Laser Cutting Company Ltd (The)

The Laser Cutting Company are one of the UK's leading laser cutting companies offering flatbed, tube, box, hollow, open section and 5-axis laser cutting services for companies throughout the UK.

With over 30 years experience, we have been providing laser cut components and laser cut assemblies for fabricators, OEMs, constructions and architectural industries, to name a few.

Our tube and 5-axis laser cutting enables us to easily cut slots, tags, bevels, weld preps and cod mouths into a wide range of section sizes, shapes and thicknesses.

For more information on our laser cutting services, please visit our website.

The Laser Cutting Company - Your partner in production.

Efficient

Whether you need flat profiles or tubular parts, free issue cutting, large batch or small batch production runs, We can be your ideal partner with;

- State of the art machines

- Technically competent and helpful staff

- Fast turnaround of cut parts

- Reliable and quality parts output

Capacity

Maybe you need laser cut stainless steel, mild/carbon steel, ERW (Electric Resistance Welded), Hermtic Seal Technology (HST) or cold drawn metals in a variety of hollow and open section shapes. Including;

- Tube (Circular Hollow Section CHS)

- Box (Square Hollow Section SQS / Rectanguar Hollow Section RHS)

- Angle

- T Section

- Channel

- Structural Beams (I beam, H beam etc)

We stock and/or purchase for customer specific needs, mill direct, if applicable.

Effective

We don't just rely on our capacity and laser cutting facilities to set us apart from the competition, by working with us we strive to provide effective services, such as:

- Speedy estimates

- Technical assistance

- Sample projects

Precise

Get ahead of the game with a laser cutting partner who values your business and understands your needs. Call the Team today, we'll be happy to help.

Jon Day - Managing Director

Rachel Sears - Sales Manager

Alan Hirst - Production Manager

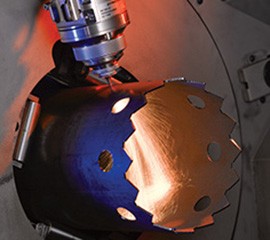

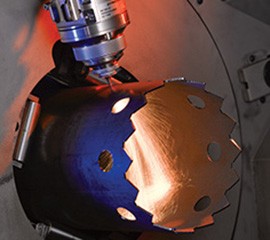

Laser Tube Cutting

We provide high quality, cost effective laser cutting of a range of tubular hollow sections. Utilising our 4 dedicated state-of-the-art tube cutting machines, we can handle a wide range of tube/box sections including:

- Circular Hollow Section (CHS)

- Oval Hollow Section

- Square Hollow Section (SQS)

- Rectangular Hollow Section (RHS)

For more information on our tube laser cutting services and how we can save you time and money with our innovative multi-axis laser cutting, please contact our Sales Team.

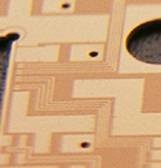

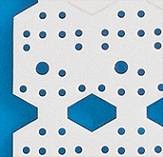

Laser Profiling

Laser machining flats, slots and complex shapes.

Tolerances for cost effective manufacture are:

1. length and width between profiled edges +/- 0.05 mm

2. profiled edge to hole centre +/- 0.05 mm

3. narrowest cut (profiled) slot 0.1 mm

4. corner radius >/= substrate thickness (specify internal corner radii to minimise risk of micro-cracking

Laser Scribing

Accurate and reliable scribing to customer specifications

Laser-scribed substrates are normally supplied without tooling or computer part program costs.

1. depth of scribing normally 30 - 50% of material thickness (or by arrangement)

2. laser pulse spacing normally 0.15+/-0.02 mm centreline to centreline (or by arrangement)

3. edge to design. Border edge to be snapped off should be at least 5 times material thickness

4. length and width between scribed edges +0.15/-0.05mm

5. laser-scribed/laser-profiled edge to first scribe line +0.15/-0.05 mm

6. scribe line to scribe line +/- 0.05 mm

5-Axis Laser Cutting

We provide extremely versatile, precise and cost effective 5 axis laser cutting for a wide range of clients throughout the UK.

Our state-of-the-art laser cutting machines and CNC technology enable use to process the most complex 3 dimensional shapes and can easily include bevel cuts, weld preps and other angled profiles up to 60o.

Laser Drilling

Accurate hole drilling (random or step and repeat).

Minimum hole diameter:

pulsing 0.1 mm

drilling 0.25 mm

Tolerances for cost effective manufacture are:

1. hole diameter +/- 0.05 mm

2. hole tapers ~ 5% of substrate thickness

3. hole centre to hole centre +/- 0.05 mm

4. wall thickness between adjacent holes >/= substrate thickness

5. wall thickness between hole edge and another edge >/= substrates thickness

6. scribed edge to hole centre +0.15/-0.05 mm

7. profiles edge to hole centre +/- 0.05 mm

8. centre of scribed line to hole centre +/- 0.05 mm

Open Section Laser Cutting

Our versatile laser cutting machines enables us to laser cut open sections with an expansive selection of complex angles, shapes and intricate cutting procedures.

Common open profiles and 3D sections include:

- Angles

- V Shapes

- Joists

- Parallel Flange Channels (PFC)

- Rolled Steel Angles (RSA)

- Universal Beams (I, H, T etc)

With many of the profiles listed above commonly found within the construction industry, we can also provide CE Marked laser cut structural steel that meets all EU legislation set out in BS EN 1090-1.

Flatbed Laser Cutting

We've been providing flat bed laser cutting services throughout the UK for over 30 years. Our sub-contract laser cutting services are used by customers in a wide range of industries across the length and breadth of the UK.

We offer laser cut mild steel, stainless steel and aluminium profiles. Please contact our Sales Team for more information on thicknesses and grades.

Other Services

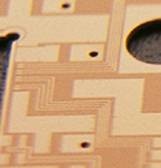

CAMERA ALIGNMENT

High quality circuits can be precision laser cut after printing or sputtering.

PROTECTIVE COATING

A protective coating can be applied before laser processing to minimise classification of molten ceramic.

REFERENCE MARKING AND DATUM CORNERS

Pencil marks, laser hole, scribed cross or other markings can be applied to your specification for positioning.

TOLERANCES

All dimensions are non-cumulative

Additional Services

On top of our sub-con laser cutting services, we provide a range of in-house and resourced services to help reduce your costs and lead time.

Additional services include:

- In-house bending (up to 130 tonnes)

- Drilling and countersinking

- Tapping

- Sub-assembly

- Welding

- Light Fabrication

- Polishing

- Power Coating

- Painting

- Plating

If you require these services, please inform our Sales Team upon enquiry.

Batch Sizes and Lead-Times

Typical batch sizes range from 1 off R & D and prototype work to many 1000s for scheduled work. Our normal lead-time is from 2 - 4 days depending on quantity. We aim to turn prototypes round in 24 hours.

We are happy to receive inquiries by email with drawings in dxf or dwg format. We aim to provide samples within 48 hours from receipt of final drawing subject to material availability.

Ceramtec, Coorstek, Kyocera Approved Suppliers

We laser cut the following materials to customer's designs:

CeramTec Materials Stocked

Rubalit 708S – 96% Al2O3

ALN Aluminium Nitride

Coorstek Materials Stocked

ADS96R – 96% Al2O3

ADS996R – 99.6% Al2O3

ADOS90R – 90% BLACK Al2O3

Kyocera Materials Stocked

A496 – 96% Al2O3

A493 – 99.6% Al2O3

These thicknesses of aluminium oxide are regularly stocked :

| Inches | MM |

| 0.005” | 0.127 |

| 0.006" | 0.15 |

| 0.008" | 0.20 |

| 0.01" | 0.25 |

| 0.0125" | 0.32 |

| 0.015" | 0.38 |

| 0.02" | 0.50 |

| 0.025" | 0.635 |

| 0.03" | 0.75 |

| 0.04" | 1.00 |

| 0.05" | 1.27 |

| 0.06" | 1.50 |

| 0.08" | 2.00 |

These thicknesses of aluminium nitride are regularly stocked :

| Inches | MM |

| 0.01" | 0.25 |

| 0.02" | 0.50 |

| 0.025" | 0.635 |

| 0.04" | 1.00 |

List of Materials Cut

We also cut the following materials:

- Ceramic tube

- Flexible circuit board

- FR4 (Black)

- Garnet

- Graphite

- Kapton polyimide film

- Magnesium oxide

- Mica

- Mylar

- Nomex*

- Nylon 66*

- Perspex

- Polyester

- PTFE*

- Pyrex

- Quartz substrates

- Quartz tube

- Silicon nitride

- Silicon wafer

- Silicone rubber

- Stainless steel foils (up to 0.25mm)

- Zirconia

Thick Film Design Rules

Validities

- The following rules are effective for the draft of thick film structures.

- These rules are continuously updated.

- The instructions are absolutely informative and represent only some guide lines for a circuit design.

Thick Film Design Rules

Materials

Substrate materials:

- Aluminium nitride ceramic (AlN)

- other ceramics in compliance with customer request

Substrates / Panel dimensions:

- standard: 4” x 4”

- maximum: 4.5” x 4.5”

Substrate thicknesses:

- standard: 0.635 mm (25 mil)

- minimum: 0.254 mm (10 mil)

- other thicknesses and shapes in compliance with customer request

Thick Film Design Rules

Ink systems The thick film inks noted below can be used.

Conductor:

- Ag/Pd

- Ag

- Au

- Ag/Pt

Multilayer / Insulation:

- Cross-over or multilayer structures with insulation / dielectric ink.

Layers Structure

Substrates printed on one side:

- Conductor lines recommended as the first printing level.

- Up to 3 conductor layers can be made with dielectric layer between them.

- Subsequent conductor layers will use the same conductor material as 1st layer.

- Multi layer structure is possible with filled via connections through the dielectric layers.

Substrates printed on both sides:

- Single back side layer (not connected to front).

- Drilled filled via connecting front to back side

Layout Rules

Distances of the printed structures to the substrate edge:

All of the following measures are valid for substrate edges as well as for scribe lines, in case of several single substrates were printed on one large substrate:

- distance edge – conductor line: > 0.2 mm

- distance edge – resistor: > 0.5 mm

- distance edge – isolation: > 0.3 mm

- distance edge – glaze: > 0.3

Design of Conductor Lines

Conductor lines in one printing level:

Conductor lines are printed directly on the substrate or the dielectric respectively.

For the minimum conductor width the dimensions below must be kept:

|

On substrate |

On dielectric | |

|

AgPd |

>0.2 |

>0.2 |

|

Ag |

>0.2 |

>0.2 |

|

Au |

>0.15 |

>0.2 |

- When widths and distances are less than 0.25 mm, the distance between two conductor lines should be 0.05 mm larger than their width.

- When widths and distances of the conductor lines are greater than 0.25 mm, they can be printed in the same relation.

- Conductor lines can be printed at any angles to the substrate edge.

- When printing conductor lines on dielectric, a side distance to the dielectric edge of 0.3 mm must be guaranteed.

- When printing over the dielectric edge it is advisable to graduate the dielectric edge

Printing Capabilities

MSP-485 Precision Screen Printer:

- Mechanical repeatability of /- 0.0002" ~ 5 µm

- Advanced U-Lign IV™ system with two high resolution CCD cameras, enable to achieve a +/- 0.001 " ~ 25 µm layer to layer repeatability.

Actual Firing Capabilities

- Max Temperature - 1050 deg.C

- Typical Temp. Uniformity - +/- 2 deg. C

Dicing Capabilities

- Resolution - 0.2 µm.

- Accuracy - 2.0 µm.

- Repeatability - 1.0 µm