Dual Metallising Ltd

Established in 1982, we are a family-run business who produces plastic metallising moulding reflectors. Our teams of highly experienced workers can provide plastic metallising moulding reflectors with a variety of finishes and can work on single items or full production quantities.

We have nurtured a reputation based upon efficiency and reliability and have a loyal customer base who returns to us because of our fast and expansive services.

Quality Approved

It is our policy to ensure our products are quality approved and conform to International Quality Management Systems Standard EN ISO 9001:2008.

Our dedicated quality approved service is focused upon customer satisfaction and is continually being improved and enhanced in order to provide our customers with the highest quality products with optimum performance and longevity.

Spray Painting On Plastic Parts

Spray painting on plastic parts is a versatile technique of reinforcing plastic substrates and we have extensive experience in this area.

Not only to we offer spray painting on plastic parts, we also provide spraying onto glass and metal products. Because we have both finishing and moulding systems available, we are a one-stop destination for the majority of our customers.

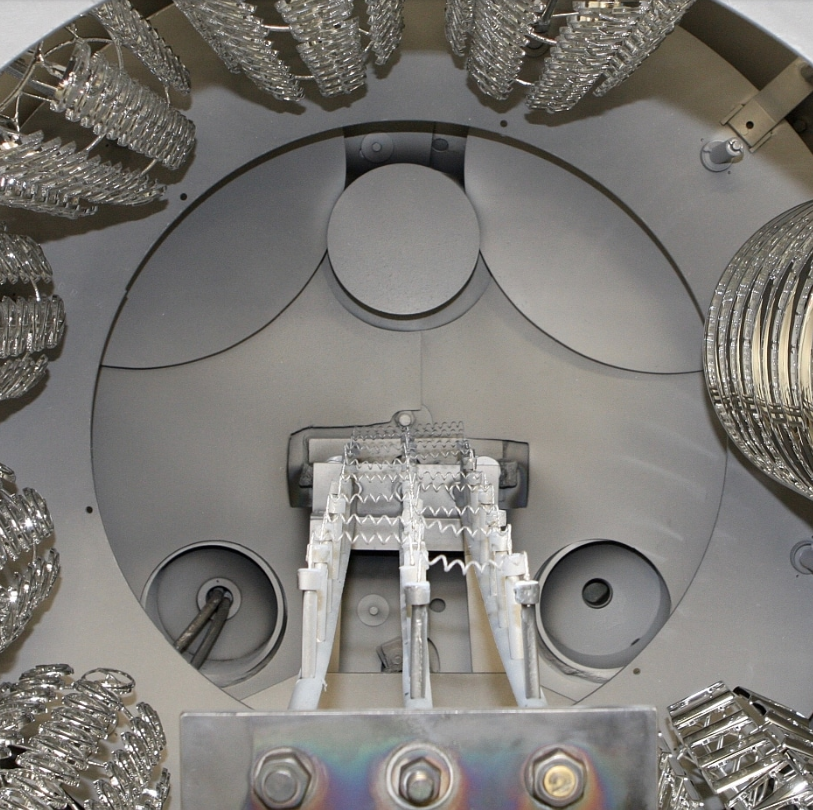

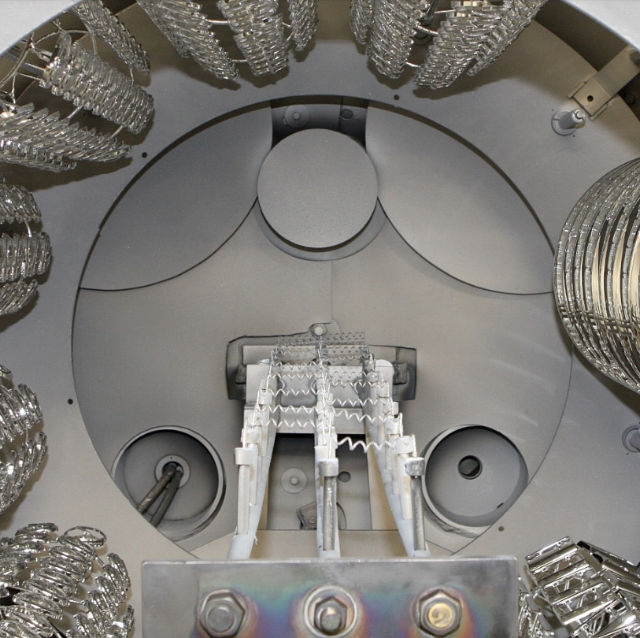

Vacuum Metallising

Our vacuum metallising services range from standard deposition to advanced plasma and in process silicone protection ideal for automotive reflectors. We can offer vacuum metallising capabilities on the majority of inert substrates except acetal polymers.

Our vacuum metallising services include:

- Facility for "Ionic Gaseous Plasma" serving as a surface preparation prior to aluminium deposition

- Polymeric layer can be offered within the vacuum metallising process by plasma and silicones to provide post metallising protection

- Various substrates undertaken

- Fast responses times

- Trials and prototypes undertaken

- Highly efficient modern plant

- Glass metallising is achievable

- Automatic base lacquer flowcoating to most substrates

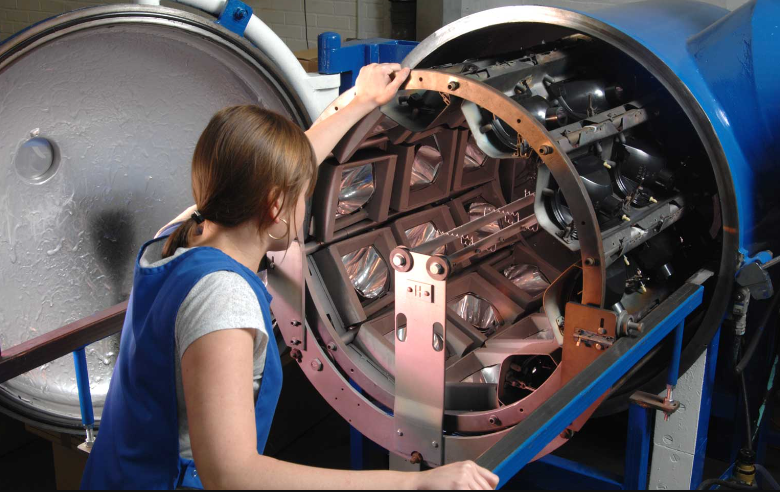

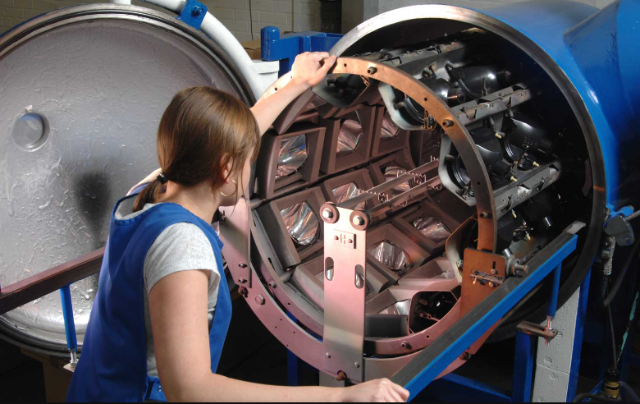

Plastic Injection Moulding

Our plastic injection moulding services are highly developed and we continually invest in this department in order to offer optimum repeatability capabilities.

Our plastic injection moulding facilities include six, innovative microprocessor controlled machines ranging from 20 to 250 tonne capacities.

Reflectors

We offer both moulding and vacuum deposition in order for us to provide complete finished reflectors in the majority of polymers.

Customers own mouldings make up the bulk of our reflector production. Prototype reflectors and bezels are one of our specialities. Diffused surfaces can be achieved on reflectors and plasma and in process silicone protection is available.

Prototype & Promotional Products

We have an excellent reputation when it comes to prototype & promotional products. We can create prototype & promotional products for point of sale and produce components on time and often on the same day.

Not only do we offer rapid response times, we cater for a variety of substrates and undertake coatings for vacuum formings in substrates including PS, PET, PC, and ABS.

Promotional Clocks

We create promotional clocks, an area growing in demand. We have a range of styles to choose from and promotional clocks available in a diversity of corporate colours.

We can also apply metallised finishes on the clocks to give them gold or chrome effects.