AML Instruments Ltd

AML Instruments are a family run business offering instrumentation, UKAS ISO 17025 calibration, service, repair, spare parts and support for a wide range of instruments / test equipment used in a variety of industries and applications.

Filter products and services

- View all categories

- Autoclaves

- Balances

- Bore Micrometers

- Calipers

- Climatic Chambers

- Counting Scales

- Depth Gauges

- Dot Matrix Printers

- Electrical Calibration

- Environmental Chambers

- Floor Scales

- Force Analysis Systems

- Force Gauges

- Force Testing Systems

- Furnaces

- General Purpose Laboratory Ovens

- Heating Ovens

- Height Gauges

- Hot Plates

- Humidity Calibration

- Incubators

- Indicators

- Laboratory Freezers

- Laboratory Fridges

- Laboratory Thermometers

- Load Cells

- Material Testing Systems

- Micrometer Heads

- Micrometers

- Moisture Measurement Devices

- Peel Fixtures

- Pressure Calibration

- Steel Rules

- Temperature Calibration

- Thermal Printers

- Thermometers

- Thickness Gauges

- Viscometers

- Water Baths

-

Carton Force Analyser - Cfa Hanatek

The Hanatek Carton Force Analyser measures the forces that limit the running speed of folding box board packaging. By measuring the stiffness of the substrate and crease bending resistance the user can optimise cartons for faster running and packaging speeds. The instrument allows individual creases to be analysed identifying problem areas in packaging design or manufacture. Industry research indicates that the packaging speeds of pre-glued skillets is governed by the energy required to open creases. The Hanatek CFA is the first instrument to isolate and accurately measure this key parameter. The instrument measures: Bending resistance, bending moment, bending stiffness, crease recover stiffness, crease folding force, crease opening force. The Hanatek CFA can measure crease folding force at 90°, crease folding force at any angle up to 145°, board stiffness at 15° and 7.5°, individual crease opening force and whole carton opening force. It features touch screen operation for quick and easy operation. There are variable sample lengths available, rotation speed and crease angle. The instrument allows you to connect to a network to allow results or printer sharing. There is an online graphical help to ensure consistent operation within test methods and the interactive help routines ensure little training is required to operate the device. The Hanatek CFA is pre loaded with ASTM/TAPPI/ISO methods with the ability to create bespoke tests and in complain with all major international standards.Request a Quote Supplied by AML Instruments Ltd -

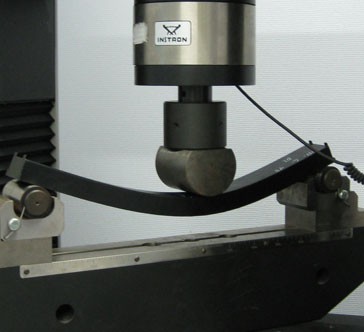

Crease And Board Stiffness Tester Cbt1

The CBT1 Crease & Board Stiffness Tester gives board manufacturers, printers and packing companies the ability to predict the 'runability' of a sample board or finished carton. The instrument measures crease folding force at 90°, board stiffness at 15° and requires no external software for operation. It automatically calculates the crease to board stiffness ratio for immediate indication as to whether the material will run correctly on a high speed packaging machine. After 15 seconds the test results is displayed on screen and a countdown timer for test completion is shown. After multiple samples are tested, the statistics (min, max, average) are updated on screen. There is an option test jaw for rounder comer packaging and option results printer to output test results to a label. There is a choice of sample cutters for the preparation of both carton crease and board stiffness samples.Request a Quote Supplied by AML Instruments Ltd -

Rub And Abrasion Tester Hanatek

The Rub and Abrasion tester (ink rub tester) brings new levels of repeatability and convenience to testing the durability of inks and coatings on any printed material. The instrument is used for testing the scuff, marking and rub resistance of cartons, films and commercial printed material. This comparative test works by abrading a printed sample against a reference material under known conditions. The results can be used to identify alternative substrates, better ink and coating formulations or the suitability of finished cartons, films or printed books, magazines and promotional materials. The Hanatek Rub and Abrasion tester can be programmed for the necessary number of cycles, enabling it to be run simultaneously with other laboratory tests. Optional test attachments offer the ability to conduct tests under harsher conditions and can be used to check the solvent resistance or the cure of UV inks. The rub and abrasion tester features fully automated touch screen operation, a choice of weights to comply to BS3110, air jet waste removal and additional attachments for scratch or wet rub test. The programmed test cycles allows tests to be run unsupervised. The rub and abrasions tester comes with a two year free warranty and an optional results printer to enable test parameters to be documented on trained samples.Request a Quote Supplied by AML Instruments Ltd -

UV Lamps

AML Instruments supply The Primarc UV Technologies broad range of medium pressure mercury arc lamps suitable for all known UV curing systems. Offering exceptional performance, the lamps provide outstandingly good service life and consistent UV output. Primarc UV curing lamps are used world-wide for the curing of inks and coatings in the printing, packaging and labelling industries as well as in a wide range of industrial environments, including CD/DVD manufacture, fibre optic cable production, wood products and electronics. All Primarc UV curing lamps are manufactured from high-clarity, vitreous silica, usually referred to as quartz. Quartz has the property of high-transparency to ultraviolet light, particularly at the shortwave end of the spectrum where over 90% of the UV energy generated is transmitted through the quartz. The electrode components are manufactured using the highest-quality materials, ensuring long and reliable lamp life. The Primarc Quality Standard ensures that each lamp is not only manufactured to the most rigorous of specifications, but also lamp performance is consistent each and every timeRequest a Quote Supplied by AML Instruments Ltd