Thermofax Ltd

With over 50 years experience within the heat treatment trade, our commitment to a quality product and customer satisfaction has been the backbone on which this family business has been built.

We house the biggest furnaces in the Midlands and Southern Regions, and have the flexibility of plant to accommodate charge weights ranging from 1 Kilo up to 30 Tonnes

They range in capacity from 1 Kilo to 30 Tonne charges.

Our general process capabilities are

- Post Weld Heat Treatment

- Stress Relieving

- Annealing

- Normalising

- Solution Treatments

- Age Hardening

- Lifting Capacity of 16 Tonnes

- 10 Large Furnaces

- Largest Bed Size of 7000mm x 8000mm

Filter products and services

-

Black Bar Heat Treatment

Heat Treatment consisting of Heating and Soaking at a suitable temperature followed by cooling under conditions such that, after return to ambient temperature, the metal will be in a structural state closer to that of equilibrium.Request a Quote Supplied by Thermofax Ltd -

Bright Bar Heat Treatment

Heat Treatment consisting of Heating and Soaking at a suitable temperature followed by cooling under conditions such that, after return to ambient temperature, the metal will be in a structural state closer to that of equilibrium. Batch Sizes up to 30 Tonnes Max Length 8.0mRequest a Quote Supplied by Thermofax Ltd -

Cast Iron Annealing

Heat Treatment consisting of Heating and Soaking at a suitable temperature followed by cooling under conditions such that, after return to ambient temperature, the metal will be in a structural state closer to that of equilibrium Materials Generally Processed - Carbon and Alloy Steels - Stainless Steels - Tool Steel - Boron Steel - Non-Ferrous Metals - High Temperature Steels - Corrosion Resistant Steels - Bolting Grades - Petrochemical Grades - Power Generation Grades - Nickel Alloys Batch Sizes up to 30 Tonnes Max Length 8.0mRequest a Quote Supplied by Thermofax Ltd -

Coil Annealing

Heat Treatment consisting of Heating and Soaking at a suitable temperature followed by cooling under conditions such that, after return to ambient temperature, the metal will be in a structural state closer to that of equilibrium.Request a Quote Supplied by Thermofax Ltd -

Full Annealing

Heat Treatment consisting of Heating and Soaking at a suitable temperature followed by cooling under conditions such that, after return to ambient temperature, the metal will be in a structural state closer to that of equilibrium Thermofax Ltd process to the following technical conditions: Full Annealing: Performed at a temperature above the Ac3 point. Inter Critical Annealing: Performed at a temperature between the Ac1 and Ac3 points. Isothernal Annealing: Annealing involoving Austenetizing followed by cooling which is interrupted by soaking for a period at a temperature at which the transformation from austenite into ferrite and pearlite, or cementite and pearlite is complete. Solution Annealing: Applied to austenitic steels. Consisting of heating to a high temperature followed by cooling sufficiently rapidly to preserve a homogenous austenitic structure on return to ambient temperatures. Spherodize Annealing: Prolonged holding at a temperature in the region of the Ac1 point, oscillating around this temperature in order to bring about the spherodization of the precipitated carbides. Sub Critical Annealing: Annealing at a temperature slightly below the Ac1 point. Materials Generally Processed - Carbon and Alloy Steels - Stainless Steels - Tool Steel - Boron Steel - Non-Ferrous Metals - High Temperature Steels - Corrosion Resistant Steels - Bolting Grades - Petrochemical Grades - Power Generation Grades - Nickel Alloys Batch Sizes up to 30 Tonnes Max Length 8.0mRequest a Quote Supplied by Thermofax Ltd -

Metal Heat Treatment

Wide range of services dependant on material specifics, futher processing and customers own requestsRequest a Quote Supplied by Thermofax Ltd -

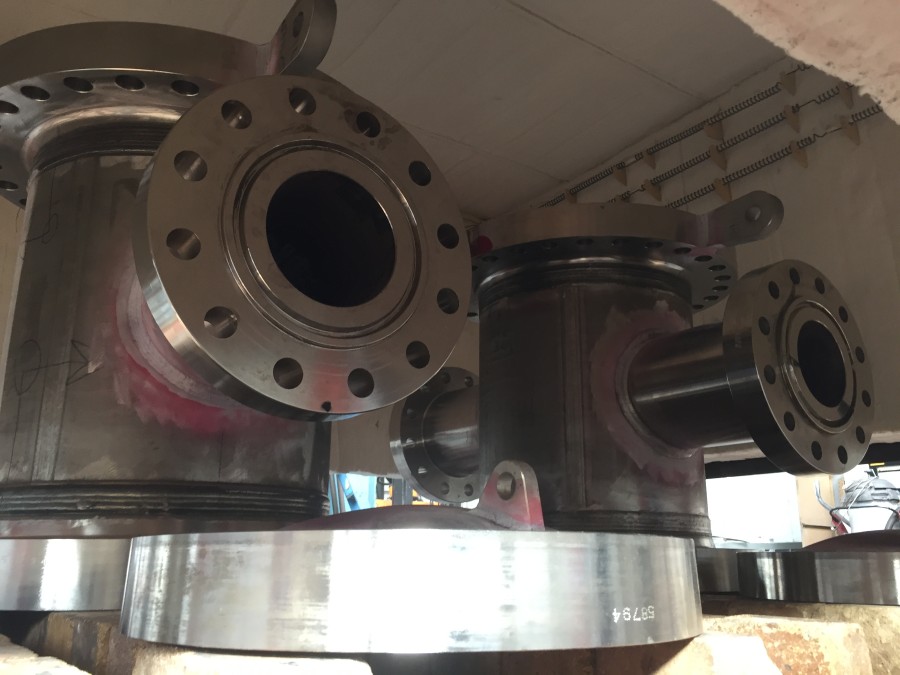

Post Weld Stress Relieving

Heat Treatment including heating to and soaking at a suitable temperature followed by cooling at an appropriate rate in order to reduce the internal stresses without substantially modifying the structure. - Post Weld Stress Relieving to Procedure Including: ASME VIII, ASME IX, BS31.1, BS31.3, PD5500:2009 - Stabilizing Treatments - Profile or manipulation Stress Relief Materials Generally Processed - Carbon and Alloy Steels - Cast Iron, Grey Iron, SG Iron - Stainless Steels - Non Ferrous Metals - Petrochemical Grades - Power Generation Grades - Nickel Alloys Fabrications up to 9m length Maximum Diameter plates/rings 7.0m For items outside the scope of our capacity please contact us directly as we can sub-contract on your behalf.Request a Quote Supplied by Thermofax Ltd -

Round Bar Annealing

Heat Treatment consisting of Heating and Soaking at a suitable temperature followed by cooling under conditions such that, after return to ambient temperature, the metal will be in a structural state closer to that of equilibrium Thermofax Ltd process to the following technical conditions: Full Annealing: Performed at a temperature above the Ac3 point. Inter Critical Annealing: Performed at a temperature between the Ac1 and Ac3 points. Isothernal Annealing: Annealing involoving Austenetizing followed by cooling which is interrupted by soaking for a period at a temperature at which the transformation from austenite into ferrite and pearlite, or cementite and pearlite is complete. Solution Annealing: Applied to austenitic steels. Consisting of heating to a high temperature followed by cooling sufficiently rapidly to preserve a homogenous austenitic structure on return to ambient temperatures. Spherodize Annealing: Prolonged holding at a temperature in the region of the Ac1 point, oscillating around this temperature in order to bring about the spherodization of the precipitated carbides. Sub Critical Annealing: Annealing at a temperature slightly below the Ac1 point. Materials Generally Processed - Carbon and Alloy Steels - Stainless Steels - Tool Steel - Boron Steel - Non-Ferrous Metals - High Temperature Steels - Corrosion Resistant Steels - Bolting Grades - Petrochemical Grades - Power Generation Grades - Nickel Alloys Batch Sizes up to 30 Tonnes Max Length 8.0mRequest a Quote Supplied by Thermofax Ltd -

Stainless Steel Stress Relieving

Heat Treatment including heating to and soaking at a suitable temperature followed by cooling at an appropriate rate in order to reduce the internal stresses without substantially modifying the structure. Materials Generally Processed - Carbon and Alloy Steels - Cast Iron, Grey Iron, SG Iron - Stainless Steels - Non Ferrous Metals - Petrochemical Grades - Power Generation Grades - Nickel Alloys Fabrications up to 9m length Maximum Diameter plates/rings 7.0m For items outside the scope of our capacity please contact us directly as we can sub-contract on your behalf.Request a Quote Supplied by Thermofax Ltd -

Steel Bar Annealing

Heat Treatment consisting of Heating and Soaking at a suitable temperature followed by cooling under conditions such that, after return to ambient temperature, the metal will be in a structural state closer to that of equilibrium.Request a Quote Supplied by Thermofax Ltd