JCS Technology

We are providers of an unrivalled, professional and comprehensive accredited testing service. Our independent material and product accredited testing service covers various areas.

They include:

- Mechanical - A comprehensive service for the determination of mechanical properties of both materials and components. In addition to four universal testing machines with temperature capability, we offer impact, vibration, wear and more

- Environmental/ageing - Thermal shock through to humidity, temperature cycling including salt spray and industrial gasses

- Flammability - Full range of testing from horizontal to smoke and toxicity

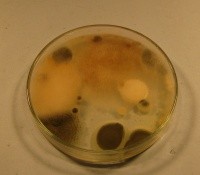

- Microbiological/fungal growth - Screening, detection and culture for food based, aerospace and other industries

- Chemical analysis - In addition to standard chemical methods, we also offer instrumental techniques

Electroplating and Surface Treatment

We are used to working with electroplating and surface treatment companies. We can offer a range of services specific to your industry. From chemical analysis of plating solutions, to current density calculations, to adhesion tests and tank contamination levels.

We are an independent, technical consultancy and an UKAS accredited, ISO certified test laboratory.

We are dedicated to ensuring our clients' products and services meet their requirements for safety, quality and performance through the testing and consultancy services we provide.

Mechanical Testing

Our extensive accredited testing services also cover mechanical testing for a variety of requirements. Our service is confidential, established, independent, and our accredited testing service also extends to a consultancy service.

Mechanical testing includes:

- Tensile testing

- Flexural testing

- Pull and peel testing

- Compression testing

- Shear testing

- Creep testing

Mould Testing

We specialise in mould testing. Our mould and mould growth challenge testing also includes a wide range of testing procedures for mould in our dedicated microbiological facility. We have assisted clients requiring mould challenge testing for a wide range of materials and products.

Our mould testing services include:

- UKAS accredited mould growth challenge testing

- Mould identification

- Shelf life testing

- Food testing

Environmental Testing

Our various accredited testing services include environmental testing.

This environmental testing includes salt spray, neutral, acidic and toxic gases for which a range of chambers sizes are available.

- Ozone testing

- Dust testing

- Fluid susceptibility

- Humidity and pressure testing

- Altitude testing

- Weathering UV/solar

- Cyclic testing

- Water testing

NEW FOR 2012

ULTRA HIGH VACUUM TESTING - Dedicated ultra-high vacuum facility to simulate space and other environments. We can provide an Evaluation of Product, Material and Surface Coatings in this unique environment.

ANOTHER NEW SALT SPRAY CHAMBER AND EXTENSION OF UKAS ACCREDITATION

Burn Testing

Our extensive services also cover burn testing. A full range of burn tests are available from horizontal burn tests to flammability testing for fuel tanks. Burn testing can be conducted to a range of standards such as FAR, JAR, BSS, BS, EN, ISO, ASTM and DIN.

- Smoke testing

- OSU testing

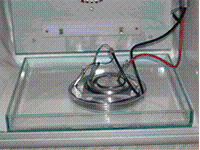

Electrical Testing

We provide a vast selection of electrical testing procedures and services. As an independent and accredited facility we are able to offer our clients the confidence in the results and service that we provide. Within the electrical testing area, we can offer a range of tests. Some are detailed below or contact us directly to discuss your further requirements.

- Voltage measurements in the mV to kV range, for both DC and AC

- Current measurements in the mA to 100 A range, for both DC and AC

- Resistance measurements in the mΩ to GΩ range

- Surface resistivity indicates conductivity and insulation resistance

- Volume resistivity indicates antistatic behaviour

- Insulation resistance

- Temperature forcing from -65°C to +150°C (environmental test)

Failure Investigation

Our experienced and dedicated team have been investigating and resolving product failures for many years. This failure investigation experience allows us to recognise indicators of failure and follow these leads to their possible root cause.

With our failure investigation skill and experience, we help you to define the problem and then recommend solutions.

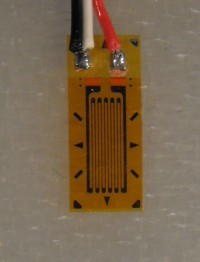

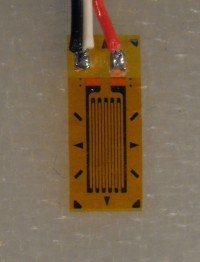

Strain Gauging

We also have significant experience with strain gauging. We have the training and experience in attaching strain gauges to a wide range of materials from composite through to ceramics.

Strain gauging of tensile samples for both longitudinal and transverse strain measurement is routine and we can encapsulate our gauges to enable conditioning of the specimen.

Physical Testing

We also carry out physical testing. These physical testing services cover all requirements and application requirements to ensure optimum safety and reliability.

Prepreg analysis is a standard suit of tests for prepreg prior to moulding:

- Resin content - usually using solvent wash to remove resin and leave the fibre

- Fibre content - remaining when resin removed

- Flow - the ability of the resin system to move just before it gels so that it is able to wet out the fibres and to bond between layers of a laminate. Good QC tool for ageing resin systems

- Volatiles - determination of the lower boiling point solvents

- Resin gel time - the time the resin takes to reach a gel point

Panel fibre content, fibre volume and void content:

- Using burn off - this is used a lot with glass fibre/resin systems. The resin is burnt off and the fibre cooled and weighed. Standards such as ASTM D2584 and BS 2782 Pt10 M1002 loss by ignition

- Acid digestion - used a lot with carbon fibre systems. The resin is dissolved in boiling sulphuric acid and then oxidised. The remaining fibres are dried and weighed. Standards such as ASTM D3171

- Adapted digestion - used for Kevlar fibre and thermoplastic fibre systems

- Density - using a variety of techniques such as BS903-A1 (ISO 2781)

- Colour - using a range of spectrometers

- Melt flow rates - for a range of materials. Standards such as ASTM D1238 ,ISO 1133, BS2782 Pt7 method 720,BS EN ISO 1133

- Wear testing - a variety of loads and substrates

- Hardness testing - a wide range of hardness tests using different indenters

- Compression set - a range of both temperatures and setting can be used. Standards such as BS903-A6, ISO815, BS ISO 815-1 Ambient+

- Medical - BS ISO 11948-1 urine-absorbing aids, Part 1 whole product testing

- Permeability testing - a range of tests available

- Soil testing - physical and chemical tests available

- Viscosity - determination the viscosity of oil using a range of techniques including a redwood viscometer

Chemical Analysis

We believe to achieve the performance required of a modern analytical laboratory requires both the deployment of skilled staff and advanced instrumentation. This coupled with being an independent and accredited laboratory gives you our customer the reassurance of both flexibility and confidence in our service.

This ethos and work ethic extends to our chemical analysis services. With our chemical analysis, we are able to combine a comprehensive range of both classical wet chemistry and instrumental techniques to give the most cost-effective solutions to most chemical problems.

Corrosion Gasses

JCS Technology supply Corrosion Gasses. For more information on Corrosion Gasses please contact us on +44 (0) 1934 644866 or ken@jcs-tech.co.uk

Mixed Gas

JCS Technology is an Independent accredited laboratory, started in 1993 with qualified and committed staff. For more information on Mixed Gas please contact us on +44 (0) 1934 644866 or ken@jcs-tech.co.uk

Electrical Resistance-coatings

JCS Technology offers accredited testing and consultancy services. We specialize in the testing of products and materials such as adhesives, composites, grease, foams, fillers, paint, coatings and more. For more information on Electrical Resistance-coatings please contact us on +44 (0) 1934 644866 or ken@jcs-tech.co.uk

Wear

JCS Technology offers accredited testing, preparation, materials and consultancy services. For further information on Wear please contact us on +44 (0) 1934 644866

or ken@jcs-tech.co.uk

Fungus

JCS Technology is an Independent accredited laboratory, started in 1993 with qualified and committed staff. We specialize in the testing of products and materials such as adhesives, composites, grease, foams, fillers, paint, coatings and more.

For more information on Fungus please contact us on +44 (0) 1934 644866 or ken@jcs-tech.co.uk