Induction Pipe Bending UK Ltd

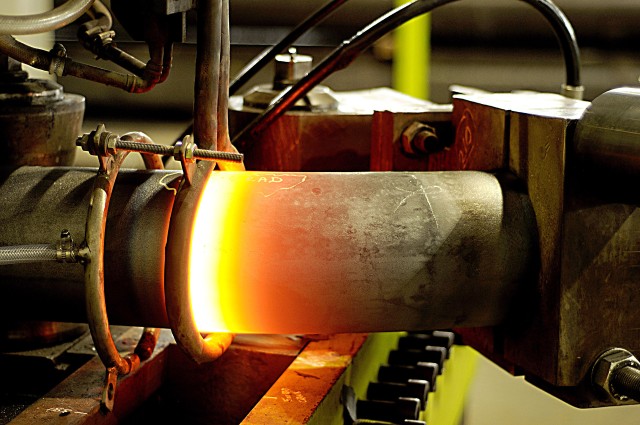

We provide induction pipe bending for companies in the offshore oil and gas production, general and process pipework and the power generation sector.

We are able to offer outstanding post-bend heat treatment applications that provide an extensive range of treatments. To help reach all our customers requirements we provide a comprehensive selection of services, additional to induction pipe bending, that includes destructive mechanical testing, non destructive testing, UKAS approved laboratory, bending, polypropylene and polyethylene coating treatments, grit blasting, pickling, and chemical cleaning.

We also provide packing and transport both internationally and within the UK. We can transport via air, sea or road and all deliveries are third party-inspected through certified agencies.