Master Bond Inc

Master Bond’s product line consists of epoxy, polyurethane, polyamide, silicone, cyanoacrylate and latex . Master Bond is a leading manufacturer of high quality adhesives, sealants, and coatings. Master Bond caters to the entire spectrum of high-tech applications, including conformal coating, potting & encapsulation, and impregnation. Master Bond’s structural adhesives offer design flexibility and provide excellent bonding performance with a vast array of 3,000 custom designed adhesive formulations. properties differ in viscosity, cure speed, temperature and chemical resistance, strength, electrical and thermal conductivity. Specific adhesive systems can be designed to meet USP Class VI certification for medical use or NASA requirements for low outgassing. Master Bond recognizes that each application presents unique property requirements that must be met. If a compound is not available in Master Bond’s vast product line to meet those requirements, their experienced research and development team will promptly formulate one. Master Bond products are successfully implemented in medical, optical, aerospace, electronic, and other industries.

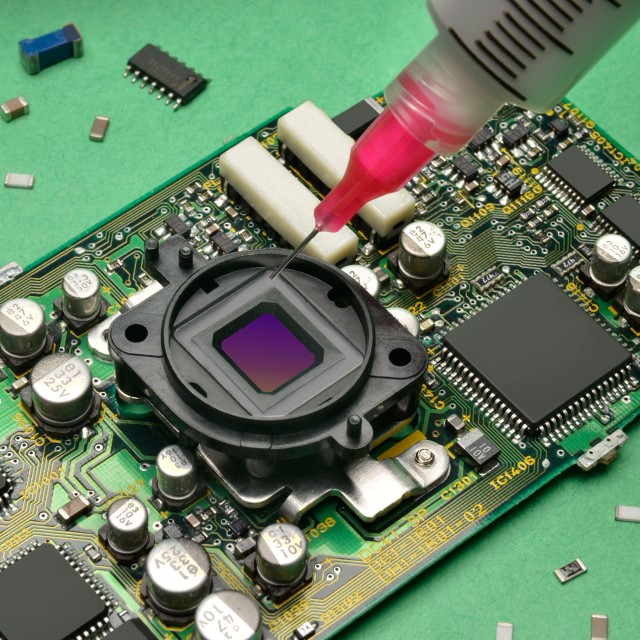

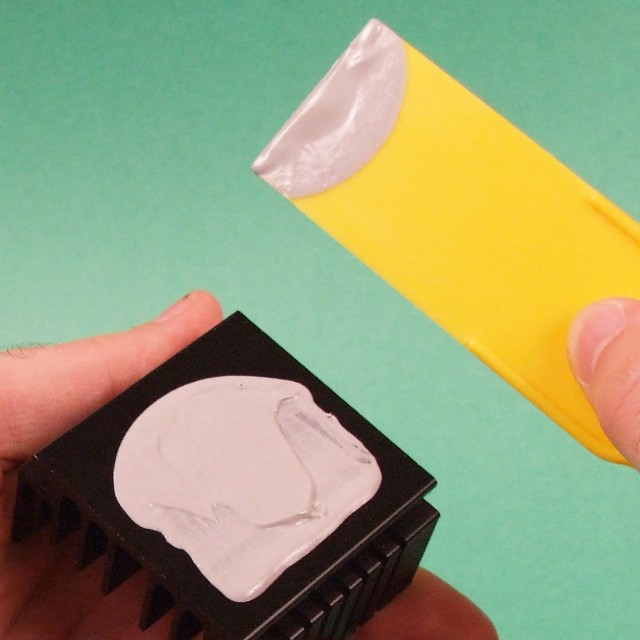

Thermally Conductive Adhesives

Master Bond manufactures one and two component thermally conductive adhesives. They include epoxies, silicones and other elastomeric systems. Special formulations for unusual service conditions are available. They include serviceability to 500°F, at cryogenic temperatures, and in high vacuum environments as well as systems that are easily repairable. Designed for easy application, these compounds can be purchased in convenient packaging. They are used on heat sinks, fan sinks, package lids, motor controls, multiplexers, sensors, power semiconductors and thermistors. Toughened systems have been successfully employed in applications requiring resistance to shock, vibration and thermal cycling.

Thermally Conductive Epoxies: Examples of Master Bond's Products

EP37-3FLFAO

For potting & bonding. Good thermal conductivity. Cures flexible. Meets NASA low outgassing certification. Cryogenically serviceable.

EP21TDCANHT

General purpose, flexibilized epoxy with high thermal conductivity. Widely used for bonding dissimilar substrates.

SUPREME 10AOHT

One part, no-mix, thermally conductive epoxy adhesive/sealant. Unlimited working life at room temperature. Oven cures at 250-300°F. Excellent physical properties. Exceptional performance.

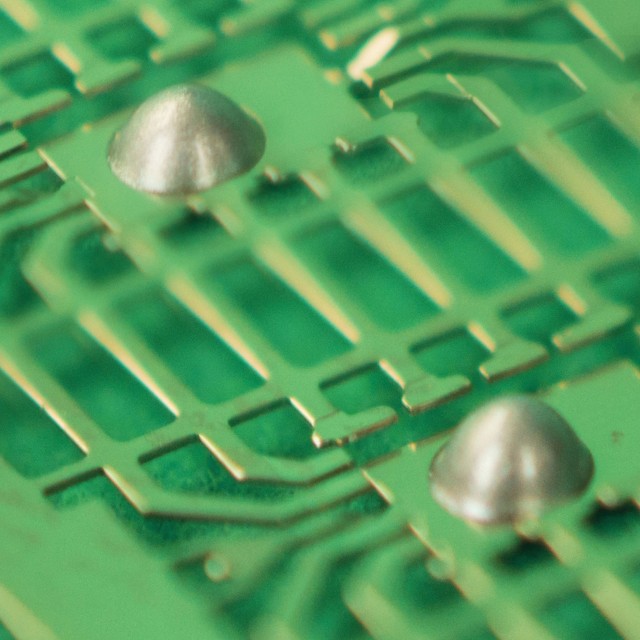

Electrically Conductive Adhesives

Master Bond’s line of electrically conductive adhesives is the number one choice for the design of tomorrow’s advanced electrical circuitry. Nobody offers more choices or solutions. The Master Bond product line includes silver, nickel, copper and graphite filled compounds. Master Bond even offer silver coated nickel systems for low resistance where cost effectiveness is crucial. Specific compounds are designed to cure at ambient temperatures or upon brief exposure to elevated temperatures. The cured products offer high physical strength, superior substrate adhesion and uniform electrical conductivity even upon exposure to hostile environmental conditions. Long term durability is excellent.

Electrically Conductive Epoxies: Examples of Master Bond's Products

EP21TDCS

Silver-filled, electrically conductive epoxy with low volume resistivity. Cryogenically serviceable. Good thermal cycling characteristics. Easy to process with a convenient 1:1 mix ratio. Superior physical strength properties.

SUPREME 10HTS

Superb, silver-filled epoxy adhesive/sealant. One part, no mix system. Heat cures at 250-300°F. Cryogenically serviceable & high temperature resistant. Meets NASA low outgassing specifications.

EP75-1

Graphite-filled epoxy adhesive/sealant for use in specialty applications as well as EMI/RFI shielding where a non-metallic filler is required. Superb resistance to moisture and chemicals. Exceptional durability.

Chemically Resistant Adhesives

Master Bond’s chemically resistant products include epoxies, polyurethanes, polysulfides, silicones and UV cures. They systems resist exposure levels ranging from occasional contact to constant immersion. They can withstand chemicals such as:

| Water | Methanol |

| Acetone | Ethanol |

| Toluene | Gasoline |

| MEK | Butylacetate |

| Mineral spirits | Potassium hydroxide |

| Isopropanol | 10% hydrofluoric acid |

| Xylene | 96% sulfuric acid |

| Bleach | 10% nitric acid |

| Steris | 50% sodium hydroxide |

| Cydex | 35% ammonium hydroxide |

| Skydrol |

Chemically Resistant Epoxies: Examples of Master Bond's Products

EP21AR

Two Component epoxy system used as adhesive, sealant, coating, outstanding resistance to acids.

EP30HT

Optically clear high temp adhesive, sealant, coating, -60°F/400°F, resistant to acids, bases and organic solvents.

EP41S-1

Two component room temp cured epoxy system featuring outstanding chemical resistance to fuels, alcohols and organic solvents.

Low Outgassing Adhesives

Low-outgassing adhesives are those that do not release a lot of volatiles or other chemical compounds. Other than space systems, the most common applications for low-outgassing products are those that involve optical components, which can be clouded or fogged by outgassed chemical compounds. Outgassing can also negatively affect sensitive electronics. Semiconductor manufacturing processes can be very sensitive to outgassing material systems. Semiconductor manufacturing and commercial vacuum processes can also suffer from outgassing issues.

Master Bond has developed various low outgassing epoxy resin based adhesive systems to meet the maximum 1% TML and maximum 0.1% CVCM acceptability criteria as outlined in ASTM E595-93. Some of these have been tested by NASA authorized facilities while others have been independently tested. These adhesives comprise both two and one component compositions requiring either ambient or elevated temperature cures as specified below. These "low outgassing" epoxy adhesive compounds are manufactured with exceptionally high quality standards in order to assure reproducible high performance even under the most demanding service conditions.

Low Outgassing Epoxies: Examples of Master Bond's Products

EP21TCHT-1

Master Bond EP21TCHT-1 is a heat resistant epoxy with a high thermal conductivity and superior electrical insulation. It is serviceable from 4K to 400°F. NASA low outgassing certified making it ideal for use in vacuum environments.

EP37-3FLFAO

Thermally conductive, lower viscosity, easy-to-use epoxy system that cures flexible. Resistant to vibration, impact and shock. For potting & bonding.

SUPREME 10HT

One part, no-mix system requiring oven curing at 250-300°F with extraordinary physical properties. High peel and tensile shear strength. Cryogenically serviceable. Resistant to vibration, thermal shock and impact.

Cryogenic Adhesives

Master Bond offers a wide range of versatile, high performance epoxy formulations designed to withstand the severe conditions found in cryogenic environments. They are available as one or two part systems, requiring either ambient or elevated temperature cures as specified below. When fully cured, these adhesive/sealants offer excellent physical strength properties, long term durability, superb chemical resistance, as well as high bonding strengths to both metallic and non-metallic substrates.

Cryogenic Epoxies: Examples of Master Bond's Product

EP29LPSP

Capable of withstanding the most severe cryogenic shocks. Very low viscosity. NASA low outgassing approved. Transparent. For bonding, sealing and potting.

EP21TDCSLO

Tough, silver filled, electrically conductive epoxy system. Has very low volume resistivity. Cures at room temperature. Offers high peel and shear strength. Passes ASTM 595 for NASA low outgassing.

SUPREME 12AOHT-LO

One component, heat cure system serviceable from 4K to +500°F (260°C). Resists aggressive thermal cycling and shock. Substantial thermal conductivity of 9-10 BTU in/ft2 hr °F. NASA low outgassing approved. Meets MIL-STD-883J Section 3.5.2 for thermal stability. Withstands 1,000 hours 85°C/85% RH.

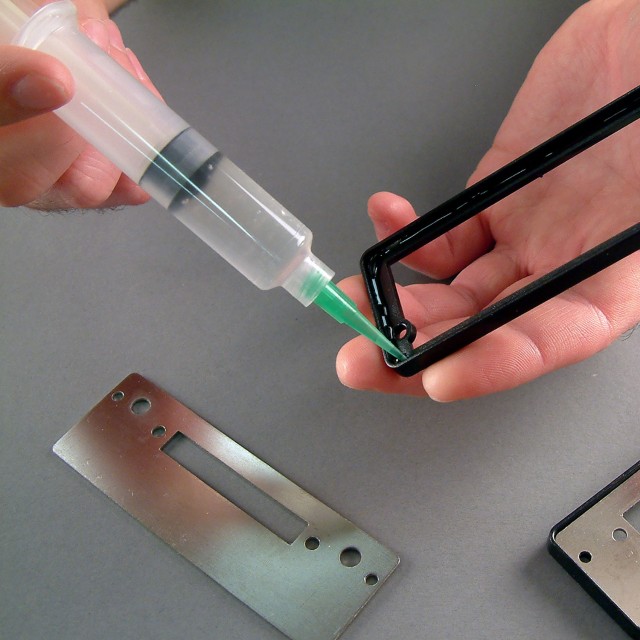

UV Curable Adhesives

Master Bond's range of UV curable bonding, sealing, coating and potting & encapsulation compounds are single component and also require no weighing or mixing prior to use. They are designed to speed productivity, eliminate waste, save energy, increase efficiency and improve reliability. UV curable epoxies, polyurethanes, polyesters and acrylics are available. Grades vary in viscosity, cure speed, hardness, strength, chemical resistance, thermal stability, electrical insulation, optical properties, etc. Environmentally safe, they emit no volatiles or vapors during cure. They remain stable even after prolonged storage at room temperatures until exposed to a UV light source. This eliminates pot life problems. Remarkably fast curing with standard UV cure equipment, these systems will greatly enhance. In most applications, cure speeds within a couple of seconds is common. This removes transient thermal exposures when adhering heat-sensitive substrates.

UV Curable Systems: Examples of Master Bond's Products

UV15

Low viscosity, rigid UV curable system with superb thermal stability. Also capable of spin coating.

UV15X-6MED-2

UV curing system with high flexibility that is biocompatible per USP Class VI testing.

UV15-7DCNV

Dual cure UV system with a secondary heat cure mechanism (250°F) for “shadowed out” areas (those not available to the UV light source). Optically clear and non-yellowing. Produces tough, durable bonds. Serviceable from -80°F to +300°F.

Master Bond: Designing Specialty Adhesives for Hi-Tech Industries

Master Bond products are implemented in the:

Aerospace Industry – systems have higher thermal conductivity and resistance up to 600°F. They are NASA low outgassing approved, cryogenically serviceable, and meet the requirements of UL94V-0 testing for flame retardancy.

Electronics Industry – products offer remarkably high electrical conductivity. Low coefficients of thermal expansion and high dimensional stabilities mean that these products can be applied to vastly dissimilar substrates with ease.

Master Bond products for Medical and Optical Industries

Medical Industry – formulations fully meet the USP Class VI protocol for biocompatibility. They retain their desirable performance upon exposure to various sterilization procedures including autoclaving, radiation, ethylene oxide and the recently developed cold sterilants.

Optics Industry – products have excellent light transmission characteristics, superb non-yellowing properties, and low indexes of refraction. They processed to exclude potentially objectionable contaminants as chlorine and other halogens as well as sodium and related elements.

Durable and corrosion resistant Master Bond products for Automotive, Transportation and Oil and Chemical Processing Industries

Automotive and Transportation Industry – formulations are extremely durable; with resistance to abrasion, mechanical shock, and vibration. They also have high shear, peel, and tensile strengths. These systems withstand water and chemical exposure and temperature extremes.

Oil and Chemical Processing – systems feature unmatched resistance to corrosion from gasoline, kerosene, alcohol, lubricants, crude oil and its derivatives, natural gas, and gaseous fuels. They offer high dimensional stability, superior abrasion resistance, underwater curing capability, and exceptional temperature resistance.