Convert Ltd

Convert Ltd is a UK based manufacturer of cable harnesses, cable assemblies and wire looms.

As a professional cable harness and wire assembly manufacturer, we specialise in the following industries:

- Automotive

- Public Transport Systems

- Medical and Scientific Equipment

- Industrial Control Systems

- Measurement and Control Equipment

Cable Loom and Wire Loom Assembly

Our cable loom and wire loom assembly services ensure your products are always manufactured to the highest specifications.

With many years of experience and products manufactured to the highest standards we aim to be your first choice supplier for all your cable assembly needs.

Our services include:

- The manufacture of Cable Looms, Cable Harnesses and Cable Assemblies in batch sizes from 1 to 1000s.

- Prototype builds, project based requirements, discrete and scheduled orders, kanban and call-off etc.

- Cable Set and Processed Cable batch sizes from 100’s to 100,000’s.

- Our strong supplier relationships ensure competitive prices, quick lead times.

- We also hold a large range of applicator tooling for use with a wide range of terminals and connector styles including Hirose, ITT, JAE, JST, Molex, Takbro and Tyco.

- We are ISO 9001 registered and our procedures and processes are designed to provide a high quality service.

Our philosophy is quality products, delivered on time at competitive prices and we work hard to ensure that we achieve this.

To provide the very best Convert customise the manufacturing process to suit your products using a range of test and production equipment.

Interconnect Harness and Wire Harness Supplier

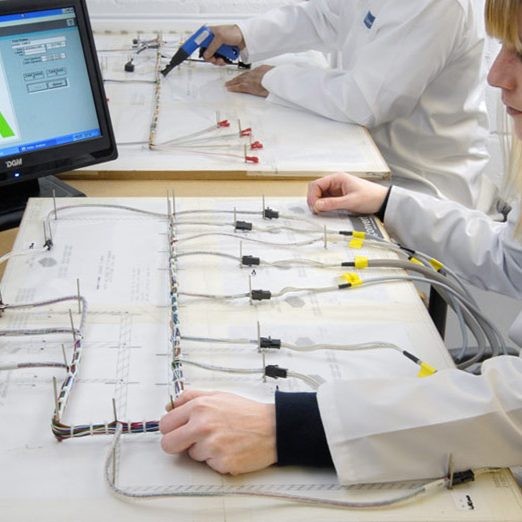

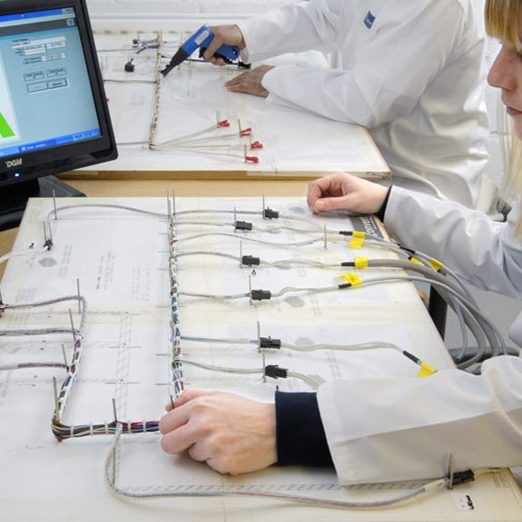

Convert Ltd. has a skilled team to perform all assembly work including the manufacture of cable harnesses and Interconnect harnesses.

These Interconnect harnesses can be made for board to board and board to panel applications.

Once inserted into housings these assemblies are ready for easy connection onto your PCB connectors.

For applications which require direct soldering to your PCB we offer a range of single circuit or multiple connector board-in crimp style solutions. Multiple connector style solutions can be offered in both vertical and right angled/side-in variations.

Complex Looms and Harnesses

Convert Ltd can also manufacture a range of complex cable looms and cable harnesses to the highest standards.

These include:

- Automotive Engine Management Looms

- Control Looms for Medical or Scientific Equipment

- Power & Control Harnesses used in Public Transport Systems and Industrial Control Systems.

Our complex looms and assemblies are always electronically and visually tested to ensure the reliability of the finished product.

Equipment

Convert Ltd continually invests in the latest technology and equipment to produce the highest quality finished products to our customer’s design an specification requirements.

We use Komax and Artos machines to process a large selection of cable and wire ranging from single-stranded/single-core cables through to multi-stranded/multi-cored cables.

Our cable processing and assembly equipment includes:

- Cable processing equipment: Artos MTX-5, Artos CS-326, Komax Kappa 230, Komax K35.

- Crimping presses: Kristen K750, Mecal TT, Takbro AP-F3 andTakbro MC-25.

- Product assembly equipment: Panduit PAT-1000 Cable Tie machine, IDC Ribbon Presses and a wide range of hand crimping tools

- Product testing and inspection equipment: Cirrus cable harness testers, Mecmesin Advanced Forge Pull Tester.

- As part of our continuous investment in equipment, we have recently invested in new Crimp Force Monitors for our Mecal TT Presses. The CFA1000 Crimp Force analyser system allows us to check the quality of all crimping operations carried out on these presses. This information helps to ensure that the quality of the crimping process is maintained from the beginning to the end of each batch of terminals applied.

- We also have a SLE SBL Micro Crimp Cross Section Lab, which allows us to cut a terminal in half and to produce a photograph of the cross section in order to help validate the crimping process. Test results from this process and from the Mecmesin Pull Tester can be provided to our customers to help show the quality and compliance of the manufacturing process

These investments in equipment help us to insure that our production of cable harnesses and cable assemblies is to the highest quality.

To request a quote or further information on Converts' Services please do not hesitate to contact us.

Product Testing and Inspection Equipment

To ensure we produce the highest quality products, we use a range of product testing and inspection equipment throughout the production process and onto Final Inspection before shipment.

Our Mecmesin Advanced Forge Pull Testers are used to validate the quality of the crimped terminations we are producing. The testers measure the tension force required to pull apart or separate the components of a wire crimp. This helps to ensure the crimp joints are fit-for-purpose and thereby ensuring the safety and quality of your products and their compliance with any required industry standards. The AFG-1000N tester is used for pull tests up to 1000 Newtons, the ILC-S 2500N is used for where pull tests up to 2500 Newtons are required.

Our CFA1000 Crimp Force analyser system allows us to check the quality of all crimping operations carried out on our presses. This information helps to ensure that the quality of the crimping process is maintained from the beginning to the end of each batch of terminals applied.

We also have a SLE SBL Micro Crimp Cross Section Lab, which allows us to cut a terminal in half and to photograph the section in order to help validate the crimping process. Test results from this process and from the Mecmesin Pull Tester can be provided to our customers to help show the quality and compliance of the manufacturing process.

Our Cirrus & Pambry Cable Harness Test Equipment is used to electrically test products. This has bespoke test fixtures to prove the functionality, of each of your products at in-process and final inspection stages.

Product Assembly Equipment

We have a wide range of automatic machines and hand tools designed to aid our skilled and trained staff to build your cable harnesses and assemblies as efficiently as possible.

These include:

- A fully automatic Panduit cable tie system which is up to six times faster than using manual cable ties around cable harnesses & assemblies.

- A JQ-6100 Sleeve & Wire Cutting Machine enables us to accurately cut large volumes of heatshrink to the correct length.

- A Techon Sealant Dispenser, which dispenses low, medium and high-viscosity fluids accurately, is used on assemblies requiring sealant to be applied as part of the manufacturing process.

- A Halo Blaze Heatshrink cutting machine & Heatshrink Processing Machine which are used in conjunction with traditional heat guns to cut & fit heatshrink to cable assemblies where required.

- The Quick 202D & Thermaltronics solder stations are used to solder cable assemblies to a variety of components, where required the Quick 870 Hotplate is used to help pre-heat components during the solder process.

- A Kingsing Cable Twisting Machine is used when required to twist multiple wires together quickly and accurately.

- An Ondal Taper S Automatic Taping Machine allows us to finish a cable harness in harness tape as an alternative to using other cable harness coverings such as braid or heatshrink. The machine efficiently wraps all types of tapes around a cable harness, including those tapes which are specifically designed for use in Automotive applications.

- A Travin TP1 Injection Moulding Machine for the manufacture of grommets and other over-mouldings used on cable harnesses.

These pieces of equipment help our staff to reduce a products assembly time, and so reducing the overall costs of manufacture, which allows us to pass these savings directly on to you.

We also stock a wide range of hand crimping tools which allow us to produce samples, proto-types and small batches of assemblies in a cost effective way, but still to the highest quality standards, you would expect.

Crimping Presses

For cable which cannot be crimped automatically and once preparation work has been completed we use our semi-automatic Mecal, Gamma, Kirsten & Takbro Presses to apply un-insulated and pre-insulated terminals.

Our Kirsten Stripper Crimper, Mecal TT & Gamma Presses also include crimp force monitoring which automatically monitors and checks the crimp forces used for every terminal applied. This information helps to ensure that the quality of the crimping process is maintained from the beginning to the end of each batch of terminals applied. Any defect crimps are separated and removed from the rest of the batch to prevent progression through the manufacturing process.

For large gauge wire or loose piece terminals we use our EM6B2 & EC65 Power Crimpers and any Bootlace Ferrules are applied using our semi-automatic MC25 Max-Crimp crimper.

Operating these machines for large or repeat orders allows us to procure large quantities of terminals on reels, helping to reduce the overall material costs for your products, savings which we are able to pass on to you.

We also hold a large range of applicator tooling for use with a wide range of terminals and connector styles including Hirose, ITT, JAE, JST, Molex, Takbro and Tyco. For small and prototype batches we hold an extensive range of hand-tools for a wide range of terminal styles.

All Crimping operations are considered a critical assembly stage and are subject to an inspection by Quality Control Staff before progressing onto the next assembly operation.

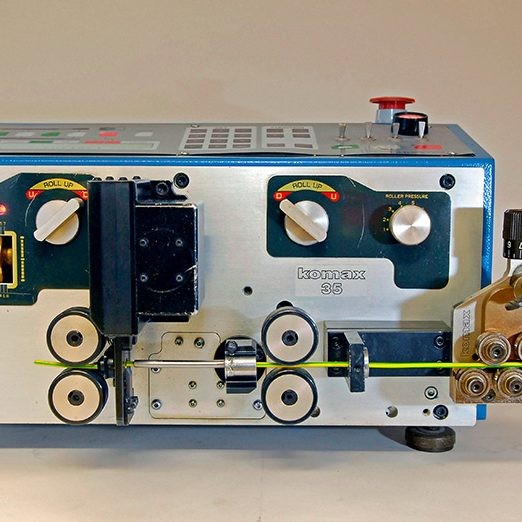

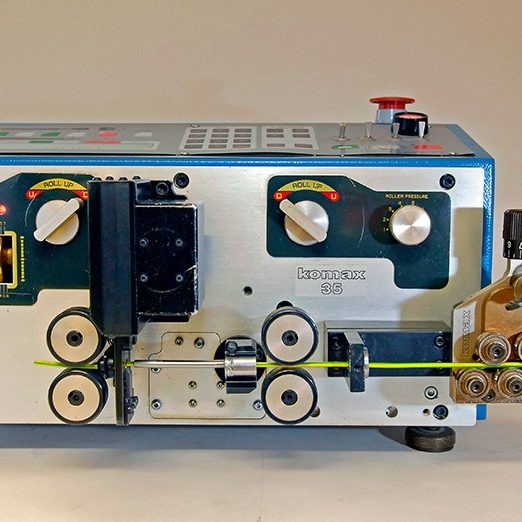

Cable Processing Equipment

Convert’s continual investment in its cable processing equipment enables us to offer our customers the best possible solution to you production requirements and ensures on going quality of the products we supply.

We use Artos & Komax Wire Preparation Equipment to process a wide range of cable and wire, from single-stranded, single-core, through to multi-stranded, multi-cored cables. These machines allow us to cut to length, strip and, where required, label a variety of cable gauges, quickly and efficiently. Various stripping options can be set independently for each end of the cable and so provide us with flexible options for both high and low batch runs.

Our fully automated Komax Gamma 255, Artos CR11 & Artos MTX machines enable a high volume of cable to be processed quickly. With up to 6 programmable work stations cable can be cut & stripped, twisted, tinned and/or crimped, in any sequence, efficiently and to a consistently high quality. These machines also includes crimp force analysers which automatically monitor the crimping forces used for every terminal applied. Any defect crimps are automatically removed from the cable and then separated from the rest of the batch by an active sorter to prevent progression through the manufacturing process.

The Artos CS-326 has its own PC interface which allows us to store all the important machine functions including cable size, cut lengths and strip lengths, to process each of your products, helping us to reduce the lead time on repeat orders. This machine has recently been modified allowing it to handle longer cuts lengths much more effectively.

Find Us on Google

We can be found on Google.co.uk