ELECTRIC - RIVETING, JOINING, ROLLER FORMING

21 February 2022ONE MACHINE - THREE PROCESSES

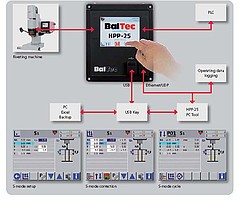

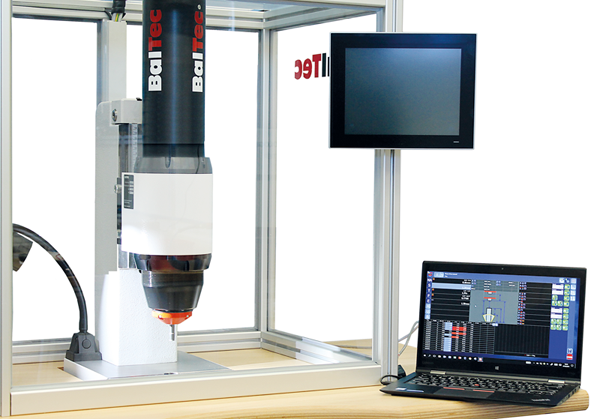

ELECTRIC with servo drive and HPPi PC Software stands for the new generation of electric riveting and roller forming machines. The servo riveting machine does not only replace pneumatic and hydraulic systems, but this innovative and patented machine concept with integrated software makes every step of the process programmable and easily adaptable to new or fast-changing requirements. And last but not least, ELECTRIC devices are compatible with the Classic line riveting devices RN/RNE.

IMPORTANT ADVANTAGES AT A GLANCE:

- Productivity gains of up to 35 % due to faster cycle times depending on the application

- Lower operating costs through efficient energy use of up to 80% (pneumatic machines)

- Reduced scrap costs through integrated process monitoring and quality assurance

- Seamless traceability thanks to integrated process data management

- Slim design reduces installation space in automatic lines

- Reduced time and effort for integration into machines through preconfigured interfaces

- Sizes/models cover the wide force range from 0.3 to 50 KN with working strokes of 100 or 200 mm.

ELECTRIC offers two construction sizes with four different models, covering a force range between 0.3 bis 50.0 kN and a stroke of 100 and 200 mm. The radial riveting units are compatible with BalTec riveting units of the Classic Line (RNE 231 and RNE 331 with an adapter).