GB Innomech Ltd

GB Innomech Ltd – Bespoke Automation SpecialistsGB Innomech excels at developing and producing innovative electro mechanical prototypes, special purpose machinery manufacturing, and bespoke automated equipment, improving our customers productivity, profitability and complianceCambridge based, with over 20 years’ experience producing feasibility studies, prototypes, bespoke automation control systems and automated assembly machinery for the pharmaceutical, medical device and other technological industry sectors, GB Innomech offers a committed team with experience in specialist automation including robot handling, PLC control, pick and place and vision systems, with skills in mechatronics, production automation, specialised automation control systems engineering, innovative bespoke design, and validation.

GB Innomech

GB Innomech is recognised as one of the UK’s leading Laboratory Automation, Industrial Automation and Manufacturing Automation specialists, offering development services to new, early stage businesses as well as some of the established FTSE 100 companies. Size is not important; but we take great pride in our ability to establish strong long term relationships at both the organisational and individual levels.

Our Quality Management System is assessed against ISO 9001:2008 and in 2009 we were awarded the Queen’s Award to Industry.

Capabilities

You have a requirement to reduce manufacturing costs or increase quality using sophisticated laboratory automation, manufacturing automation, process automation and inspection. We have the expertise and experience to analyse, design and implement your automation solutions.

Whether we are called upon to design a bespoke automation solution or build and service a number of high value repeat products our approach is founded on our understanding of how to apply different technologies as well as application specific knowledge.

Technologies

The diversity of experience that our engineering team has gathered over the years enables us to confidently select and combine techniques based upon a sound understanding of their benefits and possible limitations and integrate these to your application. Being able to combine different technologies with confidence, enables us to design and build innovative solutions that will reduce product cost and improve product quality.

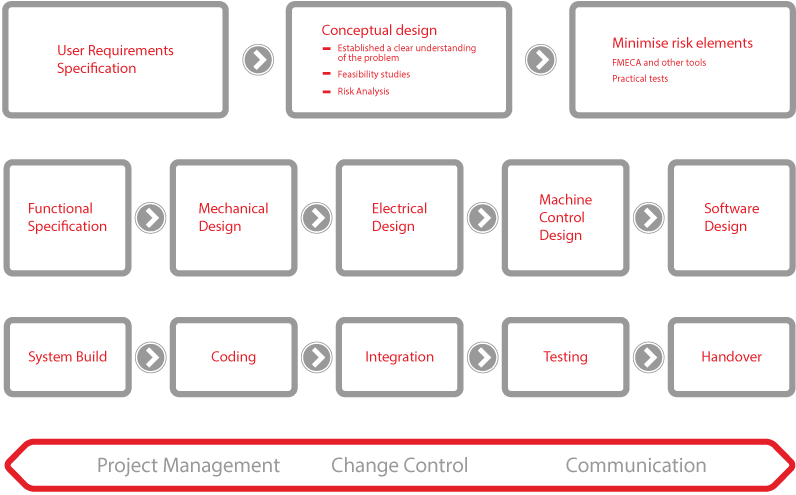

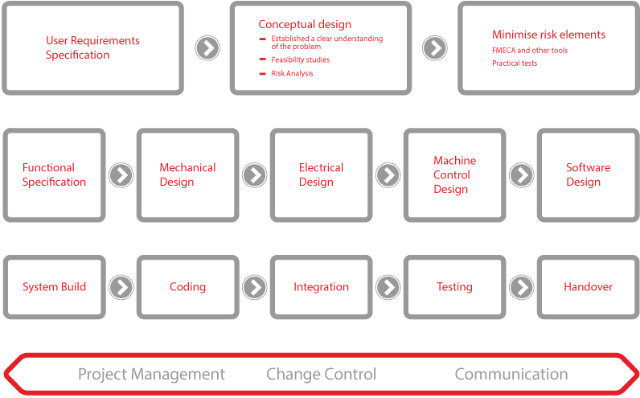

Methodology

Our risk based approach, where we undertake risk assessments throughout the project, and where we solve the ‘real’ problems, which are often different to those first perceived, has led to a strong reputation for providing innovative solutions within regulated environments. Product Development and Process Development are both extremely important aspects within this approach, which may incorporate Design studies and Feasibility studies.

Sectors

We have undertaken a substantial body of work in the Aerospace, General Engineering, and Automotive sectors and are able to apply this understanding to your project. Today our main experience lies within the Biotechnology, Laboratory and Medical sectors which have considerably influenced how we work. Again we are able to apply this knowledge to your project.

Precision Handling and Assembly

The assembly automation challenge is to move from manual or semi-automatic solutions to semi-automatic or fully automated solutions. Often assembly systems call for a transport and handling system with a high degree of positioning accuracy (in all directions) and tightly controlled accelerations and decelerations, to avoid damaging the product whilst maintaining very short index cycles. Robotic solutions are often a key element to the overall process solution.

Precision Laser Cutting and Laser Drilling

GB Innomech has used lasers extensively for non contact precision cutting systems. These fall into 3 main types, Xcimer, YAG and CO2 lasers, each having different characteristics and many variants which have to be matched to the specific precision cutting applications.

Precision Handling and Vision Inspection

In order to cope with increasingly stringent quality standards companies need to find a faster and more flexible method to inspect and measure production. The product handling characteristics and the optimum vision inspection solution, including lens type and lighting for inspection and appropriate techniques for measurement should all be assessed against the background of the range of products and speed of handling required.

Needle Winding

The machine is PC controlled enabling patterns to be stored and called up when necessary. Patterns can be edited or new patterns created upon demand. The machine uses high power brushless servos, belt drives and linear slides to provide tensions up to 1000N at 10g acceleration and phase locked speed of 4m/s. This is achieved whilst guiding the needle and wire in the stator slot with only 0.2mm clearance.

End of Line Testing

Efficacy and user safety depend on every device being assembled correctly and each of several components having mechanical properties within tight specifications. The challenge is to confirm these properties on fully assembled devices as they emerge from the manufacturing process.

Precision Powder Dispensing

Working with a variety of companies, including pharmaceutical, to enable the accurate dispensing of powder into containment systems.