EWFM

EWFM supply high quality engineering products designed for the safe transfer of liquids, gases, and other medias. Since 1999, our company has been distributing to various industries worldwide such as Oil & gas, Food & Drink and Pharmaceutical just to name a few. Our team is trained to provide our customers with an immaculate service and knowledge to ensure your projects run smoothly from start to finish.

-

Case Study: Qatar Reservoirs

16 August 2023Project Background:

In early 2021, EWFM was approached to provide a solution for drawing water/sewage from a reservoir in Qatar. The primary goal for the client was to establish a more sustainable approach to water management by recycling water rather than releasing it back into the sea. Given the scarcity of water in the arid climate of Qatar, this project was of utmost importance, especially with the upcoming World Cup. The success of the project hinged on EWFM’s contribution!

Challenges:

Environmental Concerns: The need to recycle water highlighted the environmental impact of disposing of water in the sea, and the challenge was to find a more responsible way to manage this resource.

Harsh Desert Conditions: The hot and arid climate in Qatar presented significant challenges in terms of material durability and system performance. The equipment needed to withstand these conditions.

Efficiency and Speed: The client required a solution that would expedite the recycling process, however avoiding both the scum which is gathered at the surface and the sediment collected at the bottom.

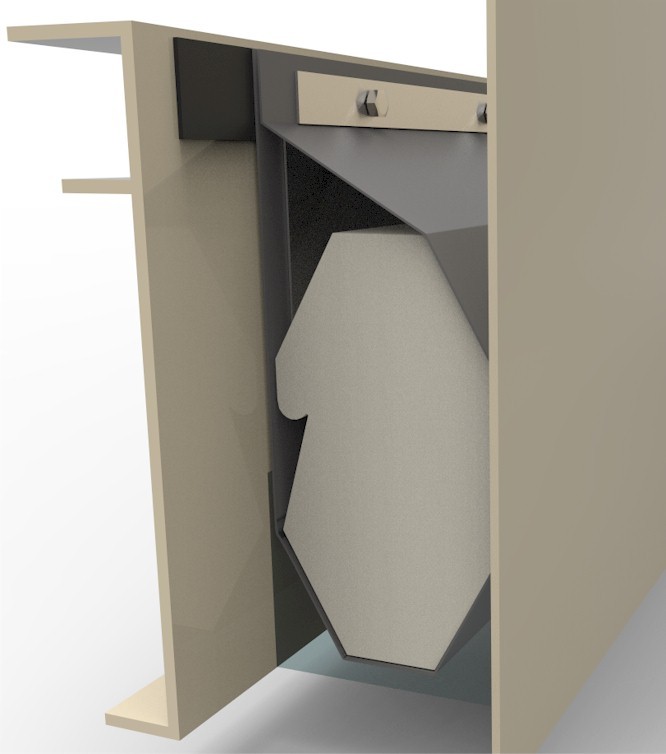

Waves: As pictured given the size of the reservoir the client needed something which could handle loads inflicted.

FRP Flange: The Floating Suction Unit had to join an FRP flange. This meant that almost the whole unit has to be self supporting.

Solution: EWFM embarked on a comprehensive project that involved designing, manufacturing, and supervising installation of 5 x 40” Floating Suction Units. These units played a crucial role in drawing water from beneath the reservoir’s surface while preventing the intake of sediment and scum. The units were manufactured in high-quality stainless steel construction, ensuring their durability in the tough desert conditions.

Main Features:

Engineering: Before and during the manufacturing phase, our team dedicated extensive time to designing a solution that met the client’s satisfaction. This involved rigorous calculations, wave analysis, finite element analysis, and more.

40″ Pipework: The images themselves tell the story – these are the largest floating suction units we’ve ever produced. The presence of people in the images provides a clear perspective on the impressive size of these units.

Swivel Joints: The most intricate part of the project, the client even travelled from Qatar to witness a Factory Acceptance Test (FAT) at our facility. The Swivels were engineered to handle increased loads, featured special seals, and were equipped to withstand challenging environmental conditions.

Floats: These floats are meticulously designed to ensure stable flotation during operation, not randomly chosen.

Supports: The support systems played a crucial role, essentially carrying the entire unit. Of particular note is the support on the Swivel Joint, boasting an 8″ bore.

Testing: Both Swivel Joints and floats underwent pressure testing, with all major welds undergoing dye penetrant testing.

Supervision: Even after shipping 5 x 40ft containers to Qatar, our commitment didn’t stop. We ensured a supervisor was on-site to assist with the installation process.

Results:

After over a year of dedication, collaboration, and hard work from the entire EWFM team and their suppliers, the project successfully reached its milestone. The onsite inspection was passed, and 5 x 40” Floating Suction Units are now fully installed.

Conclusion:

EWFM’s innovative approach, dedication to quality, and commitment to sustainable water management were key factors in the successful implementation of the Floating Suction Units for water recycling in Qatar. This project not only addressed a critical need in a water-scarce region but also showcased EWFM’s expertise in designing and delivering solutions tailored to challenging environments.

-

Project World Cup: Germany

16 August 2023It’s time for the fourth instalment of our “Project World Cup” series, where we delve into one of the international teams playing today and explore that country, along with EWFM’s projects there over the years.

The tournament has been ongoing for exactly two weeks, and like last year’s men’s World Cup, it has been filled with great goals, superb saves, and some surprising results! Favourites, England, have advanced to the ‘round of 16’, winning all three of their group games while conceding only one goal. They will face Nigeria, who has been one of the tournament’s surprise packages, securing the second spot in Group A ahead of Canada.

In today’s edition of “Project World Cup,” we’ll take a closer look at Germany, who played against South Korea in the last group game of the Women’s World Cup this morning.

About Germany:

Germany, located in the heart of Europe, is home to an estimated population of 85,887,000 people. In the football world, the country is regarded as having one of the best teams, with the men’s and women’s teams winning a combined 6 World Cups and 11 Euro Championships.

Aside from sports, Germany is well known for its beer, and it holds the traditional Oktoberfest every October, which has grown in popularity worldwide year after year. Additionally, Germany is renowned as a hub for car manufacturing and is famous for its beautiful castles.

Berlin, the capital of the country, is rich in history and boasts magnificent landmarks such as the Brandenburg Gate and remnants of the old Berlin Wall.

Five fun facts about Germany:

- Germany have the largest zoo in the world which is located in Berlin.

- Beer is considered as food in the region of Bavaria.

- There are around 20,000 castles located in the country.

- The Cologne Cathedral took 632 years to build!

- Beer is so popular in the country that all you need to do is raise a thumb to get one. If your thumb is out, it means you’re ordering one beer. If your thumb, index, and middle finger are all out then you’re ordering three beers.

EWFM in Germany:

Germany is not widely recognised for its significant presence in the oil and gas industry. In 2020, the country produced 2 million tonnes of crude oil, which accounts for approximately 0.04% of the global oil production. Germany’s primary oil field is the Mittelplate field, located in the Wadden Sea.

However, Germany is renowned for its extensive manufacturing sector, with over 220,000 manufacturing enterprises in the country. Production lines in these enterprises often involve the use of pipework, for which our Swivel Joints are integral components. Over the years, EWFM has successfully completed numerous projects in Germany, with our range of Swivel Joints being particularly popular in the country.

LNG (Liquefied Natural Gas) is experiencing a surge in demand worldwide, primarily due to the current climate crisis and the ongoing conflict between Ukraine and Russia. Germany, in particular, is seeking alternatives to the Russian gas it previously relied on, leading to an increasing need for LNG. In response, the German government has advanced plans to construct land-based terminals and lease floating terminals in the short term, while the land terminals are being built.

At EWFM, we offer Swivel Joints, Loading & Unloading Arms, and Breakaway Couplings that can all be modified for use with LNG products. If you are interested in learning more about these product ranges, feel free to reach out to our sales team or visit our website for further information.

-

Project World Cup: Netherlands

16 August 2023It’s time for the return of “Project World Cup”! A series that we started to coincide with the 22nd edition of the Men’s World Cup. Every Thursday during the group stage games we choose a country that are in action and look into the country, and what projects EWFM have completed there over the years.

This year the Women’s World Cup is being jointly shared by Australia and New Zealand. This is the first time that the Women’s edition of the international football tournament has had more than one host nation. Also, it is the first time two countries from different confederations have hosted a tournament as one is from the Asian confederation and the other from the Oceania equivalent.

Both host nations got off to great starts to their world cup campaigns with respective 1-0 wins. As for the England Women’s team, they started off with a 1-0 win over Haiti and their next game is against Denmark tomorrow morning.

In today’s edition of Project World Cup, we will be looking into the Netherlands, who earlier on today played against favourites the USA in a 1-1 draw in Wellington, New Zealand.

The Netherlands:

The Netherlands, located in the northwest of Europe, has a population of around 17,975,000 people. Known for its canals, fields of colour tulips, windmills and beautiful scenery which can be viewed by various cycle routes. Its capital, Amsterdam, has over 1 million people living in the city, with some even living on the canals that run through the heart of it. As well as the people living there, it has over 20 million tourists each year. From the Van Gough Museum to the House that diary writer Anne Frank hid in, Amsterdam and the Netherlands is full of history and culture.

Five Fun facts about the Netherlands:

- There are more bicycles than people in the country.

- It is the lowest lying country in Europe with the lowest point being 7m below sea level.

- Tulips aren’t actually native to the country as they originally came from Turkey.

- The Dutch are the tallest people in the world.

- For many years, the country has gone by the nickname ‘Holland’ which has now been dropped by the Dutch government in an effort to rebrand itself as a nation.

EWFM in the Netherlands:

The Netherlands is well known in the Oil and Gas industry for its large amount of storage tanks located in various ports around the country. The biggest in the country and in Europe is the Port of Rotterdam. In 2021, around 204.6 million metric tonnes of liquid bulk products were put through the port. Liquid bulk products include crude oil, mineral oils, LNG and others. Within the port there are also 31 tank farms which will hold some of the liquid bulk products that are being brought into the country via the port.

Earlier on in the year as many of you will know, EWFM exhibited at StocExpo which is held at the Rotterdam Ahoy. This exhibition is the leading event for the tank storage and future fuels industries. Over the three days that it was held many of the companies that have storage tank farms, visited the show to find new products and ways that they can enhance their current operations.

Over they years, EWFM has completed numerous projects with well known companies in the Netherlands. A particular hit is our range of Swivel Joints which are frequently used as parts of hose reel systems. The swivels help the hose reels to rotate and enable the flow of media through the bore. As well as that, due to the copious amounts of tank farms across the country, our newest range of floating roof storage tank seals are perfect for stopping harsh vapours stored, escape into the atmosphere. We also have a few of our other ranges that are perfect for the ports and other industries in the country including:

- Storage Tank Equipment

- Couplings

- Breakaway Couplings

- And a new addition coming to the EWFM product portfolio soon!

If you have any upcoming projects that require any of the products mentioned above, please get in contact with our sales team who will be happy to assist you! Come back next week, where will be looking into Germany.

-

EWFM comes to the Big Screen

16 August 2023EWFM and the cinema – two words you wouldn’t normally associate with each other, but now you can! At the beginning of 2021, we received an enquiry over the phone from an employee working at Long Cross Studios in Surrey. They were looking for a compact and easily rotatable product. At that time, the name of the film couldn’t be disclosed, but after a few discussions, we were informed that the product was needed for the next instalment of the Mission Impossible franchise – Mission Impossible: Dead Reckoning Part 1.

The Mission Impossible Franchise:

Since its initial release in 1996, the Mission Impossible franchise has seen the launch of seven films, with another one planned for the following year. Throughout its history, the franchise has attracted a host of talented actors, including Henry Cavill, Hayley Atwell, Philip Seymour Hoffman, Kristin Scott Thomas, and, of course, Tom Cruise.

In each movie Tom Cruise, portraying the iconic character Ethan Hunt, serves as an agent for the Impossible Missions Force, a group dedicated to thwarting threats to the world. Despite the potential for repetitiveness after seven films, the franchise is renowned for its high-quality storytelling and jaw-dropping stunts, many of which are performed by Tom Cruise himself.

The previous six films have collectively earned over $3.5 billion at the global box office, highlighting the franchise’s immense popularity. The latest instalment, Mission Impossible: Dead Reckoning Part 1, has already amassed $235 million worldwide and is anticipated to be a summer blockbuster, likely to continue its impressive box office success.

How EWFM have helped Tom Cruise create a box office hit:

You might be wondering which of EWFMs products is suitable for a film production like Mission Impossible. When the individual from Long Cross Studios contacted us, seeking a compact design with easy rotation capabilities, we had the perfect solution for them – the Compact Swivel Joint. Renowned for its suitability in limited spaces, it stands as the most compact swivel joint design currently available in the market.

For the film’s requirements, we supplied a 12” Carbon Steel Compact Swivel Joint, along with a 24” Carbon Steel Engineered Swivel Joint. These Swivel Joints were intended for use in a gripping submarine scene at the beginning of the film, involving gushing water and steam. We won’t spoil the scene for you, so you should definitely head to the cinema this weekend to experience it first-hand.

Having our products featured in such a high-profile film production like Mission Impossible: Dead Reckoning Part 1 is a testament to the quality and reliability of our engineering solutions. We are proud to help with the success of this blockbuster movie and continue to provide innovative products to cater to diverse industries, even the exciting world of cinema!

At EWFM no project or mission is impossible. Our sales team will work with you to understand your requirements and find the best possible solution. If you have any upcoming or current projects that you would like to discuss, get in contact with the team using the contact information below.

-

World Population Day

16 August 2023This week on the 11th of July was the UN observance known as “World Population Day”. The observance came about in 1989 largely after the huge public response to “Five Billion day”, the day (11th July) in 1987 when the world’s population hit five billion.

This is the time the world comes together, as designated by the United Nations, to focus their attention and seek to raise awareness on the urgency and importance of population issues, including their relations to the environment and human development.

Our world now currently holds its population at 7.8 billion people!

How EWFM can help the increase:

As the world’s population grows there is a need for more transport, transfers and distribution of liquid and gasses around the world. During these increased demands, we also need to ensure that services are keeping up with the safety regulations and the wellbeing of the worlds environment.

To do so, EWFM supply the best leading Couplers in the market that ensure just this. Our Couplers are easy and quick to use for connection/disconnection, spill-free and compatible for all industries and applications. Our extensive range of Couplings includes:

- Dry-disconnect: The go-to coupling choice when handling liquid, chemicals and gases.

- Gas: Primarily used for the loading and unloading of liquefied petroleum gas and various other gas medias.

- Aviation: Designed to handle aviation fuel and can be found at any point in the aviation fuel process.

- Cryogenic: Only used for cryogenic applications and medias, the cryogenic coupling can handle medias down to -196° C.

These ensure we can help you stay inline with these demands while keeping the world and environment safe as it vastly continues to grow.

If you or your company uses Couplings in any of your business processes, then get in contact with our sales team who will be more than happy to assist you with any current or future requirements.

-

How to… Service your MannTek Dry Disconnect Coupling

16 August 2023It’s time for the next instalment of our “How to…” series, where we provide maintenance tips to ensure the longevity of EWFM products. In previous editions, we discussed maintaining Model 2715 and 2714 Swivel Joints. In this month’s edition, we will focus on servicing a MannTek Dry Disconnect Coupling. Dry Disconnect Couplings are designed to enable spill-free, quick, and dry connections and disconnections of hoses and pipelines. To service the coupling effectively, there are specific rules that need to be followed to ensure your safety and the protection of the coupling. These are:

- Always need to depressurise the system and rinse off the parts before beginning any maintenance work.

- Do not handle O-ring seals if the material appears charred, gummy, or sticky.

- Do not touch adjacent parts with unprotected hands.

- Rinse off the parts once again before starting the “daily inspection”.

- Wear protective googles and gloves during the service.

(The below is the service instructions based on a 4” MannTek Dry Disconnect Coupling, the process will be similar for smaller and larger sizes.)

How to service the Tank unit:

- Remove the flat sealing, ensuring you don’t scratch the seal face. (Skip step if you have an NPT-Thread)

- Press down the spindle steering and turn it to release it. Take out the spindle steering, spring cap and spring from the body.

- Remove the piston and put it into a relaxing position in the valve seat.

- Replace the PTFE bushing (Pos.5) in the spindle steering.

- Replace the O-ring (pos.3) on the piston with a new greased O-ring. Ensure that there is equal pressure around the O-ring with it being pressed into the groove completely.

- Insert the piston back into the unit in a relaxed position in the valve seat.

- Replace the spring (pos.7), spring cap (pos.6) and the spindle steering (pos.4).

- Place the spindle steering back into the unit. To fix it into the correct position, press down and turn. Ensure that it is in the correct position.

- Assemble a new flat sealing (pos.12).

- Finally, make a visual inspection to ensure everything is in the correct place. Also test it works but connecting and disconnecting a hose unit with the newly service tank unit.

How to service the hose unit:

- Begin by unscrewing and removing the lock screw from the swivel ring by using a 2mm hex key.

- Mark the position of the swivel sleeve against the swivel ring with an 8mm pin. Unscrew and remove the swivel sleeve from the swivel ring.

- Change the PTFE ring (pos.25) on the top of the coupling body.

- Remove the two shafts for piston guide, by applying pressure to the driving plate packet so that it moves down 2 mm. This will release the driving plate packet from the rollers.

- Turn the driving plate to the position where the recess ends up under the rollers under pressure to the driving plate packet. Remove the driving plate packet from the hose unit body.

- Remove the protective ring.

- If needed, you can change the O-ring (pos.21) for dust protection. Ensure the handle has been dismounted and the new O-ring has been greased.

- Change the three shafts (pos.18), locking nuts (pos.19) and rollers (pos.17) to new ones. Check that the roller easily rotate now.

- Mount the protective ring back on. To ease the mounting of the protective ring applying grease on the inside of the protective ring is recommended.

- Change the O-ring (pos.24) from the groove in the coupling body. Use grease on the new part. Apply grease on the balls for best possible swivel rotation.

- Ensuring that both have been greased, Change the O-ring (pos.8) and PTFE ring (pos.9) on the driving plate back side.

- Change the PTFE bushing (pos.13) to new ones on both sides.

- Change the newly greased O-ring (pos.6) on the driving plate front side.

- Change the newly greased O-ring (pos.3) on the piston. Change the O-ring (pos.3) on the piston.

- Change the PTFE bushing (pos.16) to new ones on both sides.

- Before placing the coupling body back on the driving plate packet, make sure the part where the upper cam curve ends, is placed exactly over one roll, and the heel on the driving plate packet is placed under the hole for the shaft.

- Place the coupling body over the driving plate packet. Grab the piston guide and turn the unit upside down. Press down and turn the driving plate to the position where the driving plate heels are placed under the rollers.

- Assemble the two shafts for piston guide when applying pressure to the driving plate packet.

- Place a new flat seal (pos.29) on the swivel sleeve.

- Place the swivel sleeve over the coupling body and screw in the swivel sleeve. (Take care that the markings you made in the beginning are aligning. If necessary apply anti seize lube on the threads.)

- Use Loctite® 243 and screw the lock screw into the swivel ring without any force as this could lead to deforming of the ball bearings!

- Apply sealing wax on the top of the lock crew after screwing it in, to prevent misuse.

- Finally, make a visual inspection to ensure everything is in the correct place. Also test it works but connecting and disconnecting a tank unit with the newly service hose unit.

-

Industry Showcase: Cryogenics

16 August 2023It’s time for another instalment of the Industry Showcase. These blogs aim to delve deeper into the industries that EWFM products cater to. Previously, we have explored key information about the oil & gas, food & drink, and chemical industries, and highlighted the suitability of EWFM products for these sectors. In this month’s edition of the showcase, we will focus on the cryogenic industry. Industry forecasters predict significant growth for the cryogenic industry in the future, estimating its value to reach around £35 billion by 2030. But what is driving this increased demand for cryogenics?

About the Cryogenic Industry:

The cryogenic industry encompasses a wide range of sectors involved in the production, distribution, and application of technologies and products designed to operate at extremely low temperatures. It plays a vital role in various fields, including industrial gases, energy, healthcare, research and development, aerospace, defence, and more.

The recent increase in demand for cryogenic practices can be attributed to the climate change situation. Natural gases are often considered the future of clean energy as they are seen as a more environmentally friendly alternative to fossil fuels. They burn cleaner compared to fossil fuels, which are predominantly used at present.

To convert cryogenic materials into energy, a typical process involves a cryogenic energy facility. In this facility, cryogenic materials such as air are stored and chilled, causing them to transform into their liquid form. When the liquid air warms up, it expands, and this expansion is harnessed by a turbine, which then generates electricity.

The term given to natural gases cooled down in the cryogenic process is Liquefied Natural Gas (LNG). These gases can reach temperatures as low as -162°C, requiring the use of well-engineered products to ensure safe production and protect employees working with the materials.

What EWFM can do for Cryogenic related practices:

That’s where EWFM comes in. We offer a range of products specifically suited for cryogenic applications, including Swivel Joints, Couplings, and Breakaway Couplings.

Our Swivel Joints are available with a Nitrogen Purge feature, which surrounds the ball bearing raceways with nitrogen to prevent freezing and ensure smooth operation even in extremely cold conditions. Additionally, they are equipped with UHMW-PE seals that are specially designed for cryogenic applications. Our cryogenic swivels have undergone testing under third-party inspection, establishing their reliability and performance.

For cryogenic coupling needs, our Manntek Cryogenic Couplings and Breakaway Couplings are designed to operate at temperatures as low as -163°C and -196°C. These products comply with ISO 18683 and the new ISO 21593 standards. ISO 18683 focuses on the safety and risk assessment of LNG fuel bunkering operations, while ISO 21593 outlines the technical requirements for dry-disconnect/connect couplings for bunkering liquefied natural gas.

If you work in the cryogenic industry and are seeking products to enhance your company’s production processes, we encourage you to get in touch with EWFM. Our team is readily available to provide expertise and tailored solutions for your specific projects.

-

A Celebration of Music

16 August 2023Yesterday, on June 21st, we celebrated the Summer Solstice, marking the official start of summer in the northern hemisphere. What many people may not be aware of is that the Summer Solstice also signifies the beginning of festival season here in the UK, with Glastonbury Festival always starting the weekend after the longest day of the year. Glastonbury is a renowned festival that celebrates music and various forms of art. The inaugural festival took place in September 1970 on Worthy Farm, its current location. Back then, it attracted around 1,500 attendees. Today, the festival has a maximum capacity of 210,000 people. The festival grounds span an impressive 1,100 acres of Worthy Farm, equivalent to 500 football pitches placed side by side.

Glastonbury past and present:

Since its inception, Glastonbury Festival had been a staple for 49 years, but unfortunately, its 50th Birthday Celebration had to be cancelled due to the COVID-19 outbreak. However, in 2022, the festival finally got to celebrate its milestone, and what a celebration it was! Glastonbury is known for providing a platform for both emerging artists to shine and megastars to put on spectacular performances. The 2022 edition featured over 3,000 performances across 100 stages.

One of the highlights of Glastonbury is the three nights of music on the iconic Pyramid stage, which always feature three major headliners. Last year, the festival welcomed Paul McCartney, Billie Eilish, and Kendrick Lamar as the headliners. In previous years, we have seen legendary acts such as Oasis, Van Morrison, David Bowie, Coldplay, and many more take the stage. This year, the festival will bring back the Arctic Monkeys as headliners once again, with Guns N’ Roses making their Glastonbury debut, and the final performance in the UK by the iconic Sir Elton John, making it a truly memorable event.

EWFMs recent celebration:

EWFM had a significant reason to celebrate recently. In the past month, we underwent our annual ISO 9001-2015 Quality Standard assessment. The ISO Certificate serves as “a seal of approval from a third-party body that confirms a company’s adherence to one of the international standards developed and published by the International Organization for Standardization (ISO).”

For the 32nd time, we are delighted to announce that EWFM has once again passed the assessment without any major or minor non-conformances. This achievement reflects the dedication and professionalism of our team over the past year and highlights our commitment to maintaining a high standard.

We hope that this accomplishment further demonstrates our unwavering commitment to delivering a quality product and service to our valued customers. If you have any upcoming product needs or inquiries, please don’t hesitate to contact our sales team. They will be more than happy to assist you.

-

Hose Reel(ing) you in

16 August 2023Hose reels are key components in the loading and offloading process in the onshore and offshore industries. In this week’s blog, we will be exploring what hose reels are and their primary uses. Alongside that, we will be looking into how EWFM’s extensive range of Swivel Joints is key in getting hose reels to work.

What are hose reels and their uses:

Ship hose reels work like a garden hose; they turn and gradually release a long length of hose, which can then be rotated back to retract the hose. However, there is a difference when it comes to the media transferred through hose reels compared to a garden hose. Everyday ship hose reels will be handling substances such as oil, chemicals, and more.

Hose reels are primarily used in the loading and unloading process. In this case, we will focus on an onshore hose reel, although they can also be located on ships. The hose reel onshore will be filled with a selected media that needs to be transported to a large ship out at sea.

A smaller boat will connect to the hose reel via a coupling and then make its way to the larger ship. During this process, the hose reel will gradually rotate, releasing more and more hose. Once the smaller ship reaches a safe distance from the larger one, they will transfer the coupling to the larger ship and connect it.

The loading or unloading process can then begin. Once completed, the coupling will be detached, returned to the smaller ship, and the hose will be taken back to the hose reel.

Reels can come in different shapes and sizes depending on their location. Hose reels are often 10 meters wide or more, which means they require large Swivel Joints to facilitate the rotation of the reel.

How do EWFM’s Swivel Joints work with hose reels?

At the centre of a hose reel is a Swivel Joint. Large Bore Hose Reel Swivel Joints allow the hose reel to rotate and enable the flow of media through the bore. Our Large Bore Swivel Joints are available in sizes ranging from 10″ up to 72″ internal bore, and they can be constructed using materials such as carbon steel, stainless steel, and duplex steel. As shown in the images below, the swivels can also be marine painted to match colour specifications. We offer pressure testing, third party design and review surveys, NDE testing and much certification/documentation upon request.

If you work in the onshore and offshore sector and deal with large hose reels, please get in contact with our sales team. We have been supplying Swivel Joints specifically designed for hose reels for years, so we know what works best! Our sales team will work closely with you to ensure you get the right fit to keep your processes turning.

-

FA Cup Final Weekend

16 August 2023As we are approaching the business end of the football season, the remaining matches are all cup-related competitions. With the likes of the Champions League, Europa League, and the newly created Conference League all having their finals in the next week and a half, the oldest cup competition will also be having its final under the Wembley arches this coming Saturday. Millions across the world tune in to watch the FA Cup each year, making it second only to the World Cup final in terms of global viewership.

History of the most prestigious cup in world football:

The first FA Cup tournament was held in 1871, making it the oldest trophy in world football. The competition was won by Wanderers FC, who are no longer playing at a professional standard but will be remembered as the inaugural winners of the cup. Since then, numerous records have been set, with Arsenal winning the competition 14 times.

The cup is also known for its giant killings. The competition doesn’t just consist of the 92 Football League teams; it allows teams from the lowest of the non-leagues to take a punt at lifting the trophy. Although many will be knocked out, some have gone further than some of the bigger teams. In recent years, we saw Marine A.F.C face Tottenham Hotspur, who at the time were separated by 160 places in the footballing pyramid. Unfortunately, they would bow out after a 5-0 loss, but the exposure and the round they reached help clubs in the lower sections of the footballing pyramid to garner some extra funds that can prove vital for them in the future.

Traditions:

“Traditional” is a word that comes to mind when we think about the FA Cup. The tradition of the FA Cup is deeply rooted in English football history and holds a special place in the hearts of football fans. As we touched on above, the tournament allows clubs from all levels of the English football league system to compete, from the top-tier Premier League teams to non-league teams. Additionally, the tradition of playing at Wembley has never died out, with all teams wanting to reach the final just so they can play there. The final day, also known as “Cup Final Day,” is massive in the UK and is accompanied by pre-match festivities and entertainment.

Traditions aren’t just a part of football; they are a part of everyday life. Anyone can have their own traditions, including companies like us.

At EWFM, our traditions are:

- Providing a quality service and product.

- Ensuring a positive company culture.

A quality service and product can be proven by our consistent 31 successful audits of the ISO 9001-2015 quality standard in a row. The positive company culture can be proven by the smiling faces that walk through the office doors every day.

-

Industry Showcase: Chemicals

16 August 2023May has flown by, and as we reach the end of the month, it’s time to explore another industry that EWFM products are suitable for. In previous editions, we examined key information and statistics on the oil & gas and food & drink industries. In this month’s instalment, we will be focusing on the Chemical industry. This industry is defined as the conversion of raw materials such as oil, metals, and minerals into industrial and consumer products, and it is estimated to be worth around £54 billion in the UK.

About the Chemical Industry:

According to the European Chemical Industry Council, There are around 4,535 chemical companies based in the UK. Unlike other industries where the UK may be limited to what it can do due lack of resources and other factors, the UK is active in all the areas of chemical manufacturing. Based on revenues from 2022, the largest chemical company is Johnson Matthey which are ahead by some distance compared to their competitors.

It is the second largest industry behind the machinery & transport industry. With it being the second largest, research and development would need significant investment which it is the national leader in with around £8 billion pumped into the industry for R&D alone.

In terms of performance, during the COVID pandemic, it was a struggle for companies in the industry as it was for numerous other companies in other industries. However, due to consumers switching from services to goods, the demand increased as chemicals can be found in products that people use in everyday life. Even after getting through the pandemic, the industry has faced more obstacles including high price of energy and raw materials due to ongoing war in Ukraine.

What EWFM can do for Chemical related practices:

Within our extensive product portfolio, we offer five ranges that are specifically designed for the chemical market: Swivel Joints, Couplings, Filling & Emptying Equipment, Breakaway Couplings, and Loading Arms. These products are essential for handling corrosive substances, which pose significant risks to workers.

Our products are designed as fully contained systems, ensuring the prevention of overfilling and the recovery of harmful vapours. The benefits of preventing overfilling are twofold. Firstly, it reduces costs by minimizing waste of raw materials, packaging, and transportation resources. Secondly, it enhances operational efficiency by optimizing production processes and minimizing downtime associated with refilling and recalibration.

Escaping vapours can be hazardous to both companies and their workforce. Our vapour recovery systems safeguard the health and safety of employees by reducing their exposure to harmful substances, thereby minimising the risk of health issues. Moreover, containing corrosive vapours helps preserve the integrity of equipment and infrastructure, preventing costly damage and ensuring longer operational lifetimes.

If you work in the chemical industry and are seeking a product to enhance your company’s production processes, we encourage you to get in touch with EWFM. Our team is readily available to provide you with expertise and tailored solutions for your specific projects.

-

International Museum Day

16 August 2023Are museums your sort of hobby? Well, if they are, today might just be the perfect day for you as it is International Museum Day. Museums are defined by The International Council of Museums (ICOM) as “not-for-profit, permanent institutions in the service of society that research, collect, conserve, interpret, and exhibit tangible and intangible heritage.” Museums play a vital role in today’s society as they shed light on our past history. Sometimes, that history is not always on the right side, but it is valuable as it can educate and ensure that such events never happen again.

About International Museum Day:

International Museum Day is celebrated to highlight the significance of museums in cultures and societies worldwide. It aims to raise awareness about the importance of museums and their impact. This commemorative day was first established in 1977 and has since grown in participation, with over 37,000 museums from approximately 158 countries taking part in the event.

Each year, International Museum Day is themed around a set of goals based on the United Nations Sustainable Development Goals. In 2023, the focus will be on three specific goals: Goal 3, Goal 13, and Goal 15. Here are the definitions of each goal, as provided by the United Nations:

Goal 3: “Ensure healthy lives and promote well-being for all at all ages.”

Goal 13: “Take urgent action to combat climate change and its impacts.”

Goal 15: “Protect, restore, and promote sustainable use of terrestrial ecosystems, sustainably manage forests, combat desertification, and halt and reverse land degradation and halt biodiversity loss.”

Preservation and Longevity:

Museums are renowned for their dedication to preserving artifacts, ensuring their longevity for future generations to enjoy. Similarly, EWFM’s products exhibit a similar commitment to preservation and durability when supplied to our customers. Specifically, our range of Floating Roof Storage Tank Seals boasts an estimated lifespan of up to 20 years.

These tank seals are specifically designed to seal the tops of storage tank roofs. With 11 different types available, including primary and secondary seals for both external and internal tank roofs, they play a critical role in minimizing vapor emissions, ensuring safety, and preserving the quality of stored products.

If you would like to participate in International Museum Day, please click on the link below. It will lead you to a world map indicating the location of participating museums nearest to you.

https://livemap.getwemap.com/embed.html?emmid=19458#/search@18.1458542,-0.1048336,2.00

However, if a museum near you isn’t listed on the map, don’t let that deter you from visiting one. Museums offer a wealth of knowledge and can educate you on various topics, including those mentioned above and more.

To learn more about our products and how we can support you, please reach out to our sales team. They will be delighted to assist you with any questions or inquiries you may have.

-

Industry Showcase: Food and Drink

16 August 2023“It’s time for the next instalment of the “Industry Showcase”. In this series, we are taking a look into the industries that EWFM caters for and providing products that are a suitable match for the industry. We will explore the facts and figures behind the industries and their trends and in this instalment we will be focusing on the food and drink industry.

About the food and drink industry:

The food and drink industry is the biggest manufacturing sector in the UK by turnover, valued at £104.4 billion. The UK is considered the hub and forefront of innovation in this industry, with countries across the globe looking to Britain to identify new opportunities. However, due to constant changes in consumer habits and diets, innovation is always necessary in this industry to keep up with the trends and prevent products or services from becoming outdated.

Statistics show that the food and drink industry experienced a massive slump in revenue between 2020 and 2021 due to the COVID-19 pandemic. While there was a resurgence in 2022, it was not enough to equal pre-pandemic levels.

As I touched on above, trends in this industry are always changing. The current trends in the industry are sustainable and functional food & drinks. Despite growing costs due to inflation, consumers are willing to fork out more money to feed their habits. In 2022, consumers spent a total of £105.8 billion on food and drink, which was a 20% increase compared to 2021.

What EWFM do for the industry:

At EWFM, we have been supplying products to Yeo Valley, Timothy Taylors, and Tetra Pak, all of whom have processes involving the production of food and drink. We know that during the food production process, hygiene and cleanliness are vital, which is why our range of swivel joints, loading arms, and filling & emptying equipment can be made food grade ready with FDA approved materials and seals.

In the drinks industry, our engineered delivery nozzles and drum filling heads are a particular hit with breweries as they can be used to fill and empty casks, barrels, and IBCs. Both products can come with an overfill sensor option, which allows workers to walk away and focus on other tasks without having to worry about watching the container until it’s filled to the brim.

If you work in the food and drink industry and are looking for a product to enhance your company’s product process, get in contact with EWFM. We are on hand to provide you with expertise and solutions for your projects.

-

Case Study: Oil Direct

16 August 2023After visiting the EWFM stand at the UKIFDA Show in Liverpool in April 2022, Gavin from Oil Direct (NI) Ltd approached us for a Bottom Loading Arm to support the filling of the new tankers at his site in Northern Ireland. Having previously top loaded, bottom loading was a new challenge for Gavin.

Following on from the conversations that had taken place at the UKIFDA show, a few further telephone discussions took place with Gavin’s main priority to be the safe and fast loading of tankers in the most cost effective way. It was agreed that the Model 750 Bottom Loading Arm (our most popular Loading Arm) was the perfect solution for Gavin’s requirement.

An example of the arm had been on our stand at the UKIFDA show and had allowed Gavin a chance to see it first-hand.

Key features of the Model 750 Bottom Loading Arm which made it the obvious solution include:

- Use of a flexible composite hose instead of a rigid drop tube which provides greater flexibility for filling at different locations and different sized tankers. It also allows for arms to cross over each other meaning multiple fluids can be filled from the same station to different connection points.

- Swivel joints to allow easy manoeuvrability for the operator.

- Balancing by a gas spring cylinder instead of a counterweight system.

As you can see from the image below, it has fitted in perfectly for Gavin’s current setup. The separate smaller Standpost, provided to lock the arm in place when it is not in use, was a great addition and ensures the arm does not get damaged by being blown around in the adverse conditions that can be experienced here in the UK.

In late 2022 the arm was delivered, and Gavin has been delighted with how the Arm has worked since it has been installed,

“Really happy with the Loading Arm and so easy to use”

We are also currently discussing another arm for an additional site Gavin has, and we are looking to meet up next month in Northern Ireland to discuss this further.

Do you also load or unload road tankers? If so get in touch today and see how our great range of loading arms can support your business. Site visits are always available to discuss requirements in more detail.

-

How to... maintain a Model 2175 Swivel Joint

16 August 2023It’s time for the next edition of “How to…” series. In this series, we will be looking at how you can maintain EWFM products to ensure a longer life. In this first blog of the series, we looked at how you can maintain a Model 2174 Swivel Joint. This month, we will be discussing how you can preserve a Model 2715 Swivel Joint.

We advise all our customers to check our range of Swivel Joints every six months to ensure there is no leakage and their manoeuvrability is consistent and uniform during the rotation process. When you are surveying a Swivel Joint, it is important that there is no product within the joint.

Disassembling the Model 2175 Swivel Joint:

- Unscrew the ball plugs and the grease nipple of the female part of the Swivel.

- Block the Swivel Joint so that the holes of the ball bearing are facing downwards.

- Gradually start to turn the male of the Swivel to allow all of the balls to exit the holes. Introduce compressed air through the grease nipple hole. Alternatively, a common solvent for grease such as kerosene can be inserted into the ball raceways holes. (Only start Step 4 if Step 3 has been completed).

- Extract the male part of the Swivel Joint.

- Remove the seal in the female part and the 2 O-rings found in the male part of the Swivel.

- Clean both parts of the Swivel of any residual grease.

- Check the integrity of both parts of the Swivel Joint. If there is excessive corrosion, it is advised that you get in contact with the manufacturer as that process requires special attention.

Reassembling the Model 2175 Swivel Joint:

- Block the female part of the Swivel so that the holes of the ball bearing raceways are turned upwards.

- Insert the primary seal into the female part so that it leans on the bottom. Lubricate the seal with only a little quantity of specific grease.

- Using a brush and specific grease, grease the inside of the female part of the Swivel.

- Take the male part of the swivel and insert the 2 O-rings into the correct position. Then, using a brush again, apply the grease to the outside of the male part. (Ensure that during assembly, the numbers indicated on the sides of each part match as this can reduce working life and manoeuvrability).

- Now, you can take the male part and insert it into the female part of the Swivel.

- Once inserted, you can start to introduce the ball bearings back into the first raceway by turning the male part. The ball bearings must be inserted one at a time and continuously, in order to avoid extra space between them.

- In case all of the ball bearings are not inserted but there is no space left in the raceway, introduce a brass bar into the hole and at the same time turn the male part of the swivel, which will compact the ball bearings together.

Warning – Ensure no damage is caused to the sealing surface of the male part of the Swivel during the maintenance stages.

If you have any questions about the above or would like to order your own replacement seal kit, then please get in contact, and we will be more than happy to assist you.

-

Is AI the future of the Oil and Gas industry?

16 August 2023As many of you know, a new AI chatbot called ChatGPT is taking the world by storm. This website allows individuals to ask a question and receive a response from the chatbot, which may be better than what an average human could produce. Many people are concerned that this could be the future for various roles in different industries. The education sector, in particular, is worried because this could enable students to submit high-quality work without putting in the effort and also avoid detection that the work was produced by AI.

ChatGPT is a Microsoft-backed platform, which has led numerous other companies to try and imitate it. From recent news, it appears that companies such as Google have tried but have not achieved the same level of intelligence as ChatGPT at this time. Microsoft is looking to integrate ChatGPT into its search engine platforms and its office platform to enhance users' experience. But how does this all work?

How does ChatGPT work?

ChatGPT is a language model created to have conversations with individuals. Some have asked how it differs from a standard search engine, but there is a significant difference. Search engines gather information by indexing websites on the internet that will best answer the question you have input into their system. In contrast, ChatGPT does not have the ability to search the internet. Instead, it has been trained to answer questions using data it was fed in its early stages.

Ways that AI could change the Oil and Gas industry:

How could AI change the oil and gas industry? The following will look at four ways in which AI could do so:

- Increased efficiency: AI can analyse large amounts of data and provide valuable insights and solutions to questions in a timely manner. Its ability to reply with an answer quickly can increase overall efficiency and reduce possible downtime.

- Cost savings: Inputting data to an AI system and having it draw out answers could eliminate the need for certain individuals in your workforce. Additionally, if efficiency is enhanced, which will cut downtime, it will ultimately lead to cost savings due to systems being constantly in use.

- Predictive maintenance: Maintenance is a common theme in industries such as oil and gas. Due to wear and tear, pipelines and systems will constantly need looking at to ensure the processes move smoothly. Companies in the oil and gas industry could feed information about their systems in operation to the AI, which could monitor them and flag up when certain aspects need maintenance or repairs. Although companies will have maintenance teams on hand, sometimes things could be missed. With the introduction of an AI system that is constantly monitoring the systems, repairs and maintenance will always be spotted and can be sorted out in due course.

- Improved safety: Finally, the AI system could improve overall safety for companies in the oil and gas industry by identifying potential safety hazards that may have been missed. Safety is paramount as individuals will be working with hazardous substances from varying heights and situations. The AI system can pinpoint different safety aspects to ensure that all bases are covered, preventing employees from getting injured and providing them with a safe working environment.

AI can and will certainly help and enhance businesses in the oil and gas industry. Although we are a long way off AI taking over the world, big steps are currently being made that will certainly disrupt certain sectors now and in the future.

-

StocExpo 2023 Review

16 August 2023Now that the dust has settled on StocExpo 2023, EWFM have decided to review our time at the Rotterdam Ahoy.

About StocExpo

StocExpo is one of the largest international events in the oil and gas industry. It bought together industry professionals, experts, and stakeholders to showcase the latest innovations, products, and services in the field of Tank Storage and bulk liquid logistics. It took place from the 14th – 16th of March at the Rotterdam Ahoy in the Netherlands. The event attracted thousands of attendees from around the world and featured a range of activities, including an exhibition, conferences, workshops, and networking events.

The exhibition showcased products and services from over 200 international suppliers, covering everything from tank design and construction to safety equipment and environmental solutions. The conference featured over 40 expert speakers, who shared insights on industry trends, challenges, and solutions.

So how did EWFM Find it?

StocExpo 2023 was the companies first exhibition overseas since the Covid Pandemic. All in all, we were extremely impressed, and the show was a great success. We could not believe the worldwide audience the show attracted. Not only from Europe but we had new leads from Brazil, the Middle East to South Africa and many more. There was a steady footfall throughout the 3 days, and we walked away extremely satisfied.

The show also gave us great opportunity to see many existing customers under one roof. So, a big shout to those who travelled to visit us.

Below you can see some action shots. Our stand was a great success, we really tried to push all we do for the tank storage industry and had many products to play with. StocExpo ranked us in the top 30% of leads gathered, which we were very proud.

We will be sure to exhibit next year, but bigger and better!

-

Oscar Worthy EWFM Products

16 August 2023The most prestigious award show in the history of film returns on Sunday evening. The upcoming Oscars will be the 95th edition of the awards. During the night, 24 awards will be handed out to various actors, actresses, and directors for films that have been released over the past year. In this week’s blog, we are going to look at the biggest award show and then see which EWFM products would be Oscar nomination worthy!

About the Oscars:

Also known as the Academy Awards, the Oscars first show was on May 16, 1929. The top categories of the awards show include Best Actor or Actress in a Leading Role, Best Actor or Actress in a Supporting Role, Best Picture, Best Director, Best Costume Design, and many more. Usually the shows are smooth sailing, which is a surprise since they are all there for their dramatic performances, but last year saw some controversy when Will Smith hit Chris Rock after he included his wife in a joke.

Walt Disney leads the pack in terms of overall awards at the shows, with 26 Oscars for 22 of his films and four honorary awards. Katharine Hepburn has won four awards, which makes her the actress with the most Oscars, as for the male actors, three have won three Oscars: Jack Nicholson, Daniel Day-Lewis, and Walter Brennan. During the event, films can be nominated for more than one award, and three films are tied for the most Oscars in a night. They are Ben-Hur, Titanic, and The Lord of the Rings: The Return of the King.

Oscar Worth EWFM Products:

Enough about those Oscars, we all know you are here for the EWFM Oscars. So, without further ado, the winner for:

Product in a leading role is... Floating Suction Units: The standout performer in storage tanks and reservoirs, the floating suction unit is designed to draw the purest fuel or water from roughly 500mm below the fluid’s surface.

Product in a supporting role is... Access Systems: Always looking to support your employees safety, our range of Access Systems protects employees when working from heights. More recently we have added products to our range for lifting and moving heavy boxes or objects.

Best Costume Design is... Painted Swivel Joints: Not usually one to get all dressed up, but when they do, they look fantastic. With our range of swivel joints, we can paint to client specifications. In the past, we have had swivels painted in Hammerite blue and Bergesen green to meet shipbuilding specifications.

If you think any of our products deserve any other awards, let us know on our social media platforms. However, if one of our products from today's blog is of interest to you, get in touch. Our sales team will be more than happy to provide you with their advice and expertise on any existing or upcoming projects.

-

Industry Showcase: Oil & Gas

16 August 2023Welcome to a new monthly blog called the “Industry Showcase”. In this series we will be looking at the industries EWFM work in and what we, as a company, can supply to them. Within the showcase we will dig deep into the facts and figures behind the industries and then move onto the individual EWFM products suitable for that industry. To start off the showcase, we will be looking at the Oil and Gas Industry.

About the Oil and Gas Industry:

Oil has been in use for over 5,000 years. The oils that we use such as LPG, kerosene, jet fuel and car oils are all made from crude oil. It is said that crude oil is created using organic materials from animals and plants. During their periods of life, their bodies absorb carbon molecules, which after they die, become buried in the ground, and then turn into kerogen. The process of catagenesis will turn kerogen into hydrocarbons before eventually becoming crude oil. The world’s largest oil field can be found in Saudi Arabia which produces up to 5 billion oil barrels each day.

The oil will then be extracted from the ground and sent to oil refineries which will convert it into various oil products. It is estimated worldwide that there is around 700 refineries in operation. Once the oils have been created, they will then be shipped to storage terminals where the oil will sit until it is needed to be distributed.

Out of all the companies in the world, the USA consumes the most with around 19 million barrels each day, while the UK uses around 1.5 million. According to IBIS World, the global oil and gas industry will be worth around $4.3 trillion.

What EWFM do for the Industry:

As you can imagine from the facts and figures above, the oil and gas industry is worth a lot of money, and to generate the high quality of oil, high quality products are needed for the product process. That’s where EWFM come in. Ultimately, apart from our Aviation product range, all our other products can be used in some way in the oil and gas industry.

- Swivel Joints

- Loading & Unloading Arms

- Floating Suction Units

- Tank Seals

- Couplings

- Breakaway Couplings

- Access Systems

- Filling & Emptying Equipment

For more information on the products above, head over to their respective pages on our website. If you work in the oil and gas industry and believe any of our products could be of use, then please get in contact. Our sales team are highly trained to give you their expertise’s and solutions on your projects.

-

Valentine’s Day

16 August 2023Happy belated Valentine’s Day everyone. We hope your day was filled with Flowers and lots of chocolate! But do you know the origins of the most loving day of the year? Originally, it was a Christian feast day honouring a martyr called Valentine. A martyr is someone who has died due to their belief and faith in Jesus. Saint Valentine was a priest in the roman empire who ministered persecuted Christians. There are also many other stories that are associated with Saint Valentine with more recent ones having the theme of love.

The first Valentine’s Day celebration occurred in Paris in 1400 and has now become a commercialised day with sales of flowers and chocolates sky rocketing. According to a video by Homeschool Prep, over one billion Valentine’s cards are sent worldwide. Another activity associated with Valentine’s is the writing of poems. We thought we would keep you in the loving mood by writing a EWFM Valentine’s poem:

EWFM’s Valentine’s Poem:

“Roses are red,

Swivel Joints can be Hammerite Blue,

EWFM have the fluid transfer solution for you”.

What product do the EWFM team love the most:

Guy Curtis (General Manager): “ My favourite products that EWFM sell are Floating Suction Units. I love them due to there sheer size, having supplied units up to a 40” bore, big enough to walk through”.

Mike Phillips (Business Development Manager): “Loading & Unloading Arms are my favourite products because of the variation of designs and different applications they can be used in”.

Ben Adamson (Marketing Executive): “The products I love the most is our range of Swivel Joints. We have large selection of these, and our customers are always ordering different variations. This allows me to take unique pictures each time to post on the company’s social media platforms”.

Anne Jones (Marketing Assistant): “My favourite product is the Breakaway Coupling. The reasons why is because it keeps workers safe when dealing with hazardous substances.”

If you love our products, leave us a message, and tell us why? And if you love them that much, get in contact with our sales team who will be able to assist you in any enquiries or questions you may have.

-

How to… maintain your Model 2174 Swivel Joint

16 August 2023Welcome to a new series called "How to..." In this series, we will look at various products and how you can maintain them to give them a longer life. To start off, we will look at the Model 2174.

We advise that you check our Swivel Joints every six months to ensure that they are not leaking and that their manoeuvrability is consistent and uniform during the rotation process. To carry out maintenance, the swivel should not be in service, which ultimately means that there shouldn’t be any product in the joint.

Step 1 – Disassembling your Model 2174 Swivel Joint:

- Unscrew the ball plugs and the grease nipple on the female part.

- Block the swivel joint so that the holes of the ball bearing raceways are turned towards the floor.

- Gradually start to turn the male part of the Swivel Joint to allow all the ball to come out of the holes. To make this operation easier, it is advisable that you introduce compressed air through the grease nipple hole or alternatively, common solvent for grease such as kerosene directly into the balls raceway holes. (You can only move onto Step 4 if Step 3 is completely finished)

- Extract the male part of the Swivel.

- Start to remove the three “V” ring seals from the female part. Then remove the female adapter and the O-ring from the male part.

- Completely clean both male and female parts of any residual grease.

- Check that the integrity of both parts are still intact such as corrosion. If corrosion has occurred then refer to the manufacturer as this will require special attention.

Step 2 – Re-assembling your Model 2174 Swivel Joint:

- Block the female part of the swivel so that the holes of the ball bearing raceways are turned upwards.

- Using a brush and the specific grease, grease the inside of the female part of the Swivel Joint.

- Proceed to assembling the seals. Insert the spring (if supplied) onto the spring adapters and then insert it into the female part. The spring should lean on the bottom of the female part.

- Next, insert the three “V” ring seals one at a time which have been lubricated each with a little of the grease. After that, insert the female adapter.

- Take the male part which matches the same number on the female part and insert the greased O-Ring in its proper position.

- Using a brush and the specific grease provided, grease the outside of the male part.

- Then insert the male part into the female part while making sure you centre the seals system. Applying a little bit of pressure will be necessary to insert it. Ensure the relative alignment of the ball bearing raceways.

- Continue to push and turn the male part, then start to insert the ball bearings into the first raceway. They must be inserted continuously one by one to avoid extra space between each of them

- In case you have ball bearings left but there is no space left in the raceway, introduce a brass bar into the hole and at the same time turn the male part of the Swivel to compact the balls. Once completed screw the relative ball plug back in. Repeat this procedure for the second raceway and then screw the grease nipple in the relevant hole.

If you have any questions about the above or would like to order your own replacement seal kit then please get in contact and we will be more than happy to assist you.