Columbia Metals Ltd

Columbia Metals is one of the leading non ferrous metals stockholders in the UK. Our range includes high performance copper, nickel and stainless steel alloys for all industries and applications.

As the UK’s leading non ferrous metals stockholders we specialise in the supply of high performance alloys with excellent corrosion resistance and superior strength characteristics. All material is ex-stock physically available in our warehouse for immediate dispatch worldwide.

Additionally, and uniquely within the metal stockholding industry, Columbia Metals has established itself as a supplier of its own extensive range of special, Trademark alloys. Non ferrous metals stockholders, Columbia Metals, can supply materials with a unique blend of properties and continues to ensure that engineers have access to an exceptional choice of alloys not available from other sources.

Columbia Metals is a uniquely independent non ferrous metals stockholders company and is extremely well placed to service our domestic and global market.

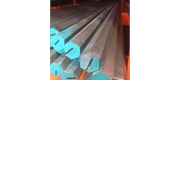

Aluminium Bronzes

Aluminium Bronzes are alloys of Copper with Aluminium. Other additions such as Iron, Nickel, Manganese and Silicon are normally made to enhance further the corrosion resistance, strength and toughness properties and other qualities such as wear and abrasion resistance.

CA102 (type)/CuAl6Ni2

This material is reasonably high strength with an excellent corrosion resistance in various acid and saline waters. It offers a rich 18 carat gold colour and is highly resistant to wear, abrasion and tarnishing. It is the only truly cold workable Aluminium Bronze available and is traditionally used for architectural/decorative and marine applications. Related Specifications include CA102/C61000/CuAl6Ni2

CA104/BSB23/DSTAN 02-833

Classed as 10/5/5 type Aluminium Bronzes these are the most commonly used grades within the UK. Mainly utilised for their high strength and excellent resistance to erosion and corrosion in seawater and many other aggressive environments. In addition these alloys offer very good wear and abrasion resistance, an ability to withstand shock loading and the retention of properties at cryogenic temperatures.

The DSTAN 02-833 / NES 833 is manufactured to the more exacting requirements of the Ministry of Defence (Navy). This also involves impact properties on sizes above 15mm and a full ultrasonic inspection to conform to Grade 1 material. Related Specifications CA104/BSB23/DTD197A CW307G/C63200/CuAl10Ni5Fe4 and NES833 / DSTAN 02-833 / DGS1043 / DGS8452

C63000 / AMS4640 / CW307G

C63000 is the most popular American grade of Nickel Aluminium Bronze. It offers high strength and hardness, a very good corrosion resistance, an excellent resistance to wear, shock and abrasion. This grade is also readily hot worked and offers a good machinability. Related Specifications C63000 / CW307G / AMS4640

Other Aluminium Bronzes From Stock

Being one of the largest stockholder of Aluminium Bronze within the UK we also have a number of other grades available for selection. These include COLSPEED 90 (free machining Aluminium Bronze), C61300, C61900, C62400, CA103, CA105, CA106, NFL-14705, DSTAN 02-834; NES834, CA107, C64200, CW301G, DGS1044, AMS4631. We are unable to put a section for each one, but others listed here are still essential alloys for the engineering industry with more information to be found at www.columbiametals.co.uk.

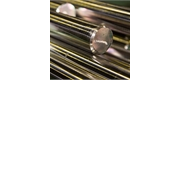

Brasses

The brasses are primarily alloys of Copper and Zinc with additions of other elements can be added to enhance machinability, corrosion resistance, strength etc. The basic zinc content varies from about 5 to 40%. Above 37% Zinc the brasses are produced by hot forming / extrusion with limited cold workability. Below 37% Zinc the brasses can be processed by cold rolling and drawing, with cold workability increasing with decreasing Zinc content.

For more Information please visit www.columbiametals.co.uk.

CZ101

This is a 90% copper 10% zinc alloy primarily supplied as a sheet grade and is classed as a Gilding Metal. The alloy offers excellent cold working properties and is generally not susceptable to dezincification and stress corrosion.

Due to its formability and its attractive rich golden colour, the alloy is widely used for architectural and decorative applications. It is also readily brazed and enamelled.

CZ106 / Cartridge Brass

This grade exhibits an excellent combination of strength and ductility for the copper zinc series. This grade is used for its outstanding deep drawing properties and excellent cold workability. Related Specifications - CZ106 / C26000 / CuZn30 / CW505L.

CZ108

CZ108 / Basis Brass, is one of the most popular grades due to its hot and cold working capabilities. Supplied primarily as a sheet grade this material is often used for general purpose and simple forming operations. Related Specifications CZ108 / CW508L / C27400 / CuZn37

CZ109

CZ109 / Muntz Metal is a lead free 60/40 alpha-plus-beta brass. It is classed as a general-purpose alloy that offers excellent hot working properties but limited cold formability. The service environment must be considered prior to selection to predict corrosion behaviour. Related Specifications CZ109 / CW509L / CuZn40 / C28000

Naval Brass CZ112

CZ112 (C46400) is classed as naval brass and is a 60% copper 40% zinc with 1% tin alloy. The addition of tin is made for extra corrosion resistance in seawater and other mildly aggressive environments. It also offers good strength levels combined with an excellent hot formability. Related Specifications CZ112 / C46400 / CW712R

High Tensile Brasses CZ114 / CZ115

CZ114 is the standard grade of high tensile brass, where the aluminium content not only assists in increasing the mechanical properties but also improves the general corrosion resistance of the alloy. It also offers a reasonable machinability and good hot stamping capabilities to enable its use for components such as gas valves, fittings, pumps and fasteners. Related Specifications: http://www.columbiametals.com/products/brass

CZ115 is also a duplex high tensile brass, but this grade has a restricted aluminium content to facilitate soldering and brazing. The additions of tin and iron impart the higher strength levels for this grade, with the tin content also improving the corrosion resistance. Related Specifications CZ115 / CW722R / CuZn40Mn1Pb1FeSn

Engraving Brass CZ120

Engraving brass CZ120 is a classic leaded machining alloy primarily available in sheet form. The alloy is an alpha beta brass with a 2% lead addition that gives the alloy its free cutting properties. Traditionally used for machine engraved nameplates and signs it also offers a good combination of strength, corrosion resistance and hot formability. Related Specifications: CZ120 / CW608N / C37700 / CuZn39Pb2

CZ121 Free Machining Brass

CZ121 is classed as Free Machining Brass, with a 3% lead addition, which is finely dispersed throughout the material. It is suited to high speed machining operations due its superior machinability, thread rolling and knurling characteristics.

Its machinability rating of 100 is the standard against which all copper alloys are rated. It also offers a good strength, it is easily soldered or brazed and has good resistance to corrosion. Related Specifications: CZ121 / CW614N / C36000 / CuZn39Pb3

CZ126 Arsenical Brass

CZ126 is classed as Arsenical Brass and is essentially a 70% copper 30% zinc alloy that is supplied in tubular form. The small addition of arsenic improves the corrosion resistance without affecting the ductility and forming characteristics of the material.

With reasonable strength levels this alloy is utilised in heat exchangers, condensers and in other components requiring general purpose tube. This material offers a good workability and can be manipulated by a number of techniques. It also lends itself to soldering and brazing. Related Specifications: CZ126 / CW707R / C44500 / CuZn30As

COLFIT - DZR / CZ132

Dezincification resistant (DZR) brass was originally developed to provide good resistance to dezincification type corrosion which is experienced by normal hot working brasses. As well as the improved corrosion resistance this alloy also offers good strength levels and is readily machined and hot forged. It is ideal for water fittings that are produced by hot stamping and machining.

Related Specifications: CZ132 / CW602N / CuZn36Pb2As

Copper and High Copper Alloys

Coppers and High Copper Alloys are those that contain more than 95% copper with only a small addition of elements such as nickel, silicon, chromium and beryllium. These additions are used to enhance properties such as strength, hardness, corrosion resistance and wear resistance, whilst maintaining some of the benefits of pure copper such as a high electrical or thermal conductivity.

The coppers include C101, C103, C106, C109 and C110 these offer varying degrees of purity and benefits as described below. Meanwhile the high copper alloys have been developed for other industrial markets. For example COLSIBRO and CHROMZIRC 328 offer high strength, low magnetic permeability and excellent conductivity levels, while the Trojan offers even higher strength levels. There is also the Silicon Bronze (COLDUR A) a fabricators dream, easily weldable and hot and cold formed, whilst offering a good corrosion resistance and strength.

C101 / ETP Copper

Electrolytic tough pitch copper is a commercially pure high conductivity grade of copper refined by electrolytic deposition which is then melted and oxidised to the "tough pitch" condition with a controlled low oxygen content. This is the normal grade for general electrical use as busbar, motor and transformer components, windings and many other current carrying applications. Related Specifications: C101 / C11000 / Cu-DPA

C106 Copper - Cu DHP

Phosphorus deoxidised copper is the grade of copper where oxygen is removed by the controlled addition of phosphorus during the melting cycle. A slight excess of phosphorus ensures complete removal of oxide.

C106 should be specified for all non-electrical applications, especially those involving assembly by welding or brazing. Phosphorus deoxidised copper is not susceptible to hydrogen embrittlement which is a serious risk with non-deoxidised grades. Related Specifications: C106 / C12200 / Cu-DHP

C103 / C110 OFE Coppers

C103 is a commercially pure grade of oxygen free copper manufactured by pouring in a protective gas atmosphere or vacuum. Related Specifications C103 / C10200 / Cu-OF / BS1433. Whilst, C110 is the purest grade of oxygen free copper, as it contains 99.99% copper and has much tighter limits on impurities than other grades. It offers the highest electrical and thermal conductivity values available from a commercially available copper alloy and like C103 is not susceptible to embrittlement when heated. Related Specifications: C110 / C10100 / Cu-OFE / BS3839

COLSIBRO / CuNi2Si

COLSIBRO® is a copper nickel silicon alloy with a remarkable blend of physical and mechanical properties achieved by a fine dispersion of nickel silicide. Its combination of high strength, wear resistance and high conductivity combined with an ease of machinability has ensured its success as an alloy of choice in many critical applications.

TROJAN / CuNi3Si

TROJAN® is our ultimate super strength copper nickel silicon alloy, specially developed to provide a unique blend of mechnical and physical properties for high performance engineering. It offers superb strength, excellent wear and corrosion resistance with very good electrical and thermal conductivities. With its combination of mechanical and physical properties TROJAN® has proven itself many times over as a more cost effective and technically superior option to alternative materials.

Beryllium Copper / C17200

BECOL-25® is a 2% beryllium containing copper alloy, capable of attaining the highest strength and hardness of any commercially available copper based grade. It is supplied in solution heat treated condition for optimum workability prior to precipitation hardening by the customer to develop its full strength and hardness. Related Specs: C17200 / CB101 / CuBe2

Silicon Bronze / COLDUR-A

COLDUR-A® is a high copper alloy with small additions of silicon and manganese to enhance the mechanical properties, corrosion resistance and workability of the material. COLDUR-A® is one of the easiest materials to work with as it offers excellent hot and cold formability, it is readily machinable and can be joined by a variety of methods.

The combination of outstanding fabrication, attractive golden bronze colour, strength levels and its high corrosion resistance make it a firm favourite with sculptors, metalsmiths and fabricators alike. Related Specifications: C65500 / CS101 / CUSI3Mn

Cupronickels

These alloys are, as the title suggests, alloys of copper and nickel. Varying degrees of Nickel and alloying additions can offer anything from a malleable material through to high strength, high modulus alloys. One thing the have in common is their excellent resistance to corrosion and erosion in marine environments. The 90/10 & 70/30 materials are the standard grades while the NES835 or Nibron Special are the higher strength grades for more demanding applications.

90/10 Cupronickel

This is a 90% copper 10% nickel alloy that also contains small but important additions of iron and manganese to enhance the overall corrosion resistance. This combined with a high ductility & toughness and wide availability makes this the most popular grade for standard applications.

The 90/10 alloy offers designers and specifiers excellent resistance to stress corrosion, erosion, and biofouling in seawater and brackish water, excellent fabrication and welding properties, a high resistance to hydrogen embrittlement and the retention of mechanical properties down to cryogenic temperatures. Related Specifications: CN102 / C70600 / CuNi10Fe1Mn /

NES779 / CW352H

70/30 Cupronickel

A 70% copper, 30% nickel alloy with additions of iron and manganese offers many advantages over the 90/10 alloy and is used for more demanding applications. Being more resistant to corrosion and erosion it also provides slightly improved strength levels over the 90/10 alloy. One notable feature is that corrosion resistance is improved in high-velocity waters (up to 4.5 m/s) and polluted seawater. This material is readily cold worked, fabricated and welded without any special material considerations. Related Specifications CN107 / C71500 / NES 780

NIBRON SPECIAL

NIBRON SPECIAL is a superb engineering material with a combination of high performance properties not found in any other alloy. With mechanical properties equivalent to B7 bolting steel and an excellent corrosion resistance in a large number of different aggressive media, NIBRON SPECIAL® is vastly superior to most other copper alloys and steels.

NIBRON is a specially formulated high strength, high modulus cupronickel and is one of the strongest copper alloys currently produced. It is highly resistant to hydrogen embrittlement, sulphide, chloride, ammonia and amine stress corrosion cracking, while offering exceptionally low magnetism and resistance to sparking, galling and seizure.

Other Cupronickel Grades

Other grades of copper nickel are available from Columbia Metals to National, Naval and Aerospace standards. These grades also offer a very high strength, an excellent resistance to corrosion and bio-fouling, high impact values and a low magnetic permeability. Grades include - NES 835 / DSTAN 02-835 / DIN 2.1504 / DTD 900/4805

Stainless Steels

Columbia Metals offers a range of Specialist Stainless Steels to suit virtually any application. The range includes the aerospace grades S80, S130 and S143, duplex and superduplex grades for offshore usage, to the higher strength 660B and 17/4PH or the heat resisting 310. With a comprehensive range of sizes and forms we can offer a unique service to both specialised industries and general engineering companys.

Super Duplex Stainless Steels S32550 / S32760

Superduplex materials are designed primarily for a combination of corrosion resistance and high strength and toughness. With a composition formulated to guarantee a PREN of greater than 40.0.

S32550 / AMAZON 256-Cu offers high strength and corrosion resistance to chemical and seawater attack. It has an equal balance of austenite and ferrite in the duplex microstructure which ensures that the mechanical properties are at least 40% higher than 316 stainless as well as superior toughness and ductility to ferritic stainless steels. With the careful control of metal purity and heat treatment AMAZON also has a stress corrosion resistance significantly higher than that of austenitic stainless steels.

S32760 / SEACOL - 760 based on the 25% Cr, 7% Ni composition with similar properties to the S32550. The addition of a small percentage of copper enhances the general corrosion resistance. The alloy is widely specified for the offshore oil and gas industry.

BS970:Grade 310

Columbia 310 is an austenitic heat-resisting stainless steel. It is noted for excellent resistance to scaling in continuous service up to 1150°C, and in intermittent heating/cooling conditions up to 1095°C.

This grade is highly resistant to oxidising acids and most common corrosive agents; and in marine conditions it shows little evidence of chloride stress corrosion cracking, outperforming lower alloy grades such as 304 and 316. In particular it has good resistance to hot corrosion in many environments including molten salts.

Precipitation Hardening Stainless Steel 17/4PH

17-4 PH is a precipitation hardening martensitic stainless steel capable of achieving very high strength and hardness after a relatively simple heat treatment. It offers excellent corrosion resistance combined with a structured range of mechanical property levels depending on the precise heat treatment applied.

It is readily machined and fabricated in the softer tempers and can then be heat-treated to exceptional strength and dimensional stability. 17/4 PH is widely used in the chemical, petrochemical, offshore, paper, food, and aerospace industries. Related Specifications: S17400 / Type 630 / 1.4542

Alloy A-286 / 660B

Alloy A-286 is special corrosion, oxidation and heat resistant, precipitation hardenable austenitic stainless steel. It is designed for long-term, high strength service up to 700°C. It offers good oxidation resistance in continuous service up to 800°C and is non-magnetic even after severe cold deformation.

Alloy A-286 has good machinability and machines best in the precipitation-hardened condition when it has a machinability rating 45% that of AISI1212 free-cutting grade. Alloy A-286 is used mainly in the precipitation-hardened condition. Related Specifications: S66286 / A286 / 660B

Nickel Alloys

The Nickel Alloys have a vast range of applications and advantages from the low thermal conductivity of the Nickel Irons to the excellent corrosion resistance in aggressive media of C276 or the high temperature and high strength use for Alloy 718. The nickel alloys have something to offer everyone. Below we have listed a few of the grades on offer from Columbia Metals Ltd, but this is not exhaustive so please call even if you cannot see what you are searching for.

Alloy 600

A non-magnetic nickel-chromium-iron high temperature alloy with an excellent combination of high strength, hot and cold workability and high corrosion resistance. It has good high temperature strength up to 1150ºC and displays freedom from stress corrosion. Related Specifications ASTM B166: N06600 / BS3076 NA14

Alloy 625

Alloy 625 is an excellent general purpose material for elevated temperature use in high strength, oxidation problem areas. It offers excellent resistance to pitting, crevice corrosion, stress corrosion, corrosion fatigue and erosion corrosion whilst maintaining its mechanical properties up to about 450ºC. It is also very resistant to a wide range of organic and mineral acids combined with good corrosion resistance to high temperature sulphides and chlorides.

Related Specifications N06625 / BS3076 NA21

Alloy 718

Alloy 718 is a precipitation hardening nickel - chromium alloy that provides a unique combination of high strength and corrosion resistance together with an excellent tensile, fatigue, creep and rupture strengths across a wide temperature range from -253ºC to 705ºC. Also the high chromium content results in excellent oxidation resistance, up to temperatures of around 980ºC.

Alloy 718 offers outstanding corrosion resistance in a variety of media. It excels in many environments including organic and inorganic acids (other than when strongly oxidising), hydrogen sulphide and sour gasses. It is also especially resistant to chloride stress-corrosion cracking. Related Specifications - N07718 / AMS 5662 / 5663 / 5664 / 2.4668

Alloy 825

Alloy 825 is a titanium-stabilised nickel-chromium-iron-molybdenum-copper alloy designed for use in extremely corrosive environments. It has a very high resistance to oxidation and outstanding resistance to stress corrosion cracking in chloride conditions. Related Specifications: N08825 / BS3076 NA16

Alloy C276

C-276 is a nickel - chromium - molybdenum - tungsten alloy displaying remarkable corrosion resistance in a wide range of processing environments. It offers excellent resistance to pitting & crevice corrosion, stress corrosion cracking and oxidising atmospheres up to 1040°C.

C-276 is selected for its resistance to wet chlorine gas, hypo-chlorites and many other aggressive chemicals. It also offers exceptional resistance to strong solutions of oxidising salts such as ferric and cupric chlorides. Related Specifications: N10276

/ C276

Alloy 80A / NA20 / BS 2HR1

Alloy 80A is a nickel - chromium alloy with additions of titanium and aluminium, enabling it to be strengthened by precipitation hardening. It is supplied in the solution treated condition for ease of machinability, but an ageing treatment will give the material very high mechanical properties, an outstanding resistance to creep at service temperatures up to 815ºC (1500ºF) and a high resistance to fatigue under very arduous conditions.

It offers excellent corrosion resistance in oxidising atmospheres including under cyclical conditions of heating and cooling. As well as a good machinability, formability and weldability using common welding methods. Related Specifications: BS3076 / NA20 / BS2 HR1 / ALLOY 80A

Alloy 36 /F1684 K93603

A 36% nickel-iron alloy that exhibits a near zero rate of thermal expansion which is approximately one tenth that of carbon steel at temperatures from around -100°C up to 200°C. Along with this very low coefficient thermal expansion, it also offers a retention of strength and toughness at cryogenic temperatures, making it suitable for a variety of low temperature applications. Related Specifications - K93603 / FeNi36 / 1.3912

Alloy 42 / K94100

Alloy 42 is an iron-nickel alloy containing 41% of nickel. It exhibits low thermal expansion characteristics, over a range of temperatures, and its CTE is matched to silicon and ceramic materials making a valuable glass-to-metal and ceramic to meal sealing alloy. Related Specifications: Alloy42 / K94100 / FeNi42

Alloy K / K94610

Alloy K is an iron-nickel-cobalt alloy whose chemical composition is controlled within narrow limits to ensure precise and uniform thermal expansion and mechanical characteristics and to provide high integrity glass-to-metal and ceramic-to-metal seals. Related Specifications: K94610 / ASTM F15 / Alloy 29/18 / Alloy K

Titanium

The Titanium alloys are the newest addition to our stock range with the Grade 5 material being the largest stock item. The Grade 5 material is the most popular and versatile of the Titanium alloys but other grades are available on request.

With material available in many forms including diameter, plate and forgings the titanium grades complement our stock of speciality materials by offering a lightweight, high strength and corrosion resistant option to our customers.

Grade 5 / 6Al-4V

Ti-6Al-4V is a two phase alpha + beta grade and is the most widely used of all the titanium grades. It is supplied in the annealed condition as per the AMS 4928R or BS2TA11 for ease of machinability and can be strengthened with a relatively simple heat treatment to offer very high mechanical properties.

The combination of these good mechanical properties (maintained up to ~400oC), a low density of 4.42 g/cm3 and a very good corrosion resistance make the Ti-6Al-4V ideal for applications in the aerospace, marine, offshore oil & gas and motorsport industries. Related Specifications: AMS4928 / Ti-6Al-4V / ASTM B348 / Grade 5 / R56400 / BS2TA11