Atlas Winch and Hoist Services (Southern) Ltd

At Atlas, we are experts in all types of winches including air, electric, diesel, hand and trailer winches. We have a wide variety of hoists and lifting equipment available for purchase or hire and offer repair, maintenance, inspection and installation services.

Within the UK and Scotland few companies can offer the same expertise and experience in the winch field.

-

LIFTING EQUIPMENT MAINTENANCE: A GUIDE TO BEST PRACTICES

13 March 2023As a lifting equipment hire company, Atlas Winch Hire & Hoist Services understands the importance of keeping your equipment in top condition. Not only is it essential for the safe and efficient operation of your machinery, but it can also help to extend the lifespan of the equipment and reduce the need for costly winch repairs. In this blog, we’ll cover the best practices for maintaining your lifting equipment to ensure that it operates smoothly and reliably.

PREVENTIVE MAINTENANCE

Preventive maintenance is a proactive approach to equipment maintenance that involves performing regular inspections and maintenance tasks to prevent equipment failure and prolong its lifespan. This includes regular cleaning, lubrication, and inspection of equipment components such as gears, bearings, and motors.

WINCH SERVICING

Winch servicing is a crucial aspect of lifting equipment maintenance. A regular winch service should include an inspection of the winch drum, cable, brake, and control system. It’s important to identify and address any issues before they become major problems that could require expensive winch repairs. Additionally, winch servicing should include an inspection of the winch’s safety systems, such as the load-limiting device and the emergency stop mechanism, to ensure they are functioning properly.

INSPECTION AND TESTING

Inspection and testing are critical components of lifting equipment maintenance. Regular inspections help to identify any issues with the equipment and ensure that it continues to meet safety standards. Testing is important to verify that the equipment is functioning properly and that it’s capable of safely handling the loads it was designed to carry. It’s essential to have qualified personnel perform these inspections and tests, who have the knowledge and expertise to properly assess the equipment’s condition.

EQUIPMENT STORAGE

Proper storage of your lifting equipment is also an important aspect of maintenance. When not in use, equipment should be stored in a dry, secure location to protect it from weather damage and theft. It’s also important to make sure that the equipment is properly secured to prevent it from shifting or tipping over, which could cause damage.

LIFTING EQUIPMENT SUPPLIERS

When choosing lifting equipment suppliers, it’s essential to choose a company that has a reputation for providing high-quality equipment and excellent customer service. This includes providing comprehensive lifting equipment services, including maintenance and winch repairs, to ensure that your equipment continues to operate effectively throughout the rental period.

In conclusion, maintaining your lifting equipment is essential for the safe and efficient operation of your machinery. Following these steps can help to extend the lifespan of your equipment and reduce the need for costly winch repairs.

At Atlas Winch Hire & Hoist Services, we understand the importance of maintaining your lifting equipment, which is why we take care of it on our customers’ behalf. Whether you need winch repairs, winch servicing, or lifting equipment hire, we’re here to help. Get in touch today at 01899 221 577 (Scotland) or 01371 859 555 (Essex) to learn more about our services and how we’ll keep your equipment in top condition.

-

THE BENEFITS OF HIRING YOUR LIFTING EQUIPMENT

13 March 2023At Atlas Winch Hire & Hoist Services, we understand the importance of having the right lifting equipment for your project. As a leading winch hire and lifting equipment hire company, we have seen the benefits that come with hiring rather than buying this equipment. In this blog, we will be discussing the advantages of hiring your lifting equipment, and why it may be a better option for your business or project.

COST-EFFECTIVE

One of the biggest benefits of hiring lifting equipment is the cost-effectiveness it provides. The cost of purchasing winches and other lifting equipment can be substantial, especially when you factor in maintenance and repair costs. On the other hand, hiring winches and lifting equipment means you only pay for the equipment when you need it, saving you money in the long run. Additionally, our winch specialists ensure that all equipment is maintained to the highest standard, reducing the risk of breakdowns and repairs.

FLEXIBLE

Another advantage of hiring lifting equipment is the flexibility it provides. With the constantly changing demands of projects, having the ability to quickly adapt to these changes is essential. Hiring equipment means that you have the flexibility to change or upgrade your equipment as and when you need to, without being locked into a long-term investment.

ACCESS TO THE LATEST TECHNOLOGY

At Atlas Winch Hire & Hoist Services, we understand the importance of staying up-to-date with the latest technology. Our winch specialists are always on the lookout for the latest and most advanced lifting equipment, ensuring that our customers have access to the best technology. When you hire equipment from us, you have access to the latest and most advanced winches and lifting equipment, allowing you to complete your projects more efficiently and effectively.

NO MAINTENANCE COSTS

When you purchase winches and lifting equipment, you are also responsible for their maintenance and repair. This can be both time-consuming and costly, especially if you do not have the necessary skills or knowledge. However, at Atlas Winch Hire & Hoist Services, we offer a range of lifting equipment services that will take care of everything for you. This means that, when you hire equipment from us, all maintenance and repair costs are covered, giving you peace of mind and allowing you to focus on your project.

REDUCED RESPONSIBILITY

When you own lifting equipment, you are also responsible for ensuring that it is stored and transported safely. This can be both time-consuming and costly, especially if you do not have the necessary storage facilities or equipment. Hiring lifting equipment reduces this responsibility, as we take care of the storage and transportation of the equipment, allowing you to focus on your project.

At Atlas Winch Hire & Hoist Services, we believe that hiring your lifting equipment is the better option for your business or project. Call 01899 221 577 (Scotland) or 01371 859 555 (Essex) today to discuss your requirements with our winch specialists. We’ll be more than happy to help you take advantage of the many benefits of hiring your lifting equipment.

-

THE LATEST ADVANCES IN LIFTING EQUIPMENT TECHNOLOGY

13 March 2023Lifting equipment is an essential component of many construction and industrial operations. In recent years, advancements in technology have made the use of lifting equipment safer, more efficient, and more reliable. In this blog, we will examine some of the latest advances in lifting equipment technology and what they mean for businesses in need of reliable lifting equipment suppliers.

ELECTRIC WINCHES: THE FUTURE OF LIFTING EQUIPMENT

Electric winches are rapidly becoming the preferred choice for lifting equipment, replacing traditional hydraulic and pneumatic winches. Electric winches are more energy-efficient and environmentally friendly, with lower emissions and less noise pollution. They are also easier to use and maintain, making them a popular choice among lifting equipment suppliers.

One of the latest advancements in electric winch technology is the introduction of smart winches. Smart winches are equipped with sensors that can monitor load, speed, and temperature, allowing for real-time control of the lifting operation. This technology not only increases safety but also improves efficiency by reducing downtime and maintenance costs.

MONITORING CAPABILITIES

As mentioned above, sensors enable winches and other lifting equipment to measure and display vital metrics to equipment operators. Load sensors are an essential safety feature in lifting equipment, allowing operators to monitor the weight of the load being lifted. In the past, load sensors were mechanical and prone to failure, but with advancements in technology, they are now highly reliable and accurate.

New load monitoring systems are now equipped with wireless connectivity, making it possible to monitor the load from a remote location. This technology allows for real-time monitoring of the lifting operation, ensuring that the load is always within safe limits.

5G REMOTE CONTROL TECHNOLOGY

A 5G remote-control system for tower cranes aimed at improving operator safety and the working environment has been developed in recent years. The system features multi-angle video surveillance, intelligent hook tracking, monitoring of crane parameters such as wind speed, and an anti-collision system that uses AI and computer vision technologies.

Having already applied 5G technology to its tower cranes, mobile cranes, concrete pump trucks and excavators, the system’s creator intends to use 5G technology across all its products in the near future.

ANTI-COLLISION SYSTEMS

Anti-collision technology remains popular on worksites, as safety is always – and should always be – a priority for those working in potentially dangerous environments. A recent project in Norway has successfully utilised AMCS Technology’s anti-collision system across a range of tower cranes from different brands.

Anti-collision technology is most beneficial on complex and/or diverse sites, where the risk is deemed relatively high. A sensor manufacturer has developed a radar sensor for collision avoidance in cranes operating in harsh environments and challenging conditions, including transport hubs and container terminals. It is able to achieve long-range resolution and make accurate distance estimates even in heavy rain, thick fog, snow, or dusty environments.

Advancements in lifting equipment technology have made lifting operations safer, more efficient, and more reliable. At Atlas Winch Hire & Hoist Services, we are committed to providing our clients with the latest and most advanced lifting equipment available. If you are in need of reliable lifting equipment, contact us today at 01899 221 577 (Scotland) or 01371 859 555 (Essex) to learn more about our range of quality hoist and winch products.

-

ANCHORS THROUGH TIME: A HISTORY OF MOORING EQUIPMENT

13 March 2023Mooring equipment is a definitive essential within a number of industries, allowing individuals to safely and securely position a vessel in place, either temporarily or for an extended period of time. Due to the variation in seabed conditions, vessel sizes, availability of space and many other factors, this certainly isn’t a ‘one-size-fits-all’ situation. For these reasons, there are plenty of different mooring options to acquire from the trusted experts at Atlas Winch Hire & Hoist Services. Read ahead for a brief history of anchors, and their continued application in the current maritime industry, with modern developments, surprising origins and a breakdown of different variants for good measure.

TYPES OF EQUIPMENT

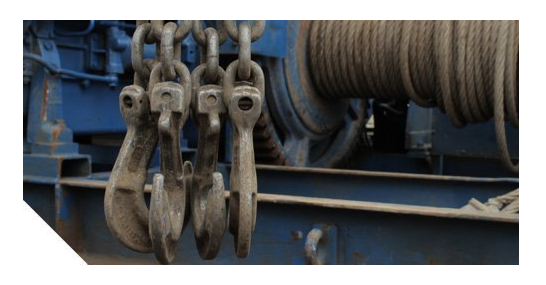

It’s hard to express the importance of mooring equipment within the maritime industry,with this comprehensive set of fittings and mechanisms used to secure the large ship or boat when it is moored at a dock. Not only is mooring equipment required in this instance, but also when vessels are secured at the wall of a lock, to buoys, or alongside another boat. At Atlas Winch Hire, our mooring systems can range from simple rope and wire mooring systems for a small personal boat, all the way to highly-technical 8 point winch systems – using heavy anchors.

Having acquired an impressive range of situational mooring equipment, we’re committed to finding solutions for all our clients. The ideal mooring solution will not only streamline processes, but can also be crucial for the safety of your vessel, other vessels, and anything you’re securing your ship to. Consider all manner of 4, 6 and 8 point mooring systems for crane and excavator barges, offshore supply and survey vessels. Mooring buoys, pennant wire ropes, schmitt brackets and panama chocks are just as desirable.

WHAT IS AN ANCHOR?

Perhaps the most widely recognised form of mooring equipment, the humble anchor usually represents a heavy object attached to a corresponding vessel by a cable, rope, or chain, which is dropped to the seabed. Usually made of a bulky metal, anchors can either be temporary or permanent. Permanent anchors are rarely moved, whereas vessels may carry one or more weighted temporary anchors. All modern anchors are designed with a separate top and bottom section, and generally the bottom half is heavier than the top, which means that it almost always turns correctly when it lands on the seabed.

EXPLORING ANCHOR TYPES

The amount of variation found within anchors both in the modern day and historically can be attributed to the range of vessel types they are used in correspondence with, and diverse seabed conditions which can be encountered. Read on for details on the three primary anchor types:

FLUKE ANCHORS

Fluke anchors are particularly popular on small vessels, as they’re lightweight, can be folded and stored very easily within limited room, and they also hold well in mud or sand. Despite these perks, the fluke anchor doesn’t hold as well on grassy or rocky surfaces, limiting usability.

PLOW ANCHORS

Plow anchors have fixed shanks and look like a plow, resetting themselves if the wind or current changes direction. Holding effectively in grass, mud, and even sand, the higher weight of these mooring utilities can take up storage room.

CLAW ANCHORS

Simple in design, the claw anchor should hold well in any seabed, but is harder to handle, adapted from the large and heavy anchors used to secure oil rigs in the North Sea, much like the plow anchor, it does not fold away and takes up a lot of storage room.

THE EARLY DESIGNS

Before the invention of the anchor as a distinctive piece of equipment, sacks of sand were often used as a substitute, though in the Bronze Age, seafarers were able to construct the first anchor as we recognise it today. It was made of a rope and a rock big enough to keep the ship still, while in other parts of the world, wooden logs filled with lead were also designed to secure vessels in the sea. The Chinese might have created the first device that visibly resembles a classic anchor back in 2,000 B.C, though the first records of an anchor with two hooked arms were found on Greek coins – dating back as early as 750 B.C.

ALTERATIONS THROUGH THE YEARS

In the 16th century, seafarers began using vertical-axed rotating machines, which could assist the crew in various anchoring operations. These machines simplified the process of releasing, holding, and manipulating the anchor functionality, setting the precedent for many modern inventions. Until the beginning of the 19th century, the majority of anchors were still being secured with a hemp rope. though finally, in 1809, one of the ships of the British Royal Navy was equipped with the first modern anchor chain.

MODERN INNOVATION

Since the latter part of the 20th century, modern innovations have come to prominence, with the spade anchor of the 1990s providing a huge improvement in performance. Successfully making use of a concave fluke, the spade is frequently used to this day. Additions including roll-bars to ensure correct setting are certainly of benefit, while lightweight foldable designs allow for easy storage and transportation. Though new anchor types are being developed to this very day, there are surprisingly few adjustments required when referring back to the classic anchors used throughout the prior decades. The majority of new designs have far too many negative features to be adopted at scale – so if it isn’t broken, don’t fix it.

OUR SPECIFIC SERVICES

We provide servicing, repairs, spares and accessories for all makes and models of winches, hoists, lifting gear and associated rigging – while our bespoke offerings are increasingly popular. With that being said, here are just a selection of our most popular applications:

EXPERT CONSULTATIONS

Fully qualified Engineers and trained onshore and offshore winch operators are available for consultation, operating Atlas or clients owned equipment as-per your requests. Alongside expert-backed advice, we can provide portable units and large specialist spoolers up to 300 tonnes in payload and 30 tonnes back tension.

WINCH OPERATION TRAINING

In-house and onsite accredited training can be provided for standard cable pulling winch operation. Non- standard winch operator training can also be made available, tailor-made to suit clients specific needs – with full certification and documentation provided, while our expansive range of winches can be acquired on a cost-effective temporary basis.

SITE AND WINCH REFURBISHMENT

We stay on top of the latest technological developments, allowing the team to service, refurbish, adapt and modify any winch. All work is fully warranted too, giving you the security and peace of mind you deserve. Worldwide service is even available, providing you with a fantastic refurbishment option wherever you’re based.

ATLAS WINCH HIRE: PREMIUM MOORING EQUIPMENT FOR VARIED NEEDS

When it comes to lifting equipment, we’re the experts you need! As a family-owned business, we prioritise delivering excellent customer service so your experience is stress-free and reliable. Brothers Denis Lavery and Anton Lavery have worked within the winch machine and lifting equipment industry for decades, using this wealth of experience to offer the essential powered winch equipment that our customers need.

As winch specialists, we aim to meet all of your lifting needs. We’re a company that stocks all of the essential equipment that you need, including lifting slings, base-mounted winches, and even load monitoring equipment. Contact our winch specialists at info@winchhire.com to discuss your hiring and buying options, both new and used, all of which will be tailored to your budget.

-

DIVINE “WINCHSPERATION” – THE HISTORY OF THE WINCH

13 March 2023Here at Atlas Winch & Hoist Services, we are passionate about what we do. Providing specialist winch services and lifting equipment solutions to a wide customer base, not only do we know the importance of winches in everyday life but we understand their greater importance over time.

From primitive ancient lifting equipment to hydraulic winch machines, the winch is a deceptively simple but incredibly powerful tool that has been a fixture in human civilization for centuries. Read on to learn more about winches’ place in history, how hydraulic and electric winches are used today, and what the future holds for winching equipment.

HOW DOES A WINCH WORK?

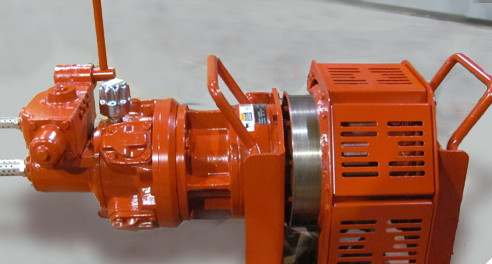

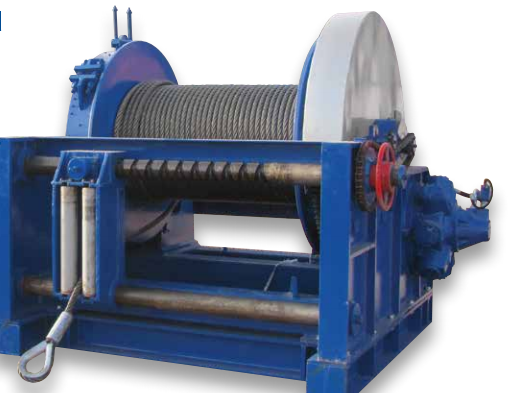

Before we tread back in time to understand the winch as a machine, it is important to know how a winch actually works. Quite simply, a winch machine is a mechanical device used to wind and unwind a cable or rope, which then can pull or lift heavy loads. Whether an electric winch or a hydraulic winch, they contain the following essential components:

DRUM

The central component of a winch machine and where the cable or rope is wound. It’s most commonly made of metal and is mounted on a rotating axle. The shape and size of the drum determine the length of cable or rope that can be used with it

MOTOR OR HAND-CRANK

This provides the power to wind and unwind the cable or rope. If a motor is used, it may be part of an electric or hydraulic winch and depends on the specific application of the winch machine. A hand crank is used for manual operation.

GEAR SYSTEM

The winch machine’s gear system consists of gears, bearings, and a clutch that transmits power from the motor/hand crank to the drum. The gear ratio determines the amount of mechanical advantage, which essentially means how much easier it is to wind the cable or rope compared to manually pulling it.

CABLE/ROPE

The cable or rope is wound onto the winch’s drum and provides the pulling force to lift or move the load. It is made of steel, synthetic fibre, or a combination of both, something that depends on the winch machine’s application and the type of load being pulled.

CONTROL SYSTEM

The control system allows the operator to control the winch’s speed and direction. It typically consists of a switch or lever that engages or disengages the motor or clutch, and a brake that prevents the drum from rotating when the winch is not in use.

In operation, the cable or rope is wound onto the drum by the motor or hand crank. As the cable or rope is wound, it stores energy in the form of tension, a tension which can then be used to pull or lift a load.

EARLY WINCHING MACHINES

The earliest winches were made of simple materials like wood and rope, and were operated manually. In ancient times, people utilized its ability to lift heavy objects, move them from one place to another, and perform a variety of other tasks.

The earliest reference to a winch machine or specialist winch usage is found in the account of Herodotus of Halicarnassus on the Persian Wars (Histories 7.36), written around 430 BC. The text describes how a wooden form of a winch machine and other winch equipment was utilised to tighten the cables on a pontoon bridge across the Hellespont. By the 4th century BC, Aristotle denoted winching equipment and pulley hoists as a common feature of architectural constructions.

As civilizations developed and grew, winching machines evolved along with them, becoming larger, stronger, and more sophisticated. During the Middle Ages, winch equipment and systems were used to hoist stone blocks into place during the construction of castles and other grand buildings.

As the Industrial Revolution swept across Europe and North America, the winch underwent a major transformation. New materials like iron and steel became available, and advances in machinery allowed for the creation of larger, stronger, and more efficient winches. These new winches were able to handle greater loads and could be powered by different forms of mechanical energy.

MODERN WINCHES

One of the most important innovations in the history of the winch was the development of the electric winch. Powered by electricity, the electric winch was much faster and more efficient than its predecessors. It could lift heavy loads with increased ease and its compact size made it ideal for a wider variety of industrial and commercial uses

Another major milestone in the history of the winch was the introduction of the hydraulic winch. This winch machine used a hydraulic system to generate the necessary force to lift heavy loads. It was much more powerful than traditional winches and could be controlled with greater precision. This made it an indispensable tool in many industrial and construction applications, where precision and speed are of utmost importance.

Air winch machines were yet another vital innovation in the history of the winch. Air winches are often confused with electric winches due to their similar appearance, but there is a distinct difference between the two. Electric winches, as the name suggests, are powered principally by electricity. Air winches, although powered by a pneumatic motor, the motors then direct compressed air to drums, which then rotate and move the winch machine.

This means air winches offer significant lifting force without using lots of electricity, making them ideal for remote regions where three-phase electricity is unavailable. Find out more about air winches here, as Atlas Winch & Hoist stocks a range of air winches, from portable models to larger capacities.

Today, winches are designed with computer-controlled systems and sophisticated software that allow for even greater control and accuracy. They can be powered by various sources, including electricity, gasoline, and diesel engines, and are used in a wide range of applications, from construction sites to offshore drilling platforms.

LOOKING TO THE FUTURE

The future of winches and winch equipment is likely to be shaped by several factors, such as technological innovation, increased safety requirements, and shifting industry needs. As technology continues to advance, we can expect to see more automation in winches and lifting machines. This may include the use of sensors, controls, and algorithms to optimize performance, improve safety, and reduce the risk of human error.

Safety will also continue to be a major concern in the design and use of winch machines. We can expect to see more safety features, such as load sensors, automatic brakes, and emergency shut-off systems, to reduce the risk of accidents and injuries. Equally, energy efficiency and sustainability will continue to be vital factors in the design and use of winch machines and equipment. More hybrid and electric winches will be used to minimize energy consumption and reduce emissions.

In addition, the use of advanced materials, such as composites, alloys, and ceramics, will continue to be an important trend in the design of winch machines. These materials offer improved strength, durability, and resistance to wear and tear, allowing for the creation of lighter, more compact, and more enduring systems. These will help create more versatile winch machines and winching equipment that is capable of handling a more expansive range of uses. This could include the development of multi-functional systems that can be used for both lifting and moving loads, as well as for other tasks such as drilling and excavating.

WINCH SPECIALISTS

Whether electric, hydraulic, or even wooden, at Atlas Winch & Hoist, we see the winch machine as an eternal symbol of strength and power, a testament to human ingenuity and man’s relentless pursuit of progress. In its timeless design and mechanical efficiency, the winch has been an essential tool for centuries and will likely continue to play an important role for many generations to come.

If you’re looking for an electric winch, hydraulic winch, or other lifting equipment, Atlas Winch & Hoist can help. From providing heavy-duty winching machines for the construction of semi-submersible offshore rigs to bridge launching, we have provided specialist winching equipment in a variety of industrial and commercial contexts. As a family business, we have been commended for our people-first, caring approach to customer service, making the experience with us stress-free and easy. If you need help working out what winch machine or winch equipment is best suited for your project, don’t hesitate to get in touch with our winch specialists by emailing info@winchhire.com.

-

FIVE IMPORTANT CONSIDERATIONS FOR A HARBOUR MASTER

13 March 2023We’re sure you are aware that the responsibility which lies on the shoulders of a harbour master really is incredibly significant. There is no question that the harbour is a dangerous and sometimes unpredictable environment, especially with the noise and large equipment. It is then imperative that the harbour master has the equipment they need to fulfil their role effectively and knows the dangers which their staff may be subject to.

Naturally, though it is nigh on impossible to mention every consideration a harbour master must look out for. After all, the role is a dynamic high-tempo position and the key characteristic every harbour master needs is the ability to adapt and problem-solve. This is, of course, what makes the role so enjoyable as every day is different and you can never expect what the future holds. So, if you’re a harbour master the first step to get right is ensuring that your harbour is equipped with everything you need to fulfil your role effectively.

MOORING BUOYS

The likelihood is that you’ll have a myriad of large vessels coming in and out of your harbour every day. It goes without saying really that these boats need somewhere to go once they sail through your harbour walls. Though this can, at times, be slightly more challenging than one might think. After all, there are a plethora of different-sized vessels and you need to accommodate all of them. This is where the mooring buoy comes in. You can purchase a variety of buoys which hold different classes of vessels so make sure that you purchase a collection of sizes and models.

ANCHORS

There are times when you will need to host large vessels for a period of weeks and sometimes even months as they have refits and other maintenance work completed. In these situations, it is vital that you secure the boat so it can withstand a variety of weather conditions and remain stable while it remains in your harbour. In some instances, this may require you to fit some slightly more heavy-duty anchors to the ship as they may not have this equipment on board. Therefore you should acquire a series of large anchors so you have this situation covered. When it comes to the role of a harbour master one thing is for sure, you need to have a myriad of equipment available to you so you have every eventuality covered. Naturally, you can’t cover every basis but you can certainly try. The easiest way to do this is by acquiring up-to-date and modern equipment so you and your staff maintain full confidence in the efficiency of the harbour. So, if you need any winch equipment or mooring equipment then make sure you contact us today!

-

HOW WINCH MACHINES HELPED TO BUILD THE MODERN WORLD

13 March 2023Naturally, there have been many inventions and introductions to the construction industry over the few centuries. Many of these have become essentials in the industry and without them, our construction costs would be far higher. These machines and inventions are the keys to unlocking the modern world and doubtless, we will invent many more groundbreaking tools before the century is over. The winch is, of course, one of the most important and significant of these machines and has led us to many new and adventurous heights. So, how has the winch had so much influence? Find out in this quick blog!

EARLY HISTORY

Winches have in fact been around for some time as the Egyptian, Roman, and Greek Empires all used the technology to move large stones. However, the difference here is these winches were manually operated. So, workers would have to pull these stone objects using only their own strength or perhaps a donkey or horse. Naturally, this does have its limitations and the birth of steam power really pushed this humble machine forward.

THE INDUSTRIAL REVOLUTION

The Industrial Revolution brought forward many walks of life. In fact, this period in human history is arguably one of the most drastic in terms of breaking down the technological and socio-economic status quo of the time. With this influx in technology, the winch really witnessed some significant change. First, there was steam power and the steam winch, then came diesel engines and winches with combustion power, and finally, we had electric power and the all-new electric winch. These powered winches really changed the game in the winch industry and many could now complete work which they would never have dreamed of.

In fact, some of the most iconic buildings and structures of the early 20th century would simply not have been possible without the technology of the modern powered winch. Landmarks such as the Eiffel Tower and the Bristol Suspension Bridge to name just a few.

MODERN-DAY

Nowadays, of course, the powered winch is a staple in all building sites and other construction areas and many projects would effectively grind to a halt without its use in some respect. In recent times construction has skyrocketed and with the increase in population throughout the entire globe there is more and more demand for new homes and office space. This has meant that we have had to scale up our construction projects. So, without the winch, the human race would seriously be in a spot of bother right now. If you’re after a winch hire service then make sure you contact us today! Our staff are extremely knowledgeable and would love to talk with you about your project.

-

SAFE HAULING: SOME OF THE DOS AND DON’TS OF WINCHING

13 March 2023Winching is a powerful tool that can help you move heavy objects or vehicles, but it can also be dangerous if not used properly. Whether you are an experienced off-roader or a beginner, it’s important to know the dos and don’ts of winching to ensure your safety and the safety of those around you. In this blog, we’ll go over some important tips and guidelines to follow when winching.

DOS:

CHOOSE THE RIGHT WINCH

Before purchasing a winch, make sure it’s the right size and strength for the vehicle you plan on using it with. A winch that’s too weak won’t be able to pull your vehicle out of a difficult spot, and a winch that’s too strong could cause damage or injury. Alternatively, winch hire from a reputable winch company is a good option.

USE A WINCH KIT

A winch kit typically includes everything you need to safely operate your winch, including cables, hooks, and other hardware. Make sure you have a winch kit and that you understand how to use all the components.

ATTACH THE WINCH CABLE CORRECTLY

Always make sure the winch cable is securely attached to the object you’re pulling. Use a clevis hook to attach the cable to a sturdy anchor point on your vehicle, and make sure the cable is not twisted or kinked.

KEEP A SAFE DISTANCE

Always keep a safe distance from the winch cable when winching. If the cable snaps, it could cause serious injury or damage. Keep bystanders at a safe distance as well.

DON’TS:

USE THE WINCH FOR LIFTING

A winch is not designed to lift heavy objects, and attempting to do so could cause damage to the winch or the object being lifted. Use a crane or other lifting device for heavy lifting.

EXCEED THE WINCH CAPACITY

Make sure you know the weight of the object you’re winching and the capacity of your winch. Exceeding the winch capacity could cause damage to the winch or even cause it to fail.

USE DAMAGED EQUIPMENT

Never use damaged winch cables, hooks, or other equipment. Always inspect the equipment before use and replace any damaged components. Winch hire from a winch company is a good way to protect against receiving any damaged equipment as they will have checked it for you.

OPERATE THE WINCH ALONE

Winching can be dangerous, and it’s important to have someone nearby to assist you if something goes wrong. Never operate the winch alone.

USE THE WINCH AS A BRAKE

Using the winch to slow down or stop a vehicle is dangerous and could cause damage to the winch or the vehicle. Always use the vehicle’s brakes to control speed and stop.

ATLAS WINCH HIRE & HOIST SERVICES

At Atlas Winch Hire & Hoist Services, we believe that winch hire from a good quality winch company

is the best option for your business or project. Call 01899 221 577 (Scotland) or 01371 859 555 (Essex) today to discuss your requirements with our winch specialists.

-

WE’RE WALKING IN THE AIR: AIR WINCHES AND THEIR USES

13 March 2023Air winches are powerful and versatile tools that can be used in a variety of applications, from construction and mining to maritime and oil and gas industries. In this blog, we’ll explore the different uses of air winches, as well as the benefits of portable air winches and air winch hire services.

AIR WINCHES AND THEIR USES

Air winches are powered by compressed air and are capable of pulling and lifting heavy loads. They’re commonly used in construction to move materials and equipment, as well as in mining to extract minerals and in oil and gas industries for drilling operations. Air winches are also commonly used in maritime applications, such as mooring and positioning ships.

One of the advantages of air winches is their ability to work in hazardous environments. They don’t produce sparks or heat like electric winches, which makes them a popular choice in explosive environments like mines and refineries.

PORTABLE AIR WINCHES

For those who need a winch that’s portable and easy to transport, a portable air winch is an excellent option. These winches are designed to be lightweight and compact, making them ideal for use in remote locations or on job sites where space is limited.

Portable air winches can be easily moved from one location to another and can be powered by a portable air compressor, which makes them an excellent choice for those who need a winch on the go. They’re also commonly used in rescue operations and in industries where space is limited, such as on offshore oil rigs.

AIR WINCH HIRE SERVICES

If you only need a winch for a short-term project or don’t want to invest in purchasing one, air winch hire services are available. These services allow you to rent an air winch for a specified period of time, which can be a cost-effective solution for those who only need a winch for a limited time.

Many air winch hire services offer a variety of winch sizes and configurations, so you can find the perfect winch for your specific needs. Additionally, hiring an air winch can save you money on maintenance and repair costs, as these services typically include maintenance and repair as part of the rental agreement.

In conclusion, air winches are powerful and versatile tools that can be used in a wide range of industries and applications. Portable air winches are ideal for those who need a winch that’s easy to transport, and air winch hire services provide a cost-effective solution for those who only need a winch for a limited time. If you’re in need of a winch, an air winch is definitely worth considering.

ATLAS WINCH HIRE & HOIST SERVICES

At Atlas Winch Hire & Hoist Services, we believe that air winch hire from a good quality winch company is the best option for your business or project. Call 01899 221 577 (Scotland) or 01371 859 555 (Essex) today to discuss your requirements with our winch specialists.

-

WHY YOU NEED A WINCH FOR YOUR CONSTRUCTION PROJECT

13 March 2023There is no doubt that winches have been a stable part of construction for thousands of years. The Egyptians for example, pioneered the technology while they built the Great Pyramids, one of the seven wonders of the ancient world. Of course, these structures took thousands of people to build and many many years. Though many experts cite that they would have been impossible to create without the use of the winch. Then of course we have the Greek empire and the Romans who took this technology further creating some of the most astonishing buildings in human history.

Nowadays in the modern world, we have a variety of different building equipment which can help us create amazing structures. This leads us to the rather pressing question, do we still need the winch? The short answer is yes, the winch is still a vital aspect of construction. In fact, without the winch, we would still struggle with many of our construction projects and the modern urban landscape would look far different than it does now. But why do we need the winch?

TIME-SAVING

Modern construction has to meet strict timing requirements which means that building projects must be as efficient as possible. Of course, there are many other ways in which construction staff can make their site more efficient but one of the main factors is their equipment. Powered equipment is far faster than the more traditional manual methods and this is on full display when it comes to the winch.

Not only is a powered winch far faster than a manual variation but it also takes far less energy for the construction worker to operate. This will mean that they can conserve their energy for other tasks in the future. This will naturally increase the productivity of the site and make work more efficient.

QUALITY CONTROL

Naturally, the work completed on a building site must be completed to a high standard. After all, poor-quality buildings are far more vulnerable to structural issues which could cause severe safety hazards. With a quality powered lift, you can allow your construction staff a good deal more time to fix the structural elements of the building into place and ensure that the structure is secure. Without a winch, this sort of work would take a much greater amount of time and likely lead to mistakes. If you need a winch hire service then make sure you come to us here at Atlas Winch And Hoist Services We have many years of experience in the industry and pride ourselves on delivering the highest quality service possible. So, get in touch with us today if you have any questions our staff are always happy to help!

-

ALL WINCHES GREAT AND SMALL: DIFFERENT TYPES OF MANUAL WINCHES

13 March 2023Today, winches come in an array of forms – you have diesel winches, electric winches, air winches and more. What about the very first winch? Well, this was, unsurprisingly, manual. In fact, winches have been in use for millennia, with records showing winches to have been used as far back as the 4th Century BC as a way to tighten naturally-made cables that supported pontoon bridges.

Though they may be less prominent than they used to be due to the upgraded mechanisms we have today, there have been various applications for manual winches, some of which are still in use. We’ve listed some examples of things that use a winch system, a few of which you will not have only used or seen before, but we think may also surprise you. Intrigued? Keep reading below!

FISHING RODS

By definition, a winch is ‘a hauling or lifting device consisting of a rope or chain winding around a rotating drum’. Based on this, then the reel of a fishing rod could technically be considered a very small winch.

The line of a fishing rod is wound around a spool; when you cast your line out to sea, the force of your swing will allow the spool to rotate and in turn release the line, which goes out to sea thanks to the bait and/or small weight attached to the end.

When you’re ready to reel in your catch (or lack of a catch!), there is a handle that acts as a crank to manually rotate the spool, allowing you to reel the fishing line back in, whereby it will wrap itself back around the spool.

There is also something called a bail on a fishing reel, which, as well as acting as a guide for the line when being wound back onto the spool, prevents the line from unwinding when it’s engaged – just like how a ratchet may work in a winch.

WELLS

The UK is home to more than 100,000 wells, despite the majority of them no longer being in use. Nowadays, people instead tend to enjoy them by appreciating their visual quaintness and any historical tales associated with them, or to make a wish with a penny (although, you may prefer to stay away from them if you aren’t a fan of The Ring).

Water can be obtained from wells through various methods, such as via a pump or pulley system, or even – that’s right, you guessed it – using a winch.

Many traditional wells would operate by tying the end of a rope to the handle of a bucket, then tying the other end around a log or other spherical piece of wood (in later years this may have been swapped for more industrial materials, in some cases) suspended between two posts. At the end of this piece of wood would be a wheel (that the wood would be joined into) or a handle (that would instead be joined into the wood).

When this wheel/handle would be turned, the rope would wind or unwind around the log, allowing the bucket to be lowered down into the well then lifted back up again once it had filled up with water.

When comparing this to a modern day winch mechanism, you can see that the log acts as a spool, the wheel/handle acts as a crankshaft and the rope acts as a winch cable.

CHILDREN’S TOYS

Perhaps the smallest example in this list, winches have been, believe it or not, used in children’s toys. Of course, this example is not exclusive to all toys, but there are certainly some out there that utilise a winch mechanism!

Think of a toy crane or truck; these often come with small pieces of string with little hooks on the end that can be attached to corresponding toy pieces, then a small winder for the child to rotate in order to reel the string back in (which rotates around this piece) and lift or haul the smaller toy piece.

Another example that we know to have been made before is a DUPLOⓇ retro-style diver, whereby there is a block (that could be connected to a matching dingy) with a miniature spoil on it, complete with string that was then also attached to a small figurine wearing a diving helmet. This spool could be rotated to reel the diver back into the boat, as if coming out of the depths of the sea!

Granted, these are based on real-world applications of full-sized winches, but the mechanics are there all the same, albeit on a much smaller scale.

CAPSTAN

There are many kinds of boat winches – a lot of winch *which are in prominent use today, such as mooring winches, anchor winches and mast winches. The one we are going to focus on, however, is the capstan – one of the larger manual winches there has been.

Though they are still in use today, modern capstans are powered by motors or hydraulics. As for manual capstans, these were used on old sailing ships (from as early on as the 14th Century AD) and required several people to operate them. They were used to move items of heavier weights, such as anchors or large sails, on a ship with ropes.

They worked by having a timber drum with holes at the top, through which wooden bars would be slotted, then a rope was attached to this drum while the other end was tied to whichever object needed moving. In order to operate it, crew members would each take a hold of one end of the wooden bars and push it to rotate the drum of a capstan in a clockwise direction, often singing a type of sea shanty in order to coordinate their rhythm.

This would then wind the rope around the drum, thus hauling whatever the rope was attached to at the other end.

Other winches used in a nautical setting include a mast winch, which are small hand winches used on sailboats to get the sails up easier and quicker, and manual boat winches, which were used back in the day to haul in fishing boats to shore.

THEATRE WINCH

When it comes to theatre productions, people will be focused on what’s happening on stage, rather than what’s going on behind the scenes. What if we told you that behind the scenes there would be some people operating winches? That’s right, the use of winches is actually very common in theatrical productions.

Nowadays, many theatres, especially those who put on large productions, will use some form of electrical winch, since these are easy and safe to use and can carry more weight than manual ones. However, manual winches were the first type of winch to be used in theatre many years ago and some smaller scale theatres will still use them today, likewise some schools may also use them for their stage productions.

You may wonder why they’re actually needed – what could need hauling in a theatre production? Quite a lot of things, actually. In fact, the very first thing you see is likely to be operated using a winch – the curtains. Stage curtains are often made of very heavy fabric and tend to be quite large, so it is much easier to lift these using a manual winch to reveal the stage.

Not only can manual winches be used to lift the curtains, but they are also used to lift and/or move heavy stage equipment or scenery. For example, imagine a play needed to indicate a change from day to night, a wooden scenery cut out of the sun could be raised using a winch whilst a separate winch is used to lower a scenery cut out of the moon.

ATLAS WINCH HIRE & HOIST SERVICES

Are you looking for a company that specialises in all things winches? Then look no further than Atlas Winch & Hoist Services. As winch specialists, we stock all the essential winch equipment you could need across various industries, from air winches for use in construction to mooring equipment for use in marine sectors.

If you would like to enquire about the products we supply and how to hire them, then don’t hesitate to get in touch today by emailing us at info@winchhire.com. Alternatively, you can phone us on 01899 221 577.

-

SPOOLING IN LOVE: HOW TO FIND THE PERFECT WINCH HIRE COMPANY

13 March 2023Winches come in all sizes and for varying applications. Nowadays, many businesses and individuals rely on them for a number of reasons, whether it be as simple as living in the countryside and needing one to tow a vehicle out of the mud in an emergency, or requiring the use of heavy duty winches for the smooth operation of a business.

Of course, these aren’t your average everyday item that you can buy from your local shop down the road, not to mention they also cost a pretty penny to buy outright. This is why it is a smart idea to employ the services of a winch company. By opting to hire your winch(es), you will benefit from quality equipment for a fraction of the price, as long as you need it for.

We’ve put together this guide offering you our top tips on what to look out for when choosing a winch hire company, so that you are receiving the best service possible to cater to your needs. Keep reading on to learn more.

1 | PROVEN WINCH SPECIALISTS

When choosing a winch company to hire or buy your pulling equipment, one of the most reasonable factors to look at is whether or not the company you are looking at specialises in winches. If they sell some types of winches alongside their other products but this isn’t their focus or speciality, then they may not be as adept at assisting you with your winching needs as a specialist winch company.

By hiring from a company who specialises predominantly in winches, not only are they more likely to have a better supply of relevant products that you may need, but they will have the knowledge and expertise in this area should you require any advice or guidance.

For example, if you know that you need a winch for a project but aren’t sure what type of winch you require or if the winch you have in mind will be capable of performing that task you require it for safely and efficiently, then a winch specialist company would be able to offer you advice on whether the winch you intend to hire will be suitable or if there is one that is better suited to your needs.

Furthermore, this could even end up saving you money, as they appreciate the importance of using the right winch for the right job; so, if there was a smaller, cheaper winch that would be perfect for your needs as opposed to an unnecessary larger one that you otherwise intended on using, they would be able to make you aware of this.

On top of that, you will have more peace of mind knowing that you are purchasing your equipment from a company who knows their stuff, which is then likely to be reflected in the products they offer, as well as offering you reassurance that they will be able to help should something go wrong later down the line.

2 | TESTED PRODUCTS

Due to the often large-scale and dangerous applications with which many winches are required for operation, it is vital that they are safe to use with no faults. As such, you want to know that the company you plan to hire your winch from sells reliable, safe-to-use products.

Reliable winch companies, as part of their professional responsibilities, should perform rigorous testing and inspections on their products before supplying them to customers. If they do not offer reassurance of this anywhere on their website, then don’t be afraid to reach out and ask them what, if any, tests they perform on the winch equipment that they sell.

Since winches involve the hoisting of heavy items, should they fail when in use, the damage and safety risks that could occur as a result have the potential to be extensive. Of course, this could also cause delay in your business operations, whereby time and money are truly of the essence. No doubt, you want your business to function smoothly and your workers to be safe, which is why hiring winch equipment that has been thoroughly tested should be in your best interest.

3 | SERVICING AND MAINTENANCE

Even if you have workers who are trained to work with winches and hoisting equipment, that’s not to say that they are qualified to fix these should they develop a fault. Established winch companies are aware of this, which is why they may offer servicing and maintenance as part of their services.

Subsequently, you can rest assured that if you do hire a winch from them and something goes wrong with it, that they will proactively resolve this so that it is up and working again for you to use as required, rather than having to return it or receiving absolutely no form of compensation for the inconvenience.

This is extremely useful, as you won’t be responsible for having to find a reliable third-party to carry out any repairs or servicing on the equipment you purchase. If this is offered by a winch hire company, we recommend that you still check that the engineers they provide to carry out any maintenance or repair work are fully qualified.

If these engineers are fully qualified and experienced, then they may also be offered to help operate the equipment you hire (both onshore and offshore), or even your own winch and hoisting equipment, should you or anyone within your company not have the necessary training to do so – which leads us on to our next point.

4 | TRAINING

It’s all very well hiring winch equipment to help progress with a specific project, but this seems a tad redundant if you then don’t have the necessary understanding or experience in how to safely and correctly use this.

A good winch company will account for this and offer training to you to teach you how. It could be in-house training or on site, but check to see that they offer accredited training for standard cable pulling winch operation. Some may even offer more bespoke training for non-standard winch operation, tailoring this to suit your specific needs.

Whether or not you actually require any training in this regard, noting that a winch company offers this suggests that they are reliable, knowledgeable and trustworthy, offering the best solutions to their customers. Customer satisfaction is (at least it should be) prioritised by every legitimate business, as it is the customers that are ultimately required for keeping a business thriving and having a positive reputation, which in turn attracts even more customers and profit.

5 | RELIABLE TRACK RECORD

One of the best evidential indicators of a reliable company is by seeing examples of their work. When it comes to a winch company, if they have any case studies showcasing how their products or services have been used in action, then this shows that other businesses have faith in their business to trust them to help their own.

This is also a good way to learn more about the products they offer and how they can be used in different applications. It also gives them an opportunity to show off their knowledge, further painting themselves as a company who knows what they are doing and can be trusted with your requirements. Boasting is not a bad thing when it comes to business, as competency is essential for potential customers to see.

Another way to learn how good a winch company’s track record is, as with any company, is by reading any reviews and testimonials from previous customers. These should be found on trustworthy review websites only, such as Google reviews, so that you know the feedback is genuine and from a real person, rather than fake or biassed.

ATLAS WINCH HIRE & HOIST SERVICES

If you’re in need of winch equipment, then look no further than Atlas Winch & Hoist Services – we’re here to meet all your lifting needs.

We have over 30 years of experience providing lifting equipment hire for all major industries, including utilities, construction, oil, gas, renewables and engineering. Though we are based in Essex and Scotland, we offer our winch hire services all across the United Kingdom, providing you with reliable winch hire and lifting equipment to meet your professional needs, no matter how big or small your project is.

Get in touch with us today to enquire about the products and services we offer and how we can help you. For our Scotland office, please call 01899 221 577; for our Essex office, please call 01371 859 555. Alternatively, you can email us at info@winchhire.com.

-

Sea Work 2015 Commercial Marine Exhibition and Forum

18 January 2019Atlas Winch & Hoist Services Ltd are delighted to announce that they will be exhibiting at Seawork 2015 in Southampton, 16th -18th June 2015.

This is the first time we have exhibited at this particular show and we are very excited to showcase our extensive range of winches, deck equipment and accessories.

Look out for further details of what will be on show, who will be there and much more, both on our website and on our Facebook page.

-

Atlas Scotland Are Recruiting

18 January 2019We are delighted that due to the continued steady growth of the business, Atlas Winch & Hoist in Biggar are recruiting. We have two new positions:

- WORKSHOP FOREMAN

- YARD PERSON / LABOURER

Both positions require enthusiastic, flexible personnel, who are willing to learn and work as part of a very successful team. Please see below the detail for each vacancy. Please don’t hesitate to contact us regarding either post.

WORKSHOP FOREMAN

To oversee and take care of the day to day running of a small plant workshop, ideal candidate should have some experience working with diesel engines, hydraulics, auto electrics and fabrication.

Managing a workforce of 10-12 and reporting to the Operations Manager and Managing Director you would work primarily from our main yard in Biggar with potential for some travel and overtime.

Successful candidate must hold a full U.K. driving licence.

A generous salary and benefits package is offered, subject to experience and qualifications. Further opportunities will exist for the right candidate.

Applications in writing should be made to :-

Una Stewart

Atlas Winch & Hoist Services Ltd.

Old Station Yard

Station Road

BIGGAR

ML12 6DQ

Tel. 01899 221577

Email :- info@winchhire.com

YARD PERSON/ LABOURER

Responsibilities would include maintaining and organising yard area, loading and unloading of vehicles, Steam cleaning plant and general labour duties. Experience in this type of work would be advantageous.

Applicants should be enthusiastic, flexible and willing to learn. Training would be given where necessary.

Candidates must hold a full U.K. driving licence

Good rate of pay and some overtime available.

Applications in writing should be made to :-

Una Stewart

Atlas Winch & Hoist Services Ltd.

Old Station Yard

Station Road

BIGGAR

ML12 6DQ

Tel. 01899 221577

Email :- info@winchhire.com

-

August News: Challenging Water Pump Removal

18 January 2019Atlas Southern recently carried out a challenging water pump removal from a 42 metres borehole at Olympic Park in East London.

Atlas utilised a lightweight 1,000kg tripod fitted with an 800kg compact, electric winch to successfully complete the pump extraction efficiently and safely.

Both items are made by French manufacturer Huchez whom Atlas represent exclusively in the UK.

Please contact us for more information on this and the other winches and equipment we have available for hire and sale.

-

May News: Offsore Wind Energy 2017

18 January 2019In collaboration with Marotechniek B.V. come and visit us at ExCeL London, Stand S-H30, Holland Pavillion

From the 6th to the 8th June Atlas will be exhibiting at the Offshore Wind Energy exhibition at London ExCel. The event represents the largest offshore wind conference and exhibition in the world and will be attended by all leading and emerging players in the wind energy sector from all over the globe.

Atlas are proud to collaborate with Dutch manufacturer Marotechniek for the exhibition with whom we have worked closely in this specialist field for a number of years. As partners Atlas and Marotechniek can offer the complete package; design, sales, rental, installation, service and testing for winches, controls, HPU’s and various ancillary equipment. Together we have already designed and supplied a number of hoisting and cable pulling solutions that keep us at the forefront of this highly competitive renewable industry.

Come and visit us on stand S-H30 within the Holland Pavillion and discover what we can do for you.

-

Atlas Winch and Hoist Services at Liftex 2016

18 January 2019A huge thank you to all who visited us at Liftex 2016 in late November.

The exhibition was a great success and the move to Aberdeen seemed to work for many of us. It was good to meet up with friends and colleagues, old and new and both rekindle and establish business relationships and opportunities. The exhibition gave us the opportunity to showcase the wide range of both Huchez and Marotechniek winches we have on offer. We were delighted to have Sandrine Teggin of Huchez join us on the stand for most of the show. Sandrine’s product knowledge and understanding is excellent and it was good to have that available to us. Thanks again to our many customers and suppliers.

-

December News: LEEA Success

18 January 2019After being a development member of LEEA for a number of years, Atlas Winch & Hoist Services were delighted to have their membership status upgraded to Full LEEA members in November. This was due in no small part due to the investment made by both branches to increase the number of LEEA qualified engineers and technicians and also to give those engineers and technicians a wider range of qualifications. Huge congratulations to all staff that achieved new qualifications this year. We are very proud of our team. This latest achievement following on from attaining ISO

9001:2015

accreditation in June of this year means that Atlas should be your number one choice for the installation, service, test and repair of all your lifting and rigging equipment. Call us to discuss your specific requirements, we are here to help.

-

Getting Ready For Liftex 2016

18 January 2019This month we are busy preparing for Liftex 2016 in Aberdeen. From 23rd – 24th November we will be exhibiting at the Aberdeen Exhibition and Conference Centre.This is the first time in the events history that it has been held in Scotland, so we are keen to make it extra special. Atlas Winch and Hoist will be among over 100 exhibitors at what has become the go-to event in the lifting industry. We at Atlas will be exhibiting our diverse and comprehensive range of winches and lifting equipment, featuring products from our leading partners Huchez and Marotechniek.Why not get along to meet with our team and find out more about what Atlas can do for you. You will find us on Stand No. 73.

-

Successful Learners Training To The Fore

18 January 2019Atlas Winch & Hoist Services Ltd. have had a productive few months developing both the business and personnel. Alongside attaining ISO9001 in June, we have been busy expanding our LEEA qualifications and other training. Through May, June and July we had four personnel on different LEEA training courses.

Firstly in May Calum Craig successfully passed his Part 1 entrance certificate, a great achievement given that Calum is still relatively new to the lifting industry.

Then in Mid-June Denis Lavery achieved a Pass with Distinction in the Lifting Machines Manual Diploma, not a surprise that Denis managed a pass with distinction given he was jointly awarded the Gordon Loveridge Memorial Prize by LEEA some years ago. Come July it was the turn of Thomas Houston and Darren Gray to undertake more training. Thomas was delighted to pass the Lifting Equipment General Diploma and Darren was even more delighted when he passed Lifting Machines Powered Diploma with Distinction.

It is not just in Biggar that the training development is taking place, at Atlas Southern Paul Skingle recently completed a Management course, which will assist him in developing his role as Works Supervisor. All LEEA qualifications are being enhanced at Southern also, with the courses being booked for the autumn.

Our policy of continued training and personal development is something we are very proud of and is something we will continue to promote.Well done to all on the recent achievements and good luck to all those who have more training in the near future.

-

Hire Fleets Bolstered With New 20 Tonne Grundowinches

18 January 2019Hire Fleets bolstered with new 20 Tonne Grundowinches

Throughout the summer Atlas Winch & Hoist Services have been adding new Grundowinches to the hire fleets of both branches. The final batch of winches are due to arrive shortly and we are very excited to announce that amongst this final batch are two RW20B Grundowinches, 20 Tonne Trailer Mounted Cable Pulling winches, fitted with 1,200 metres of wire rope. These will be a huge addition to the hire fleets, along with the 5 Tonne and 10 Tonne Grundowinches already purchased this summer. Look out for further details of these 20 Tonne and other cable pulling winches. Atlas can assist with all your cabling requirements, small, large or very large! Don’t hesitate to contact us for details on specification, availability, rates etc. We look forward to hearing from you.

-

Seawork International Exhibition in Southampton

18 January 2019Earlier this month we exhibited at the industry renowned Seawork International Exhibition in Southampton. We were delighted with the amount of people who took the time to visit our quayside stand and meet with both Denis and Anton Lavery. We certainly feel we had a successful few days, making new contacts, re-acquainting ourselves with old friends and catching up with existing customers and suppliers.

The opportunity to showcase some of the mooring and deck equipment, in particular the Transvictory, Marotechniek and Thern range of winches that we both stock and have access to, was very worthwhile. We believe that those who visited our stand got a real insight into what Atlas does, we certainly pride ourselves in being specialists in the supply of equipment for marine, renewable and offshore applications, providing mooring systems, deck and rigging equipment, air, electric, diesel and hydraulic winches for projects throughout the U.K., Europe and the rest of the world.

A big thank you to all who took the time to call in and see us. Please do not hesitate to contact either of our offices with any specific requirement or if you simply have a general enquiry that we may be able to help with.

-

Cable Pushing Machines

18 January 2019Atlas Southern has taken delivery of the first of its new Cable Pushing Machines from ‘Plumett’ of Switzerland.

The machines are hydraulically operated and for complete flexibility can be offered with either a petrol or electric HPU depending on your site conditions.

Compact and easily operated cable pushers can be used for tunnels, duct or open trench cable installations. Cable pushers can assist with particularly long cable pulls and the design also reduces the loads and stresses imposed on cables during installation.

Contact us now for more details and hire rates.

-

More LEEA Training Succsess

18 January 2019Atlas Winch & Hoist Services were delighted to learn this week that John Dickie recently passed his LEEA Lifting Machine Powered Diploma with Credit. This is a great achievement, especially given that John has only been working with us for 16 months. Congratulations John, keep up the good work!

-

April News: New Sales Contact for North East

18 January 2019Atlas Winch & Hoist Services would like to announce the appointment of a new sales contact for the North East Area.

We are delighted that Jeff Mann (Formerly of Spanset Ltd) will be take care of our interests and customers in the North East Area with immediate effect. Jeff has a vast of experience in the both the lifting gear industry and the North East itself.

Jeff will be assisting both existing and new clients alike.

He can be contacted by email sales@winchhire.com and by mobile 07939 364238

. Where he will be happy to can help in sourcing all your winching and lifting equipment needs.