Tritec Developments Ltd

Electronic Product Design: specialising in the close integration of electronics, software and mechanical development Tritec’s team of engineers are experienced in all stages of the product design process, from concept and feasibility studies, through detailed development and prototyping, to production documentation and low volume manufacturing.

Low Volume Electronic Product Manufacturing

We offer in-house low volume manufacturing service. Our production department is very experienced in high precision electro-mechanical assembly and at working to the highest quality standards for clients in medical, nuclear and defence industries. If your requirements are for higher volumes, we can also assist in sourcing suitable manufacturers for your products.

Control Systems Engineering

We offer the full range of factory automation services whether you require full design, build and installation of control panels and cabinets or just require a PLC programming or an initial feasibility study.

Our experience in implementing both small and large scale automation projects enables us to offer the full range services from feasibility studies, through equipment specification and procurement, process control design and build to installation, commissioning, documentation and training.

Fibre Optic Installation Equipment

Tritec also manufactures its own range of fibre optic installation equipment including the FASE II fusion splicer for jointing optical fibre and the HSO II heatshrink oven for protecting the spliced joints

Tritec

What we offer: TRITEC offer the complete range of design consultancy services. Our skills can be broken down into two main areas:

Electronic Product Development

Control Systems Engineering

Whatever your project our team has the skills to help you at any stage; from initial concept to completed design.

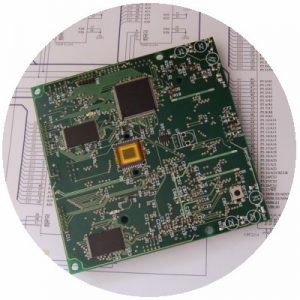

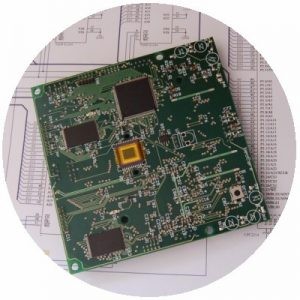

Electronics Development

Tritec offer a comprehensive and high quality electronics development solution to industry, small businesses and start up companies. We provide a complete service, from initial concept through to final production manufacture, and can assist in the compilation of product specifications with our clients to ensure cost effective and efficient designs.

Our philosophy is to use smart designs within all electronics development, reducing complexity wherever possible. This attention to detail at the design stage reaps its benefits throughout the product life cycle – not only reducing component cost and assembly times, but also increasing reliability of the product.

If you think Tritec can help you with any of your current projects or you would like more information please contact us.

3D Printing

Increasingly 3D printing is used for many applications for ‘fit and feel’ or even functional trials; from prototype mounting brackets through to full production enclosures for small run products. Tritec’s in-house 3D printing facility enables it to quickly produce rapid prototypes from its range of FDM 3D printers.

Parts can be printed in a range of materials including PLA, ABS, PETG or flexible TPU. Capable of print volumes up to 300mm x 300mm x 400mm and resolutions down to 50µm, our printers can produce exceptional surface finishes but we can also hand-finish or paint the parts to simulate the final production appearance.

We have a range of 3D printing services:

- Send us a 3D model or an STL file and we can produce your part – in whatever quantities you require – and ship the finished parts back to you.

- Send us a sketch or 2D engineering drawings of a part and we’ll create the 3D model from it, and ship the finished part back to you.

- Or simply give us an outline specification. We can work with you to develop your design, prior to printing and shipping.

Please contact us for more information.

Project Management

Tritec understand the importance of efficient project management for delivering high-quality products on time and to budget. The quality of a design may rely on the quality of the engineers working on the project, but the effectiveness of the final product usually relies on the quality of the project management.

Our experience coordinating multi-disciplinary teams enables us to produce tightly integrated products meeting all the design requirements. Tritec are familiar with all aspects of structured project planning and management and can implement any of the following stages of a project for our clients:

- Resource planning

- Financial planning

- Quality planning

- Risk planning

- Acceptance plan

- Procurement

- Review

Manufacturing

Tritec offers a full manufacturing service, either for production of electronics products developed in-house, or for your own existing designs.

Our production department is very experienced in high precision electro-mechanical assembly and at working to the highest quality standards for clients such as the Ministry of Defence and the nuclear industry.

Prototyping

Tritec can manufacture low volumes of your product for prototyping and testing purposes. We can provide pricing for various quantities, enabling you to choose the most cost-effective option.

Our skilled team can also carry out reworks and modifications to existing hardware where changes are required.

Optical Design

Whether implementing a machine vision system, designing an optical sensor or selecting illumination optics Tritec has the expertise and knowledge of the latest optical design technologies to provide the most effective solution.

Designing illumination systems and specifiying optical filters, Tritec has design experience throughout the visible and infrared spectrum. Tritec has also been involved in many projects involving optical fibres and are experts in the design of fibre optic fusion splicing machines

As part of machine vision projects Tritec has successfully designed sub-micron resolution viewing systems using both CCD and CMOS sensors. Close integration with the image processing requirements of the system ensures that cost effective and efficient designs are achieved.

Mechanical Design

Our mechanical design team has experience in designing a wide range of components from sub-micron alignment mechanisms to ergonomically designed enclosures.

The engineers at Tritec have the expertise to select and design for any manufacturing technique including precision machining, fabrication, castings, 3D printing and plastic mouldings.

Using the latest Creo Elements 3D CAD software enables Tritec to quickly produce rendered images to help visualisation of the designs. Detailed 2D manufacturing and assembly drawings can also be generated from the finished models to provide the complete production package.

Software

Years of development experience across a wide range of platforms and technologies enables Tritec to tackle any software project.

We have a particular focus on producing high quality software – well-structured, well-commented and easily maintainable. This enables easy modifications and the addition of new functionality in the future.

Alongside our own developments, we can bring in-house software which was initially produced elsewhere – for example where it is no longer possible or practical for the original developers to continue with maintenance. Tritec can then modify, fix or upgrade it as required.

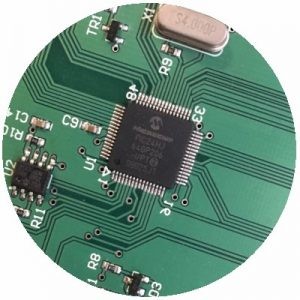

Embedded Microprocessor Design

Experience in embedded C and C++, across 8-bit, 16-bit and 32-bit microprocessor systems enables Tritec to tackle any embedded circuit design. Our capability covers numerous processors and chipsets, and extends across the entire spectrum of embedded development – from bare metal initialisation, through low level device drivers to high level control software.

Embedded software is often developed as part of a complete design solution, in conjunction with electronics hardware designed in-house. However we can also provide embedded software for both bespoke and off-the-shelf external hardware designs.

Hardware

Tritec’s skills cover the complete range of electronics hardware design services.

Our experienced hardware designers use simulation tools to optimize and prove designs, with system modeling and circuit proofing before commitment of design to prototyping. Best practice and in-house gained knowledge then ensure that your product has the best opportunity of achieving electromagnetic compatibility during its compliance testing – negating the need for multiple test submissions and hence a quicker time to market.

For those clients wishing to take their product to market we offer in house manufacturing and technical product support. Alternatively we always supply a comprehensive manufacturing package for any clients who want to manufacture elsewhere.

Process Control Design and Build

Tritec’s experience in control systems engineering enables us to offer process control design and build capabilities in all aspects of process automation.

Our capabilities include:

- PLC Design (inc Mitsubishi, Allen Bradley and Siemens PLCs)

- Multi-axis Servo Systems Design

- Pneumatics Systems Design (including SMC & Norgren)

- Safety System Design (including Pilz PNOZ)

- Control Panel Design, Build

- Human Machine Interface (Keypads & Touch Screen)

- Embedded PC Controllers (with Win32 front-end)

- Integration with existing client Control Systems

- Mitsubishi MELSMART Approved Motion Systems Specialist

Concept

Occasionally clients come to Tritec with a great product idea but are uncertain of the best way to proceed. Tritec can work with them at this early stage; discussing the concept, making recommendations and refining their ideas.