Advanced Engineering (Middleton) Ltd

With in excess of 40 years experience, AE Mixers are established as a leader in the design and manufacture of mixing equipment for fluid processing applications.

We design and produce highly efficient mixers used throughout the food processing, paint production, petrochemical and cosmetic industries. Our production workshop is staffed with skilled operators trained to produce high quality equipment.

For high shear mixers, we produce the unrivaled solutions.

Filter products and services

-

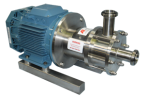

Inline Single Stage ADIL3S/F

Shaft sealing is normally by means of double mechanical cartridge shaft seal, with an effective thermosyphon circulation system and accessories to provide seal cooling and lubrication to seal facesRequest a Quote Supplied by Advanced Engineering (Middleton) Ltd -

Inline Single Stage ADIL3S/M

Four interchangeable rotor/stator cutter options are available as standard which cover most requirements. Special purpose designs can also be produced to cover particular problems. With these machines the design of the rotor/stator cutters in the dispersion head is such that it eliminates the total closure of cutter slots during operation. This results in a high shear effect enhanced by the high peripheral speeds achieved. The rotor design also induces a high working pressure within the dispersion head for maximum conveying effectRequest a Quote Supplied by Advanced Engineering (Middleton) Ltd -

Inline Single Stage ADIL3S/SF

Rotor/stator combinations can be selected to achieve coarse, medium, fine and superfine dispersions. This choice will depend upon the results required and the viscosity, throughput speed and processing time of the process materials. Total interchangeability of the cutter sets provides a very wide choice of options, from three stages of superfine processing for extreme results, to three stages of coarse processing for the less demanding dispersions, all with intermediate stages in between.Request a Quote Supplied by Advanced Engineering (Middleton) Ltd -

Inline Single Stage ADILS/01

General Purpose Stator Rotor Combination, for the greatest throughput of product. Used for the blending of fluids, disintegration of solids, dispersing of agglomerates and preparation of coarse emulsions.Request a Quote Supplied by Advanced Engineering (Middleton) Ltd -

Inline Single Stage ADILS/02

Slotted Stator Rotor Combination, used for the breaking down, shredding and dissolving of fibrous, polymeric and elastomeric solids.Request a Quote Supplied by Advanced Engineering (Middleton) Ltd -

Inline Single Stage ADILS/03

Square Hole Screen Stator with Standard Rotor, used for rapid size reduction of soluble and insoluble granular partly milled solids. Products include polymers into oil, aqueous emulsions and suspensions of low solid content.Request a Quote Supplied by Advanced Engineering (Middleton) Ltd -

Inline Single Stage ADILS/04

Single Castle Rotor and Double Castle Stator, for the production of emulsions and suspended solids with products of average viscosity.Request a Quote Supplied by Advanced Engineering (Middleton) Ltd -

Inline Single Stage ADILS/05

Double Castle Rotor and Triple Castle Stator, to produce low viscosity emulsions, and suspended matter with low solids content, where high particle reduction is requiredRequest a Quote Supplied by Advanced Engineering (Middleton) Ltd -

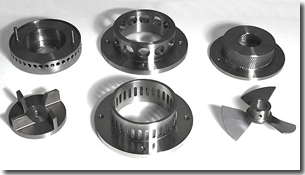

Interchangable Mixer Heads

At AE Mixers, not only do we provide a professional and comprehensive service for the supply of mixing units, but we also offer an exceptional parts service. This includes the supply of high-quality interchangeable mixer heads. To find out more about this cost-effective service, visit our website.Request a Quote Supplied by Advanced Engineering (Middleton) Ltd -

Intermediate Bulk Containers (IBC) Mixers

Intermediate Bulk Containers (IBC) - Mixers supplied by Advanced Engineering (Middleton) Ltd