DP Seals Ltd

As a leading global supplier of precision custom rubber seals, gaskets and mouldings, DP Seals plays a key role in serving the Aerospace, Defence, Subsea, Energy, Oil & Gas, Medical, Sports Equipment, Motorsport and Industrial markets.

DP Seals regularly takes on problems where others have failed. It is this hard-earned reputation for innovative problem solving combined with knowledge and experience in specifying formulas and compositions for materials that have proved invaluable, especially where high performance and longevity in sometimes hazardous environments are of paramount importance.

AS 9100 Rev C, accredited, the company has been making custom rubber mouldings for over 35 years and employs some 50 people at its three Poole sites.

Download the following guides and brochures on our website :

- Custom rubber moulding guide

- Rubber To Metal Bonding guide

- Corporate brochure

- Aerospace brochure

- Energy brochure

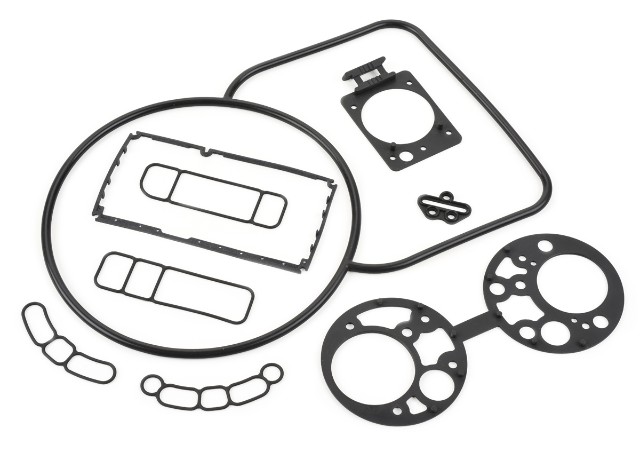

Custom Rubber Seals

We produce custom molded seals and rubber components in everything from small irregular batches through to 500,000 units per month.

We also specialise in rubber to metal bonding.

Custom Rubber Gaskets

DP Seals specialises in manufacturing custom rubber gaskets to the highest tolerances for the harshest environments.

All the gaskets we produce are custom designed and manufactured. We can produce rubber gaskets to any profile or shape for both low volume and high run orders. If you require an off-the-shelf gasket we’ll happily recommend an alternative manufacturer.

Find out more about the reasons for choosing custom versus standard rubber parts.

Custom Rubber Mouldings

DP Seals manufacture custom rubber mouldings designed to the highest possible tolerances. This includes simple products right up to hugely complex dual material, conductive and semi-conductive rubber components. Catering for both low and high volume we specialise in transfer and compression moulding and also have expertise in rubber to metal bonding.

Find out more about the benefits of choosing custom versus standard rubber parts

Rubber components

At DP Seals we pride ourselves on being able to provide specialist advice in selecting and developing exactly the right blend of materials to meet a vast range of performance requirements.

Manufacturing everything from self-lubricating O-rings for emergency buttons to large anti-vibration mounts for Saab Viggen fighter fuel tanks, DP Seals has built up unrivalled expertise in advanced rubber technology for extreme environments, such as FFKM, VITON Extreme, low-temp HNBR and specialist silicones.

In-house specialists advise on material selection - and can create custom blends to meet performance targets – and work hand-in-hand with customer design engineers to ensure the end products meet specification.

3D Printing and Prototype Development.

In house tooling

Whether producing multi-cavity tools for mass production or one-off tools for prototypes, the busy in-house tool room benefits from the latest technology: state-of-the-art vertical machining centres and advanced CNC lathes and mills augmented by advanced spark erosion and wire cutting capabilities.

CAD/CAM & 3D Printing

Direct, high-efficiency CAD/CAM links from client engineer desktops to the tool room, ensuring accurate prototype tooling in optimum time without compromising precision or quality. The ability to manipulate 3D solid models allows the most effective layers for tooling to be identified, whilst 3D printing of custom seals and mouldings further shortens prototyping times to speed the clients’ development programmes.

Quality control

From limited-run prototyping to Kanban/JIT-integrated volume production, DP Seals manufactures all to the highest standards of quality and precision. Whether it’s a WRC engine gasket manufactured in dozens per year or 7mm±0.1mm diameter balls manufactured at 300,000 per month for use in car suspensions, everything is fully integrated into the company’s rigorous AS 9100 quality regimen - incorporating BAE Systems accreditation and ISO 9001 - and strictly monitored and enforced by the company’s dedicated quality unit. Fully automated CNC cryogenic (-130°C) cleaning - one of the most advanced installations of its kind in the world - ensures flash and defect-free output.

Rubber To Metal Bonding Expertise

DP Seals is also a leading exponent of in-tool rubber-to-metal bonding, producing a wide variety of mouldings for aerospace, brewing, automotive and computer peripherals. And by combining this with its materials knowledge, the company was one of the first to successfully bond optimised HNBR to stainless steel for aircraft refuelling installations inside the Arctic Circle.

Download our free rubber to metal bonding guide

Tool & Mould Making

Whether we are producing one-off mouldings for prototypes, or multi-cavity moulds for mass production, our busy in-house tool room benefits from having the latest rubber mould tool design technology.

Operated by dedicated and highly trained staff all CNC machinery is directly linked to our design centre, closing the link between client engineering, drawing and custom tooling. This eliminates an area for potential error.

Read more about our patented tooling & moulding system which enable us to produce small, close tolerance, flashless mouldings that no-one else can match.

Rubber Fluorination Services

Gas fluorination is ideal for small or complex rubber components. Surface property modifications are maintained across all edges, angles, openings and holes without any effect on the rubber.

Benefits include:

- greatly reduced coefficient of friction

- enhanced adhesion and bonding

- increased chemical resistance, controlled permeation and improved wettability.

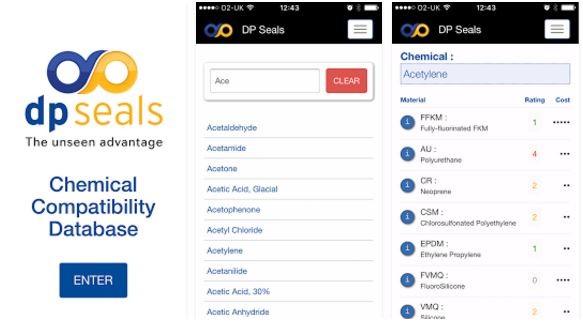

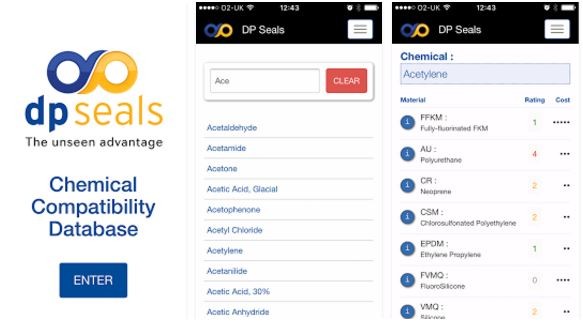

Use Our Rubber Chemical Compatibility Database

Our Chemical Compatibility Database (CCD) has been created to help you make the right choice of materials for the environment that your product has to operate in. Enter the name of your chemical in the box on our website and this will bring up an alphabetical list as soon as you start typing. You can select and compare different types of rubber for performance as well as cost.

Why not watch our videos on chemical compatibility and more. Lots of handy tips and advice.

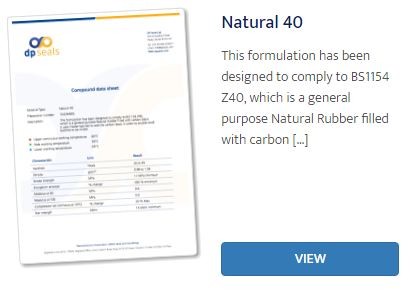

Rubber Compound Data Sheets

Download data sheets for some our our most commonly used rubber materials.

Or,

Why not download our rubber chemical compatibility app too so you can check material performance whilst you're on the move!

Free rubber mouldings resources

- Watch our videos with helpful tips and advice for designing rubber seals

- Use our Design Engineers Checklist to help you design rubber mouldings

Customer Testimonials

"As someone who has been assessing suppliers for over 20 years it was quite apparent to me that DP Seals are technical experts and industry specialists. In meeting our 4M and QCDES standards it was their personal touch and attention to detail that helped set them apart".

Natasha Witcombe

Technical Procurement Engineer

Ricoh

Find out what other customers have to say about us by visiting our testimonials website page.

Newsletter Sign Up

Sign up for our newsletter right here