Northern Label Systems

Northern Label Systems Limited is based in Lancashire in a location close to Preston and Southport and has been built on a reputation for supplying high quality labels at the best possible prices.

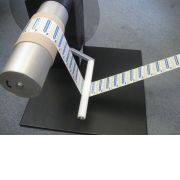

We supply label printers by Zebra Technologies, Citizen and Toshiba TEC as well as wide variety of label sizes and colours with a different adhesive types to suit all label printers and all applications.

-

Zebra release new ZD series label printers

11 February 2020Zebra have now released the all new ZD220 series of label printer. This series will replace the GC series which will become discontinued in January 2020.

The ZD220 will certainly prove to be a popular choice with customers needing a simple printer that will reliably print small rolls of labels for many years.

Main features:

- Single LED status indicator

- Single button for feed/pause

- USB connectivity

- OpenACCESS™ for easy media loading

Like the GC420 series the ZD220 series will consist of a direct thermal (no ink ribbon required) and thermal transfer (ink ribbon required) version.

Being an entry level printer the only option you can have on the printer is a peel off unit. This allows the label to be dispensed from the lining paper and the next label will print when the first label has been taken.

Like the GC, GK, GX and also the LP series before them the ZD series takes standard labels which are up to 5″ (127mm) in diameter on 25mm cores. The printers only come in a 200dpi (dots per inch) version so a GX430t will be needed for applications where a higher definition print is needed (for ingredient labels etc).

-

How do I calibrate my Zebra GK420d Label Printer?

11 February 2020The quickest and easiest way to calibrate your Zebra GK420D label printer is to hold the green FEED button down. First the light on the button will flash once then it will do a double flash. Let go of the button after the double flash and the printer will start to feed labels forward slowly. This is the calibration process and only takes a few seconds.

If you are using Zebra Designer to print your labels then you may find it easier to get the label design on the screen then go to FILE and PRINTER SETTINGS then under the ADVANCED SETUP tab simply press the CALIBRATE button in the bottom right corner of the screen.

If neither of the above works after a couple of attempts then make sure you have the correct label size in the settings of your label design software and you are using the correct gap sensor. Labels on a backing paper with a gap between them and no black line printed on the reverse of the backing paper should use WEB SENSING or LABEL WITH GAPS sensor and if you use continuous label or card stock or labels with gaps that also have a black line printed on the reverse of the backing paper then you should select the MARK SENSING or LABEL WITH MARKS sensor.

If you still cannot get your printer to calibrate then you will need to print a profile of the label sensor settings. To do this simply hold the green feed button. The light on the button will flash once then do a double flash then three flashes. Keep button held until it flashes seven times then take your finger off of the button. This will then print a graph that looks like the one below:

The graph should show a ‘spike’ where it picks up the label gap. If the graph shows no spikes then the label gap sensor is either dirty or faulty.

-

What is the Difference Between Direct Thermal and Thermal Transfer Labels?

30 September 2019Thermal Transfer printing uses an ink ribbon to transfer the printed image from the heated printhead of the label printer onto the surface of the label while Direct Thermal printing transfers the image directly onto a heat sensitive material.

There are advantages and disadvantages to both methods. Direct Thermal label printing does not require a label printer that uses an ink ribbon, therefore making it a cheaper label printer. However, the labels are generally slightly more expensive. This said there is no ink ribbon cost so the actual printed label cost is very similar. Direct Thermal label printing also requires the label printer’s printhead to be in direct contact with the label itself. If you are printing high volumes of labels you will find that the printhead wears out quicker than one used for Thermal Transfer label printing. This should be a major consideration if printing in volume as printhead life will be reduced by between 25% and 50%. The cost of a printhead varies but is usually around 40% – 50% of the cost of a small desktop label printer and 15% – 25% the cost of a mid-range or industrial quality label printer.

The printed label will also differ in quality. Direct Thermal label printing is usually only used for labels that will have a short shelf life such as shipping labels and best before dates. This is because the heat resistant labels used generally fade in daylight over a few weeks or months depending on the level of UV light. Even when the labels are in an indoor office environment the label will generally start to fade after 12 months.

Direct Thermal Labels with a ‘Top Coat’ are available to ensure more resistance to UV light, though this means an increase in label price. Most Direct Thermal labels are the uncoated type and are used for short term labelling solutions.

Thermal Transfer label printing uses exactly the same method of printing i.e. heated elements heating up and cooling down very quickly on a thermal printhead. However, with thermal transfer label printing an ink ribbon is used to transfer the printed image onto standard paper labels or synthetic labels. The end result is a printed label that will not fade in sunlight and will generally be readable for many years. Because an ink ribbon is used this acts as a ‘buffer’ between the printhead and the label itself leading to increased printhead life.

Thermal Transfer label printing can be used to print paper as well as synthetic type labels including polypropylene, polyethylene, vinyl and polyester in both matt and gloss.

The disadvantages of Thermal Transfer label printing is that the label printer required is slightly more expensive. However, Thermal Transfer label printers can be used to print Direct Thermal labels too by simply removing the ink ribbon. Just remember though, because you may use an ink ribbon to print there is one more thing to run out of!