Brooks Forgings Ltd

Brooks Forgings Ltd, established in 1960, is a leading UK manufacturer of Forged, Fabricated and Machined components.

We have a comprehensive range of manufacturing processes at our UK based facility and this aids buyers source their full requirements from one supplier.

These processes include:

- Robot Forging

- Upset Forging (16 cells)

- Drop Forging (10 cells)

- Horizontal Counterblow Forging

- Hand Forging

- Machining (14 cells)

- Fabrication & Assembly

- Robot Welding (5 cells)

- Flash Butt Welding

- Hot & Cold Bending

- Hot & Cold Pressing

- Thread Rolling

- Ring Rolling

- Swaging & Pointing

- Die Sinking

- Marking & Traceability

- Forging Simulation

- 3D Printing

- Reshoring

- 250 Tonnes of Raw Material

- 2500 Pallets of Customer Stock

Robot Forging

As part of an on-going development strategy, Brooks Forgings has an active interest in the latest manufacturing technology.

We now have several robotic automated processes at our manufacturing site and our ongoing goal is to increase production capacity and quality, reduce our carbon footprint, and remain competitive against foreign manufacturers with low labor costs.

Automated Horizontal Upset Forging

We are pleased to announce that we have moved forward with the installation of a FANUC six-axis robotic arm. The robotic arm has been integrated with an automated bar feeder, induction heater, and an Etchells MultiForge machine, creating a fully automated horizontal upset forging production line. Please see the video below or by clicking here

We currently have several MultiForge machines at our forging facility and all tooling is cross-compatible via a quick-change system. Programming data can be stored and linked to each tooling set, enabling us to manufacture components on the automated production line as and when required with little downtime.

Upset Forging

Upset Forging is just one of many forging processes available from Brooks Forgings Ltd.

If you are looking for upset forged components please contact us today with your requirements.

Our Upset Forging Capabilities, our capabilities include both vertical closed die and horizontal split die upset forging machines. Capacity from 6mm – 100mm diameter bar stock up to 10 meter lengths, including flat, square and hexagonal material.

We also have the diversity to manufacture forgings from a wide range of materials. Ranging from carbon steels through to exotic alloys… we can help you with your forging requirements.

Contact us today with your upset forging requirements.

Drop Forging

Drop Forging is just one of many forging processes available from Brooks Forgings Ltd. If you are looking for drop forged components please contact us today with your requirements.

We have a total of 9 Drop Forging hammers, producing components up to 75KG.

The Benefits of Drop Forging; The drop forging process improves the strength of the metal by aligning the grain along the lines of potential stress, which cannot be achieved through casting, machining or fabrication. These types of components are used by our customers in agriculture, transportation, defence, mining, forestry, medical and other industries.

Horizontal Counterblow Forging

Horizontal Counterblow Forging is the latest addition to our manufacturing capability.

A Model C Chambersburg Automated Horizontal Counterblow System has been installed at our manufacturing site based in Stourbridge, increasing our capacity to 16 hot forging cells.

This process can achieve a more uniform product, using less energy compared to other forging processes. High volume, and consistent, production of excellent quality forgings with improved lead times. We believe that the introduction of Counterblow Forging will enable us to offer the lowest possible production cost for medium to high volume forging in the UK.

Reshoring

Brooks Forgings is committed to the ongoing development of its capabilities and rebuilding confidence in British manufacturing.

Key reasons for buyers reshoring to the UK:

• Communication problems

• Quality & environmental issues

• Slave labour issues

• Tax rates & import tariffs

• Exchange rate fluctuation risk

• Loss of intellectual property

• Larger volume commitment and investment

• Counterfeit materials and components

• Automated manufacturing in the UK

• Hidden and additional costs

Please do speak with us today if you are looking to reshore component production to the UK.

For more information on reshoring, please visit our website.

Fabrication & Assembly

We supply fabricated metal components both locally and worldwide to many industries including Civil Engineering, Petrochemical, Power Generation, Defence, and Transportation.

Our fabrication processes include Machining, Bending, Profiling, Grinding, Cropping, Punching, Laser Cutting, Robot Welding, and Flash Butt Welding.

Please do visit our website for more information on our fabrication processes.

Heritage & Metalwork Replication

Replicating ironwork / metalwork from bygone years is a process in which we are involved on a regular basis.

We have developed an extensive range of specialist machinery that is multi-functional, enabling us to maximize the production of replicated components. This combination of modern machinery and traditional skills means that our customers have the best of both worlds.

The scale of the replication work involved can be from a simple railhead or scroll, to a full panel of ironwork.

Please do contact us today to discuss your heritage ironwork or replication requirements.

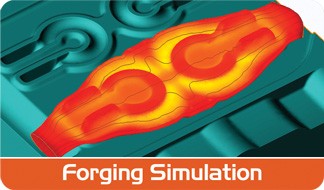

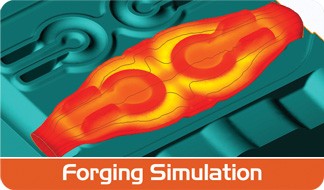

Forging Simulation

Forging Simulation can help improve lead times and avoid costly mistakes caused by the production of incorrect dies.

Brooks Forgings Ltd uses the latest QForm forging simulation software, enabling the development and optimisation of tooling to accurately simulate and analyse the forging process.

It is possible to identify flaws in the early stage of tooling design such as inadequate impression filling, laps or folds, and flow-through defects.

The software also allows engineers to optimise the process further by varying starting material diameter, forging forces, and analysis of die tooling stresses to improve durability and longevity.

Holding Down Bolts

We supply Civil Engineering projects with many different types of holding down bolts. Our extensive on site manufacturing capabilities enable us to offer swift turnaround for orders.

Our on-site facilities also enable us to supply bolt boxes and assemblies made to customers requirements.Specialising in the manufacture of Standard & Specials M6-M100 up to 8000MM length.

Make Brooks Forgings your one source for all of your foundation bolting requirements -- all direct from one manufacturer. Please contact us today with your requirements. We are certified to CE EN1090 and EN15048 by Lloyds Register. This is to comply with the Construction Products Regulation 305/2011.

Eyebolts

At Brooks Forgings Ltd we manufacture a diverse range of Eyebolts used in many industries. Our fully equipped tool room, alongside our CAD/CAM facilities, enables us to produce specials to customer requirements.

Additionally, we hold supplies of blank forgings ready for rapid conversion and despatch.

Sizes Ranging from M6 to M100 (1/4” to 4”)

Our Eyebolt range includes:

• Palm Eye Bolts (Straight Sides)

• Shackle Eye Bolts (Curved Sides)

• Din 444 Eyebolts

• Swivel Eyebolts (Increased Eye Thickness)

• Lift Suspension Eyebolts

• Collared Eye Bolts Imperial Thread

• Collared Eye Bolts Metric Thread

• Dynamo Eyebolts (Commercial Pattern)

• Dynamo Eyebolts

• Sling Rod Eye Bolts (Integral Forged Eye)

• Bow Nuts

• Eye Nuts

• DIN 582 Eye Nuts

• DIN 580 Eyebolts

• Curled Eye Bolts

• Ring Eye Bolts

• Nib End Eyebolts

• Scaffold Restraint Eyebolts

• Eyebolts & Eyenuts to BS1320

Hammerhead T Bolts

For Standard and Non-Standard Hammerhead T-Bolts, Brooks Forgings Ltd are your number one choice. Hot Forged in the UK. Metric or Imperial Threads.

Sizes from M24 up to M100 and up to 6000mm Length & Special head forms manufactured on request

Our manufacturing capacity includes:

• DIN 7992

• DIN 186

• DIN 188

• DIN 261

Shackles

Specialists in the manufacture of Non-Standard Shackles to our clients exact specifications.

Our Standard Shackle Range Includes:

• Large D Shackles to BS 3032

• Small D Shackles to BS 3032

• Large Bow Shackles to BS 3032

• Small Bow Shackles to BS 3032

• Overhead Power Line Shackles to BS 3288

We can manufacture up to a maximum body diameter of 100mm (4” Dia)

Special Bolts & Fasteners

Brooks Forgings Ltd have extensive on-site processes to manufacture a diverse range of Special Bolts in the UK.

Our range of special bolts includes:

- Tee bolt round head

- Tee bolt square head

- Cheese head square bolt

- Round tapered bolt

- Tee square bolt

- Tapered oval bolt

- Cup headed bolt

- Cup square

- Spill plate bolt

- Heavy duty square bolt

- Countersunk square bolt

Special Bolts can be produced in a range of materials including:

- Carbon & Alloy

- Super Alloys

- Stainless

- Duplex

- Non Ferrous

Find us on You Tube

Find us on YouTube! Please visit our channel today!