FTL Technology Ltd

FTL Technology delivers custom engineered solutions for critical applications.

Across a wide range of industries, from oil and gas through to food and pharmaceuticals, our experienced team of engineers will optimise the efficiency of your business by resolving problems based around leakage, friction and wear.

From single components to complete sealing systems, FTL Technology focuses on the needs of the customer as well as the application. This allows us to deliver excellence as standard across every project we undertake. Whatever your sealing challenge, our team has the experience and hte expertise to deliver a precision engineered solution.

Custom Seal Kits

At FTL Technology, we believe in the importance of custom engineering for the best possible outcomes. Using our experience and our global network of trusted supply partners, we can assemble a custom sealing kit containing all the elements required to keep your application performing to its full potential.

Our team of sealing experts and engineers will recommend the components and materials to work best for the unique demands of your application. Supply lines are fast and reliable, resulting in quicker lead times and cutting your operational downtime to a bare minimum. With downtime low and efficiency high, you can concentrate on giving the best level of service to your customers.

Whatever your sealing challenge, FTL Technology can give you a fast, high quality solution precision engineered to your exact application.

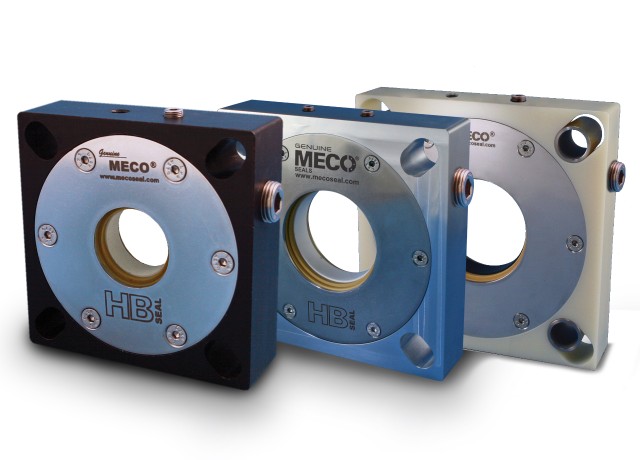

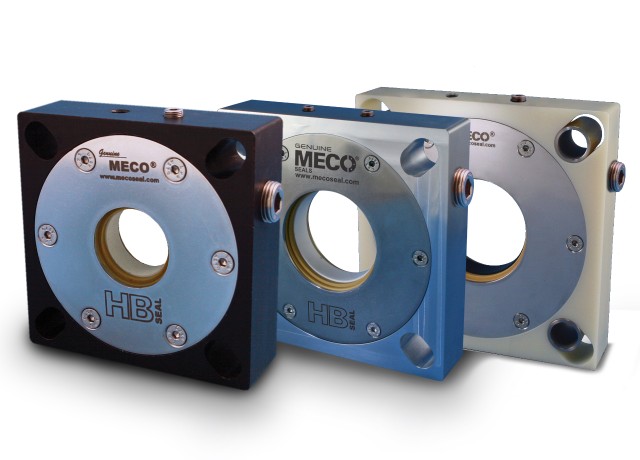

MECO Seals

The innovative MECO shaft seal is designed specifically for process machinery, where braided compression packing and conventional mechanical seals fail to provide an efficient seal system.

With a MECO mechanical shaft seal, FTL Technology will help reduce downtime and material losses, improving overall efficiency.

Unlike other sealing systems, MECO seals:

- Accommodate shaft runout up to 6mm

- Won't fret or undercut the shaft

- Can be installed on damaged or worn shafts

- Have split capability, for simple installation and reduced maintenance

- Tolerate angular misalignment

- Allow condition monitoring and aid preventative maintenance

Unlike conventional seals, a MECO seal can be adjusted in the field for peak performance throughout its entire service life - and because FTL Technology delivers unique sealing solutions which can't be found on the shelf, our experts can retrofit to almost any mechanical shaft system.

MECO seals can be FDA and ATEX approved, and compatible with virtually all media.

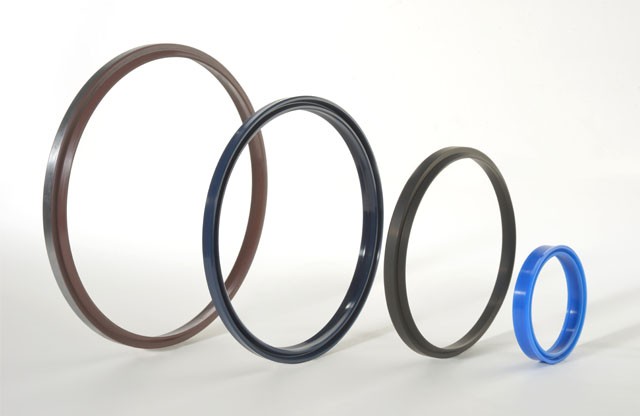

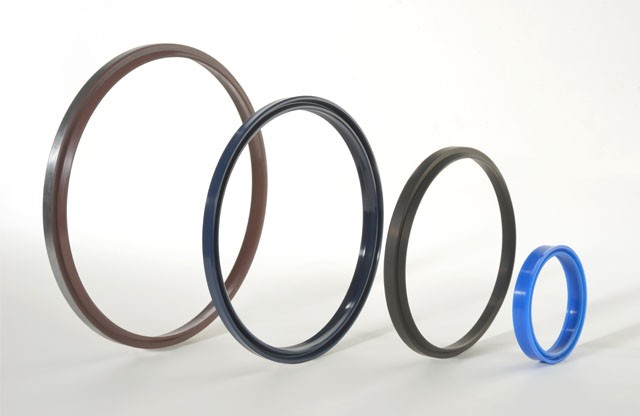

Mechanical Face Seals

Mechanical face seals are synonymous with heavy duty rotary sealing applications. They are specifically designed to operate in environments where there is a high level of external contamination such as mud, sand, dirt and water.

Their robust simple design can be packaged neatly into a wide variety of equipment where reliability and a long service life are imperative to ensure end user satisfaction.

FTL Technology’s seal rings are manufactured from a close grained cast iron material to offer the very best combination of wear and corrosion resistance. The excellent tribological characteristics of this material allow mechanical face seals from FTL Technology to be used in applications with a rotary speed up to 10m/s. Under extreme service conditions, the metallurgical qualities of our cast iron material provide outstanding resistance against seizure and scoring.

The seal rings are statically sealed and have their face load generated by two toric O ring seals. These are critical elements to ensure maximum performance of the overall seal system. High thermal resistance, chemical compatibility and low compression set are essential criterion for toric O-ring seals.

Our elastomers have all been specified to have an ideal spread of mechanical properties required for specific use with mechanical face seals. A range of NBR, HNBR, VMQ and FPM materials and hardness are available which allow mechanical face seal solutions to be used in a wide range of demanding applications.

Heavy Duty Rotary Seals

FTL Technology has long been a supplier of heavy duty rotary seals into the steel, marine, paper and power industries. Our knowledge and experience of these sectors coupled with our appetite for solving sealing problems, makes FTL Technology an ideal partner to work with.

Our product solutions are specified as original equipment for reliability and performance or into the MRO market in response to customers wishing to improve the reliability of their equipment. Seals are manufactured in NBR, HNBR and FPM compounds to suit all operational and ambient conditions. Seal geometries are available which can withstand pressures up to 5 Bar (72 PSI) and peripheral speeds up to 40m/s.

Our engineers provide a consultative service where to ensure that the application parameters, seal specification and surrounding hardware are perfectly aligned. With this, we can be sure that seal systems designed and manufactured by FTL Technology achieve the expectations of our customers.

Heavy Duty Hydraulic Seals

FTL Technology has long been a supplier of heavy duty hydraulic seals into a wide range of industries, including steel and metal processing. Seals are manufactured in NBR, HNBR, FPM and PTFE compounds to suit a broad range of operational and ambient conditions. Seal geometries are available which can withstand pressures up to 600 Bar and linear speeds up to 5m/s.

Our seal systems are optimised to the exact needs of each application. In the case of gauge control cylinders for example, short strokes and high frequencies have to be accommodated whilst imparting the least amount of friction and stick slip. In this case, a combination of PTFE composite seals and wipers would be used to ensure superior sealing performance and a long service life. For seals used on the main ram of an extrusion press, rubber fabric chevron seals are the chosen solution to ensure maximum durability and reliability.

Our engineering team provides a consultative service to ensure the application parameters, seal specification and surrounding hardware are perfectly aligned. With this, we can be sure that seal systems designed and manufactured by FTL Technology achieves the high expectations of our customers.

Advantages

- High sealing efficiency

- Optional split design

- Low friction

- High media compatibility

Common Applications

- HAGC cylinders

- Bend and balance rams

- Forging presses

- Extrusion presses

- Segment cylinders

Pneumatic Seals

Ensuring that a pneumatic seal system performs efficiently without leakage is the primary goal when specifying a suitable pneumatic seal system. Pneumatic seals themselves stay leak free by minimising friction and wear. This is achieved by a complex combination of material performance and geometric design. Since pressures are generally limited to 10 bar, the use of single system rod, piston and wiper seals are typically used.

Rod Seals

Rod seals are installed in reciprocating equipment to retain compressed air or oil under high pressure. They should operate individually or in combination with other rod seals to produce an efficient leak-free system. The design and material of rod seals varies greatly and is dependent on the specific application. Your FTL Technology engineer will use their sealing experience to specify the right design for any application in any relevant industry.

Wiper Seals

Wipers, or scrapers, are used to scrape dirt, foreign particles and moisture from shafts as they retract into the system, preventing damage to internal components. FTL Technology can supply wiper seals in metal, PUR, NBR, FKM and filled PTFE materials to meet the specific demands of any application. Wiper seals can be adapted for operation in pneumatic, hydraulic or heavy duty systems, improving sealing efficiency and protecting equipment against unscheduled downtime.

Piston Seals

FTL Technology offers a wide range of piston seal solutions, with any design carefully considered for optimal alignment to your application. Pistol seals can operate either individually or in compact form as a double-acting system to ensure the control or eradication of leakage across the piston. Our engineers can help to develop a piston seal solution suitable between 10 bar pressure and over 400 bars, where high extrusion resistance is critical.

Advantages

- Low friction

- High sealing efficiency

- Simple installation

- Large thermal temperature range

PTFE Seals

FTL Technology is a leading authority when it comes to providing engineered solutions using PTFE seals. We offer a wide range of PTFE compounds for applications that require a seal to perform in demanding application conditions.

FTL offers a range of PTFE seals in various different profiles for different applications, including rotary shaft seals, rod seals, piston rings and spring energized PTFE seals.

To ensure PTFE seals provide optimum sealing, the base PTFE compound is mixed with fillers to improve the mechanical properties of the material. Tensile strength, extrusion resistance and hardness are improved by adding commercial compounds such as bronze, carbon and glass fibre.

Where extreme levels of abrasion resistance are required - especially those found in dry running applications - advanced inorganic fillers are used which enable performance boundaries to be stretched even further.

Advantages

- Low friction at high pressures and speeds

- Low stick slip

- High media compatibility

- High abrasion resistance

- Simple installation

Inflatable Seals

Inflatable seals are toric elastomeric seals with a hollow section, filled either pneumatically or hydraulically to create an effective sealing solution.

Common applications include airlock doors and hatches, dome valves and sterilising equipment, frequently used in the semiconductor, food process and chemical industries.

FTL Technology will work to identify the key challenges you face in your application, before designing an inflatable seal solution optimised to your unique operational requirements. Get in touch with a specialist FTL sealing engineer to learn more about inflatable seals.

Spring Energised Seals

Spring energised seals, also known as 'all-in-one' T-seals, are used in a wide range of static and dynamic applications, particularly in extreme temperatures with high resistance to chemical media.

FTL Technology will use high performance elastomers and precision spring geometry in order to optimise a spring energised seal for the exact demands of the application.

These seals also deliver outstanding extrusion and compression characteristics.

Advantages

- Low friction coefficient and compression set

- Capable of sealing at high speeds, up to 15 m/s

- Universal chemical compatibility

- Good thermal resistance

- Withstands pressures above 2000 bar (back-up rings)

Compression Packings

Compression packing, also known as braided packing, varies by both braid materials and braiding methods. Both gland packing and shaft packing for pumps and valves can be optimised with the correct material choice for the pressures, temperatures and media encountered. Ranging from cotton to graphite packing braid choices, our engineers can design a combination to perform best in your application.

FTL Technology can identify the correct packing material for your requirements, with considerations ranging from pressure and temperature extremes through to material compatibility. By advising on the right choice of material, our engineers can help your pump or valve require less frequent maintenance and a longer lifespan.

Why FTL for Packings?

- Product Quality | We enjoy a proud reputation for our consistently exceptional standards, working with both OEM and MRO alike

- Flexibility | We supply standard and customised setups, as well as uniquely tailored sealing kits for every kind of pump and valve

- Volume | We have the resources to meet both low and high volume requirements, delivering what you need when you need it

- Support | We provide a uniquely personal service from the first call to completion, working hard to exceed every expectation

Across oil and gas, power generation, food, pharmaceutical and chemical processing applications, our experienced team of sealing engineers can advise you on the optimal packing material for your exact specifications. With FTL Technology, your equipment will perform to a higher standard with greater reliability and lower operating costs.

Gaskets

Gaskets from FTL Technology are specifically engineered to be highly effective and reliable mechanical seals under the stresses of high compressive loads and extreme temperature ranges.

FTL gaskets are manufactured from combinations of metallic elements and soft sealing materials, with different arrangements delivering different properties beneficial to a range of industrial applications. Installation is simple, keeping your operational downtime to an absolute minimum.

Our gasket ranges are available in a number of standard thicknesses, but we are happy to engineer a gasket to your exact specification.

Our range includes:

- Kammprofile gaskets

- Metal jacketed gaskets

- Spiral wound gaskets

Bearings

Plain bearings are predominantly used in reciprocating applications, but can also be found in rotary or oscillating applications.

By operating without the need for additional lubrication, plain bearings offer a high degree of flexibility to the application designer. Often working in close conjunction with a sealing system, plain bearings help to reduce system friction and wear as well as running costs.

FTL Technology has the experience to specify a material and manufacturing process which optimises seal performance under any conditions. With other considerations including the criticality of the dynamic interface, and special coatings to artificially generate optimal surface conditions, FTL Technology is the team to trust for bearing solutions.

Our bearings are available in a range of materials, including:

- Carbon

- Thermoplastic

- PTFE

- Polyester

- Glycodur

- Composites