Brother Moulding Division

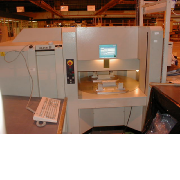

The Moulding division of Brother Industries (UK) Ltd, (formerly known as GKK Plastics), was formed in 1990 delivering a precision injection moulding and assembly service to a blue chip client base. We are part of the global Brother Group consisting of over 30,000 employees worldwide, with access to the Brother Network and knowledge centres.

Based on a 24,000 sq. metre site in Wrexham, North Wales with good transport links to all areas of the UK. We supply Plastic Mouldings to a diverse range of markets including Electronics, Medical, Agricultural and Construction industries and can provide a total manufacturing service from concept design to finished product.

As specialists in the moulding of technical components, we have extensive assembly experience in both high and low volume manufacturing. Our highly efficient operation and continuous improvement philosophy ensure we remain extremely competitive and can offer the very best value to our customers.

At Brother we will always strive to offer an exceptional service and to meet and exceed our customer’s expectations.

Filter products and services

-

Injection moulding Acetal Whitchurch

Acetal is a high-performance engineering polymer often used for parts that would otherwise be made of metal. Chosen for its distinct characteristics, it is widely used in both machining and injection moulding. There are two types of acetal. Homopolymer, produced by DuPont as Delrin®, consists of a chain of identical oxymethylene units. Copolymer, introduced by Celanese as Celcon®, consists of a chain of alternating oxymethylene and oxyethylene units. While the two acetals differ in some ways, they share basic characteristics.

Feel free to call us for more information.Request a Quote Supplied by Brother Moulding Division -

Injection moulding Acetal Wrexham

Acetal is a high-performance engineering polymer often used for parts that would otherwise be made of metal. Chosen for its distinct characteristics, it is widely used in both machining and injection moulding. There are two types of acetal. Homopolymer, produced by DuPont as Delrin®, consists of a chain of identical oxymethylene units. Copolymer, introduced by Celanese as Celcon®, consists of a chain of alternating oxymethylene and oxyethylene units. While the two acetals differ in some ways, they share basic characteristics.

Feel free to call us for more information.Request a Quote Supplied by Brother Moulding Division -

Injection Moulding Chester

Our Moulding Division has machines ranging from 25 tonne to 550 tonne. These are automated using high-speed robotics to ensure process consistency and to maximise efficiency. This, combined with Lean Manufacturing techniques used by our team of Engineers, means we can increase productivity, reduce cost and ensure we develop the most efficient process for our customers.

Please contact us for more information.Request a Quote Supplied by Brother Moulding Division -

Injection Moulding Crewe

Our Moulding Division has machines ranging from 25 tonne to 550 tonne. These are automated using high-speed robotics to ensure process consistency and to maximise efficiency. This, combined with Lean Manufacturing techniques used by our team of Engineers, means we can increase productivity, reduce cost and ensure we develop the most efficient process for our customers.

Please contact us for more information.Request a Quote Supplied by Brother Moulding Division -

Injection moulding glass filled PA6

Nylon 6 is a Polyamide, A crystalline material that is tough, resilient and creep resistant. Nylon 6 is made from Caprolactam and is used extensively in the fibre markets. Nylon 6 is very suitable injection moulding parts and can be extruded. It can be modified to increase rigidity and impact resistance. It is used in Bearings, washers, screw caps, conservatory roof parts, power tool housings, laser tags, connectors, strapping and Brush bristles.Request a Quote Supplied by Brother Moulding Division -

Injection moulding glass filled PA66

PA66 is a Polyamide, a semi crystalline material with very high strength and stiffness. The Material is low viscosity and therefore flows very easily. Typical Applications include automotive parts such as fans, grilles, door handles, kitchen appliances, castors and bearings. Types of grade available are impact modified, glass fibre and bead filled, flame retardant, mineral filled High viscosity (extrusion), and Heat stabilised.

Please call for more information.Request a Quote Supplied by Brother Moulding Division -

Injection moulding glass filled PA66 Chester

PA66 is a Polyamide, a semi crystalline material with very high strength and stiffness. The Material is low viscosity and therefore flows very easily. Typical Applications include automotive parts such as fans, grilles, door handles, kitchen appliances, castors and bearings. Types of grade available are impact modified, glass fibre and bead filled, flame retardant, mineral filled High viscosity (extrusion), and Heat stabilised.

Please call for more information.Request a Quote Supplied by Brother Moulding Division -

Injection moulding glass filled PA66 Crewe

PA66 is a Polyamide, a semi crystalline material with very high strength and stiffness. The Material is low viscosity and therefore flows very easily. Typical Applications include automotive parts such as fans, grilles, door handles, kitchen appliances, castors and bearings. Types of grade available are impact modified, glass fibre and bead filled, flame retardant, mineral filled High viscosity (extrusion), and Heat stabilised.

Please call for more information.Request a Quote Supplied by Brother Moulding Division -

Injection moulding glass filled PA66 Northwich

PA66 is a Polyamide, a semi crystalline material with very high strength and stiffness. The Material is low viscosity and therefore flows very easily. Typical Applications include automotive parts such as fans, grilles, door handles, kitchen appliances, castors and bearings. Types of grade available are impact modified, glass fibre and bead filled, flame retardant, mineral filled High viscosity (extrusion), and Heat stabilised.

Please call for more information.Request a Quote Supplied by Brother Moulding Division -

Injection moulding glass filled PA66 Shewsbury

PA66 is a Polyamide, a semi crystalline material with very high strength and stiffness. The Material is low viscosity and therefore flows very easily. Typical Applications include automotive parts such as fans, grilles, door handles, kitchen appliances, castors and bearings. Types of grade available are impact modified, glass fibre and bead filled, flame retardant, mineral filled High viscosity (extrusion), and Heat stabilised.

Please call for more information.Request a Quote Supplied by Brother Moulding Division