Drallim Industries Ltd

A technology driven British engineering group with global presence. We bring our customers, innovation in design, manufacture and quality service, covering a broad spectrum of products and markets. Form relationships with both customers and suppliers that will improve quality in all aspects of final product and purchased materials

Filter products and services

-

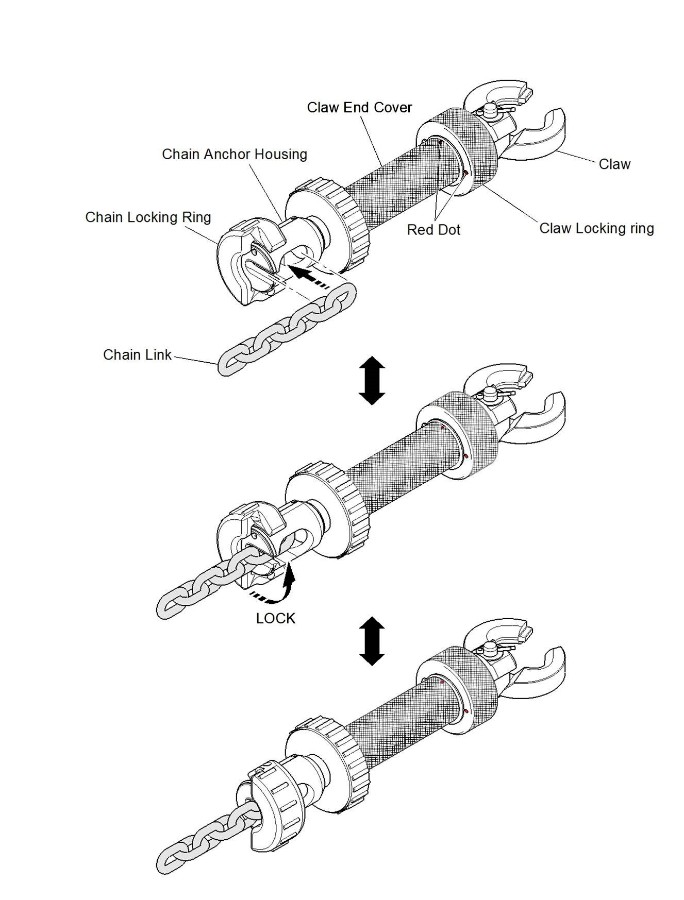

Standard Quick Release Coupling

This is a rugged, heavy-duty tensioner for use in all situations. At one end is a double-jaw claw-type connector, operated by a quarter turn of a knurled hand grip, which attaches to a securing ring or other suitable strong point. At the other end of the coupling is a chain pocket into which the nearest link of the lashing chain, after all, the slack has been taken up, is secured by means of a half-turn of the lock. Turning the built-in handwheel on the body of the coupling produces the required tension in the lashing. Quick-release is effected by a quarter turn of the handgrip.Request a Quote Supplied by Drallim Industries Ltd -

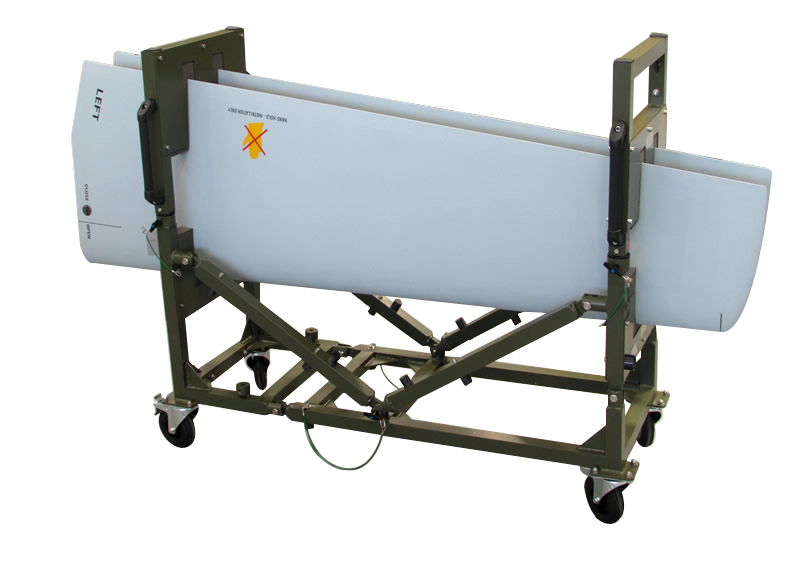

Storm Chocks

One of Europe's largest airlines recently highlighted chocking problems in adverse wind conditions. Drallim Aerospace was invited to find a method to minimise the phenomena. Drallim devised the aptly named Storm Chock which proved to be the perfect solution to ensure that the aircraft would be securely moored during high wind/storm conditions. This was then added to our range of Aircraft Chocks for the industry. The Storm Chock Assembly is a combined rubber chock and polyester webbing with attachments that make it suitable for securing both nose and main undercarriage of all size airframes. Each lashing has a load rating of 2000Kg (4409lb). The storm chock is designed to be used lashed together in pairs and tightened using the integral ratchet-tensioning device.Request a Quote Supplied by Drallim Industries Ltd -

Storm Chocks

One of Europe's largest airlines recently highlighted chocking problems in adverse wind conditions. Drallim Aerospace was invited to find a method to minimise the phenomena. Drallim devised the aptly named Storm Chock which proved to be the perfect solution to ensure that the aircraft would be securely moored during high wind/storm conditions. This was then added to our range of Aircraft Chocks for the industry. The Storm Chock Assembly is a combined rubber chock and polyester webbing with attachments that make it suitable for securing both nose and main undercarriage of all size airframes. Each lashing has a load rating of 2000Kg (4409lb). The storm chock is designed to be used lashed together in pairs and tightened using the integral ratchet-tensioning device.Request a Quote Supplied by Drallim Industries Ltd -

Storm Chocks

One of Europe's largest airlines recently highlighted chocking problems in adverse wind conditions. Drallim Aerospace was invited to find a method to minimise the phenomena. Drallim devised the aptly named Storm Chock which proved to be the perfect solution to ensure that the aircraft would be securely moored during high wind/storm conditions. This was then added to our range of Aircraft Chocks for the industry. The Storm Chock Assembly is a combined rubber chock and polyester webbing with attachments that make it suitable for securing both nose and main undercarriage of all size airframes. Each lashing has a load rating of 2000Kg (4409lb). The storm chock is designed to be used lashed together in pairs and tightened using the integral ratchet-tensioning device.Request a Quote Supplied by Drallim Industries Ltd -

Storm Chocks

One of Europe's largest airlines recently highlighted chocking problems in adverse wind conditions. Drallim Aerospace was invited to find a method to minimise the phenomena. Drallim devised the aptly named Storm Chock which proved to be the perfect solution to ensure that the aircraft would be securely moored during high wind/storm conditions. This was then added to our range of Aircraft Chocks for the industry. The Storm Chock Assembly is a combined rubber chock and polyester webbing with attachments that make it suitable for securing both nose and main undercarriage of all size airframes. Each lashing has a load rating of 2000Kg (4409lb). The storm chock is designed to be used lashed together in pairs and tightened using the integral ratchet-tensioning device.Request a Quote Supplied by Drallim Industries Ltd -

Storm Chocks

One of Europe's largest airlines recently highlighted chocking problems in adverse wind conditions. Drallim Aerospace was invited to find a method to minimise the phenomena. Drallim devised the aptly named Storm Chock which proved to be the perfect solution to ensure that the aircraft would be securely moored during high wind/storm conditions. This was then added to our range of Aircraft Chocks for the industry. The Storm Chock Assembly is a combined rubber chock and polyester webbing with attachments that make it suitable for securing both nose and main undercarriage of all size airframes. Each lashing has a load rating of 2000Kg (4409lb). The storm chock is designed to be used lashed together in pairs and tightened using the integral ratchet-tensioning device.Request a Quote Supplied by Drallim Industries Ltd -

Storm Chocks

One of Europe's largest airlines recently highlighted chocking problems in adverse wind conditions. Drallim Aerospace was invited to find a method to minimise the phenomena. Drallim devised the aptly named Storm Chock which proved to be the perfect solution to ensure that the aircraft would be securely moored during high wind/storm conditions. This was then added to our range of Aircraft Chocks for the industry. The Storm Chock Assembly is a combined rubber chock and polyester webbing with attachments that make it suitable for securing both nose and main undercarriage of all size airframes. Each lashing has a load rating of 2000Kg (4409lb). The storm chock is designed to be used lashed together in pairs and tightened using the integral ratchet-tensioning device.Request a Quote Supplied by Drallim Industries Ltd -

Storm Chocks

One of Europe's largest airlines recently highlighted chocking problems in adverse wind conditions. Drallim Aerospace was invited to find a method to minimise the phenomena. Drallim devised the aptly named Storm Chock which proved to be the perfect solution to ensure that the aircraft would be securely moored during high wind/storm conditions. This was then added to our range of Aircraft Chocks for the industry. The Storm Chock Assembly is a combined rubber chock and polyester webbing with attachments that make it suitable for securing both nose and main undercarriage of all size airframes. Each lashing has a load rating of 2000Kg (4409lb). The storm chock is designed to be used lashed together in pairs and tightened using the integral ratchet-tensioning device.Request a Quote Supplied by Drallim Industries Ltd -

Storm Chocks

One of Europe's largest airlines recently highlighted chocking problems in adverse wind conditions. Drallim Aerospace was invited to find a method to minimise the phenomena. Drallim devised the aptly named Storm Chock which proved to be the perfect solution to ensure that the aircraft would be securely moored during high wind/storm conditions. This was then added to our range of Aircraft Chocks for the industry. The Storm Chock Assembly is a combined rubber chock and polyester webbing with attachments that make it suitable for securing both nose and main undercarriage of all size airframes. Each lashing has a load rating of 2000Kg (4409lb). The storm chock is designed to be used lashed together in pairs and tightened using the integral ratchet-tensioning device.Request a Quote Supplied by Drallim Industries Ltd -

Storm Chocks

One of Europe's largest airlines recently highlighted chocking problems in adverse wind conditions. Drallim Aerospace was invited to find a method to minimise the phenomena. Drallim devised the aptly named Storm Chock which proved to be the perfect solution to ensure that the aircraft would be securely moored during high wind/storm conditions. This was then added to our range of Aircraft Chocks for the industry. The Storm Chock Assembly is a combined rubber chock and polyester webbing with attachments that make it suitable for securing both nose and main undercarriage of all size airframes. Each lashing has a load rating of 2000Kg (4409lb). The storm chock is designed to be used lashed together in pairs and tightened using the integral ratchet-tensioning device.Request a Quote Supplied by Drallim Industries Ltd