrobial technology to protect the coating from microbes such as bacteria, mould and fungi. Benefits of applying antimicrobial technology into the Fluregiene 200™ include:

Anti-fouling

- Low COF Surface coating (0.08 – 0.2 static)

- Corrosion resistance and excellent chemical resistance

- Excellent chip and abrasion resistance

- Reduces and prevents build-up of contaminates

- Excellent flexibility

- Dirt and debris less likely to attach to the surface

Microbial & bacteria growth inhibitor

- Using patented BioCote® antimicrobial technology against microbial growth

- Inhibits and reduces microbial growth on protected coating

- Protects treated surfaces against bad odours, staining and material degradation

Easy clean and reduced cleaning intervals

- Provides continual microbial reduction on coating

- High PTFE content allows easy wipe down and cleaning

- Provides more hygienic and cleanable surface than brushed or finished steels

Applicable to a wide range of parts and components such as door handles, elevator buttons, airport seating and gym equipment, the Fluregiene 200™ will be highly beneficial for these surfaces. BioCote® also has real-life data to support the application of this antimicrobial technology in environments such as health care, transport, education, public areas and much more.

For more information on Fluregiene 200™ and Everlube® Coating Products please contact our coatings team on:

Tel: (44)1386 421444

Email: -contact us form

-

Fluregiene 200™ Protecting your surfaces for longer.

8 February 2022Curtiss-Wright Surface Technologies, Everlube® Coating Products have partnered with BioCote® to expand their fluoropolymer coating product range to create Fluregiene 200™: an antimicrobial coating that is ideally suited for many surfaces and environments.

Based on existing Everlube® coating technology, the new Fluregiene 200™ is a unique fluoropolymer coating that offers low friction, easy-clean properties combined with superb chemical and abrasion resistance. With a view to improving hygiene standards, Everlube® Coatings have integrated BioCote® antimicrobial technology to protect the coating from microbes such as bacteria, mould and fungi. Benefits of applying antimicrobial technology into the Fluregiene 200™ include:

Anti-fouling

- Low COF Surface coating (0.08 – 0.2 static)

- Corrosion resistance and excellent chemical resistance

- Excellent chip and abrasion resistance

- Reduces and prevents build-up of contaminates

- Excellent flexibility

- Dirt and debris less likely to attach to the surface

Microbial & bacteria growth inhibitor

- Using patented BioCote® antimicrobial technology against microbial growth

- Inhibits and reduces microbial growth on protected coating

- Protects treated surfaces against bad odours, staining and material degradation

Easy clean and reduced cleaning intervals

- Provides continual microbial reduction on coating

- High PTFE content allows easy wipe down and cleaning

- Provides more hygienic and cleanable surface than brushed or finished steels

Applicable to a wide range of parts and components such as door handles, elevator buttons, airport seating and gym equipment, the Fluregiene 200™ will be highly beneficial for these surfaces. BioCote® also has real-life data to support the application of this antimicrobial technology in environments such as health care, transport, education, public areas and much more.

For more information on Fluregiene 200™ and Everlube® Coating Products please contact our coatings team on:

Tel: (44) 1386 421444

info@cwst.co.uk

-

Advance Engineering Show 2019

25 April 2019 -

Engineering Materials Live Show

25 April 2019 -

New Challenges in Tribology 2019

27 March 2019CWST will be exhibiting at “New Challenges in Tribology” at the IET Birmingham: Austin Court on the 27th and 28th March.

Tribology is the study of friction, wear, lubrication, and the design of bearings; the science of interacting surfaces in relative motion.

This two-day event will address the current challenges in Tribology, along with the developments of materials, corrosion and surface coatings.

This event will bring together leading members from the community to hear key information from our invited speakers.

Alongside this there is an opportunity to view the posters entered into the competition and an opportunity to interact with the exhibitors on show.