Aquajet Machining Systems Ltd

As the UK's official OMAX distributor, Aquajet offer a complete range of OMAXCNC precision waterjet machines along with genuine OMAX accessories and consumables. Aquajet is part of a global network and can rely on 3 decades of knowledge and experience of high pressure cutting systems.

Utilising the latest technology from OMAX® Corporation, Aquajet are able to offer sub-contract machining to some of the tightest tolerances in the industry and have a highly skilled team of factory certified technicians which ensures we are ideally placed to assist you either in a sub-contract service or as a machine customer.

We work with many blue chip companies throughout the UK & Northern Europe. We specialise in short batch runs and tight tolerance machining. Our manufacturing facility is equipped with state of the art OMAX machining centres. Aquajet complies to Quality standard BS EN9001.

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world and its versatility has also allowed us to support the rapid growth of the stone and tile industry.

Aquajet offers a full catalogue of services including:

- Highly specialised subcontract job shop

- Machine sales (free lifetime software upgrades and support)

- Spare parts

- Service & Support

UK distributor of Rhino Board – latest innovative sacrificial cutting substrate

Aquajet offers knowledge and value that is second to none.

Precision Engineering At Its Most Innovative

Aquajet is a quality focused company delivering J.I.T components to the precision engineering sector. Our unique position coupled with our state of the art manufacturing technology and highly skilled professional team allow us to service single prototype development to multi-run production. The proven Aquajet approach supports lean manufacturing and is proven to reduce inventory overheads while providing net or near net parts thus reducing further processing cost.

An abrasivejet pressurises water up to 55,000 pounds per square inch (psi) [379) megapascals (MPa)] and then forces it through a small Precious stone orifice at 2500 feet (762 meters) per second, or about two and half times the speed of sound. We can usually meet tolerance requirements between ±0.005 to 0.001" [0.03 mm], it can cut virtually any profile with almost no limitations in geometric flexibility.

OMAX machines use a "direct drive" pump technology which delivers ~ 90% of its power to the nozzle reducing the impact on our natural resources and protecting them for future generations. The OMAX Intelli-MAX control suite reduces cutting time, increases precision, and lowers operating costs by automatically optimising the tool path creating your part with minimal energy waste. From rapid hole drilling in challenging materials like titanium and nickel alloy to profiling tiny details in stone, composite, ceramic, and glass, Aquajet are at the forefront of waterjet applications technology and utilise this expertise to deliver an efficient and economical service that exceed customer expectation time and time again.

Specialists in Stone and Tile Cutting

At Aquajet, we utilise our OMAX JetMachining centre and its advanced technology to cut virtually any material up to 200mm thick and to a tolerance of + or - 0.05 depending on material. With the high level of precision and accuracy provided by our in-house OMAX machines, together with the latest software and technical knowledge, we can successfully work with your chosen material and deliver a cost effective and highly professional cutting service.

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world and its versatility has allowed us to support the rapid growth of the stone and tile industry. Abrasive waterjets can work quickly and effectively with a variety of materials, including some not typically associated with machining shops. Stone is difficult to machine conventionally but our facilities have enabled us to complete projects with the upmost intricacy and speed using low-pressure pierce capabilities and highly skilled expertise.

Whether you require a simple stone cutting service, or need a custom made floor in-lay, Aquajet can manufacture and deliver your material using the most sophisticated abrasive waterjet technology, customer support and at a competitive price.

Architectural Design & Bespoke Signage

Aquajet and its creative department – Rare Earth Design, have a wealth of expertise in the design and manufacture of architectural products, including corporate and industrial tile solutions and bespoke signage.

With the high level of precision and accuracy provided by our in-house OMAX JetMachining Centre, together with the latest intuitive software and technical experience, we can realise your design inspirations.

From complex marble in-lays to create that perfect floor space, to smaller and more intricate profiling, we pride ourselves on our ability to provide a tailored and individual service ensuring you receive the perfect product.

From functional metal work to personalised artistic interpretations, our waterjet machining technology provides a cost effective alternative to traditional processes and can present your LOGO or branding in a totally unique and professional manner.

Aquajet focuses on both traditional and contemporary projects in the retail and commercial markets, delivering the highest quality architectural solutions. Whatever your budget - we ensure attention to detail throughout, allowing us to offer a truly bespoke service and satisfaction guaranteed.

Rhino Board - Unapologetically Tough - Unbelievably Simple

Rhino Board is the best sacrificial water-jet cutting surface to reach the UK market, working excellently with both abrasive and non-abrasive water-jet cutting.

The innovatively designed sheets give an even flat cutting surface and save precious installation time, filling a bed in seconds.

Rhino Board's polypropylene honeycomb core sheets are comprised of cylindrical polyolefin tube straws bonded into a close packed hexagonal matrix to produce a low bulk density core material.

A Rhino Board sheet weighs less than a comparable amount of the old style bricks currently available, (approximately 48% less) which saves on shipping costs and does not affect the durability of the product.

The benefits:

Longer Lasting - Rhino Board may be easily repaired thus reducing frequency of maintenance and replacement

Simple & Fast - Rhino Board eliminates having to build a bedout of smaller bricks which is timeconsuming during setup and removal.

More Durable - Rhino Board will not fall apart - there are noscrews used due to the patented bondingprocess, making repairs to the Rhino Boardpossible with a simple hot glue gun.

Environmentally Friendly - Rhino Board creates less polypropyleneresidue in the water tank, reducing cleaning operations and maintenance, saving youtime and money.

Rhino Board can be recycled.

As the UK distributor, we at Aquajet stock a variety of sheet sizes and can also cut to specific requirements.

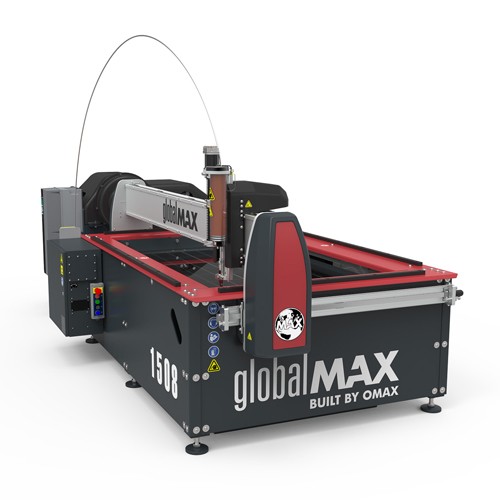

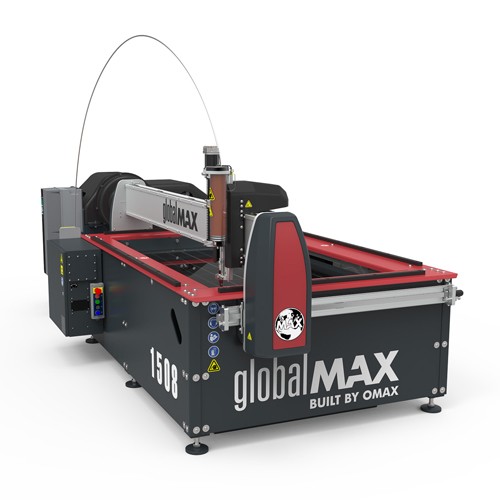

Machines

- Omax 2626 XP (Ultra precision with error mapped table)

The 2626XP incorporates stainless steel tank with high resolution drives all mapped to the table to deliver dynamic positioning of up to 0.01mm.

- Omax 2626

Small footprint 660mm x 709mm cutting area for smaller parts.

- Omax 2652

Our most popular tool-room machine offering 660mm x 1220mm cutting area and tooling mount as standard.

- Omax 5555

Offering 1300mm x 1300mm of cutting area ideal for larger precision parts and R&D facilities.

- Omax 55100

Larger workhorse with the ability to use 2.5m x 1.25 metre stock sheets while maintaining the accuracy and ease of access associated with the Omax cantilever Range.

- Omax 60120

3 metre x 1.5 metre cutting area, Patented Intelli-TRAX drive system for optimum accuracy, Dual bridge, multi nozzle configurations available,

- Omax 80160

4 Metre x 2 metre cutting area, constructed using high precision ballscrews for customer who prefer traditional ballscrews and ground rails.

- Omax 80X (Extendable)

4 metre x 2 metre 80X up to 8 metre x 2 metre 80x – 3, Using the latest Intelli-TRAX drive system available in configurations including multi bridge, multi nozzle, offers touch screen control on the axis ends for ease of use. A true class leader.

- Omax 120X (Extendable)

3 metre bridge with available in lengths from 2 metres to as long as is required. The 120X incorporates The Intelli-TRAX drive system and is available now. The 120X is the most versatile waterjet machining centre solution on the market today. Allowing for levels of accuracy unrivalled throughout the waterjet industry

Maxiem Waterjet Profile Centres

MAXIEM JetCutting Systems are simple, reliable, and efficient abrasive waterjet machines offered at affordable prices. Never before have the benefits of waterjet technology been so accessible to fabrication shops, metal service centers, trade schools, job shops, and architectural, sign, stone and gasket shops as they are now with the MAXIEM line of machines.

Shops can produce quality parts from virtually any type of material thanks to the robust Intelli-MAX® Software loaded into every MAXIEM machine. These software controls are easy-to-use and eliminate the need for complicated G-code programming knowledge.The X-Y tables on MAXIEM machines incorporate the Intelli-TRAX™ traction drive technology and a Motorized Z-Axis. The mechanics of the drive system allow for superior performance in harsh abrasive waterjet environments and help provide exceptionally high-quality parts.

MAXIEM JetCutting Center models include the 2040, 2030, 1530, 1515, and the 0707

- MAXIEM 2040s feature X-Y cutting travels of 160 inches x 79 inches (4,064 mm x 2,006 mm), table sizes of 189 inches x 81 inches (4,801 mm x 2,057 mm), and maximum table loads of 250 pounds/square foot (1221 kg/squaremeter).

- MAXIEM 2030s provide X-Y travels measuring 122 inches by 79 inches (3,100 mm x 2,006 mm) and table sizes of 151 inches by 81 inches (3,835 mm x 2,057 mm) that handle the same maximum supported material loads as the MAXIEM 2040.

- MAXIEM 1530 model X-Y travels measure 122 inches x 62 inches (3,100 mm x 1,575 mm), and its table size is 151 inches by 69 inches (3,835 mm x 1,752 mm) with a maximum material load of 250 pounds/square foot (1221 kg/squaremeter).

- MAXIEM 1515 X-Y travels measure 62 inches x 62 inches (1,575 mm x 1,575 mm). Table size is 92 inches x 69 inches (2,337 mm x 1,752 mm), which supports maximum material loads of 250 pounds/square foot (1221 kg/squaremeter).

- MAXIEM 0707 JetCutting Centers are the ideal industry standard abrasive waterjet machines. Their X-Y cutting travels of 30 inches x 30 inches (762 mm x 762 mm) and maximum table loads of 250 pounds/square foot (1221 kg/squaremeter) make the 0707 machines perfect for prototyping or research and development environments and for shops making their first foray into waterjet cutting technology.

Abrasive Water Jet Cutter

Aquajet has been the UK distributor of OMAX Waterjet Machining and MAXIEM JetCutting Centres for over 25 years.

Ask us for a test cut to experience the OMAX difference! Request A Demonstration

For more information on waterjet machines, pumps, accessories and more call us on 01257 248 480 or email sales@aquajet.co.uk

Waterjet Service

Aquajet Machining Systems Ltd is the UK’s Premier Supplier Of Precision Waterjet Systems. For more information on waterjet machines, pumps, accessories and more call us on 01257 248 480 or email sales@aquajet.co.uk

Waterjet Cutter Knowledge

What is a Waterjet? Waterjet machining is one of the fastest growing machining processes today. Using water as a cutting method for soft materials has been around for decades!

Waterjets can be used to cut materials such as composites, metals, glass, stone, concrete, ceramics & rubber.

To learn more about Waterjet Cutting click here.