Karmelle Ltd

Karmelle is a British manufacturer of multi-sector liquid filling, capping and labelling equipment. We specialise in complete lines, building bespoke filling machines, capping machines and labellers entirely in-house. Our team takes pride in this unique turnkey service, which encompasses everything from project management to product aftercare.

Whether you're looking to invest in an entry-level filling machine, or single source a complete liquid packaging system, we can help. Visit www.karmelle.com to learn more.

Filling Machines

At Karmelle Ltd, we manufacture a wide range of liquid filling machines, both semi-automatic and fully-automatic. This state-of-the-art bottling machinery is tailor-made to customer specifications, and suitable for the chemical, pharmaceutical, food and drink and personal care industries.

Our range of filling machines includes:

Semi-automatic filling machines

Automatic filling machines

Drum and IBC filling machines

Capping Machines

Karmelle Ltd's liquid capping machines offer flexibility, speed and reliability. Using quality materials, tried-and-tested technology and the latest technology, we build equipment to meet your needs - whether you're looking for a stand alone capper to support your existing line, or a complete packaging system.

Our range of cappers includes

· Single head pick and place capping machines

· Karmelle Spindle Cappers

· 4CT capping machine

· Automated cap feeding systems

Labelling Machines

Karmelle offers a wide range of state-of-art labelling machines. Our systems are fast and reliable, accurately dispensing on average 100 million labels before any major maintenance is required.

Labelling systems available include:

· Basic promotion flash labelling

· High accurate servo driven primary labelling

· Label application with date and batch coding

· Print and apply labelling utilising state of the art print engines

· Pallet labelling

· Outer case labelling

· Main frame PLC controlled front, back and wrap round labelling

· Full pharmaceutical specification with camera inspection and reject facility

Bench Top Filling Machine

The Karmelle Ltd Bench Top Filler is a compact, semi-automatic filling machine, ideally suited to short runs and small volumes.

Powered by compressed air, this model is flexible, accurate, and capable of rapid changeovers. Its small footprint makes it perfect for simple bench-top mounting, while its pneumatic primary function is safe for hazardous areas of wash-down facilities.

Boom Arm Filling Machine

Highly versatile, the semi-automatic Boom Arm Filler can be adapted to suit customers' needs. Its volumetric pump is available in five or ten litre double acting strokes, allowing the user to select the amount dispensed. Volumes can be adjusted by a hand-wheel, while flow is controlled by either positional or check valves, depending on the viscosity of the product.

A flowmetre of the Boom Arm Filler is also available.

Semi Automatic Volumetric Vertical Filling Machines

Karmelle Ltd's versatile vertical filling machines are suitable for small-to-medium batch sizes, and volumes of between 100 millilitres and 5 litres.

Mounted on a stainless steel frame, they allow the operator to manually place a container, before filling it and removing it from the filling table.

A mass flow meter vertical filling machine is also available.

Karmelle Mini Monoblock Filler

Originally designed for a UK spirits manufacturer, the Karmelle Mini Monoblock comprises a rotary filler, capper and labeller.

This compact, fully automatic machine can fill 10 ml - 1000 ml containers at a rate of up to 30 per minute, depending on volumes. Its uniquely small footprint makes it ideal for customers with limited space.

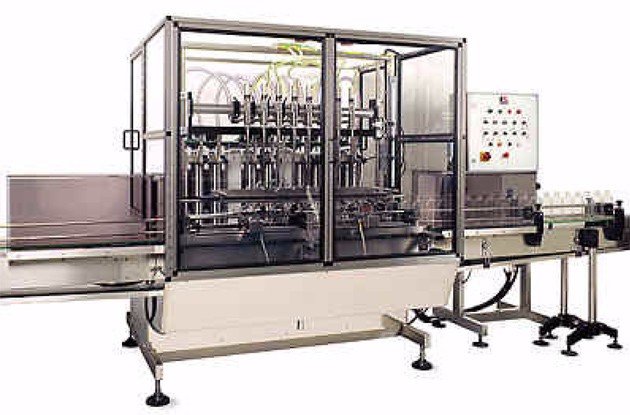

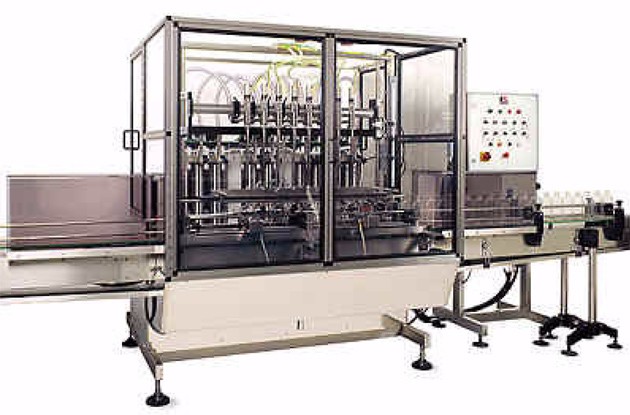

Automatic Volumetric filling machines: vertical and horizontal

Karmelle's fully-automatic in-line volumetric filling machines are built on multiple-head modular frames, and suitable for an array of products - including oils and chemicals. Customers can choose between a single and double acting line pump:

Vertical:

Karmelle offers four kinds of vertical (single acting) volumetric filling machine: VIP F050, VIP F100, VIP F200 and VIP F500.

Horizontal:

The Karmelle HIP F1000 A6 6 head volumetric filling machine is fitted with double acting fully automatic volumetric pumps. A state-of-art model, it allows the user to adjust volumes, and can fill several different containers if required.

Karmelle Flowmeter Filling Machine

Karmelle's inline Flowmeter filling machine is fully automatic, and suitable for a wide variety of products. Featuring interchangeable nozzles, it can be set up for bottom-up filling, top filling or neck entry, and supplied as either semi-automatic or fully-automatic.

Rotary Filling Machine

Ideal for larger batches, Karmelle Ltd's highly efficient Rotary bottling machine can run at speeds of between 40 and 200bpm.

Customers can choose from the following filling options:

Gravimetric

Vomumetric

Flow Meter

Balanced Pressure Systems

EK40 Inline Pick and Place Capping Machine

Karmelle's EK40 Inline Pick and Place Capping Machine is a single head indexing capper, ideal for medium-sized batch runs. Capable of reaching speeds of up to 28 one-litre bottles per-minute, this versatile machine is designed to allow for quick cap changeovers - making it a reliable and efficient.

The specification includes:

Stainless steel construction

Environmental guarding

Quick release change parts

Spindle Capping Machine

Karmelle's versatile Spindle Capper can be operated as a semi or fully automatic unit. Fully adjustable, it is capable of handling a variety of containers and closures at speeds of up to 200-per-minute.

The specification includes:

304 stainless steel frame

Container guide belts with height adjustment

Interchangeable spindles

Easy change parts

Karmelle 4CT Capping Machine

Karmelle's 4CT Capper is capable of tightening caps on glass, plastic and metal containers of virtually any shape.

This versatile capping machine's adjustable speed control enables it to precisely match conveyor speeds, while the lack of chuck, transfer wheel or timing mechanism means that containers can be processed continuously or at random.

The specification includes:

Stainless steel finish

Handwheel adjustment for different containers and caps

Fully interlocked machine guarding

Rotary Capping Machine

Ideal for larger batch-sizes, Karmelle's automatic Rotary Capping Machines are designed to handle virtually any size and style of cap and container.

The specification includes:

304 stainless steel frame

Environmental guarding

Fully automatic system

No-bottle-no-cap operation

Flash Labelling Machine

A side labelling system with a servo labelling head, offering throughput speeds of up to 100 labels per-minute. This PLC controlled labelling machine can accept label rolls with a 44mm or 76mm core and 300mm outside diameter.