AVA Ltd

AVA have been specifying and producing anti-vibration mount solutions for 70 years. No-one understands the complexities of anti-vibration technologies or materials better. Mountings are manufactured from high grade rubber compounds specially developed to offer excellent mechanical properties and extended service life.

World wide reputation in vibration control, used in all spheres of technology isolating vibration, protecting equipment. Many different designs suiting variety of applications. Each design provides for a number of load carrying capacities.

Anti Vibration Mount

Range covers many different designs suiting a variety of applications. Each design provides for a number of load carrying capacities. Advice on the most suitable mountings for a specific application obtainable from our technical department.

- Anti Vibration Mountings: Elevate Your Experience with A.V.A. Limited

- Unlock the A.V.A. Limited Advantage: Exceptional Anti-Vibration Mounts Crafted with Care

- Explore Unrivaled Quality and Performance in Our Top-Tier Anti-Vibration Mounts

- Crafted in the UK for Unmatched Quality and Precision

- Durable Anti-Vibration Mounts Engineered for Longevity

- Budget-Friendly Solutions for Cost Savings on Maintenance and Replacements

- Benefit from Decades of Expertise, Rooted in Manufacturing Excellence Since 1930

- Experience Unmatched Customer Service and Value that Sets Us Apart

Anti Vibration Mountings Products

We manufacture rubber bonded-to-metal products to customers specific requirements.

Painstaking in our selection of metal, rubber and bonding materials, meticulous in our preparation of the bonded surfaces and the bonding process. The result is a totally reliable mounting.

Anti Vibration Product Selection

Having established the deflection requirements for your application it may not be easy to decide which of the many different types of mounting will be most suited to the application in question. Mountings of different size and type together in the same installation is not recommended, please call us on 01252 733 040 to discuss or click and leave us your contact details.

Rubber Mounts

We specialise in the supply of rubber mounts including synthetic rubbers made of polymers and co-polymers of organic compounds. Our full range of bespoke rubber mounts can be manufactured to suit your specific applications. We currently supply rubber mounts to a wide range of industries including:

- Military

- Energy

- Automotive

- Aerospace

AL Series

The AL series of mountings offer a captive installation and have been designed to isolate medium/high frequency vibration. The property of increasing stiffness with deflection helps provide smooth cushioning to movements in compression whilst a rebound washer fitted internally limits the movement resulting from reverse loads. The mountings are particularly suitable for applications where movement resulting from dynamic loads has to be accommodated and restrained. To determine the natural frequency of a particular mounting under load, the "effective deflection" should be used. This is given with the load/deflection characteristics on the lower of the two scales for each series. Typical applications include the mounting of mobile equipment, e.g. mobile compressors, generators and fan and motor equipment.

- AL 30

- AL 40

- AL 50

Bump Stops

We have a large range of bump stops and bonded feet and are able to supply a variety of different thread thicknesses.

All stops and feet are manufactured to the usual high standard that you would expect from A.V.A and include our own unique bonding process to ensure a maximum lifespan.

Heavy Duty Isolators

The heavy duty isolator series are designed to be used in compression. The range available is covered by three different sized products, each of which can be manufactured in a variety of different rubber compounds to offer a wide range of load deflection characteristics from 500N to 18KN per unit.

The high deflection characteristics of the 4008 and 4014 series mountings make them particularly suitable for applications where the load acting on the mountings may be subject to large variations during the normal operating cycle of a machine. The 4008 and 4014 series are ideal for isolating generating sets, air compressors, large fan and motor sets, vibratory hoppers, concrete panel moulds, transformers and heavy industrial equipment.

The 4022 series is the smallest of the group and is designed to isolate medium to high speed machinery operating at running speeds in excess of 2000rpm.

PLEASE NOTE: All Heavy Duty Isolators are now manufactured in compliance with ROSH standards.

Machine Feet

The 223 and 264 series mountings are designed to isolate vibration from lightweight workshop machinery, such as lathes, punches, grinding machines machine tools, vacuum equipment and ancilliary plant. They are easy to install and both ranges have a facility for height adjustment to allow levelling of the equipment. The rubber base of the foot locates the machine by friction and prevents it from travelling across the floor. Both ranges are manufactured in oil resistant rubber.

Note: The 223 and 264 series mountings are designed for industrial applications only. The rubber element may cause staining on decorative floorings. Advice for specific applications can be obtained from our technical department.

- 223 Series

- 264 Series

MS Series

Avacone mountings are designed to offer flexibility in the axial direction but limited movement radially. These characteristics make the mountings particularly suitable for mounting mobile equipment where movement in the horizontal plane has to be accommodated and restrained. Avacone mountings offer a compact design and can usually be installed into existing chassis members. All Avacone mountings are identified by the letters ‘ms’ at the start of the part number.

The mountings should always be used with the top and bottom rebound washers fitted above and below the mounting to form a fully captive arrangement and to prevent excessive movement resulting from shock and inertia loads.

The ms236 and ms238 series can be supplied fitted in a pedestal base. There are several sizes available in the range. Advice on the most suitable mounting for a given application can be obtained from our technical department. Typical applications include the mounting of gearboxes and transmission equipment, liquid storage tanks, mobile generating sets, mobile compressors, marine engines, radiators, and vehicle cab mountings.

- MS 236

- MS 238

- MS 243

Pedestal Mounts

The Pedestal series offers offer a uniquely versatile solution to a wide range of applications. The baseplate fixing lends itself to installations where ease of fitting is a priority.The Pedestal series is a general purpose mounting suitable for a wide range of industrial applications. Typical applications include the mounting of static generating sets, fan and motor sets, load cells, vibratory hoppers, water pumps etc.

The range available covers four different sizes. Each size is manufactured in a range of different hardness compounds to offer a wide range of load deflection characteristics. The array of different type numbers available in each series helps to make it easier to arrive at a solution to any vibration problem where there is an uneven weight distribution resulting in dissimilar loads at each mounting position.

- P2

- P3

- P5

- P6

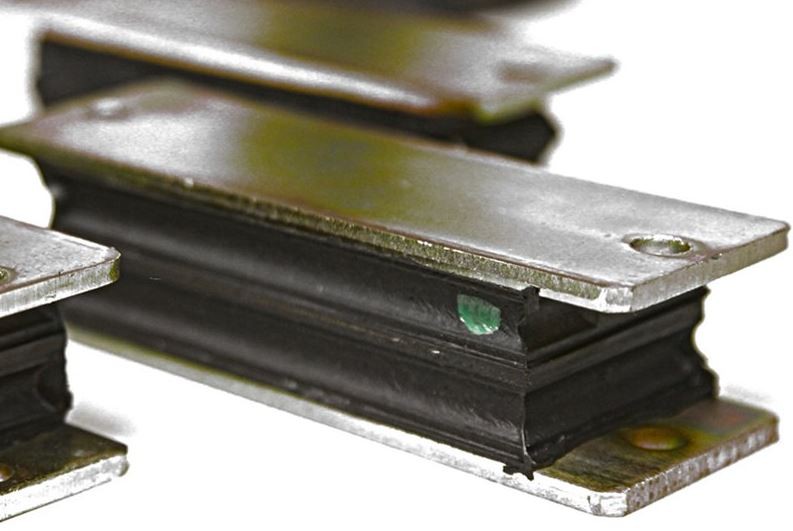

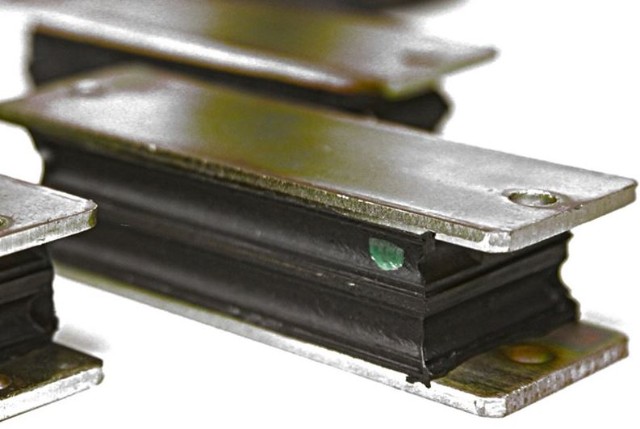

Sandwich Mounts

The sandwich mounting, so called because of its layered construction, is a well proven established design that provides an economical method of isolating heavy industrial machinery.

The steel fixing plates either side of the mounting are separated from each other by a rubber element bonded to a steel centre plate. This design gives the sandwich mounting a high load carrying in a small compact shape. This feature is particularly useful where the mountings are required to have a high load carrying capacity and at the same time a high degree of either horizontal or torsional flexibility.

Sandwich mountings may be used to decouple modes of vibration by the use of mountings inclined at an angle beneath equipment and for applications where it is desirable to accommodate relative movement between adjacent structures such as overhead gantries and walkways.

The range available covers three different sizes. Each size can be manufactured in a range of different hardness compounds to offer a wide range of load deflection characteristics to suit customer specific requirements.

Typical applications include the mounting of diesel engines, machine tools, test beds, vibratory hoppers and conveyors, concrete block-making machines, large exhaust systems etc.

SCM

The scm range offers a pedestal style fixing and utilises the properties of rubber loaded both in compression and shear. This provides good stability, an extended linear/deflection characteristic and also a long service life. The stiffness characteristics of the scm range along each of the three principal elastic axes of the mounting are all different. This feature is particularly useful when there are limitations imposed on the positioning of the mountings as it makes possible an almost infinitely variable range of stiffness combinations simply by changing the orientation of the mountings.

The scm800 series covers the load range 1kN to 12kN and has a specially designed rubber element that enables the mountings to be used at deflections up to 15.0mm. This enables the mountings to isolate equipment running at speeds down to 600 rpm. The high deflection characteristics of the scm800 series make the mountings particularly suitable for applications where high levels of isolation are required. They may also be used in applications where shock loads have to be accommodated. Individual mountings may be used to deflect up to 20mm without risk of damage.

The scm900 series covers the load range 2kN to 15kN and offers deflections up to 6.25mm.

The scm range of mountings can be used to isolate generating sets, compressors, pumps, fan and motor sets, vibrating screens and hoppers, load cells/weighing equipment, water chillers, condensing units and many other forms of industrial equipment.

Two Bolt Mounts

The two bolt series covers a wide range of products offering a variety of load deflection characteristics. Generally mountings are supplied with a male fixing at each end. For some mountings a range of different length fixings are available. A number of mountings are available with male/female fixings and occasionally female/female fixings can also be supplied. Mountings with female fixings tend to be considerably stiffer than those with male fixings as the female metal part penetrates into the rubber body reducing the elasticity of the mounting. The size and shape of the mounting usually determines whether it is possible to be offered with either a female fixing at one end or both ends. The table below lists the range of sizes covered and the type of fixings available.

Each series is manufactured in a range of different hardness rubber compounds, offering a wide range of load deflection characteristics. The load deflection figures given in the table represent the maximum recommended load for each series. In order to achieve a good service life it is best practice to select a mounting from the middle of the load range that you require.

This is particularly important when large amplitudes need to be isolated. The asterisk (*) highlights mountings that are made to special order, where minimum order quantities will apply.

- Hexagonal Bobbin Mounts