Brother Moulding Division

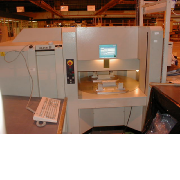

The Moulding division of Brother Industries (UK) Ltd, (formerly known as GKK Plastics), was formed in 1990 delivering a precision injection moulding and assembly service to a blue chip client base. We are part of the global Brother Group consisting of over 30,000 employees worldwide, with access to the Brother Network and knowledge centres.

Based on a 24,000 sq. metre site in Wrexham, North Wales with good transport links to all areas of the UK. We supply Plastic Mouldings to a diverse range of markets including Electronics, Medical, Agricultural and Construction industries and can provide a total manufacturing service from concept design to finished product.

As specialists in the moulding of technical components, we have extensive assembly experience in both high and low volume manufacturing. Our highly efficient operation and continuous improvement philosophy ensure we remain extremely competitive and can offer the very best value to our customers.

At Brother we will always strive to offer an exceptional service and to meet and exceed our customer’s expectations.

Filter products and services

-

Assembly Shewsbury

Brother Industries (UK) Ltd. has over 25 years of experience of both high volume flow lines and cell assembly techniques. Our Production Engineers adopt Lean Manufacturing methods to ensure the process is as efficient as possible.

Please call for more information.Request a Quote Supplied by Brother Moulding Division -

Assembly Stoke-on-Trent

Brother Industries (UK) Ltd. has over 25 years of experience of both high volume flow lines and cell assembly techniques. Our Production Engineers adopt Lean Manufacturing methods to ensure the process is as efficient as possible.

Please call for more information.Request a Quote Supplied by Brother Moulding Division -

Assembly Whitchurch

Brother Industries (UK) Ltd. has over 25 years of experience of both high volume flow lines and cell assembly techniques. Our Production Engineers adopt Lean Manufacturing methods to ensure the process is as efficient as possible.

Please call for more information.Request a Quote Supplied by Brother Moulding Division -

Assembly Wrexham

Brother Industries (UK) Ltd. has over 25 years of experience of both high volume flow lines and cell assembly techniques. Our Production Engineers adopt Lean Manufacturing methods to ensure the process is as efficient as possible.

Please call for more information.Request a Quote Supplied by Brother Moulding Division -

Ball pressure test

The Brother Moulding Test-Ball has been the contractor's choice for over 50 years and continues to be the most trusted pneumatic test ball in the industry. The ball pressure test is designed for applications from pressure testing and blocking of residential DWV systems to repair maintenance and installation of municipal infrastructure.

For information please call us.Request a Quote Supplied by Brother Moulding Division -

Ball pressure test Chester

The Brother Moulding Test-Ball has been the contractor's choice for over 50 years and continues to be the most trusted pneumatic test ball in the industry. The ball pressure test is designed for applications from pressure testing and blocking of residential DWV systems to repair maintenance and installation of municipal infrastructure.

For information please call us.Request a Quote Supplied by Brother Moulding Division -

Ball pressure test Crewe

The Brother Moulding Test-Ball has been the contractor's choice for over 50 years and continues to be the most trusted pneumatic test ball in the industry. The ball pressure test is designed for applications from pressure testing and blocking of residential DWV systems to repair maintenance and installation of municipal infrastructure.

For information please call us.Request a Quote Supplied by Brother Moulding Division -

Ball pressure test Northwich

The Brother Moulding Test-Ball has been the contractor's choice for over 50 years and continues to be the most trusted pneumatic test ball in the industry. The ball pressure test is designed for applications from pressure testing and blocking of residential DWV systems to repair maintenance and installation of municipal infrastructure.

For information please call us.Request a Quote Supplied by Brother Moulding Division -

Ball pressure test Shewsbury

The Brother Moulding Test-Ball has been the contractor's choice for over 50 years and continues to be the most trusted pneumatic test ball in the industry. The ball pressure test is designed for applications from pressure testing and blocking of residential DWV systems to repair maintenance and installation of municipal infrastructure.

For information please call us.Request a Quote Supplied by Brother Moulding Division -

Ball pressure test Stoke-on-Trent

The Brother Moulding Test-Ball has been the contractor's choice for over 50 years and continues to be the most trusted pneumatic test ball in the industry. The ball pressure test is designed for applications from pressure testing and blocking of residential DWV systems to repair maintenance and installation of municipal infrastructure.

For information please call us.Request a Quote Supplied by Brother Moulding Division