SERPRO Ltd

At SERPRO, absorbents are essential to keeping workplaces clean and safe. Our products are equipped to handle all type of liquid spills from water to oil, hazmat and chemical spills. Our absorbents come in a variety of weights and sizes such as pads, mats, socks and booms.

We also stock specialised absorbents for chemical spills, loose adsorbents, security tags and more.

-

4 Fun Things to do with a Drip Tray

1 September 2023here are four fun and creative things you can do with a plastic drip tray:

- Mini Zen Garden: Turn the drip tray into a miniature Zen garden by filling it with sand or fine gravel. Add small decorative rocks, pebbles, and even tiny succulent plants. You can use a rake to create patterns in the sand, providing a soothing and calming activity.

- Artistic Resin Tray: If you enjoy crafting, consider turning the drip tray into a unique resin art piece. Mix and pour colored resin into the tray to create a beautiful, glossy surface. You can embed various items like dried flowers, small shells, or even glitter to add visual interest.

- Indoor Plant Tray: Transform the plastic drip tray into a base for an indoor plant arrangement. Fill it with a layer of decorative stones or pebbles, place potted plants on top, and then surround the pots with more stones. This can serve as a stylish way to display and care for your indoor plants.

- Sensory Play Station for Kids: If you have kids, the plastic drip tray can become a sensory play station. Fill it with various sensory materials like colored rice, kinetic sand, water beads, or even finger paints. Kids can explore textures, colors, and engage in imaginative play.

Remember, these ideas are just starting points – feel free to get creative and adapt them to your preferences and available materials. Always consider safety and cleanliness, especially when working with materials that could potentially get messy or require supervision, such as resin or small items for kids' play.

-

Preventing Spills in the Workplace

3 April 2023Liquid spills are a common hazard in the workplace, and they can pose a significant risk to both employees and visitors. Slip and fall accidents resulting from liquid spills can lead to serious injuries, which can be costly for both the individuals affected and the business. Fortunately, there are several steps that employers can take to prevent liquid spills in the workplace. Here we will discuss some of these preventive measures.

The first step in preventing liquid spills in the workplace is to identify the areas where spills are most likely to occur. This may include areas where liquids are frequently used, such as kitchen or bathroom facilities, laboratories, or manufacturing areas. Once these areas are identified, it is important to develop a plan to minimize the risk of spills. This plan should include procedures for handling liquids, as well as policies for cleaning up spills promptly.

One effective way to prevent liquid spills is to use spill containment products. These products are designed to contain spills and prevent them from spreading. Spill containment products may include spill berms, spill pallets, and spill kits. These products can be placed in areas where spills are most likely to occur and can be used to quickly contain and clean up spills.

Another effective way to prevent liquid spills is to provide employees with proper training on handling liquids. This may include training on how to properly use and store liquids, as well as training on how to respond in the event of a spill. Employees should be trained on the importance of promptly reporting spills so that they can be addressed before they become a hazard.

Regular maintenance and inspection of equipment and facilities can also help to prevent liquid spills. Leaking pipes or containers can be a significant source of spills, so it is important to inspect these regularly and repair any leaks as soon as they are identified. In addition, equipment should be properly maintained to ensure that it is in good working order and not likely to cause spills.

Finally, it is important to establish clear policies and procedures for cleaning up spills. This should include the use of appropriate cleaning materials and equipment, as well as guidelines for disposing of any contaminated materials. Employees should be trained on these procedures and should be encouraged to report spills promptly so that they can be cleaned up quickly and safely.

In conclusion, preventing liquid spills in the workplace requires a proactive approach. Employers should identify areas where spills are most likely to occur, develop a plan to minimize the risk of spills, provide employees with proper training, regularly maintain and inspect equipment and facilities, and establish clear policies and procedures for cleaning up spills. By taking these steps, employers can help to ensure the safety of their employees and visitors and reduce the risk of costly slip and fall accidents.

-

Using Oil Absorbing Spill Kits in Marinas

3 April 2023Marinas are important facilities for boaters and watercraft enthusiasts. They offer a safe haven for boats, provide fueling stations, and often have shops and restaurants nearby. However, marinas are also vulnerable to oil spills, which can have serious consequences for the environment, wildlife, and the local economy. That is why it is essential for marinas to have effective oil absorbing spill kits on hand to deal with such incidents.

An oil spill can occur in a marina for various reasons, including human error, equipment failure, and natural disasters. Regardless of the cause, it is crucial to act quickly and efficiently to minimize the damage. An oil spill can have immediate and long-term consequences for the environment. It can harm marine life, birds, and other wildlife by suffocating them, blocking their breathing passages, and damaging their reproductive systems. Additionally, oil spills can damage boats, docks, and other infrastructure, leading to significant economic losses.

Oil absorbing spill kits are an essential tool for marinas to respond to oil spills promptly. They typically contain sorbent materials such as pads, booms, and pillows that absorb the oil and contain the spill. These materials are specially designed to attract and hold oil while repelling water. As a result, they are highly effective at soaking up oil spills and preventing them from spreading further.

When using oil absorbing spill kits in marinas, it is essential to follow proper procedures to ensure that the spill is contained safely and efficiently. First, the spill must be identified and reported to the appropriate authorities immediately. Then, the area must be cordoned off to prevent people from accidentally entering the contaminated area. The spill kit should be deployed promptly, and the sorbent materials should be used to soak up the oil. Once the spill is contained, the sorbent materials must be disposed of properly to prevent further contamination.

The use of oil absorbing spill kits in marinas has several advantages. First, they are easy to use and can be deployed quickly, allowing for a rapid response to a spill. Second, they are cost-effective compared to other cleanup methods, such as vacuum trucks or skimmers. Third, they are environmentally friendly because they do not use chemicals that can harm marine life or the environment. Fourth, they can be used on both land and water, making them versatile and adaptable to different spill scenarios.

In conclusion, marinas are vulnerable to oil spills, which can have serious consequences for the environment and the local economy. Therefore, it is essential for marinas to have effective oil absorbing spill kits on hand to respond promptly to spills. These kits are cost-effective, easy to use, and environmentally friendly, making them an ideal tool for responding to spills in marinas. By following proper procedures and using these spill kits, marinas can minimize the damage caused by oil spills and protect the environment and wildlife.

-

How melt blown polypropylene works as a super absorbent

2 March 2023Melt blown polypropylene (MBPP) is a type of nonwoven material that is used in a variety of applications, including as a super absorbent material. MBPP is made by melting and extruding polypropylene resin into fine fibers, which are then blown by hot air to create a porous, nonwoven material.

The structure of MBPP allows it to absorb liquids and other materials quickly and effectively. The fine fibers create a large surface area, which increases the material's capacity to absorb fluids. The pores in the material also help to trap and hold liquids, preventing them from leaking or spilling.

MBPP can be treated with various chemicals or coatings to enhance its absorbent properties. For example, it can be treated with surfactants to increase its wettability and improve its ability to absorb nonpolar liquids, such as oils and greases. It can also be treated with antimicrobial agents to prevent the growth of bacteria and other microorganisms.

MBPP is used in a wide range of absorbent products, including diapers, feminine hygiene products, medical dressings, and spill cleanup materials. It is preferred for these applications because it is lightweight, highly absorbent, and has good fluid distribution properties. Additionally, MBPP is generally low cost, making it an attractive option for manufacturers looking to produce absorbent products at scale.

-

Keeping Workshops Clean and Safe

2 March 2023Workshops are an integral part of many industries where various types of work are carried out. These workshops often involve the use of different types of chemicals, oils, and other substances that can create hazardous and unsafe working conditions for employees. To ensure that these workshops remain clean and safe, the use of absorbents has become a popular solution.

Absorbents are materials that are used to absorb and contain liquids, such as oils and chemicals, to prevent them from spreading and causing damage. There are different types of absorbents, including natural and synthetic materials, such as clay, sand, and polypropylene. The use of absorbents in workshops has many benefits, including reducing the risk of slips, falls, and injuries, as well as preventing environmental damage and pollution.

One of the most significant benefits of using absorbents in workshops is that they can help prevent slips and falls. When liquids are spilled on the floor, they create a slippery surface that can be hazardous for employees, increasing the risk of accidents and injuries. Absorbents can quickly and effectively absorb these liquids, creating a dry surface that is safer to work on.

Additionally, absorbents can help prevent environmental damage and pollution by containing spilled liquids. When chemicals and oils are spilled on the floor, they can seep into the soil and groundwater, causing contamination and harm to the environment. Absorbents can prevent this from happening by quickly containing the spill and preventing it from spreading.

Furthermore, the use of absorbents in workshops can help create a more efficient and organized working environment. Absorbents can be used to create designated spill areas, preventing spills from occurring in other areas of the workshop. This can help employees quickly locate the appropriate materials to clean up a spill, saving time and increasing productivity.

It is important to note that not all absorbents are suitable for all types of liquids. For example, some absorbents may not be effective in absorbing certain types of chemicals. It is essential to choose the appropriate absorbent for the specific type of liquid being used in the workshop.

In conclusion, the use of absorbents in workshops can have significant benefits, including increased safety for employees, prevention of environmental damage, and increased efficiency. When selecting an absorbent, it is important to choose the appropriate material for the specific type of liquid being used to ensure maximum effectiveness. By implementing a clean and safe workshop environment, companies can promote the health and safety of their employees, as well as prevent environmental harm and increase overall productivity.

-

The purpose of ISO 14001 environmental management systems (EMS)

2 March 2023ISO 14001 is an international standard for environmental management systems (EMS). It provides a framework for organizations to manage their environmental responsibilities in a systematic and efficient manner. The standard specifies the requirements for an EMS, including the development of environmental policies and objectives, the identification and control of environmental aspects, the implementation of programs to manage these aspects, and the monitoring and reporting of environmental performance.

The purpose of ISO 14001 is to help organizations minimize their negative impact on the environment and comply with applicable environmental regulations and laws. It also helps organizations improve their overall environmental performance and reduce their costs by reducing waste and increasing energy efficiency.

Organizations can become certified to ISO 14001 by undergoing a third-party certification process. This involves an independent assessment of the organization's EMS by a certified auditor, who verifies that the organization is in compliance with the requirements of the standard. Once certified, organizations must continually improve their EMS and undergo regular audits to maintain their certification.

ISO 14001 is widely recognized and is used by organizations of all sizes and sectors, including manufacturers, service providers, public sector organizations, and non-profit organizations.

-

Using Oil Absorbent Pads

3 January 2023Oil absorbent pads, also known as oil absorbent mats, are designed to absorb oil, gasoline, and other hydrocarbons from water, soil, and other surfaces. They are commonly used in a variety of settings, including industrial facilities, marinas, oil spills, and automotive repair shops.

Oil absorbent pads are made from a variety of materials, including polypropylene, polyethylene, and other synthetic fibers. These materials are highly absorbent and can hold several times their weight in oil or other hydrocarbons. The pads are typically flat and rectangular, with a sponge-like consistency that allows them to easily conform to the contours of a surface.

Oil absorbent pads are used in a variety of ways, including:

- Spill cleanup: Oil absorbent pads are often used to contain and clean up oil spills in industrial facilities, marinas, and other locations. They are placed around the spill to absorb the oil and prevent it from spreading.

- Automotive repair: Oil absorbent pads are used in automotive repair shops to clean up oil and other fluids that may leak from vehicles.

- Environmental protection: Oil absorbent pads are used to protect the environment from oil spills and other hydrocarbon contamination. They are often used in conjunction with other spill containment and cleanup equipment, such as booms and skimmers.

- Industrial applications: Oil absorbent pads are used in a variety of industrial settings to absorb oil and other fluids that may be present in the work environment.

Overall, oil absorbent pads are an important tool for preventing and cleaning up oil spills and other hydrocarbon contamination, protecting the environment and ensuring the safety of workers and the public.

-

Storage of Hazardous Chemicals

3 January 2023All substances that are classified as a physical or health hazard must be stored in a designated area.

The storage area should be made of noncombustible material, and it should have a fire-resistant door.

Hazardous substances must not be stored in areas where they can come into contact with food, drink, or tobacco products.

—

The main goal of storing hazardous substances is to keep them away from humans and the environment.

When storing hazardous substances, it's important that they are stored in a way that prevents them from being released into the environment. Containers should be kept closed, labeled and in a dry place away from any sources of heat or cold.

In general, storage containers should be made of materials that are not easily penetrated by chemicals and can withstand the pressures created by the substance (e.g., strong plastic).

—

There are various ways to store hazardous substances. One of the most popular solutions is to use a drum. This container is usually made from steel, aluminum, or fiberglass. It has a lid and an opening for pouring substances in and out. Another solution is to use a tank. Tanks come in various sizes and shapes, which makes them suitable for storing different kinds of liquids and solids. They are often used for storing water, gasoline, oil, or other liquids with low viscosity that can be stored at room temperature without any change in their properties.

We should always make sure that we store hazardous substances properly so they don't cause any harm to people or the environment around us.

—

There are a number of ways to store hazardous substances. One way is by storing them in containers that are specifically designed for hazardous substances. Another way is storing them in a place where they will not be easily accessible to people who do not have the appropriate training and equipment.

The best way to store hazardous substances is by using the right type of container which is specifically designed for that purpose. This will ensure that the substance will remain secure and safe from any accidental exposure or spillage.

—

Hazardous substances are substances that have the potential to cause injury or illness if mishandled. They can be found in a variety of industries and it is important to take the necessary precautions for handling and storing them.

The best way to store hazardous substances is in a container that has been specifically designed for hazardous materials. These containers should be made of material that will not react with, or release harmful chemicals when exposed to, the stored substance. Containers should be closed tightly and labeled with an appropriate warning label, such as “Danger - Corrosive” or “Caution - Flammable”.

—

Hazardous substances are substances that are typically toxic, corrosive, or flammable and can pose a risk to the environment or human health. These substances can be found in industrial settings like factories, laboratories, and chemical plants. Hazardous substances also include those that are used in the home for cleaning purposes like bleach.

The storage of hazardous substances is regulated by different organizations depending on the type of hazardous substance. For example, the Environmental Protection Agency regulates storage of chemicals while OSHA regulates storage of combustible materials.

There are many ways to store hazardous materials safely and securely. The first step is to identify what hazards exist for each substance you have at your workplace or home so you can create a plan for how to store it accordingly.

-

Spill Kit Contents. What should be in a Spill Kit?

3 October 2022For most people, the word “spill” conjures up images of clumsiness, messes, and accidents. But in the world of industry, spills are a serious issue that can have devastating consequences. That’s why it’s so important to have a spill kit on hand at all times.

A spill kit is a collection of Absorbents and other products that are used to clean up spills. They are designed for a variety of different types of spills, including oil, fuel, diesel, and chemicals.

The importance of having spill kits as part of your spill response plan cannot be understated..

Not sure what to include in your spill kit? This article has everything you need to know about spill kits.

What is a Spill Kit?

A spill kit is a collection of products that are used to clean up spills. Absorbents are the most important part of a spill kit, as they are used to absorb the spill and prevent it from spreading. Other items in a spill kit may include gloves, goggles, aprons, and disposal bags. Spill kits are an essential part of any spill response plan.

There are many different types of spill kits available on the market, and each one is designed for a specific type of spill. Oil spill kits, for example, are designed to absorb oil and prevent it from spreading. Fuel spill kits are designed to do the same for fuel, diesel, and other flammable liquids. Chemical spill kits are designed to absorb and neutralize corrosive or hazardous chemicals.

What should be in a Spill Kit?

The spill kit contents will vary depending on the type of spill it is designed for. However, there are some common items that should be included in every spill kit. These items include:

- Absorbents: Absorbents are the most important part of a spill kit, as they are used to soak up the spill and prevent it from spreading. There are many different types of absorbents available, including pads, booms, socks, and granules. Choosing the right absorbent will depend on the type of spill you are dealing with.

- gloves: Gloves protect your hands from harmful chemicals and other contaminants that may be present in the spill.

- Goggles: Goggles protect your eyes from splashes and airborne contaminants.

- Aprons: Aprons protect your clothing from spills and stains.

- Disposable bags: Disposable bags are used to store contaminated materials until they can be disposed of properly.

When to use a Spill Kit?

Spill kits should be used whenever there is a chance of a spill occurring. This could be during the transfer of liquids between containers, when using dangerous chemicals, or when working with flammable liquids such as fuel or diesel. Spill kits should also be kept in areas where spills are likely to occur, such as in workshops, garages, and laboratories.

How to use a Spill Kit?

Using a spill kit is fairly straightforward. The first step is to identify the type of spill you are dealing with and choose the appropriate absorbent material. Once you have done this, you can begin absorbing the spill using the absorbent pads or other materials. Once the majority of the spill has been absorbed, you can begin cleaning up any remaining residue with soap and water.

Spill Kits and the environment

Spill kits play an important role in protecting the environment from potential harm. By quickly absorbing spills and preventing them from spreading, spill kits help to minimize the impact that accidents can have on sensitive ecosystems. In some cases, using a spill kit may even help you to avoid hefty fines for environmental damage.

To wrap things up

Spill kits are an essential part of any workplace safety plan. By having a spill kit on hand, you can quickly respond to accidents and minimize the risk of harm to people and the environment.

-

Using Absorbent Pads and Wipes

1 September 2022When handling or storing flammable liquids in bulk, there is a very real risk of fire or explosion. The consequences of a fire or explosion are often catastrophic, so companies need to have measures in place to prevent such an incident from happening. The primary way to prevent fires is through the use of effective industrial storage solutions. However, if you can’t fully eliminate the risk of a fire starting, you can control it by using the right equipment and processes. The most reliable way to do so is by using oil and fuel absorbing pads and wipes as well as other oil-absorbing materials that are designed specifically for this purpose. Read on to discover more about oil-absorbing materials and how they can help you improve your safety protocols in an industrial setting.

What are oil absorbing pads and wipes?

Oil absorbing pads and wipes are a type of non-woven material that is designed to absorb and trap oil-based liquids. These pads can be made from a variety of different materials, including paper, polypropylene, synthetic fibers, and more. Why do businesses and industrial facilities use oil absorbing pads and wipes? The main reason to use them is to prevent the spread of oil. If there are spills, these pads and wipes will be able to catch and collect them, greatly reducing the risk of that liquid spreading further. This will help to prevent any fires or explosions arising from the flammable properties of oil. If someone is working with flammable liquids, they can use oil absorbing pads or wipes to protect their skin. If a person comes into direct contact with a flammable liquid, it can cause chemical burns. These pads and wipes will prevent this from happening.

Why is it important to use oil absorbing material?

In order to prevent fires, explosions and other dangerous consequences of flammable liquids coming into contact with other substances, it is important to use oil absorbing materials. First of all, these pads and wipes can catch and trap oil from spills, reducing the risk of it spreading further. They can also absorb oil from the hands of nearby workers. This is particularly useful for when you’re working with machines and equipment where you’ll be in contact with flammable liquids. If you use oil absorbing materials, you can reduce the amount of oil that comes into contact with other substances. This can greatly reduce the risk of those substances catching fire or causing an explosion.

The benefits of using oil absorbing materials

Reduced risk of fires and explosions - As we’ve already discussed, the main reason to use oil absorbing materials is to prevent fires and explosions from occurring. - Reduced risk of injuries and accidents - When a person comes into direct contact with a flammable liquid, it can cause chemical burns. - Better, safer working conditions - When you use oil absorbing materials, you’re preventing the risk of fires, explosions, and the spread of flammable liquids. This will help you to create better, safer working conditions and reduce the chance of injuries.

How to use oil-absorbing materials properly

When you’re handling or storing flammable substances, it’s important to be extra careful. You should always follow safety protocols, and when dealing with spills, you should use oil absorbing materials. When using oil absorbing pads or wipes, you need to ensure that they’re fully impregnated with the right amount of liquid. They should be damp enough to absorb oil but not so wet that they’re dripping. You should also ensure that the pads or wipes are kept in the right containers. You should use the right containers for different kinds of substances. You should also label those containers with the type of substance they contain. These details should be noted on the label of the containers. This will help you to keep track of the different substances and will also help you to control the spread of those substances.

How to choose the right type of oil-absorbing material

There are many different types of oil absorbing materials available on the market. Depending on the type of substance that you’re dealing with, there are different types of oil absorbing materials that you can use.

- Paper - Paper is the most commonly used type of oil absorbing material. It is suitable for use with a wide range of different oils.

- Fabric - Fabric is another common type of oil absorbing material. It is suitable for use with oils that contain a high percentage of solids. This includes crude oil, diesel, lubricating oils, and more.

- Synthetic fibers - Synthetic fibers are also an effective type of oil absorbing material. They are often used to trap and collect oils that contain a large amount of solids. These include crude oil, hydraulic oils, and more.

- Loose fibrous materials - Loose fibrous materials are another type of oil absorbing material. They are generally suitable for use with oils that contain no solids. This includes oils like motor oils, gear oils, and more.

Which are the best brands of oil-absorbing materials?

If you want to buy oil absorbing materials, you should keep a few things in mind. You should consider the type of materials that the pads and wipes are made from, as well as their size and weight. You should also check the reputation of the company that makes the pads and wipes. There are a number of different brands of oil absorbing materials on the market. Some popular brands include Fentex, Serpro, Veosorb, Evo and more. These brands make a variety of different oil absorbing pads and wipes, which can be used in a variety of different industries.

-

2022 product catalogue now available

3 May 2022The latest version of our 2022 catalogue is now available for download.

Containing many new and exciting products including a new range of wipers.

Displaying the very in spill management and containment equipment currently available.

DOWNLOAD THE SERPRO CALATLOGUE HERE -

NEW RANGE OF BATTERY ACID AND HAZCHEM SPILL KITS FROM SERPRO

1 November 2021For the safe, quick and effective clean up of spilled acid.

An acid spill can be very dangerous to both human health and the environment. The liquid contained in most batteries (lead and sulphuric acid) can cause fires, employee injuries, groundwater contamination, and soil contamination.

In three sizes, the Serpro Battery Acid Spill Kit, 20, 30 and 40 Litre, contains products designed for containing, neutralising and cleaning up batteries and other acids after spills. The kit decontaminates the area and quickly restores it to a safe and usable state.

-

The Best way to Trap Oil and Fuel Leaks from Plant and Machinery

8 September 2021The Best way to Trap Oil and Fuel Leaks from Plant and Machinery.

Indoors or outside on a site, SpillTector® will absorb oil leaks and fuel spills without holding up work.

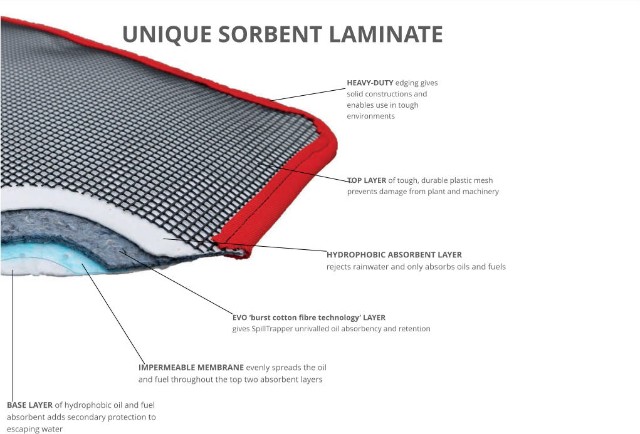

Originally taking two and a half years of development and field-testing the SpillTector® is now a market leader in the plant hire and construction trades. It has been designed to outperform all other construction site spill protection mats and delivers unrivaled absorbency at unbeatable prices. The multi-layer absorbent mat with its unique 'burst cotton' layer has given the SpillTector® added absorbency and oil retention. The laminated layers absorb even more oil than ever and lets the rain and water run free.

SpillTector® used with the unique Flexi Tray allows you to wheel plant straight onto the absorbent Mat with little effort or fuss and the tough mesh grid withstands heavy use while allowing oil to be absorbed. The unique sorbent laminate traps oil and allows rainwater to flow away, protecting the ground from contamination. Meeting the challenge of environmental and workplace protection, SpillTector® effortlessly catches leaks and spills day-in, day-out, allowing the job to be completed without interruption. Tough enough for the harshest working environments and with the best performance in the industry.

Since 2014 SpillTector® has been developed to absorb even more oil and fuel whilst letting the rain run free! Designed by market leaders in Spill Control, the multi-layer SpillTector® Mat uses years of absorbents knowledge and experience. A key ‘eureka’ moment was in September 2015 when a layer of EVO Recycled® burst cotton super absorbent, manufactured only by Fentex in the UK, was added to the SpillTector® laminate. This gave the SpillTector® the added absorbency and oil retention to make it the best in the market.

Available in four sizes that are up to 10% bigger than competitors, SpillTector® has become more versatile than ever.

-

Kitchen Spill Kits

8 September 2021Our range of solutions for the removal of oil spills in commercial kitchens, restaurants and homes offers unbeatable quality and performance. Our spill kits are available in all sizes and configurations to meet the requirements for the absorption of most water, petroleum based and chemical based liquids. When it comes to cleaning up a workplace after an accident or a leak in a busy restaurant you want something that works as expected.

Prepare to respond to any kind of emergency situation with our quality spill kits. It is recommended that all kit components be stored in the portable container and their position must be indicated in the written instructions on the packaging. Spill kits must be inspected every week to ensure that all components are in good condition and that the kit is complete

Serpro Spill Control Kits provide the necessary components to react to small leaks of hazardous liquids and chemicals. An accidental spill by an employee can put employees and others at risk.

The source of the leak can be controlled by keeping the leak as small as possible. Cover the entire contamination site with absorbent materials such as absorbent cushions, pads or absorbent socks/booms. For minor spills, use a containment snake to surround it and limit the flow.

Our oil leak kits can be used to clean hydrocarbons such as engine oil, kerosene, diesel, gasoline and hydraulic oil and in addition vegetable and liquid cooking oils. Which type you choose depends on the liquid you clean in case of a leak.

It is possible to get a suitable emergency spill kit tailored to the specific needs of your company. Whether it's a leak or spill in any part of your building or home you can protect yourself and your employees with Serpro Spill Management products.

-

Spill Response and How It Works

8 September 2021Following specific procedures when cleaning up hazardous spills is critical to employee safety and facility safety. Make sure everyone knows the specific role they play in this process.

Most types of companies have hazardous chemicals, and all employees should know what to do in an emergency or cleanup situation. There are specific programs and specific employees assigned to these programs. If done correctly, these procedures can save lives, injuries, and property.In most cases, the first person to report a leak is a incident responder who will not involved in the actual cleanup. Once reported, the Health and Safety Officer is responsible for ensuring that proper procedures are in place.

As soon as possible, employees who are authorized to come into close contact with the spill should use warning signs or tape to seal off the leak. If the leak occurs indoors, emergency personnel should immediately seal the ventilation ducts and open doors and windows leading to the outdoors to allow the vapor to dissipate.

Then, the spill team should place barriers such as absorbents around the spill to prevent it from spreading. Common materials used for this are polyurethane, PVC or absorbent polypropylene socks. Socks can block and absorb dangerous spills and once used should be treated as hazardous waste. On the other hand, you could use a flexible barrier can this only prevent spillage but not absorb the fluid. Sandbags are not designed to absorb harmful substances and must not be used for cleaning. Flood dikes are extremely important to prevent materials from spilling into storm drains or sewers and further polluting the environment.

At this time, HAZMAT technicians should be taking over. The first process is to characterise the leak location by identifying the chemical substance in the leak and then determining the hazard. This characterization is done through the use of direct-reading instruments that provide quick information about environmental conditions. There are a variety of instruments available, including combustible gas monitors, detection tubes, and field instruments. Technicians should also pay attention to open pits and material piles that may be unstable.

Once the characteristics of the scene are determined, the Hazmat Team Leader will determine whether the leak requires special handling, and then order appropriate handling procedures. In most cases, absorbent compounds will be spread on the spill. These compounds are usually granular and absorb the material. They should be inert and therefore cannot react with the chemicals they absorb. Then, add disposable absorbent pads, which are also inert to absorb the remaining material. Then place these pads and compounds in OSHA-approved containers for disposal.

Although this process is routine most of the time, if the material is flammable or close to electricity, special precautions should be taken when shoveling and use a non-sparking shovels and gloves and turning off all electronic equipment for cleaning before use.

Finally, the contaminated material is transported to an approved hazardous waste material facility, where it is processed and reused or rendered harmless, and then sent to a landfill.

After a leak occurs, all relevant personnel must undergo decontamination procedures. Employees pass by the workstation, where their PPE is cleaned and thoroughly washed with water and detergent. This washing liquid is discarded and the worker takes a shower. At this point, the cleaning process is complete.

In the event of a dangerous leak, everyone has a job. Get a thorough understanding of your situation so that you can help your facility, avoid injuries and complete the cleanup effectively.

-

The Brand New Muckyz Scrub Industrial Wet Wipe

1 April 2021SERPRO Ltd present the brand new Muckyz Industrial wet wipe. Bursting with approximately 80 high GSM sheets per tub, these wipes are great for everyday use in any industry. Muckyz Scrub heavy duty rough wipes are used across a range of industries for tough muck or mess.

REMOVES GRIME, OIL, GREASE AND MUCK FROM HANDS AND MACHINERY!

- Kills viruses and bacteria

- Easy access pop-top stops wipes drying out

- Designed for tough stains

- Low carbon footprint - Made in Britain

For further information, please contact us on 01622 236 303, 07882553900 or sales@serpro.co.uk.

-

Bunded Drum Trays

1 April 2021SERPRO Ltd Bunded Drum Trays are Ideal for storage of 25L drums and smaller small containers, these drum trays can also be used as contained decanting areas, helping to keep floor contamination to a minimum.

- Can be used to catch drip and leaks under machinery, vehicles and plant

- Ideal for storage of 25L drums and small containers

- Grids to keep containers clear of leaked fluid

- Removable grids for easy cleaning

- Corrosion free

- 100% recycled plastic construction made in Britain

For further information, please contact us on 01622 236 303, 07882553900 or sales@serpro.co.uk

-

Serpro Short Run Custom Security Tag Printing

1 April 2021There is no-one else in the country that will print as small a quantity as us. Most companies will only print 1000's as a minimum, we will print the amount you need.

Custom printing options allow for branding while reducing copy ability and enhancing security. Customisation options vary depending on the type of seal you require, they regularly include:

- Your choice of wording

- A barcode for faster processing

- A wide selection of colours

- A company logo

- Qr coding enabling many different scanning options.

Call us now on 01622 236 303

-

The Brand New Muckyz Smooth Industrial Wet Wipe

1 April 2021Muckyz hand and machinery wipes remove grime, oil, grease and muck. The high grade wipes will provide you with a quick, clean and solvent free solution.

- Heavy duty smooth or scrub wipes available

- Kills viruses and bacteria

- Not tested on animals

- Easy access pop-top

- Easy access pop-top stops wipes drying out

- Designed for tough stains

- Low carbon footprint - Made in Britain

For further information, please contact us on 01622 236 303, 07882553900 or sales@serpro.co.uk.

-

Swans and duck rescued from Clayton-le-Moors oil spill

1 April 2021A GROUP of swans and an Aylesbury duck who were rescued from an oil spillage have now been released back into the wild.

The birds were recovered by a team of five RSPCA animal welfare officers who found them covered with oil in the canal near Victoria Street at Clayton-le-Moors on October 5.

Oil can be extremely dangerous to water birds, leaving them vulnerable to dying from hypothermia by reducing the natural water proofing in their feathers, but fortunately the officers were able to take the flock they had found to Stapeley Grange Wildlife Centre in Nantwich to be cleaned.

-

About SERPRO Ltd

1 April 2021About SERPRO Ltd

SERPRO are international suppliers of industrial absorbents, spill kits, security tags and spill management products.

Our range includes:Spill Kits - Security Tags - Oil Absorbents - Evo Absorbants - Chemical Absorbents - MRO Absorbents - Bunded Workfloors - IBC Containment - Bunded Spill Pallets - Tamper Evident Seals - Body Fluid Spill Kits - Drip Trays - Dirteeze hand Wipes - Marine Absorbents - Clay Absorbent Granules - Plant Nappy - Spilltector - Spill Pans - Steel Containment Cabinets - Hazmat Absorbents - Anti-Static Oil Only Absorbents - SpillPod - Oil Removal Chemicals

We manufacture or assemble many of the products ourselves and can match virtually any of our competitors products. -

M5 traffic delays as oil spill leads to southbound delays

1 April 2021There are delays on the M5 this morning (October 29) following an oil spill.

One lane of the motorway was closed southbound after a vehicle broke down between J8 M50 to J9 A46 (Tewkesbury).

However, due to an oil spill this closure will have to remain in place.

Highways England tweeted: #M5 Southbound J8 #Strensham towards J9 #Tewkesbury.

"Due to an oil spill from the vehicle involved, the lane 3 closure will remain in place until the spillage has been treated and deemed safe to reopen."

Traffic cam pictures show long queues of traffic on the motorway.

-

Japan to send a new team of experts to Mauritius over oil spill clean up

1 April 2021Japan to send a new team of experts to Mauritius over oil spill clean-up. The team is said to include officials from Japan International Cooperation Agency. Japan has told the Mauritian Prime Minister that it will provide long-term assistance. On Aug. 7 Mauritius had declared a state of environmental emergency due to the oil spillage.

-

Custom Printed Security Tags and Seals

1 April 2021SERPRO Ltd supply a wide range of Custom Printed Security Tags and Seals. We provide quick turnarounds with no minimum orders required!

Serpro security seals offer trustworthy and reliable protection for a wide range of items, such as:

- Shipping Containers

- Sensitive instruments on important equipment

- Freight being transported across the country

- Bags, Carts and cabinets

Contact Serpro Today for Custom Printed Security Tags and Seals

01622 236 303

07882553900

-

VIRAWIPE High Performance Surface Sanitiser

9 November 2020NHS approved protection against formation of bacteria and superbugs.

Proven to Kill at least 99.999% of disease causing microorganisms including MRSA, Norovirus and Hepatitis B and C.

The VIRAWIPE is a premium product that can safely be used in the home, in community care, in transport settings like cruise ships and airlines, in the food sector including restaurants as well as in hospitals. The information provided is intended to show that this new and innovative product has a clear potential to reduce hospital acquired infections.

.Rapid control against: -

- Noro Virus (Winter Vomiting Disease Virus, Norwalk Virus) using FCV as the surrogate

- Bacteria –

- Fungi –

- and to a limited extent bacterial and fungal spores

A safe mild liquid with excellent skin compatibility that can be sprayed near and, if the need arises, on patients including premature babies and the elderly.

A non-toxic, non-corroding and biodegradable multi-purpose product with excellent cleaning abilities.

The wipes used in ViraWipe are a tough high-loft type of wiper, much more usable compared to the standard non-woven thin type cloths normally used.

VIRAWIPE is currently untested on COVID-19, however, COVID-19 has an "envelope" structure around each virus. This suggests it will be sensitive to VIRAWIPE as it kills 99.9% of similar "enveloped" viruses in under 5 minutes.

For more information please visit our website here or contact us on 01622 236 303 or sales@serpro.co.uk