Thermofax Ltd

With over 50 years experience within the heat treatment trade, our commitment to a quality product and customer satisfaction has been the backbone on which this family business has been built.

We house the biggest furnaces in the Midlands and Southern Regions, and have the flexibility of plant to accommodate charge weights ranging from 1 Kilo up to 30 Tonnes

They range in capacity from 1 Kilo to 30 Tonne charges.

Our general process capabilities are

- Post Weld Heat Treatment

- Stress Relieving

- Annealing

- Normalising

- Solution Treatments

- Age Hardening

- Lifting Capacity of 16 Tonnes

- 10 Large Furnaces

- Largest Bed Size of 7000mm x 8000mm

Metal Heat Treatment Specialists

Since forming in 2001, Thermofax has established an impressive reputation for sub-contract metal heat treatment services within the UK

Through continued improvement and investment, Thermofax has gone from strength to strength allowing us to become a dominant force within the metal heat treatment industry, whilst still achieving high customer expectations and consistently providing quality products and customer satisfaction.

Industries Served:

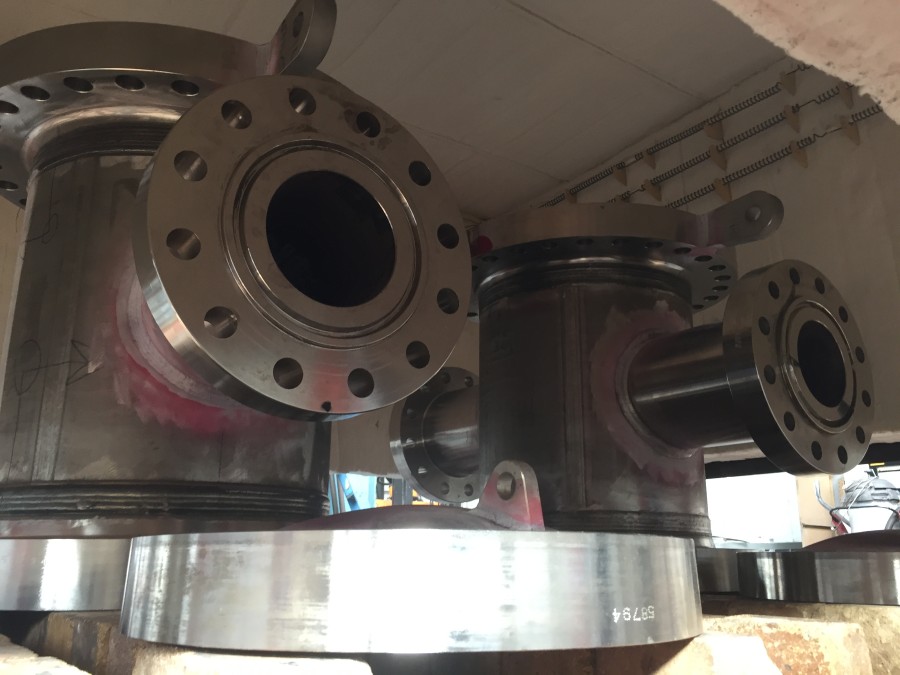

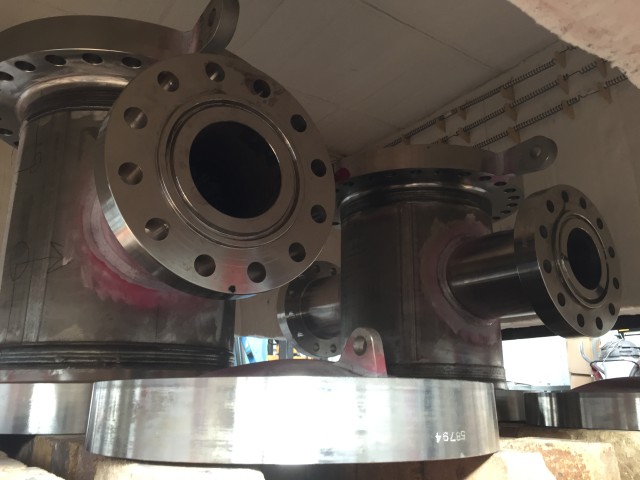

- Petrochemical

- Oil and Gas

- Power Generation

- Automotive

- Defence

- Marine

- Aerospace

- Construction

- Agriculture

- Food Processing

For more information please contact our technical sales team on Tel: 01384 230214

Annealing

- Sub-Critical Annealing

- Spherodise Annealing

- Isothermal Annealing

- Lamelar Pearlitic Annealing

- Austenitic Annealing

- Re crystallizing

- Solution Annealing

- Tempering

Materials Generally Processed

- Carbon and Alloy Steels

- Stainless Steels

- Tool Steel

- Boron Steel

- Non-Ferrous Metals

- High Temperature Steels

- Corrosion Resistant Steels

- Bolting Grades

- Petrochemical Grades

- Power Generation Grades

- Nickel Alloys

Batch Sizes: up to 15 Tonnes

Max Length: 7.3m

Normalising

- Normalising

- Normalise and Temper

- High Temperature Softening

- Solution Treatment

Materials Generally Processed

- Carbon and Alloy Steels

- Petrochemical Grades

- Power Generation Grades

Batches: up to 30 Tonnes

Maximum: single bar length – 9.3m

Stress Relieving

- Post Weld Stress Relieving to Procedure Including: ASME VIII, BS31.1, PD5500

- Stabilizing Treatments

- Thermal Stress Relieving

- Profile or manipulation Stress Relief

- Material Specific Stress Relieving

Materials Generally Processed

- Carbon and Alloy Steels

- Cast Iron, Grey Iron, SG Iron

- Stainless Steels

- Non Ferrous Metals

- Petrochemical Grades

- Power Generation Grades

- Nickel Alloys

Fabrications: up to 9m length

Maximum Diameter: plates/rings 6.5m

Please e-mail us with your enquiry sales@thermofax.co.uk

Procurement

If we cannot accommodate your requirements within the capacity of our plant, or do not carry out the process, we will be able to offer an alternative supplier within our heat treatment community.

We can also source solutions for other associated processes including:

- Straightening and Reeling

- Flattening

- Sawing

- Laboratory Testing

- Shot Blasting

- Chemical Cleaning and Pickling

- Steel Sourcing

Tempering

- Tempering up to 7.3m

Carbon and Alloy Steels

Bolting Grades, B7, L7

Non Ferrous Metals

- Oxidisation of Titanium Tubes

- Creep Flattening of Titanium

- Paint Burn Off

- Refractory Dry Out

Thermofax Ltd

Block 2, Grazebrook Industrial Park

Peartree Lane, Dudley

West Midlands, DY2 0XW

Tel: 01384 230214 Fax: 01384 253551

Email: sales@thermofax.co.uk