Analog Devices Ltd

Analog Devices, Inc. operates at the centre of the modern digital economy, converting real-world phenomena into actionable insight with its comprehensive suite of analogue and mixed signal, power management, radio frequency (RF), and digital and sensor technologies. ADI serves 125,000 customers worldwide with more than 75,000 products in the industrial, communications, automotive, and consumer markets. ADI is headquartered in Wilmington, MA. Visit www.analog.com. Both Linear Technology and Maxim Integrated are now part of Analog Devices.

Analog Devices provide efficient solutions for power management and power conversion applications in the automotive, telecommunications, industrial, medical, computing, military and high-end consumer markets using high-performance analogue ICs. Our power ICs can provide unrivalled power densities and software design simulation tools to provide both fast and accurate power module and power supply designs.

Products for power management include: switching regulators, linear regulators (LDO), µModule regulators, PMIC & Multifunction, inductorless (charge pump) DC/DC converters, LED driver ICs, power control, battery management, current source, system supervisor, hot-swap controllers, monitor and control, energy harvesting, super capacitor chargers and power management evaluation kits.

-

Analog Devices and Marvell Showcase Next-Generation 5G Massive MIMO Radio Unit Platform at Mobile World Congress 2023

24 February 2023Analog Devices, Inc. (Nasdaq: ADI), a global semiconductor leader that bridges the physical and digital worlds to enable breakthroughs at the Intelligent Edge, and Marvell Technology, Inc. (Nasdaq: MRVL), a leader in data infrastructure semiconductor solutions, have announced their next-generation 5G massive MIMO (mMIMO) reference design platform with support for Open RAN.

The combination of ADI’s latest RadioVerse® Transceiver SoC and the Marvell® OCTEON® 10 Fusion 5G baseband processor – the industry’s first 5nm digital beamforming solution for 5G, improves the time-to-market for advanced mMIMO radio units and O-RAN support with up to 40% lower energy consumption, smaller size, and lower weight. The OCTEON 10 Fusion baseband processor also provides flexible L1 implementation, with hardware and software reuse across the RU (Radio Unit) and DU (Distributed Unit) to facilitate evolving L1 splits among operators worldwide over the coming years, while the RadioVerse SoC provides extensive digital RF front end capabilities including field proven DPD.

“As mMIMO radio functionality grows in complexity, more specialised silicon approaches are required,” said Alex Jinsung Choi, Chairman of the O-RAN ALLIANCE. “Reference designs like the one created by ADI and Marvell help catalyse the O-RAN market for 5G mMIMO radio units by enabling advanced configurations that meet network operators’ high expectations for power efficiency and performance.”

Together, the RadioVerse Transceiver SoC and the OCTEON 10 Fusion processor support the entire signal chain with unmatched RU system efficiency. The ADRV9040 RadioVerse Transceiver SoC includes substantial digital capabilities including linearisation algorithms for boosting power amplifier efficiency and performance, as well as digital channel filters which reduce interface rates. The OCTEON 10 Fusion 5G baseband processor has specialised accelerators optimised for efficiently processing complex beamforming algorithms, along with dedicated processors for the low PHY baseband which can be configured for the various O-RAN split 7.2x configurations.

“Infrastructure vendors face many challenges when developing O-RAN mMIMO radio units, including access to optimised semiconductors,” said Joe Barry, Vice President of Marketing, Systems & Technology in the Communication and Cloud Business Unit at ADI. “The performance and efficiency of this platform makes industry-leading technology available to both established and emerging vendors.”

“Marvell is pleased to collaborate with ADI in taking mMIMO radios to the next level,” said Will Chu, Senior Vice President, Processors Business Group at Marvell. “The combination of Marvell’s OCTEON 10 Fusion 5G baseband processor and ADI’s leading RF transceiver technology provides OEMs a 5G Open Radio Unit reference design that scales the capabilities and performance of next-generation mMIMO beamforming at the lowest possible power.”

The reference design, which is expandable to support a 64T64R configuration, supports 32 transmit and receive antennas (32T32R) with 400MHz of operational bandwidth and 300MHz of instantaneous bandwidth. The OCTEON 10 Fusion 5G baseband processor and RadioVerse SoC leverage hardware accelerators as well as the industry-leading RF and digital baseband process nodes shipping commercially - 16nm and 5nm respectively - delivering up to 40% reduction in energy consumption per bit as compared over the previous generation. The platform enables Network Energy Savings (NES) modes, which deliver additional power savings.

The platform is on display at Mobile World Congress within ADI’s booth (Hall 2, 2B18) and Marvell’s booth (Hall 2, 2F34).

About Analog Devices

Analog Devices, Inc. (NASDAQ: ADI) is a global semiconductor leader that bridges the physical and digital worlds to enable breakthroughs at the Intelligent Edge. ADI combines analogue, digital, and software technologies into solutions that help drive advancements in digitised factories, mobility, and digital healthcare, combat climate change, and reliably connect humans and the world. With revenue of more than $12 billion in FY22 and approximately 25,000 people globally working alongside 125,000 global customers, ADI ensures today’s innovators stay Ahead of What’s Possible. Learn more at http://www.analog.com and on LinkedIn and Twitter.

About Marvell

To deliver the data infrastructure technology that connects the world, we’re building solutions on the most powerful foundation: our partnerships with our customers. Trusted by the world’s leading technology companies for over 25 years, we move, store, process and secure the world’s data with semiconductor solutions designed for our customers’ current needs and future ambitions. Through a process of deep collaboration and transparency, we’re ultimately changing the way tomorrow’s enterprise, cloud, automotive, and carrier architectures transform - for the better.

Disclaimer: This press release contains forward-looking statements within the meaning of the federal securities laws that involve risks and uncertainties. Forward-looking statements include, without limitation, any statement that may predict, forecast, indicate or imply future events, solutions, or achievements. Actual events or results may differ materially from those contemplated in this press release. Forward-looking statements speak only as of the date they are made. Readers are cautioned not to put undue reliance on forward-looking statements, and no person assumes any obligation to update or revise any such forward-looking statements, whether as a result of new information, future events or otherwise.

-

Join Analog Devices at MWC 2023 and Experience the Future of Connectivity Today

16 February 2023Analog Devices, Inc. (Nasdaq: ADI) invites the public to experience the future of connectivity today through interactive demonstrations and expert discussions at Mobile World Congress (MWC) 2023. Visit Hall 2, Booth #2B18 to learn how ADI aims to minimise environmental impact, enable and accelerate breakthrough innovations, and enrich customers’ lives through solutions which reduce energy consumption, shorten design cycles, and enable the future of work.

ADI’s solutions enable customers to deliver innovative, advanced Radio Units (RUs) faster using conformance tested reference design platforms with commercial grade RU IP. ADI's experts will be on hand to discuss RAN energy saving solutions and demonstrate platform interoperability. Furthermore, ADI’s Consumer team will demonstrate their latest innovations in connectivity with applications such as mixed reality (MR) headsets and audible wearables.

Radio unit demonstration highlights:

- ADI's next-generation massive MIMO (mMIMO) Reference Design with 40% power savings - This 32Tx/32Rx mMIMO radio unit reference design is based on the latest ADI RadioVerse® ADRV904x system on chip (SoC) with fully integrated digital front end and collaborator’s advanced baseband processor. This design solution provides 40% power savings compared to competing solutions, enabling lighter, smaller radios and faster time to market.

- Creating more sustainable networks with advanced micro-sleep modes - Since the Radio Access Network (RAN) consumes 70% to 80% of total network energy, energy savings modes are critical to reducing the carbon footprint across 5G networks and lowering OPEX spending. ADI RadioVerse solutions provide the path forward to meeting the upcoming 3GPP Rel. 18 network energy saving (NES) modes for 5G RAN. See how these potential energy savings are realised in an interactive model of micro-sleep and hibernation modes across multiple Open Remote Unit (O-RU) configurations.

- Next-generation 5G mmWave beamforming platform - Upgrade macro, small cell, and indoor 5G deployments across the entire 24 to 47GHz bands. This 8T8R 400MHz solution highlights ADI’s latest O-RAN 7.2 split compliant mmWave reference platform, with a proven 25% efficiency improvement in analogue beamforming based entirely on ADI silicon solutions.

In a world where virtual connections are increasingly part of everyday life, ADI will present several advancements in consumer technology which enrich the sensory experience with realistic human interactions:

- MR headset: Enabling the future of work with the Metaverse - Integrating emerging virtual worlds into everyday lives take a huge technological effort: Intelligent Edge devices, 5G/6G infrastructure, and the green energy to power it all. ADI advancements are making this possible.

- Hearable solutions: Life, exactly how it is supposed to sound - Filtering out, amplifying, or enhancing the sounds of life when appropriate helps people experience perfect sound, every day. Context-aware, hearable solutions change how people work, play, and rest from anywhere.

- USB-C fast charging, battery insights, and protection: Fast charging your life's work - Improving charging efficiency puts less wear on batteries and extends the lifespan of devices. USB-C fast charging technology keeps phones, headphones, or gaming devices going at the speed of daily life, with the highest efficiency and safety in the smallest footprint.

For details about ADI’s O-RU Radio Platform, visit ADI's O-RU Radio Platform web page. The interoperability proven platform with fully functional end to end calls is on display at Mobile World Congress (MWC) within ADI’s booth (Hall 2, 2B18). For more information, visit ADI's MWC web page.

-

Are you attending ISE 2023 in Barcelona next week, 31st January to 3rd February?

27 January 2023ProAV Solutions Beyond Expectation

Join Analog Devices at the Integrated Systems Europe (ISE) show, the world’s largest exhibition for audio visual and systems integration professionals. Visit us at booth #5C250 and discover ADI’s industry-leading portfolio for home entertainment, high performance audio technology, and innovative video signal processing. Speak with our experts to discover how we can help you enhance your entertainment experience.

Preview Our Live Demonstrations

►

Audio Networking Technology Based on ADSP-SC598

Learn how the ADSP-SC598 can run Linux®, decode and render Dolby® Audio™, and run an AES67 audio networking software simultaneously for a more efficient audio experience.►

Audio Bus A²B Transceiver for Conference Room Connectivity

Analog Devices’ audio bus A²B® transceiver, with its plug and play feature, is ideal for conferencing room applications, as it delivers high quality audio at low latency.►

HDMI 2.1 Transceiver with On-Screen Display

Experience how the industry’s first HDMI® 2.1 transceiver, supporting 48 Gbps and integrated OSD, will accelerate truly immersive 8k experiences in the conferencing space.►

Icron: 4k Video and USB 2.0 Extension over LAN

See Icron’s USB 2.0 RG2304S extender system in action showcasing advanced feature interoperability with SDVoE and networking capabilities powered by the ExtremeUSB® extension ASIC chipset.Click below to preschedule a private meeting during the show.

Book an Appointment -

Analog Devices CEO Vincent Roche Joins World Economic Forum’s Alliance of CEO Climate Leaders

24 January 2023Analog Devices, Inc. (Nasdaq: ADI) has announced that its Chief Executive Officer and Chair of the Board of Directors, Vincent Roche, has become a member of the World Economic Forum’s Alliance of CEO Climate Leaders. Analog Devices is the first semiconductor company to join the Alliance, a global community of more than 120 CEOs and Senior Executives from large multinational organisations committed to accelerating the pace of climate change action across their value chains.

“Analog Devices’ core purpose is to work with our customers to create the technological breakthroughs that enrich lives and the world around us,” said Mr. Roche. “From electrification to energy management to industrial efficiency, a focus on combating climate change is woven throughout our business and operations. Joining the Alliance is a natural reflection of our ambition and actions to advance sustainable solutions globally to enable and accelerate the net zero transition. We look forward to working with and alongside Alliance members across our industries.”

Founded in 2014 as a World Economic Forum initiative, the Alliance and its members seek to involve policy makers in their shared commitment to reducing emissions by more than 1 gigaton annually by 2030 and reaching net zero by 2050. The Alliance publishes white papers and reports to guide leaders on carbon removal, as well as facilitates cross-industry collaboration and knowledge sharing.

“We are delighted to have Vince join us as a member of the Alliance of CEO Climate Leaders,” said Pim Valdre, World Economic Forum’s Head of Climate Ambition Initiatives. “Analog Devices’ commitment to achieve net zero by 2050 or sooner is just one example of its ESG excellence that can inspire others in the semiconductor industry to follow. We look forward to adding the experience and vision offered by Vince and the Analog Devices team.”

About Analog Devices

Analog Devices, Inc. (NASDAQ: ADI) is a global semiconductor leader that bridges the physical and digital worlds to enable breakthroughs at the Intelligent Edge. ADI combines analogue, digital, and software technologies into solutions that help drive advancements in digitised factories, mobility, and digital healthcare, combat climate change, and reliably connect humans and the world. With reported revenues of more than $12 billion in FY22 and approximately 25,000 people globally working alongside 125,000 global customers, ADI ensures today’s innovators stay Ahead of What’s Possible.

Learn more at www.analog.com and on LinkedIn and Twitter.

All trademarks and registered trademarks are the property of their respective owners.

-

Are you attending CES 2023 in Las Vegas, from 5th to 8th January?

16 January 2023Join Analog Devices at the Las Vegas Convention Center, West Hall, booth #4725 and experience life at the Intelligent Edge through interactive demonstrations and expert discussions.

Connecting the physical and digital worlds by both sensing and processing at the edge will make data and insights available where decisions are made, resulting in faster and more effective execution. Stop by booth #4725 to learn how the Intelligent Edge will impact every moment of our lives, big or small, to solve some of the world’s greatest challenges by enabling a more efficient, safer, and sustainable future.

For more information on panel sessions and on stand demonstrations, visit the www.analog.com/ces website.

“Insights from the Edge” Panel Sessions: ADI executives will be joined by experts and thought leaders in a series of conversations about how technology is enriching lives and accelerating human breakthroughs. All discussions will be held at ADI’s booth. For any updates on panel sessions or details regarding ADI at CES, please visit www.analog.com/ces.

-

Analog Devices and Seeing Machines Work Together to Accelerate Safer Driving Through Sophisticated Advanced Driver Assistance Systems

3 January 2023Analog Devices, Inc. (Nasdaq: ADI), a global semiconductor leader, and Seeing Machines (LSE:SEE), an advanced computer vision technology company that designs AI-powered operator monitoring systems to improve transport safety, announced a collaboration in support of high-performance driver and occupant monitoring system (DMS/OMS) technology.

Long-haul driving and congested traffic are two scenarios where driver fatigue and distraction often occur and frequently cause accidents, resulting in injury or worse. New and sophisticated advanced driver assistance systems (ADAS) are rapidly evolving to support safety across increasing, varied levels of autonomous capability.

The collaboration pairs ADI’s advanced infrared driver and high-speed Gigabit Multimedia Serial Link™ (GMSL) camera connectivity solutions with Seeing Machines’ artificial intelligence (AI) DMS and OMS software to support powerful eye gaze, eyelid, head, and body-pose tracking system technology that more accurately monitors driver fatigue and distraction. The combined solution will readily meet European Commission General Safety Regulations (GSR) and European New Car Assessment Program (Euro NCAP) requirements. It is also conducive to enabling future occupant monitoring features and a range of in-cabin camera placement options, previously unworkable due to challenges related to power efficiency, functional safety, hardware footprint, and image quality.

Semi-autonomous driving systems rely on in-cabin DMS and OMS to recognise and address driver fatigue and distraction. These systems must operate in all lighting conditions and require proper infrared lighting to ensure image quality on a frame-by-frame basis necessary for eye tracking in real time. The combined solution from ADI and Seeing Machines leverages ADI’s industry-first infrared driver for DMS and OMS, capable of delivering up to 100W of peak power in a compact and functionally safe solution. This allows for a non-intrusive, smaller camera module in a vehicle’s cabin.

Seeing Machines’ AI software interprets signals from the optical hardware, monitors and diagnoses the problem, and combines with ADAS features to enable output signals to warn drivers and vehicle occupants when necessary.

“Seeing Machines exists to get people home safely, and our work with ADI aims to support semi-autonomous driving with increased safety levels to deliver what we call ‘supervised automation’,” said Nick DiFiore, SVP and GM of Automotive at Seeing Machines. “ADI’s proven automotive-grade, near-infrared drivers and GMSL devices enable a sophisticated optical path to provide critical illumination and high-speed video bandwidth for real-world and real-time processing of interior cabin environments.”

“Cabin monitoring is complex and requires careful integration of infrared illumination, image capture, data processing, and algorithm layers to achieve a real-time response,” said Yin Wu, Director of Automotive Product Line Management at Analog Devices. “Together with Seeing Machines, we are supporting the automotive industry with pragmatic solutions to help reduce collisions and save lives.”

ADI’s MAX25614 IR LED driver and GMSL serializer and deserializer (SerDes) connectivity solutions are supporting Seeing Machines’ FOVIO DMS and OMS solutions.

ADI's Automotive Electrification and Cabin Experience Solutions

ADI’s innovations are making a positive planetary scale impact in automotive electrification and experience. By leveraging technology synergies across Automotive and Sustainable Energy, ADI aims to accelerate the transformation of mobility and the grid towards Net Zero emissions. ADI is also enabling the Digital Cabin and Safe Mobility revolution through its technology leadership in Audio Processing, Data, and Video Connectivity platforms which are advancing consumer applications and safety-critical ADAS in the vehicle. Our leadership in Battery, Power, and Energy Management solutions enables high performance, reliable, and safe operations across the entire electrification ecosystem—including EVs, Energy Storage Systems, the Clean Energy Grid, and more. With a focus on measuring and advancing sustainability at every step, our innovations in software and wireless technologies allow for localised real-time mission-critical decisions to enable Intelligence at the Edge.

About Analog Devices

Analog Devices, Inc. (NASDAQ: ADI) is a global semiconductor leader that bridges the physical and digital worlds to enable breakthroughs at the Intelligent Edge. ADI combines analogue, digital, and software technologies into solutions that help drive advancements in digitised factories, mobility, and digital healthcare, combat climate change, and reliably connect humans and the world. With reported revenues of more than $12 billion in FY22 and approximately 25,000 people globally working alongside 125,000 global customers, ADI ensures today’s innovators stay Ahead of What’s Possible. Learn more at http://www.analog.com and on LinkedIn and Twitter.

About Seeing Machines

Seeing Machines (LSE: SEE), a global company founded in 2000 and headquartered in Australia, is an industry leader in vision-based monitoring technology that enable machines to see, understand and assist people. Seeing Machines’ technology portfolio of AI algorithms, embedded processing and optics, power products that need to deliver reliable real-time understanding of vehicle operators. The technology spans the critical measurement of where a driver is looking, through to classification of their cognitive state as it applies to accident risk. Reliable “driver state” measurement is the end-goal of Driver Monitoring Systems (DMS) technology. Seeing Machines develops DMS technology to drive safety for Automotive, Commercial Fleet, Off-road and Aviation. The company has offices in Australia, USA, Europe and Asia, and supplies technology solutions and services to industry leaders in each market vertical. www.seeingmachines.com

All trademarks and registered trademarks are the property of their respective owners.

-

Analog Devices’ Precision Medium Bandwidth Signal Chain Platform Connects a Wide Range of Sensors

20 December 2022Analog Devices, Inc. (ADI) has introduced a precision medium bandwidth signal chain platform improving system performance for signal bandwidths of DC to approximately 500kHz towards industrial and instrumentation applications. The new platform offers a host of complete signal chains with customisable solution options and a curated suite of development tools, such as LTspice® simulations, to simplify the design journey. These robust signal chains, designed for both time and frequency measurement precision, allow for end systems that can accept inputs from the widest array of sensor and measurement modalities from IEPE vibration and acceleration to temperature and pressure. The signal chains also support engineers in designing with confidence and tackling the most demanding precision instrumentation challenges in areas such as Condition Based Monitoring (CbM), large channel count or distributed data acquisition systems (DAQ), position and motor control, and sonar.

- Discover adaptable precision medium bandwidth signal chains including application-specific design tools, purpose-developed knowledge bases, and customisable solutions: https://www.analog.com/en/applications/technology/precision-technology/precision-medium-bandwidth.html

- Watch a video about ADI's robust Industrial Signal Chains: https://www.analog.com/en/education/education-library/videos/6312668688112.html

- Find application notes and technical articles about CbM from ADI: http://www.analog.com/cbm

- Connect with engineers and ADI experts on EngineerZone™, an online technical support community: https://ez.analog.com/precision-technology-signal-chains/precision-medium-bandwidth

The signal chains included within the platform feature precision and power component selections that prioritise combined AC and DC accuracy design requirements, with options for single or multichannel systems as well as higher channel density for the largest channel count systems. Examples of precision medium bandwidth signal chain options provided with the platform include those that allow scaling of AC precision versus power for instrumentation, low latency options for motor control and position sensing, and highest density options using signal chain µModule SIP solutions or multichannel converters. Large channel count system designers can choose from signal chains where channel synchronisation is a priority, whether in channel-isolated or non-isolated systems.

Precision Medium Bandwidth Key Features:

- Optimising signal chain resolution and gain delivers the 16-bit to 24-bit accuracy required, across the widest range of sensor bandwidths, for amplitudes both small and large

- Flexibility to prioritise between noise performance, signal bandwidth, and power enables reuse of optimum layout and multiple use cases of the circuitry with simple software updates

- Options for higher channel densities give the ability to scale the precision measurements to distributed or centralised large channel count scenarios

Pricing and Availability

Product

Full Production

Description

Price Each per 1,000

Packaging

Now

DC to 204kHz, Dynamic Signal Analysis, Precision 24-Bit ADC with Power Scaling

$7.32

28-Lead LFCSP (4mm x 5mm x 0.75mm w/ EP)

Now

Precision, Low Noise, CMOS, RRIO Op Amp (single)

$0.90

5-Lead SOT-23

Now

Zero-drift, single-supply, rail-to-rail input/output operational/amplifier

$1.28

6-Lead SC70

Now

18-Bit, 2MSPS, μModule Data Acquisition Solution

$23.49

49-Ball CSPBGA (7mm x 7mm)

Now

16-Bit rail-to-rail DACs with I2C interface

$3.41

10-Lead DFN (3mm x 3mm w/ EP)

-

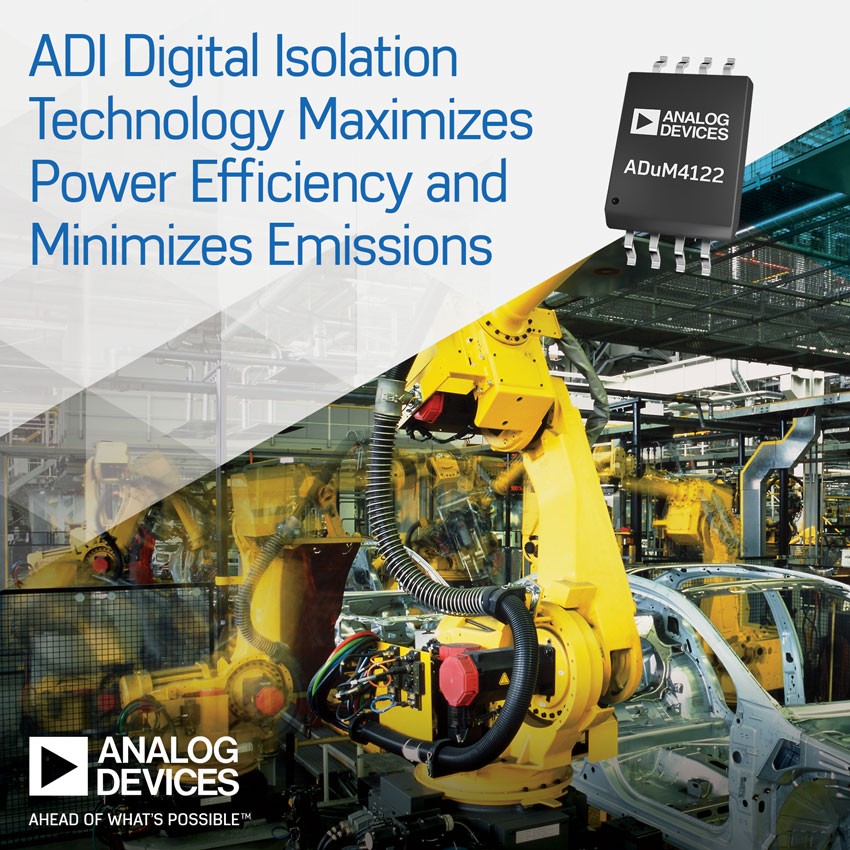

How Real-Time Control, Safety, and Security Are Driving Technological Innovation in the Factory of Tomorrow

15 December 2022Widening prosperity is combining with the proliferation of sensors and extensive cloud connectivity to accelerate the pace of change in factory systems and equipment.

The way in which factories operate is changing fast in the face of powerful economic and technological forces. The most agile factory equipment manufacturers will thrive in this fast-changing environment, as they develop increasingly connected and intelligent systems which help factories become more flexible and safer, while maintaining security as they extend connectivity. Increased use of automated and autonomous systems will reduce factories’ dependence on labour for repetitive or intricate manual operations.

Semiconductors will be at the heart of this new generation of industrial automation equipment, providing the processing, control, and sensing functions required to operate effectively in connected environments.

Analog Devices (ADI), which has always thrived at the intersection of the analogue and digital worlds, has a close-up view of the technological changes that new factory automation equipment calls for. Its expertise in the fields of sensing, signal conditioning, digital signal processing, wired and wireless connectivity, and software bring it close to the challenges that its industrial customers face, enabling it to develop application-oriented solutions that accelerate OEMs’ time to market. ADI’s goal is to help customers innovate through technology and be prepared for whatever the future brings, while continuing to support legacy systems by providing guaranteed long-term availability of industrial parts.

What the future brings is profound disruption, which has its roots in a welcome trend: the global spread of prosperity.

Widening Prosperity

This century has seen a notable rise in disposable incomes in parts of the world that have traditionally been regarded as developing countries. As a result, demand for manufactured goods is growing globally, putting pressure on manufacturers to expand production while supplying an increasingly diverse set of product configurations, in order to satisfy regional and national variations in demand.

At the same time, the global growth in prosperity is shrinking the availability of cheap, unskilled manual labour. The one-time boost that manufacturers have gained in the past 30 years from off-shoring production to low cost locations such as China is evaporating, as wages in these locations rise, and the workforce, now increasingly well-educated, loses its appetite for performing repetitive manual operations for low pay. In the future, manufacturers will be seeking to increase competitiveness by deploying automation technology rather than moving to a new low cost location.

The Smart and Connected Factory

New technological capabilities are also helping manufacturers gain additional value from expenditure on factory automation equipment.

A proliferation of miniature, high performance semiconductor sensors alongside pervasive connectedness are creating a deluge of data on machine and process performance. There is now more potential than ever for rich, new applications of data analytics, such as machine health monitoring and preventive maintenance. At the same time, the increasing use of programmable hardware and software-defined electronics functions enables rapid reconfigurations of factory processes and tools.

The factory of tomorrow, then, will be more agile and responsive to demand, more automated, and more reliable. It will require fewer human operators and will face less disruption due to unplanned maintenance.

So which technologies in the analogue and digital semiconductor worlds are going to enable this new model of factory automation?

Sensors - The Key to Machine Health Monitoring

MEMS sensor technology is enabling the development of new sensor types that are small, robust, and able to precisely measure vibration and motion. For instance, low noise, wide-bandwidth accelerometers offer the high precision and accuracy required to identify subtle changes in the vibration signature of a machine. Coupled with sensor analytics software, these devices enable equipment operators to pinpoint the source of a potential failure long before it occurs and apply preventive maintenance measures in good time.

Machine health monitoring is an application that is not confined to conventional factory settings. Mobile or remote industrial equipment may use a wireless connection to report diagnostic information and operating status to a central controller. Running on battery power or intermittent power sources such as solar energy, this kind of application requires a very low power sensing solution.

High Speed Connectivity on the Factory Floor

The proliferation of sensors throughout factories and process plants is generating vast flows of real-time data. Legacy communication protocols between sensor nodes and PLCs, such as 4mA to 20mA control loops, are giving way to ultrafast industrial variants of the Ethernet protocol, enabling increasing integration of operational technology (OT) infrastructure in the factory with information technology (IT) in the enterprise.

In responding to this new demand for high speed data transfer in the factory, OEMs need to future-proof their system implementations, so that they support not only industrial Ethernet protocols in use today, but also the emerging time-sensitive networking (TSN) variant of Ethernet, which is likely to become the standard wired networking technology for real-time industrial communications. To support this transition, ADI provides an Ethernet platform which enables systems to swap from one Ethernet protocol to another without the need for hardware redesign.

Robust, wireless sensor network technologies are also required for connecting sensor nodes in locations that are hard to reach with physical wiring. Wireless network technologies such as SmartMesh® and WirelessHART, which are designed to operate in tough IoT applications, provide a proven and high performance method of connecting industrial automation equipment without wires.

Safety Systems for Autonomous Machines

Autonomous vehicles and cobots offer a huge scope for widening the application of automation in factories and warehouses. The challenge for industry is to guarantee safety, ensuring that autonomous machines are fully environment-aware. Advanced radar and lidar technologies are raising the standard of accuracy and precision in object and proximity detection and 3D mapping applications.

Protecting the Factory from Online Attack

With the growth in connectivity comes a heightened risk of attack by hackers intent on extorting payment from factory operators, or by state-sponsored attackers tasked with causing disruption to high value industrial systems.

As factory operators connect more and more nodes to the cloud, they open up new entry points for hackers to exploit. Semiconductor-based connectivity systems need robust security optimised for embedded systems. Analog Devices is developing new solutions to meet emerging security threats to industrial systems, thus helping to future-proof customers’ industrial infrastructure.

Configurable Production Processes

The factory of the future must be capable of quick adaptation to new demands and new workflows; the key is to build flexibility into industrial automation technology products at the architecture level. One approach which can support this need for flexibility is software-defined I/O, which can be configured as analogue or digital, and input or output, without altering wiring.

Pushing the boundaries of today’s technology, ADI already supplies a robust and flexible industrial output solution, which enables full software configurability of the analogue output to support a variety of industrial standards.

Integrating Analogue, Digital, and Software

The development and production of industrial automation equipment is becoming an increasingly high tech undertaking, driven by the need to meet end user demand for higher throughput, more configurability, safer operation, and more cloud integration. At the same time, pressure to get to market quickly with new, more sophisticated designs continues to intensify.

Analog Devices’ response is to provide customers with an integrated offering, providing market-oriented solutions for applications including, among others, machine health monitoring, high speed connectivity, and safety and security systems. It will do so by combining analogue, mixed-signal, and digital components with firmware and software to solve the most pressing development problems that its customers face, enabling them to respond rapidly and effectively to the intensifying technological and economic challenges of today and tomorrow.

-

Join Analog Devices at CES 2023 to Experience Life at the Intelligent Edge

13 December 2022Analog Devices, Inc. (Nasdaq: ADI) invites the public and media to experience life at the Intelligent Edge through interactive demonstrations and expert discussions at CES 2023.

Visit the ADI booth: Connecting the physical and digital worlds by both sensing and processing at the edge will make data and insights available where decisions are made, resulting in faster and more effective execution. Stop by booth #4725 at the Las Vegas Convention Center West Hall to learn how the Intelligent Edge will impact every moment of our lives, big or small, to solve some of the world’s greatest challenges by enabling a more efficient, safer, and sustainable future.

“Insights from the Edge” Panel Sessions: ADI executives will be joined by experts and thought leaders in a series of conversations about how technology is enriching lives and accelerating human breakthroughs. All discussions will be held at ADI’s booth. For any updates on panel sessions or details regarding ADI at CES, please visit www.analog.com/ces.

Panel sessions:

- The Future of Automotive: Bringing Personalised and Immersive Experiences into the Vehicle

- Thursday, January 5, 11:30-11:55 a.m.

- Participants: ADI, Jaguar Land Rover, and Harman

- The Ocean’s Critical Role in Combatting Climate Change

- Friday, January 6, 12:00-12:25 p.m.

- Participants: ADI and Woods Hole Oceanographic Institution (WHOI)

Demonstrations: Explore 30 live demos featuring ADI’s technology to see how the Intelligent Edge will continue to advance the efficiency, safety, and sustainability in our daily lives from the ordinary to the extraordinary.

- Automotive: Explore how ADI’s innovations are enabling a more personalised, immersive, safe, and sustainable mobility experience. ADI’s advancements in connectivity, audio processing platforms, and power management solutions are pioneering a seamless transition from home to vehicle.

- Consumer: Discover how ADI’s technology is making the office work from anywhere, as well as streamlining and enhancing the way we create and enjoy movies, music, and media.

- Digital Healthcare: See how ADI’s sensing technologies in a range of wearables continuously monitor body vital signs to support the management of health and sleep patterns.

- Industrial: Watch how terrain-based navigation and stabilisation is helping to make workdays safer and more productive. See ADI’s technology in action as it helps vehicles operate more safely and efficiently in agriculture, on construction sites, and more.

Award-winning tech: Learn more about the ADTF3175 which earned a 2023 CES Innovation Award for opening up endless possibilities in augmented and mixed reality. The ADTF3175 is the industry’s first high-resolution, industry quality, indirect Time-of-Flight module for 3D depth sensing and vision systems. The CES Innovation Awards are based upon descriptive materials submitted to the judges. Consumer Technology Association (CTA) did not verify the accuracy of any submission or of any claims made and did not test the item to which the award was given.

About Analog Devices

Analog Devices, Inc. (NASDAQ: ADI) is a global semiconductor leader that bridges the physical and digital worlds to enable breakthroughs at the Intelligent Edge. ADI combines analogue, digital, and software technologies into solutions that help drive advancements in digitised factories, mobility, and digital healthcare, combat climate change, and reliably connect humans and the world. With reported revenues of more than $12 billion in FY22 and approximately 25,000 people globally working alongside 125,000 global customers, ADI ensures today’s innovators stay Ahead of What’s Possible. Learn more at www.analog.com and on LinkedIn and Twitter.

- The Future of Automotive: Bringing Personalised and Immersive Experiences into the Vehicle

-

IC Eases the Design of 48V/12V Dual Battery Automotive Systems

30 November 2022The future of 48V/12V battery systems in automobiles is just around the corner. Most of the major automobile manufacturers across the globe have been working on proving out their systems for the past few years and it is evident that their implementation will be relatively near term. This is a necessary and crucial step in the long and arduous journey to the fully autonomous passenger vehicle that does not require a human at the controls and has true autonomous driving. Nevertheless, this doesn’t mean the 12V battery is going away; there are far too many legacy systems in the installed vehicle base for this to occur. This means that autonomous cars will have both a 12V battery and a 48V battery.

This fact means that the vehicles’ internal systems will either run off the 48V lithium-ion (Li-Ion) battery or the 12V sealed lead-acid (SLA) battery - but not both. Nevertheless, in addition to having two separate charging circuits for these individual batteries due to their respective chemistries, there must also be a mechanism that allows charge to move between them without causing any damage to the batteries or any of the systems within the vehicle. Moreover, having two batteries also allows for redundancy should one of them fail during operation.

While this certainly complicates the design of the various electrical subsystems within the vehicles, there are some advantages to be gained. According to some auto manufacturers, a 48V-based electric system results in a 10% to 15% gain in fuel economy for internal combustion engine vehicles, thereby reducing CO2 emissions. Moreover, future vehicles that use a dual 48V/12V system will enable engineers to integrate electrical booster technology that operates independently of the engine load, thereby improving acceleration performance. Such compressors are already in the advanced stages of development and will be placed between the induction system and the intercooler, using the 48V rail to spin-up the turbos.

Globally, fuel economy regulations have been tightening, while autonomous driving capability with connectivity continues to proliferate in new automobiles. Accordingly, the 12V automobile electric system has reached its usable power limit. Simultaneously, as if these changes are not already enough, there has been a significant increase in automotive electronic systems. These changes, coupled with related demands for power, have created a new spectrum of engineering opportunities. Clearly, the 12V lead-acid battery automotive system with its 3kW power limit must be supplemented.

Furthermore, there are new automobile standards that impact how these systems need to work. The automotive standard, known as LV 148, combines a secondary 48V bus with the existing automotive 12V system. The 48V rail includes an integrated starter generator (ISG) or belt start generator, a 48V Li-Ion battery, and a bidirectional dc-to-dc converter, which can deliver tens of kilowatts of available energy from the 48V and 12V batteries. This technology is targeted at conventional, internal combustion automobiles, as well as hybrid electric and mild hybrid vehicles, as auto manufacturers strive to meet increasingly stringent CO2 emission targets.

New Power Solution for 48V/12V Battery Systems

This new standard requires the 12V bus to continuously power the ignition, lighting, infotainment, and audio systems. Whereas, the 48V bus will power active chassis systems, air conditioning compressors, adjustable suspensions, electric superchargers, turbos, and even regenerative braking.

The implementation of an additional 48V supply network into vehicles is not without significant impact. Electronic control units (ECUs) will be affected and will need to adjust their operational range to the higher voltage. This will necessitate that manufacturers of dc-to-dc converters will also need to introduce specialised ICs to enable this high power transfer.

Accordingly, Analog Devices’ has designed and developed a few dc-to-dc converters that can enable this energy transfer with very high efficiency to conserve energy while simultaneously minimising the thermal design aspects.

The need for a bidirectional step-down and step-up dc-to-dc converter that goes between the 12V and 48V batteries is clearly required. Such converters could be used to charge either of the batteries while simultaneously allowing both batteries to supply current to the same load if required in the system. From a legacy perspective, these initial 48V/12V, dual battery, dc-to-dc converter designs used different power components to step-up and step-down the voltage.

Analog Device’s LT8228 is a bidirectional dc-to-dc controller that uses the same external power components for step-up conversion as it does for step-down conversion. This device is a 100V bidirectional constant-current or constant-voltage synchronous buck or boost controller with independent compensation networks. The direction of the power flow is automatically determined by the LT8228 or is externally controlled. The input and output protection MOSFETs protect against negative voltages, control inrush currents, and provide isolation between terminals under fault conditions such as switching MOSFET shorts. In step-down mode, the protection MOSFETs at the V1 terminal prevents reverse current. In step-up mode, the same MOSFETs regulate the output inrush current and protect themselves with an adjustable timer circuit breaker.

Furthermore, the LT8228 offers a bidirectional input and output current limit as well as independent current monitoring. Masterless, fault-tolerant current sharing allows any LT8228 in parallel to be added or subtracted while maintaining current sharing accuracy. Internal and external fault diagnostics and reporting are available via the fault and report pins. The LT8228 uses a 38-lead TSSOP package.

The LT8228 is a 100V, bidirectional, peak current-mode synchronous controller with protection MOSFETs. The controller provides a step-down output voltage, V2, from an input voltage, V1, when in buck mode or a step-up output voltage, V1, from an input voltage, V2, when in boost mode. The input and output voltage can be set as high as 100V. The mode of operation is externally controlled through the DRXN pin or automatically selected. In addition, the LT8228 has protection MOSFETs for the V1 and V2 terminals. The protection MOSFETs provide negative voltage protection, isolation between the input and output terminals during an internal or external fault, reverse current protection, and inrush current control. In applications such as battery backup systems, the bidirectional feature allows the battery to be charged from either a higher or lower voltage supply. When the supply is unavailable, the battery boosts or bucks power back to the supply.

To optimise transient response, the LT8228 has two error amplifiers: EA1 in boost mode and EA2 in buck mode with separate compensation pins VC1 and VC2, respectively. The controller operates in discontinuous conduction mode when reverse inductor current is detected for conditions such as light load operation. The LT8228 provides input and output current limit programming in buck and boost mode operation using four pins: ISET1P, ISET1N, ISET2P, and ISET2N. The controller also provides independent input and output current monitoring using the IMON1 and IMON2 pins. Current limit programming and monitoring is functional for the entire input and output voltage range of 0V to 100V.

Furthermore, the LT8228 provides masterless, fault-tolerant output current sharing among multiple LT8228s in parallel, enabling higher load current, better heat management, and redundancy. Each LT8228 regulates to the average output current eliminating the need for a master controller. When an individual LT8228 is disabled or in a fault condition, it stops contributing to the average bus, making the current-sharing scheme fault tolerant.

Additional features include:

- Feedback voltage tolerance: ±0.5% over temperature

- Bidirectional programmable current regulation and monitoring

- Extensive self-test, diagnostics, and fault reporting

- Programmable fixed or synchronisable switching frequency: 80kHz to 600kHz

- Programmable soft start and dynamic current limit

- Masterless, fault-tolerant current sharing

Conclusion

The LT8228 brings a new level of performance, control, and simplification to 48V/12V, dual battery, dc-to-dc automotive systems by allowing the same external power components to be used for step-down and step-up purposes. It operates on demand in buck mode from the 48V bus to the 12V bus or in boost mode from 12V to 48V. When starting the car or when additional power is required, the LT8228 allows both batteries to supply energy simultaneously to the same load. This gives power conversion designers a feature rich, bidirectional converter that can easily configure 12V and 48V battery systems, which will be required for the fully autonomous vehicles of the near future.

-

Analog Devices Announces World’s First Long-Reach, Single-pair Power over Ethernet (SPoE) Solutions for Smart Building and Factory Automation

22 November 2022Analog Devices, Inc. (Nasdaq: ADI) has announced the world’s first Single-pair Power over Ethernet (SPoE) Power Sourcing Equipment (PSE) and Power Device (PD) solutions to help customers drive greater levels of intelligence into smart buildings, factory automation, and other applications at the edge of traditional networks. The new offerings facilitate powered, last-mile connectivity for factory and building automation through real-time power management, telemetry, extremely low standby power consumption, and ease of installation.

“The Intelligent Edge is one of the most exciting developments of the digital era as computing power is pushed to previously inaccessible applications and locations,” said Leo McHugh, Vice President of Industrial Automation at Analog Devices. “Analog Devices is committed to delivering the unrivalled technology and solutions our customers need to leverage the full potential of the Intelligent Edge in smart buildings and factories as well as many more applications in the future.”

Enabling Digital Buildings of the Future

Analog Devices’ new SPoE solutions, LTC4296-1 and LTC9111, address the challenges of providing power and data to devices, even in remote, difficult to access endpoint locations. Analog Devices’ solutions aim to help new families of endpoint applications to be seamlessly powered and accessed across the network and used to assess local factors such as asset health, environmental conditions, security metrics, and more. The localised awareness and control they offer are the building blocks of the digital buildings of tomorrow.

Analog Devices’ SPoE solutions reduce reliance on localised power and batteries by using a single twisted pair of Ethernet cables to provide efficient, reliable, easily installed power at reduced size and weight. Combined with ADI Chronous™ ADIN1100 and ADIN1110 10BASE-T1L, Industrial Ethernet solutions, customers can reliably transfer both power and data over one kilometre – a significant increase from previous Ethernet standards.

Interoperable Efficiency

Analog Devices’ new LTC4296-1 5-port SPoE PSE with Classification and LTC9111 SPoE PD with Polarity Correction products support both SPoE and Power over Data Line (PoDL) variants of single-pair powering. SPoE augments Single Pair Ethernet (SPE) to provide more reliable, fault-tolerant, and interoperable point-to-point power solutions, delivering up to 52W. Both products are 802.3cg compliant and support Serial Communication Classification Protocol (SCCP).

- For more information about ADI’s LTC4296-1 5-port SPoE PSE, visit analog.com/ltc4296-1

- For more information about ADI’s LTC9111 SPoE PD, visit analog.com/ltc9111

- For more information about ADI’s Power-over-Ethernet (PoE) and Single-Pair Power-over-Ethernet (SPoE) Interface Controllers, visit https://www.analog.com/en/product-category/power-over-ethernet-poe-interface-controllers.html

- For more information about ADI’s Chronous™ Industrial Ethernet portfolio, visit analog.com/chronous

-

Analog Devices Shows Solutions for Smart and Sustainable Manufacturing at SPS 2022

7 November 2022ADI to display solutions that empower the intelligent edge in applications including robotics, condition-based monitoring, advanced sensing, and factory digitisation

Analog Devices, Inc. (ADI) will present world-class technology and solutions which help empower the intelligent edge for smart and sustainable manufacturing at the SPS 2022 exhibition from November 8-10 in Nuremberg, Germany. See how ADI helps customers to sustainably increase productivity by improving system flexibility and efficiencies.

Visit ADI’s stand in Hall 5, booth 110 to experience the full range of ADI solutions for the digital factory, including:

ADI’s Open-Source Complete Autonomous Mobile Robot showcases how ADI’s interoperable technology platforms and ROS software drivers reduce development overhead, accelerating time to market. Precise robot navigation and accurate obstacle avoidance is enabled by high accuracy depth sensing, intelligent AI processing and mapping. The ADBMS6948 battery monitor and ADI Trinamic™ solutions for efficient wheel drives are designed to enable a complete AMR system to be easily architected and optimised for industrial environments.

Experience a Seamlessly Connected Edge to Enterprise industrial automation environment, with ADI Chronous™, Ethernet-APL for IP-addressable field devices, IO-Link® connected factory sensors and actuators, and software configurable control systems. See how key measurement data and auxiliary diagnostic information is aggregated in real time to capture new insights, reducing waste and increasing overall production efficiency. ADI’s interoperable, Time Sensitive Networking (TSN) technology showcases how both standard Ethernet traffic and time-critical traffic can coexist in a converged network, facilitating seamless factory upgrades and flexible manufacturing.

ADI will showcase Motion Control Solutions that optimise performance for reduced energy consumption through precision position sensing and control, efficient power quality monitoring, and predictive asset health management for reduced system downtime. Watch the insights live, as the power quality of the motor drive is monitored with the ADE9430 and associated software solution. Other highlights include ADI Trinamic™ low power, low resonance motion control technology, ADI MagIC+ multiturn position sensor capable of tracking movement even when power is removed, and ADI OtoSense™ artificial edge intelligence and MEMS vibration technology for real-time condition monitoring.

Conference Presentations

Analog Devices experts are making technical presentations at the Exhibition Forum in Hall 5. The speakers will provide guidance on intelligent edge sensor design for asset health monitoring, describe the state of the art in industrial connectivity, and explain how ADI technology for empowering the intelligent edge can help industrial companies achieve sustainable smart manufacturing.

Visit the ADI SPS 2022 website for more information on the conference presentations and for details about the demonstrations at the ADI stand.

About Analog Devices

Analog Devices, Inc. operates at the centre of the modern digital economy, converting real-world phenomena into actionable insight with its comprehensive suite of analogue and mixed signal, power management, radio frequency (RF), and digital and sensor technologies. ADI serves 125,000 customers worldwide with more than 75,000 products in the industrial, communications, automotive, and consumer markets. ADI is headquartered in Wilmington, MA. Visit http://www.analog.com.

-

Analog Devices and AUO Team Up to Introduce Safe, Power Efficient Widescreen Displays to the Automotive Market

3 November 2022ADI’s industry-first matrix LED driver enables local dimming to enhance the in-cabin experience while improving power and safety

Analog Devices, Inc. (Nasdaq: ADI) has announced that AUO Corporation (TPE: 2409) will use ADI’s matrix LED display driver technology in their market-leading automotive widescreen display portfolio. This industry-first technology enables local dimming, significantly improving power consumption by a minimum of 50% and supporting functional safety requirements.

To deliver a more immersive experience, vehicles are incorporating widescreen displays throughout the cabin. Increased automation and autonomy are pushing the requirements of these displays from a typical infotainment hub to a safety centre with visuals surrounding the vehicle. Furthermore, the automotive industry is accelerating the transition to electric vehicles, where power consumption is increasingly important.

To meet these requirements, ADI has developed a unique approach called local dimming that drives LEDs behind the screen in the car display unit. Developed through a proprietary power process technology, the driver integrates all external switching positive channel field effect transistors (PFETs), enables high resolution and high contrast ratio for large automotive displays, provides improved diagnostics of LEDs, and reduces ghost images. The system reduces power consumption by a minimum of 50% compared to the traditional edge lit display. ADI’s power portfolio is ASIL-B to D rated, a critical consideration for many automotive manufacturers that require functional safety features to ensure reliable operation within the vehicle.

ADI aims to enhance the in-cabin experience by enabling energy-efficient widescreens capable of local dimming through proprietary power management and processing solutions, as well as high resolution displays through Gigabit Multimedia Serial Link™ (GMSL) serialiser and deserialiser (SerDes) connectivity solutions.

“To help us maintain our leadership position in the market as one of the world’s top automotive display manufacturers catering to some of the largest OEMs, ADI's local dimming automotive display drivers deliver the power efficiency consistent with the quality standard of the AUO brand,” said Simon Hsu, Head of Automotive Business Unit at AUO. “AUO AmLED displays feature power savings, excellent sunlight readability and high contrast ratio, which greatly upgrade driving safety and in-cabin entertainment experience. In response to the trend of smart mobility, AUO continues to advance display technology, and we look forward to further collaborations with the ADI team.”

“The future of the automotive experience is to bring consumer features into the vehicle,” said Patrick Morgan, Corporate Vice President of Automotive Electrification and Sustainable Energy at Analog Devices. “Through this collaboration, our technology and leadership for high performance automotive power enables bringing the next wave of widescreen displays into the market with significantly improved power consumption and full functional safety capabilities.”

AUO uses the MAX25500 4 x 24 automotive LED matrix driver for its local-dimming automotive displays. It is available now and is part of ADI’s family of automotive local dimming display drivers.

Packaging

Product

Packaging

Functional Safety

MAX25500AUMA/V+T

48-pin TSSOP-CU

QM

MAX25500ATMA/V+T

48-pin TQFN-CU

QM

MAX25501AUMA/V+T

48-pin TSSOP-CU

ASIL B

MAX25501ATMA/V+T

48-pin TQFN-CU

ASIL B

MAX25500 Evaluation Kit

QFN and TSSOP

QM

MAX25501 Evaluation Kit

QFN and TSSOP

ASIL B

About AUO

AUO is an enthusiastic, technology-driven company, delivering products and solution services that advance the frontier of innovation for display, system solutions, industrial intelligence, healthcare, and energy. The company is based in Taiwan and operates across Asia, the US and Europe. Additionally, AUO has also been named to the Dow Jones Sustainability World Index since 2010. Visit https://www.auo.com.

About Analog Devices

Analog Devices, Inc. (NASDAQ: ADI) operates at the centre of the modern digital economy, converting real-world phenomena into actionable insight with its comprehensive suite of analogue and mixed signal, power management, radio frequency (RF), and digital and sensor technologies. ADI serves 125,000 customers worldwide with more than 75,000 products in the industrial, communications, automotive, and consumer markets. ADI is headquartered in Wilmington, MA. Visit https://www.analog.com.

-

Analog Devices Engineers a Sustainable Future at electronica 2022

24 October 2022Discover how ADI is shaping the future with solutions aimed towards intelligent manufacturing, efficient building solutions, greener and safer cars, and a healthier lifestyle

Analog Devices, Inc. will showcase its innovative technology and solutions for industrial automation and instrumentation, automotive, healthcare, consumer and communications applications at electronica 2022 from November 15-18 (Munich, Germany in hall C4, booth 125.)

- For more information on conference presentations and demo details, visit the ADI electronica 2022 website.

With over 30 demos, keynote speeches, and technical presentations from ADI experts, visitors will discover how ADI is working to engineer a sustainable future through areas such as intelligent factory and building automation, smart robotics and autonomous machines, automotive electrification, immersive in-cabin experiences, sustainable energy and grid stabilisation, 5G and next-generation connectivity, intelligent and safe consumer devices, and preventive digital healthcare.

Demo Highlights:

Industrial Automation and Instrumentation

Industrial and building automation systems are rapidly digitising, combining sensing, connectivity, and analytics to enable a new level of energy efficiency to unlock key insights and deliver personalised outcomes. Demonstrations featuring advanced intelligent motion control, asset health monitoring, seamlessly connected intelligent edge devices, and efficient power management showcase just some of the ways ADI’s technologies are building a more sustainable industrial future. Examples include communications technology to unlock the intelligent edge in the digital factory, advanced optical sensing for controlling robots with pinpoint accuracy, and integrated systems for intelligent building automation.

ADI’s technologies are helping automotive manufacturers transform the in-cabin environment with audio, voice, Ethernet, and display solutions, as well as advanced battery solutions for electric vehicles. Through ADI’s technology, the automotive industry can offer more immersive, personalised in-cabin experiences. Demonstrations include a complete battery management system for lithium-ion energy storage, the ADI LISTN™ platform allowing the concurrent operation of two independent voice assistants inside the cabin, and Gigabit Multimedia Serial Link™ (GMSL)-based SerDes solutions enabling automotive OEMs to deploy high resolution sensors in tomorrow´s software-defined vehicles.

ADI is working with customers to shape the future of digitised and decentralised healthcare, helping to make care more accessible and affordable for all. Smart sensors, precision analogue, high-performance signal processing, and advanced algorithms are at the heart of ADI’s healthcare solutions. Featured demos include a non-contact health monitoring system, an industry-first vital signs monitoring module placed on or inside a patient’s mattress or pillow, and an exercise bike with a low-cost power meter which also supports an ADI biometric sensor platform for activity tracker wristbands. ADI’s Health Sensor Platform 4.0, an open-source reference design for a chest patch providing 24/7 vital signs monitoring, will also be featured.

A display wall will highlight innovative consumer devices developed by customers and supported by ADI’s digital signal processing, audio, video, power, and software solutions. Products will include low power wireless headphones and best-in-class soundbars as well as next-generation consumer devices creating highly immersive interactions between people and technology. Communications solutions on display will include a high-speed wireless data interconnect system and optimised power designs for 5G RF signal chains.

-

Analog Devices and Keysight Technologies Join Forces to Advance the Adoption of Phased Array Technology

13 October 2022Analog Devices, Inc (Nasdaq: ADI) and Keysight Technologies, Inc. (NYSE: KEYS) has announced their collaboration to advance the adoption of phased array technology. This technology is key to realising ubiquitous connectivity and sensing by simplifying development stages associated with creating satellite communication, radar, and phased array systems.

Analog Devices’ family of phased array platforms are used to accelerate customers' beamforming developments by providing a total solution that can then be tested and calibrated with Keysight phased array test solutions. This collaboration brings together the entire ecosystem by aiming to provide a total design, test, and calibration solution. Phased array antennas are the enablers of next-generation wireless communication applications as well as signal intelligence and earth observation applications.

“We are pleased to collaborate with Analog Devices to bring innovative phased array technology to a wide variety of new customers and their use cases,” said Peng Cao, Vice President and General Manager for Keysight’s Wireless Test Group. “Keysight’s state-of-the-art measurement solutions have transformed phased array test times from minutes down to seconds. Working closely with Analog Devices, we have demonstrated a 70 times faster measurement speed while maintaining excellent accuracy. Bringing together the beamforming advances of Analog Devices and measurement innovation from Keysight, our customers will now have the opportunity for a complete, end-to-end solution for phased arrays which will accelerate time to market and deliver exceptional performance.”

“Our customers are demanding more than just a beamforming IC, but rather a total system level solution with the test and calibration of the array. By utilising ADI’s system platforms, the collaboration between ADI and Keysight intends to help accelerate the adoption of phased array platforms for higher data rate communications and sensing solutions,” noted Bryan Goldstein, Vice President of Aerospace and Defense at Analog Devices.

Access the developer’s kit here: https://www.analog.com/en/design-center/evaluation-hardware-and-software/evaluation-boards-kits/x-band-development-platform.html

About Keysight Technologies

Keysight delivers advanced design and validation solutions that help accelerate innovation to connect and secure the world. Keysight's dedication to speed and precision extends to software-driven insights and analytics that bring tomorrow's technology products to market faster across the development lifecycle, in design simulation, prototype validation, automated software testing, manufacturing analysis, and network performance optimization and visibility in enterprise, service provider and cloud environments. Our customers span the worldwide communications and industrial ecosystems, aerospace and defence, automotive, energy, semiconductor and general electronics markets. Keysight generated revenues of $4.9B in fiscal year 2021. For more information about Keysight Technologies (NYSE: KEYS), visit us at www.keysight.com.

About Analog Devices

Analog Devices, Inc. (NASDAQ: ADI) operates at the centre of the modern digital economy, converting real-world phenomena into actionable insight with its comprehensive suite of analogue and mixed signal, power management, radio frequency (RF), and digital and sensor technologies. ADI serves 125,000 customers worldwide with more than 75,000 products in the industrial, communications, automotive, and consumer markets. ADI is headquartered in Wilmington, MA. Visit https://www.analog.com.

-

Analog Devices Announces Multiprotocol Industrial Ethernet Switch Platform

11 October 2022Pre-certified protocol solution reduces development time

Analog Devices, Inc. (ADI) has introduced the ADIN2299, a multiprotocol industrial Ethernet switch platform, to address the connectivity needs of industrial and process automation, motion control, transportation, and energy automation. The industrial Ethernet switch platform is designed to operate in a star, line, or ring topology. The ADIN2299 is a highly integrated and tested solution that contains a communications controller, a two port 10/100Mbps Ethernet switch, memory, physical layer (PHY), and protocol stacks. The ADIN2299 hardware, coupled with its software and pre-certified industrial protocols, reduces system integration time while providing fast time to market.

- Download data sheet, order samples and evaluation boards: https://www.analog.com/en/products/adin2299.html#product-overview

- Watch a video about the ADIN2299: https://www.analog.com/en/education/education-library/videos/6309821448112.html

- Connect with engineers and ADI product experts on EngineerZone™, an online technical support community: http://ez.analog.com

The ADIN2299 reduces design and debug time by not only providing the protocol stack but also the RTOS, file system, drivers, and TCP/IP. An application processor can connect to the switch platform via a UART, SPI or Ethernet interface. The ADIN2299 software enables the application processor to connect to a unified interface so that various industrial protocols can be utilised without requiring any changes to the application processor software. This eliminates the learning curve associated with incorporating additional protocols. Customers can now leverage a single field device hardware design to support multiple industrial protocols. Another critical element of the ADIN2299 is cyber security. It has a secure boot and secure update feature which ensures that only verified code is executed, reducing possible disruptions in the field caused by cyber attacks.

An ADIN2299 evaluation kit is available for platform assessment and system development. An application example is provided to demonstrate end-to-end, host-to-network and interface-to controller communication. Once an application development board is connected via UART, SPI, or Ethernet interface with the ADIN2299 evaluation board, protocol communication can be evaluated using a PLC or controller simulator. This allows for a complete verification before integrating the ADIN2299 into a system.

ADIN2299 Key Features:

- Multiprotocol Support: PROFINET, EtherCat, EtherNet/IP, Modbus TCP

- Pre-Certified Protocols

- Ease-of-Use: Fully integrated, tested, and drop-in ready hardware and software solution

- Cyber security: Secure Boot / Secure Update

- Bandwidth: 10/100Mbps

- Low Latency and Power

- Small Form Factor: 194 CSPBGA

Pricing and Availability

Product

Full

Production

Price Each Per 1,000

Packaging

ADIN2299

Now

$81.05

194 CSPBGA

About Analog Devices

Analog Devices, Inc. operates at the centre of the modern digital economy, converting real-world phenomena into actionable insight with its comprehensive suite of analogue and mixed signal, power management, radio frequency (RF), and digital and sensor technologies. ADI serves 125,000 customers worldwide with more than 75,000 products in the industrial, communications, automotive, and consumer markets. ADI is headquartered in Wilmington, MA. Visit http://www.analog.com.

-

Wearable Technology Trends in Healthcare

6 October 2022What are the markets of interest for Analog Devices and what is ADI’s current offering?

Analog Devices (ADI) is a semiconductor manufacturer and solutions provider for several industry markets. We have five target markets: industrial, communications, automotive, consumer, and medical. The medical market can be divided into several subsegments. These include medical imaging, vital sign monitoring (VSM), and medical instrumentation. We are active in every subsegment where market demand typically varies by region and due to geographical location. Noticeably, over the last couple of years, VSM has been one of the fastest growing segments in every region.

Ten years ago, VSM applications were mainly found in hospitals and professional rescue units such as ambulances and helicopters. The biggest market was for bedside monitors and monitors in intensive care departments. These high-end systems support multilead ECG measurements, oxygen saturation, body temperature, and CO2, and measure several other parameters. Now, VSM is becoming a part of our day-to-day lives. Wearable VSM systems make it possible for physicians to remotely monitor their patients. Instead of recovering from a surgery in the hospital, patients can be discharged sooner and recover in the comfort of their home. This not only helps reduce costly medical expenses but can also improve recovery time as recovery is often quickened in a private environment. Remote VSM systems can also allow elderly people to live independently for a longer time. With the aging population, elderly care houses are becoming unaffordable, so a remote monitoring system enables fewer professionals to monitor a bigger group of people. VSM for sports and exercise is trending as well. This helps people not only monitor their vital parameters, but also shows feedback on whether the exercise is effective.

Can you speak about ADI’s portfolio of sensors and how easy it is to integrate them into a device?

The market has changed rapidly. ADI used to make individual building blocks for signal conditioning and conversion into the digital domain. Now we support complete analogue front ends that include everything from the analogue input stage up to the digital interface, including self-calibration and temperature compensation. We also include the sensor element where possible, so we now have single chip solutions for biopotential measurement, bioimpedance sensing, optical PPG measurement (for heart rate, heart rate variability, and SpO2 monitoring), motion tracking, and accurate body temperature sensing. All these subsystems have integrated ADCs, so it is very easy to measure a certain parameter and include the measurement readings in your final application or system without the need for building a complex circuit diagram with discrete components.

Optical sensors make it possible to measure heart rate at a single spot on the body, but you can also measure heart rate variability (a measure for stress level detection) or oxygen saturation (the percentage of red blood cells carrying oxygen). We started with discrete amplifiers to interface photodiode currents, followed by analogue front ends, conditioning the photocurrents, and then integrated current sources to control the LEDs used for controlling the light emitted in the system. Because not every electronic engineer is an optical engineer, we developed a half-dozen optical modules. These modules combine the analogue front end, one or more photodiodes, and the required LEDs to support a complete optical system. These are very small and optimised to reduce time to market and cost in this very competitive market.

What are your latest solutions in the field of healthcare?

With reference to our latest introductions, we recently launched a biomedical analogue front end called ADPD4000. In a wearable device, you often measure more than just one parameter, such as heart rate, activity, skin impedance, oxygen saturation, and body temperature. Why would you use an individual chip or sensor for every measurement? Doing so would increase the overall board size, the required power, and, certainly, the overall system cost. The latest introduction makes it possible to do all these measurements, with exception of motion, with just one chip. The chip directly connects to biopotential electrodes to measure cardiac signals. It’s able to measure galvanic skin response for stress or mental state tracking. It has eight inputs to measure photocurrents and eight current sources to drive LEDs. In addition, the chip supports auxiliary inputs to measure capacitance and temperature. With a chip like the ADPD4000, you can build a wearable VSM system that’s very power efficient, small, and cost-effective.

How has this changed the way our health is monitored in the last years?

The medical market used to be doctor-centric, meaning that we used to only visit a doctor when not feeling well or for a more obvious health problem, for example, after having an accident. Technology - and especially the electronic industry - has had a big impact on the overall healthcare market while creating a more patient-centric approach. We, as the consumer (or patient), have more options on how to monitor our health conditions and where to go for our healthcare and medical services. While having access to wearable devices, we can monitor important vital parameters on a daily basis and are able to detect changes or anomalies at a much earlier stage compared to the past when we only recognised an issue when it impacted our well-being. The advantage of monitoring our parameters and detecting anomalies at an earlier stage is that we can start the treatment of certain diseases before they progress and cause permanent damage to the body.

As an example, there are many people suffering from hypertension, which is also known as high blood pressure. In some situations, this is a well-known issue; however, there are also many occasions where hypertension isn’t causing any visible symptoms. Over a longer period, this high blood pressure can result in either stroke, heart failure, arterial fibrillation, or several other risky diseases. Hypertension can be treated very easily by lifestyle changes and medication to reduce the risk of health complications. Wearable devices that are monitoring critical vital parameters can frequently save lives or prevent health events that may lead to permanent damage.