AdaptTech Manufacturing Solutions Ltd

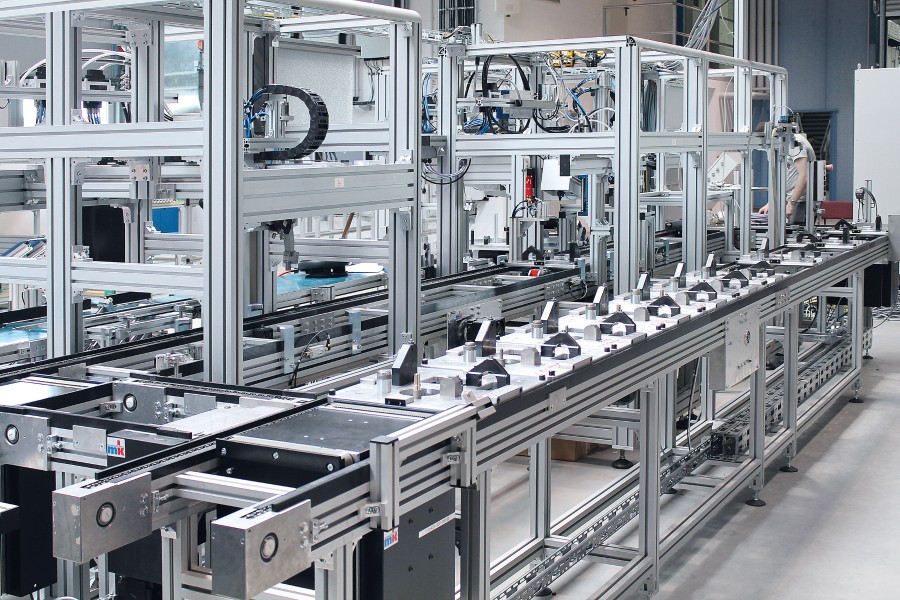

AdaptTech supply the complete mk Technology Group product range for the whole of the UK and Ireland.

We have been operating in the UK since 2000 (formerly as mk Profile Systems Ltd) and still continue to experience significant growth. We are a family run business that prides itself on excellent customer service.

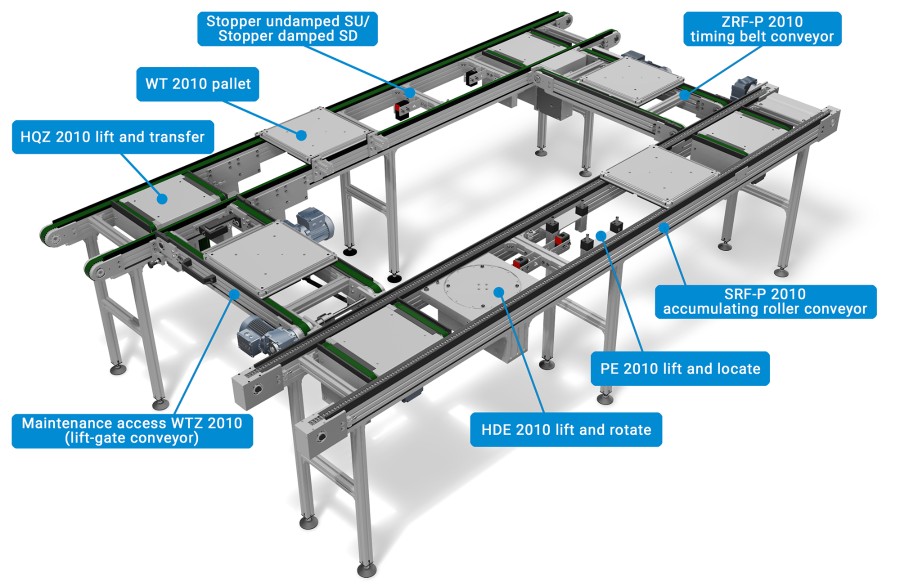

We can provide the mk aluminium profiles and accessories in kit format, or as an assembled item. We can also assist with your design and selecting the most appropriate products from our range to create the best solution for your requirements. Similarly, the full range of mk conveyors and transfer systems can also be purchased via AdaptTech for any UK and Irish customers. Again, we can help with the design and realising the most appropriate solution to your conveying needs. All of the mk products are modular and can easily be adjusted, enhanced and integrated with one another.

Filter products and services

-

Conveyor Manufacturers

We can offer a suitable conveyor system for a huge range of goods that require transporting and a wide range of implementation conditions. Select from 24 standard systems or tell us your requirements and we will design and build a conveyor to your unique specifications.Request a Quote Supplied by AdaptTech Manufacturing Solutions Ltd -

Conveyors and Conveyor Systems

Supply of Conveyors and Conveyor Systems manufactured by mk Technology Group

Request a Quote Supplied by AdaptTech Manufacturing Solutions Ltd -

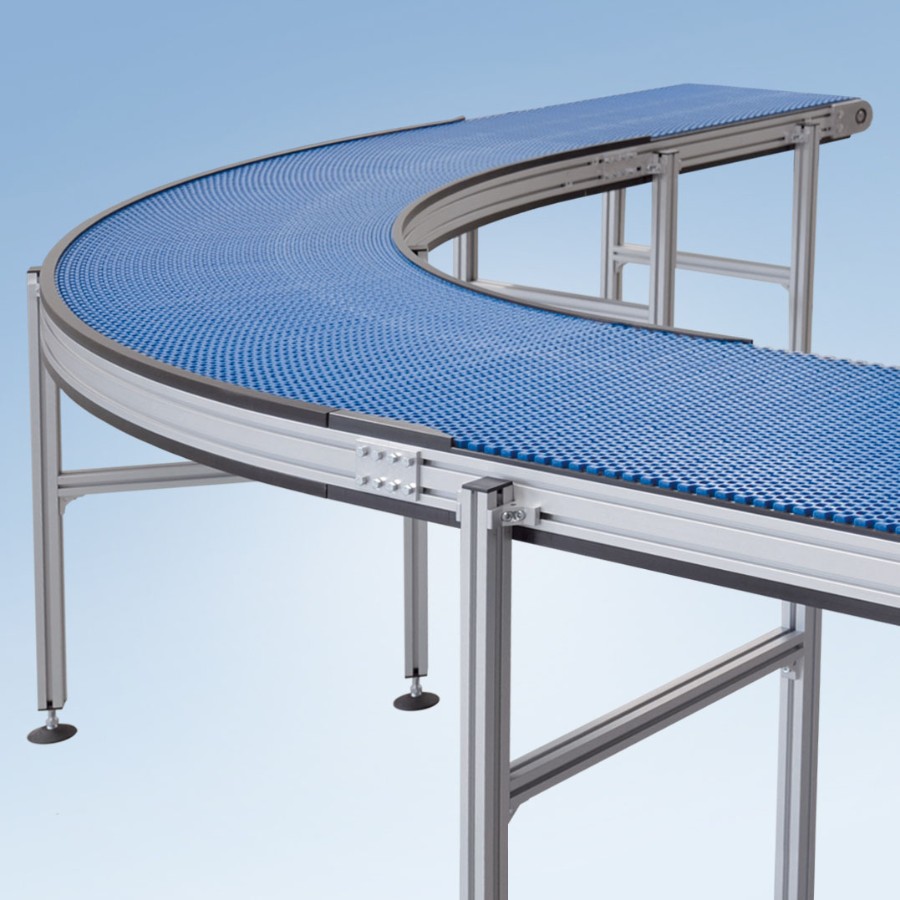

Curved Belt Conveyors

The conveyor system KFG-P 2040 is based on our 40 Profile Series, and is compatible with all other mk conveyor systems. The exterior profile frame features 10mm T-slots which allow for the direct mounting of additional accessories such as side rails, sensors etc. The structural profiles used ensure rigid construction with excellent load bearing capacities, whereby the indicated values for maximum loads and speeds are directly dependant, and thus vary. The conveyor features a Ø 19mm rolling nosebar which allows for the transfer of small parts. Automatic belt tensioning is built into the tails which compensates for normal belt stretch, while at the same time ensuring a fixed, unchanging installed dimension. The compact center drive features no external protrusions when using our standard motor.Request a Quote Supplied by AdaptTech Manufacturing Solutions Ltd -

ECO Incline Belt Conveyor

The KFG-P 2000 ECO Conveyor is based on the mk 2000 profile and with its compact design is suitable for conveyance of all small parts. ECO is an abbreviation of economic and thus profitability - high material quality and fulfillment of customer requirements at an excellent price. The technology of the inclined conveyor is based on our GUF-P 2000 unit, which has been produced thousands of times and consequently is proven and reliable. Thanks to the limited number of variants fast delivery and high availability are ensured. The ECO incline Conveyor conforms to factory safety regulations and can be delivered preset with various speeds. A motor protection switch or frequency inverter for controllability/cycle operation are available as optional accessories. A corrugated cleat edge serves as the side guide, transverse cleats serve as the carriers. With the optimal ratio of effective width to total width the conveyor is ideally suited for integration into existing systems, such as injection moulding machines. Due to the mobility it can be used flexibly as a movable transport unit for filling containers or wire-mesh boxes.Request a Quote Supplied by AdaptTech Manufacturing Solutions Ltd -

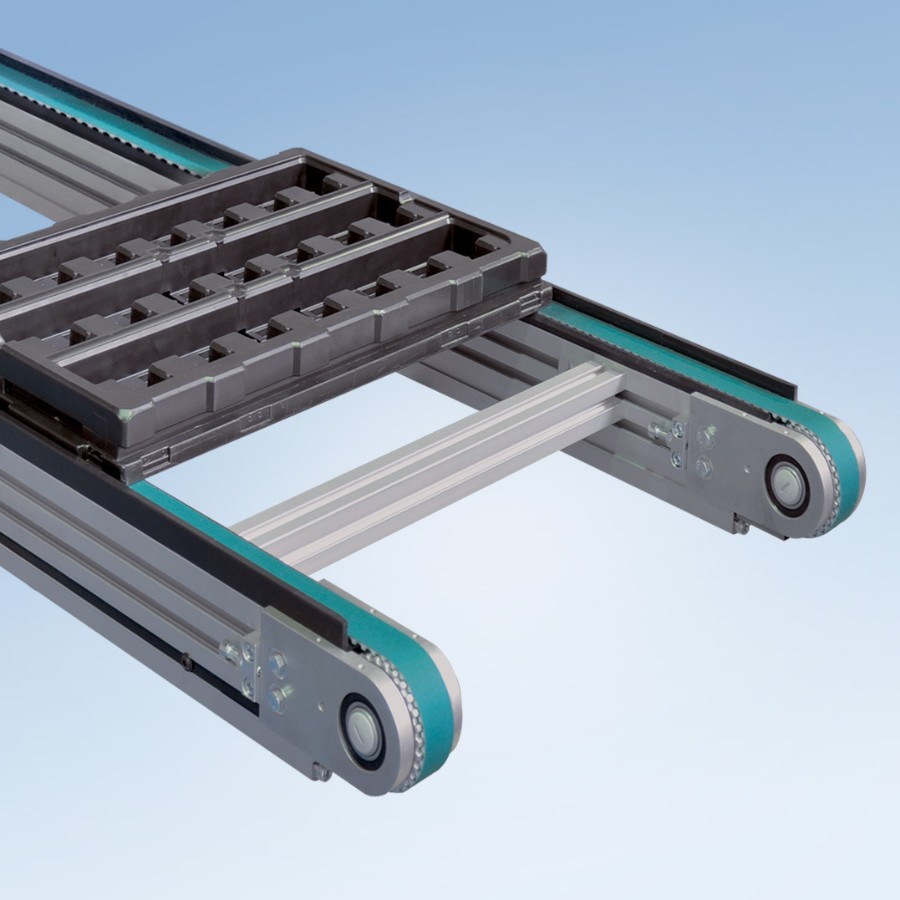

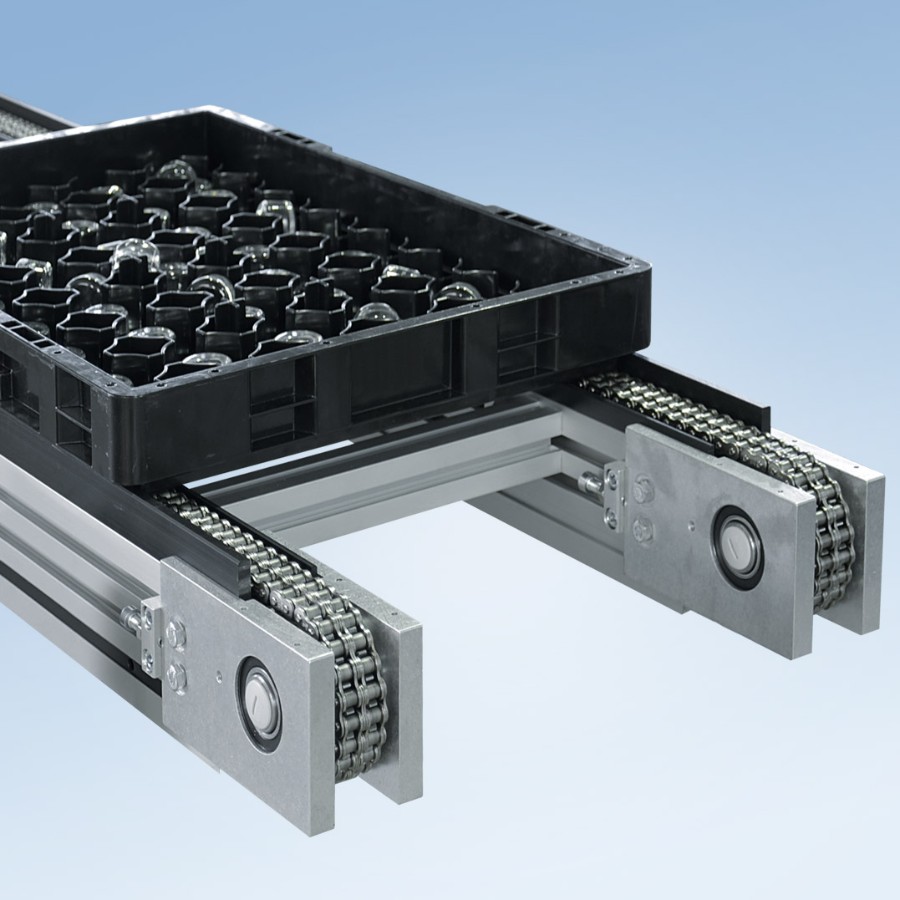

Flat Top Chain Conveyor

The modular mk flat top chain conveyor system SBF-P 2254 is ideal for product handling in either stand-alone or integrated applications. Applications can be found in packaging, manufacturing, bottling, glass, food, medical and pharmaceutical industries. Conveyors can be manufactured quickly and economically using the various individual components. Due to their modular construction, later reconfigurations necessitated by product or production changes can be accomplished with relatively little effort.

The system is available in two standard widths and can accept chain from a variety of suppliers. Conveyor frames are manufactured using our Profile 2254, which features a 10mm T-slot. Accessories such as side rails, stands etc. can easily be mounted to the conveyor at any time. The chain is completely guided using wear strips on the running side as well as the return. A special feature of the modular design is the use of individual subassemblies. Components designed specifically for this conveyor system ensure a simple and quick assembly of the individual elements into a complex material handling system.Request a Quote Supplied by AdaptTech Manufacturing Solutions Ltd -

Gravity Roller Conveyor

The gravity roller conveyors, RBS-P 2065 and 2066 are used in many areas of industrial automation. The RBS-P 2065 and 2066 roller conveyors differ only in the fact that the 2065 conveyor frame profile, the rollers project over the side profile (suitable for over-wide goods), while for the RBS-P 2066 the conveyor frame profile serves as side rail. An extensive selection of different roller types makes the system extremely flexible and usable for a broad spectrum of applications. The conveyors can be delivered as straight conveyors, as well as curved conveyors. The roller diameters 20,40, and 50mm ensure safe and trouble-free transport of small, as well as large, workpieces. The longitudinal T-slots of frame profiles can be used for fastening of side rails, stands, sensors or other accessories.Request a Quote Supplied by AdaptTech Manufacturing Solutions Ltd -

Heavy Duty Belt Conveyors

The use of our rigid structural Profile mk 2251 (50 x 80 mm) to manufacture the conveyor frame allows System GUF-P 2041 conveyors to accommodate loads of up to 150 kg (330lbs). The components used in the drive and tail assemblies are also specifically designed to handle these loads. The Ø 85mm drive roll standard for this system further ensures that all available motor power is transfered to the belt. A further advantage of this system is an almost unlimited selection of belt types, including cleats and sidewalls. Each side of the conveyor frame features two system T-slots (10mm opening) for integration into existing equipment, or for the attachment of stands, side rails and other accessories. Additional noteworthy details include the use of galvanized slider beds for reduced belt friction, sealed ball bearings and crowned rollers for simple belt tracking and alignment.

Request a Quote Supplied by AdaptTech Manufacturing Solutions Ltd -

Incline Conveyor

The KFG-P 2000 conveyor system is based on the mk 2000 profile, and with its compact design is suitable for conveying small parts of all types through vertical transportation.

Request a Quote Supplied by AdaptTech Manufacturing Solutions Ltd -

Lift System

The new mk Lift System has a base frame made with 50 series and can be utilised to help streamline manufacturing processes. The lift unit with a slewing ring and timing belt conveyor SRF-P 2010 has a capacity of 300 kg. A counter weight and motor including holding brake can secure a load of up to 600 kg. Additional pegs are incorporated at transfer stations. Feed-in and storage area with reinforced SRF-P 2012 cater for a load of 300 kg/m and up to 1,200 kg total capacity, during 3m/min. The entire system is provided by mk who work closely with their customer during the consultation, planning and implementation stage of the system. Their concept offers both space and cost saving to a customers¿ manufacturing process and the lift can be easily disassembled for transportation purposes. The high load capacity is based on mk¿s extensive 50 series profile range and is both low maintenance and wear-resistant.

To view our video on this product click here:https://www.youtube.com/watch?v=CO-C3kXcLyo

Request a Quote Supplied by AdaptTech Manufacturing Solutions Ltd -

Linear Glide Module 100 x 100 mm

Profile mk 2011 (100mm x 100mm) is used for the structural beams in this linear module. The profiles are reworked and feature a high-quality surface coating which provides a low friction surface while enhancing the profile with added wear resistance. Standard features of the linear modules include trapezoidal spindles with POM-nuts which are protected from contaminants by a stainless steel cover strip. These linear modules are maintenance free. On request special configurations are possible including stainless steel spindles, trapezoidal bronze nuts, ball screws, as well as motor driven modules. The linear modules are available in 3 basic manually operated configurations; Linear Module with Handwheel, Linear Module with Handwheel & Scale and Linear Module with Handwheel & Mechanical Display. The VST is available with one carriage or with two carriages with opposing travel.Request a Quote Supplied by AdaptTech Manufacturing Solutions Ltd