Applied Vibration Ltd

Since 1976, Applied Vibration Limited has been designing and manufacturing a range of vibrating feeders, conveyors, screens, tables and elevators for product handling applications. Applied Vibration Ltd designs machinery suitable for use in varied industrial sectors, such as Food Production, Pharmaceutical, Chemical, Glass Manufacture, Recycling and Waste Recovery, Hardware and Component Handling, Extractive (Minerals and Cement) and often other Special Applications on request.

-

Hopper Feeders improve production efficiency of vibrating screen, feeding and conveyor applications

1 November 2018Used in production lines across multiple industries, a well-designed vibrating hopper feeder can help a screening, conveying or feeding application become more efficient and effective within the production process.

A self-discharging bulk storage hopper is capable of storing and then discharging components in a controllable, continuous stream - thus avoiding any interruption in production. The design of the hopper with accompanying electromagnetic or vibrating motor drive unit should produce a progressively increasing product velocity towards the end of the hopper. This motion prevents mass flow and creates an untangling and thinning out effect on the material/parts, reducing them to a manageable quantity.

This is particularly beneficial when the hopper is feeding onto a conveying plain or a vibrating screen. When released from the hopper feeder with such control onto a screen, for example, material empties out onto the screening panel in a thin layer, allowing the smaller components to drop through the screen easily and separate out efficiently as per the design of the vibratory screen unit. Similarly, when discharged onto a conveyor or vibrating feeder, the even spread of material allows for smooth and accurate product transfer along the conveyor or out of the feeder.

A hopper feeder can be supplied in carbon steel, stainless steel or full food quality manufacture. Used individually or in multiples and, if necessary, utilising a vibratory transfer feeder, a hopper feeder can also be designed to deliver material/parts to precisely where required in a pre-existing production line set-up.

We at Applied Vibration Ltd have designed and manufactured vibrating hopper feeders to a range of industries including food and beverage, recycling, glass, waste – handling a variety of different materials and specifications. If you would like more information, or to talk to a member of our team about your specific application, please don't hesitate to get in touch.

-

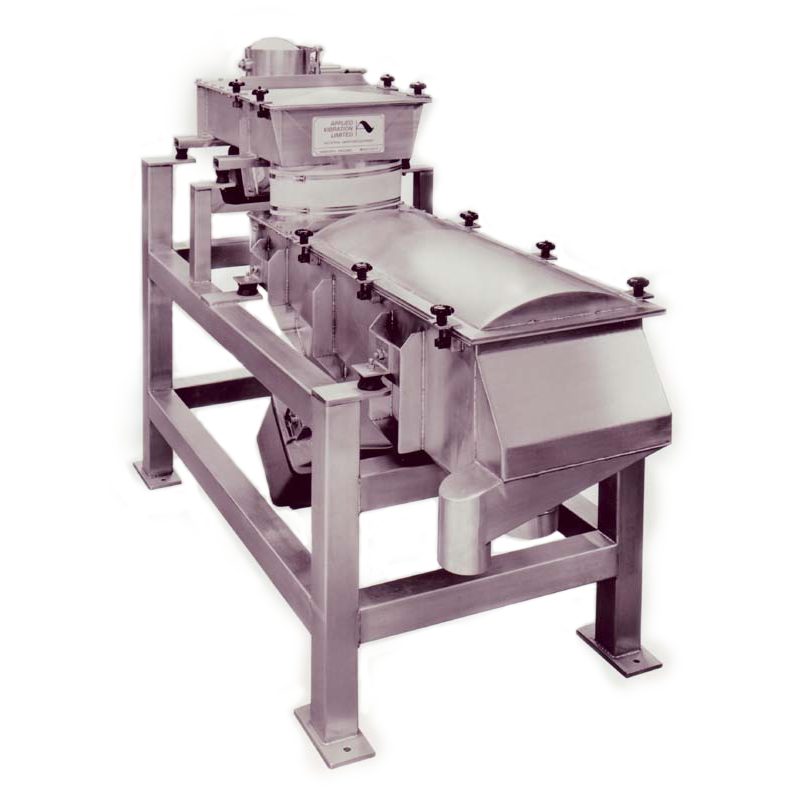

Linear vibrating screens provide efficient screening by incorporating conveying element

1 November 2018With efficiency at the forefront of any processing line, separating out materials – whether for coarse grading, fine grading, de-dusting, dewatering or protective screening – can prove to cost time and space when the separation process is not efficiently incorporated into the rest of the line. However, a vibrating screen with a predominantly linear product displacement incorporates a conveying element as well as separating, meaning that product can be separated as required whilst passing onto the next process in the line and retaining production efficiency.

A linear vibratory screen can be designed in open or fully enclosed construction with bodies manufactured from carbon or stainless steel – or combinations of both materials. These combine lightness with strength and high wear resistance for a long working life. Open construction models often discharge under-sized product into a storage hopper or conveyor. Enclosed models, incorporating either bolted or quick release dust tight covers against atmospheric pollution, collect in conveying pans and discharge through a spigot outlet below.

With the ability to convey whilst separating, a linear vibrating screen is often used for container filling and safety screening – protecting against agglomeration, over-sized product or large particles which could cause problems in processing or quality control further down the line, whilst maintaining optimum feed rate. Another common application is to incorporate a hopper with a screen – discharging from the hopper, removing the fines and feeding the material onto an inspection deck, thus improving the efficiency of inspection.

A linear unit can be fitted with a single screening deck, multiple decks, or with interchangeable panels if the unit is to handle varying materials, all offering easy clean down and maintenance. As with all industrial vibration equipment, wear to the deck or panels is minimal and excellent separation characteristics mean minimal pegging or blending during operation. An electromagnetic drive unit can be fitted for control over conveying speeds, or alternatively a vibrator motor for high capacity throughput and continual operation.

Linear vibration screens are successfully used for:

- Coarse grading – of bulk materials where extreme sizing accuracy is not required

- Fine grading – for high accuracy over particle sizes less than 3mm down to 50 microns

- De-dusting – for the extraction of undersized particles

- Protective screening – for the removal of oversize particles, impurities and other foreign bodies etc.

- Separation – for removal of coarse material from fines

- Dewatering – for recovery of solids from washing media

- Extraction – for removal of non-soluble impurities from washing and carrier fluids.

If you would like more information on how linear vibrating screens work or the applications in which they can be implemented, please get in touch.

-

The advantages of using a vibratory feeder, conveyor, screen or table to handle recycled materials

1 November 2018The materials handled within the recycling industry are vast and varied; from paper and plastics to glass and wood, metals and textiles to building materials and more - and the ways in which these materials require handling through processes arguably even more so. The advantage of vibration technology is that it too is vast and varied, and the many methods of vibration handling can be used in equipment designs that solve a range of recycling applications.

Material separation by size and dewatering

In most cases, materials need to be separated out into what is usable for recycling and what is waste. A linear vibratory screen provides efficient separation by size whilst feeding onto the next process. This is often used to separate dust from usable materials, or to remove oversize pieces from bulk product – policing the material so that the usable product is separated from anything that requires further processing. In cases of bottles, particularly glass or plastic, liquid residue can often cause a problem that can be solved with a dewatering screen. By feeding the glass or plastic over a screen, vibrating equipment can separate the liquid from the material – the material feeding onto the next process or into a container, and the liquid draining out to a separate specified area. This solution is efficient and effective, and care has been taken with vibrating screen designs to ensure that clean down is easy.

Compacting materials to settle peaks and fill to capacity

When materials such as recycled plastics, glass or metal are filled into bulk bags or IBC containers, filling the containers to maximum capacity can prove tricky. The irregular parts often fill on top of one another, rather than spreading out to the corners of the container, and can also start to ‘cone’ into a peak at the top. In order to ensure filling capacity and bag stability, a vibrating table can be implemented to compact the material – encouraging movement into the corners of the container and levelling out the peaking material at the top of the bag. Low level vibratory tables sit close to the floor, and as container filling issues are usually detected prior to hopper installations, can be designed to suit pre-existing filling set ups.

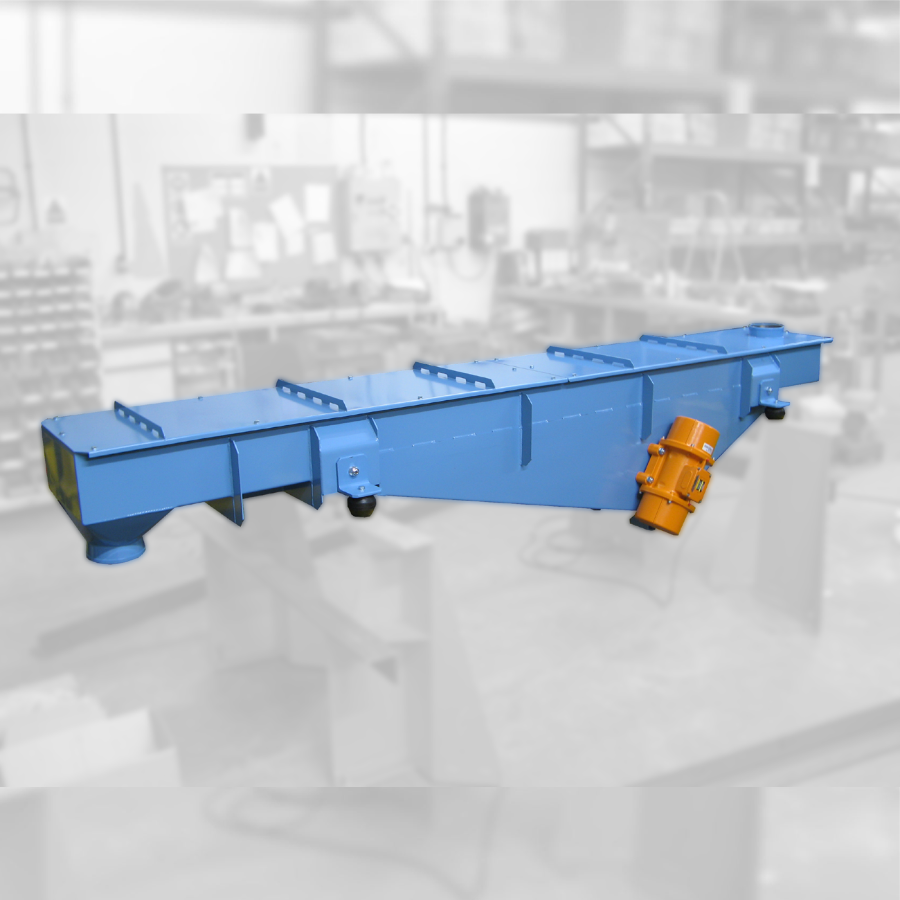

Moving materials efficiently from A to B

Efficient movement of materials and transporting those materials between two locations is one of the most common requirements in the recycling industry. A vibratory conveyor, driven by twin vibrator motor drives, is well suited to such applications, providing efficient high volume conveying with low power consumption. Unlike belt conveyors, the trough or tubular structure of a vibrating conveyor does not require routine maintenance as the conveying trough does not easily wear down and there are no points in which material could get trapped. This also makes for easy clean down, reducing the amount of inefficient time within a time-conscious industry.

Controlling material feed for spreading over inspection belts or filling into containers

A vibratory feeder offer the same time-saving qualities such as easy clean down and low wear, but uses an electromagnetic drive that allows for control over the flow of material. This is particularly advantageous within the recycling industry when needing to regulate flow or fill a container to a certain weight. The instantaneous stop/start control allows for accuracy in precision filling applications, and the ability to slow down or speed up product flow allows for versatility in feeding a variety of materials, as often is the case with recycling processes. The control that a vibrating feeder offers is also often used to spread material over wide video inspection or picking belts – spreading the product out into a manageable stream in order to allow for effective video inspection or for an operative on the picking belt line.

With the versatility and ability to handle such a range of materials and solve a multitude of problems, industrial vibration handling equipment is one of the unsung heroes of recycled materials handling. For more information on how a vibratory conveyor, feeder, screen or table could handle a specific recycled materials application or problem, please don’t hesitate to get in touch.

-

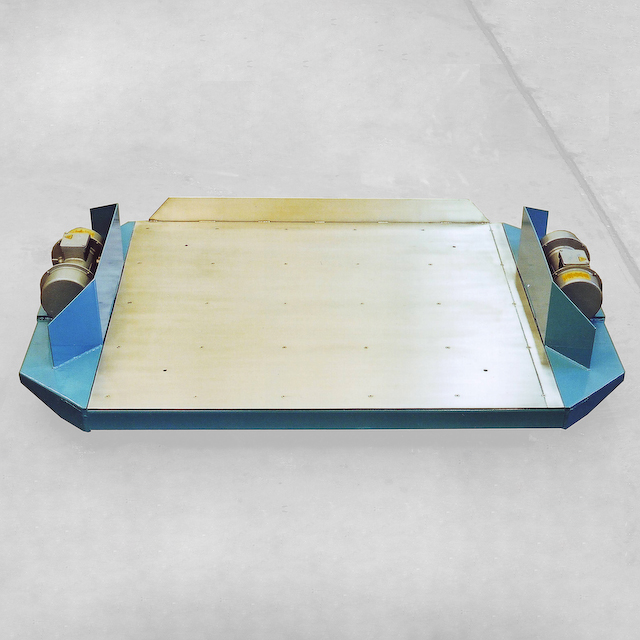

The most effective vibrating feeder design for wide belts and process lines

1 November 2018Often there is a need to feed a fine or very low burden depth of material across a wide belt or process line, thus requiring a wide, but relatively short, conveying trough. A vibrating feeder is the perfect solution for this application, though many designs rely on using multiple drives to feed across the width of the unit.

This is problematic, as using multiple drives can prove to be very expensive and it can be difficult to ensure that consistent performance will be achieved across the width of the trough. This is why we at Applied Vibration Ltd design and manufacture wide, short, and, most importantly, single drive vibrating feeders.

Our wide vibratory feeder units use our own range of electromagnetic drive units that are designed to give complete control over a fine feed, across the entire width of the trough. The design we have developed helps to keep the stainless steel conveying plain flat, therefore providing consistent and reliable material throughput across the width of the trough and onto the next process.

These wide vibrating feeders are often used in conjunction with a wide hopper with a narrow outlet to match the short length of the feeder, thus distributing material across the width of the feeding trough (as it is important to remember that the process of vibration will not automatically spread and distribute the product evenly). The electromagnetic drive provides complete control and instantaneous stop/start over the material, and typical applications have included feeding heat treatment furnaces, food processing lines, cookers, dryers, magnetic separation equipment and optical sorting machines.

Please don’t hesitate to contact us if you would like more information on vibrating feeders for wide belts and process lines, or have questions about any of our equipment.

-

Packing production lines benefit from Compaction Feeder Unit that compacts and feeds containers

1 November 2018We have recently been approached by a number of companies looking to compact materials within a container – in a box, or a bag – whilst feeding onto the next stage of a production line. Despite the different materials and industries, the aims and issues surrounding these enquiries were very similar, and a compaction feeder unit provided the solution.

The aims are most often to fill a container to its optimum level, either ensuring that their customers receive the correct amount of material in a container of bought produce, or for efficient use of storage internally. Their main issues were that machine-packed material does not often fill efficiently out at the bottom of the box, and instead fills parts on top of one another causing blockages at the sealer when the box cannot be shut or sealed. Similar issues were also found in sealing bags, with the additional problem that when bags fill inefficiently and air gaps form between particles or products, bags become very difficult to stack and can pose as a health and safety issue when stored in bulk.

A vibratory table is one of the most recognised solutions to help material compact and nest closely together in order to reach capacity volume within a container. However, to use a vibrating table in this instance would mean moving the container from the packing line, onto the table, and then back onto the sealing machine - interfering with production line flow and efficiency.

A compaction feeder unit, however, compacts material in a container whilst feeding it along a length and onto the next process. Designed to compact the specific material within an application, and often to fit a pre-existing production line, a compaction feeder maintains production efficiency by working seamlessly within the line. Moving the box or bag along its length, the material within compacts down so that the box or bag can be sealed. Air gaps are removed from the material, meaning that when bags are sealed they are more stable and secure. A compaction feeder can also be use earlier in the line, compacting material so that more can be added to reach the optimum level within the container, in a similar way that a vibrating table may be used on a filling station.

A compacting feeder can be designed to suit large or small containers, and can be manufactured in carbon or full food quality stainless structure for hygiene sensitive areas such as food or pharmaceutical lines. Guide rails or liners can be used in order to perfectly position the container onto the next process, and the length of the unit is usually just over a meter long (though will be longer if the material is particularly tricky to compact, or the production line requires a longer length).

If you would like to know more about compaction feeder units, or whether they could help your application, please don’t hesitate to get in touch.

-

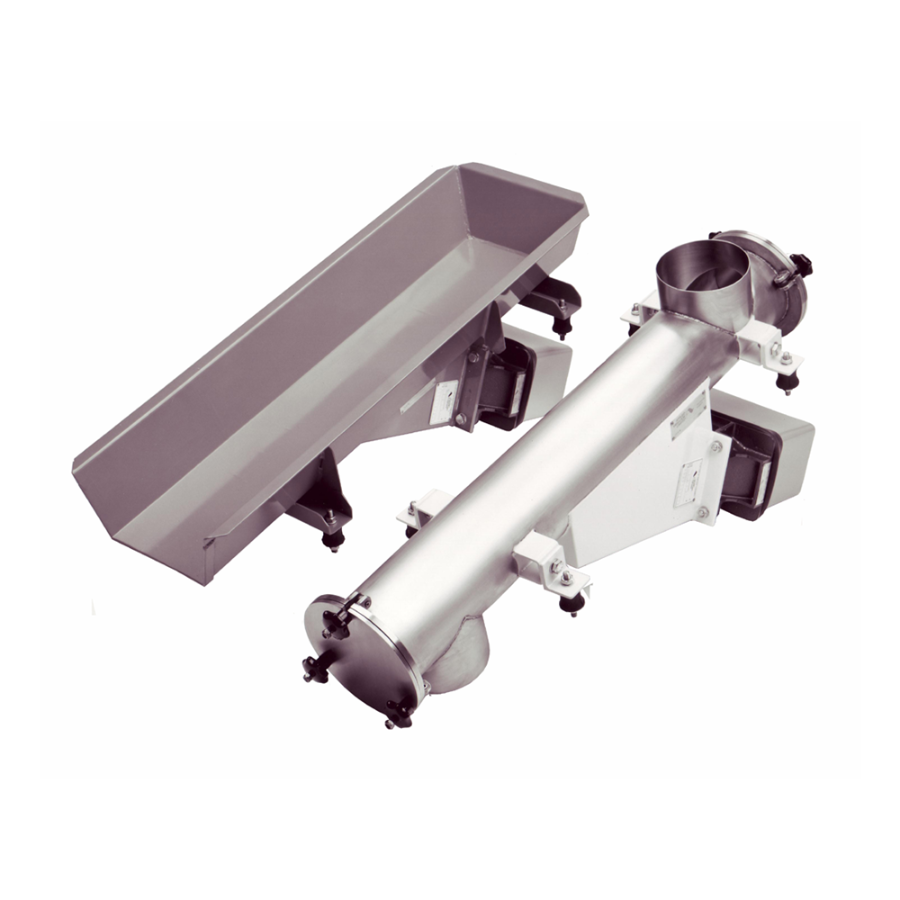

The benefits of tubular feeders for dust tight conveying

1 November 2018Handling and packaging in the pharmaceutical, cosmetic and chemical industries can prove difficult when products prone to producing dust not only have the danger of contaminating other products, but can also cause atmospheric pollution in sensitive areas of production lines if not handled correctly. There are a number of ways to tackle this issue, but one of the most effective proves to be the use of vibrating tubular feeders for dust tight conveying.

Mitigating dangerous product or areas

In many chemical handling applications, mitigating the risk of potentially dangerous dust clouds is top priority. The dust tight construction and robust design of tubular feeders ensure that all material remains within the equipment at all times. Hazardous area drives can also be used within high risk lines.

Designed to suit pre-existing or planned process line

Simple flexible sleeves can be used to allow product flow from a feeder to other processing equipment, and as such a tubular feeder is suitable for feeding to mixers, weighers, vibrating sieves and screens. A buffer hopper can allow any specific batch to be metered in a controlled rate and, when used with an electromagnetic drive unit, excellent stop/start control over a product can be achieved for use in product weighing applications.

Tubular feeders can be designed in full stainless steel pharmaceutical quality construction, with no internal components such as conveying screw flights. This means that they are entirely crack and crevice free and have no internal components that need to be dealt with separately – resulting in a very easy and time effective clean down.

Easy clean down to achieve hygiene standards

With thorough and efficient clean down incredibly important in order to achieve both pharmaceutical hygiene standards and production efficiency, quick release dust tight end plates can be designed and manufactured for the units, ensuring that product is fully contained during running time but easily opened up for clean down and inspection when required.

Tubular feeders can be designed and manufactured in a variety of lengths and diameters, and provide a range of throughputs to suit the specific application and product to be handled. If your application is in need of efficient dust tight conveying, a vibrating tubular feeder could provide the perfect solution.

-

Showcasing Applied Vibration Limited's product handling solutions with new website launch

11 April 2017Throughout our 41 year history, Applied Vibration Limited have serviced a wide range of industries - our designs developing from the heavy duty carbon steel structures of furnace charging systems to the hygienic, fully welded and polished structures of the pharmaceutical and food industries. It seems only right that our new website launch should reflect this in focusing on the range of industries that we supply solutions to today.

Vibration is a versatile technology that can be used in many different industrial applications - often to feed and convey materials, to separate sized particles, to lift product and also to compact bulk material into a smaller size.

These functions can be used to suit a wide array of industries with very different specifications and regulations: from compacting concrete in dusty construction sites to conveying powders in a pristine chemical plant, or removing wine from broken glass bottles to feeding and weighing cereals onto a packaging line - as well as everything in between. 'The possibilities are endless' as they say, and we very much enjoy the challenge of designing equipment to handle such a variety of materials and applications.

We hope that this new website conveys this passion for vibration technology, which has been at the heart of the company since it was founded by Graham Wilkes in 1976. His enthusiasm lives on in the work we do today, and we are very proud to both design and manufacture our equipment in house with a dedicated team determined to create the best possible solution for every customer's application.

Please take a look around our website, www.appliedvibration.co.uk and don't hesitate to get in touch if you think our product handling solutions could help you.