Plastics – Not To Be Thrown Away But Recycled Properly

2 August 2019Plastics are one of the most useful materials ever discovered. The generic term of ‘plastic’ covers many very different materials. It includes organic materials like cellulose acetate to highly specialised engineering materials like PTFE or carbon fibre. Plastics are used in nearly all industries and are an integral part of some industry sectors such as automobile, medical, aeronautical, electronics, to name but a few. Often the switch to plastics is driven by environmental considerations, e.g. saving of natural resources such as forests, metals, and energy conservation through weight reduction. Plastics are lightweight, easy to process, relatively inexpensive and readily available and because of these benefits, their importance to competing materials is constantly increasing.

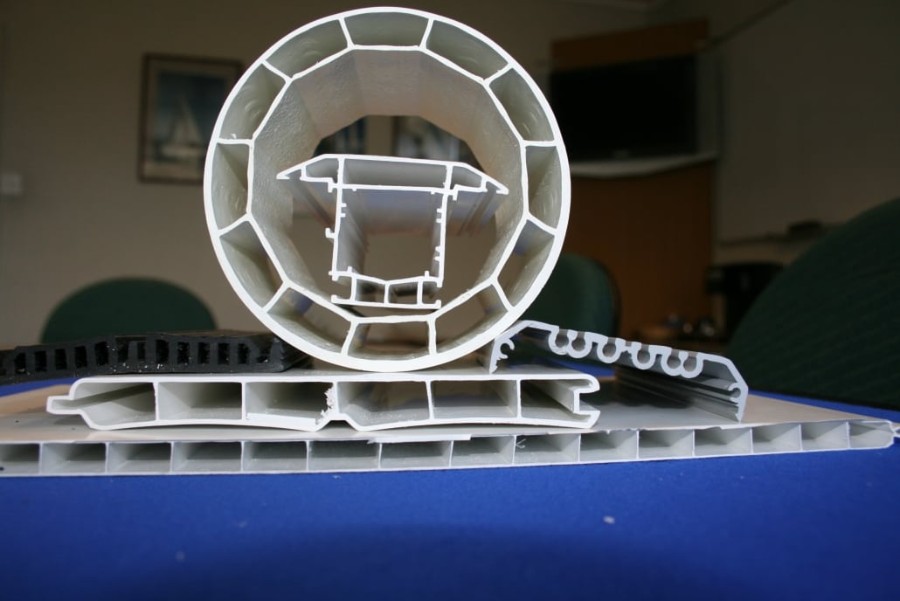

Plastics in different formulations have been with us now for over a century and due to the versatility and usefulness of the materials are here to stay. Nowadays a world without plastics would be almost impossible. For example, there are very few alternative materials that can be used in hospital operating theatres – lightweight and hygienic. PVC is used in buildings for wiring and insulation, UPVC windows replace wood, last longer and do not need to be treated every few years. UPVC windows are easily recycled and the reprocessed material has a good commercial value.

D W Plastics manufactures long-life plastic products and does not make single-use products. Many products are made in UPVC or PVC, the properties of which have excellent sustainability criteria. PVC has also proven to be repeatedly recyclable providing the potential for a further important reduction of its environmental footprint. It is important that recyclability is taken into account from the very beginning, as early as the product design stage. Some plastics are not compatible with each other when recycled, so this should be considered during the design phase of any plastic products.

The European plastics industry, and particularly the PVC industry, is pro-active its approach and commitment to recycling and material development. However, it is a worldwide problem which will involve cooperation from other countries. We are all responsible for the prevention of plastic waste pollution around the globe and must ensure that the waste does not end up in our countryside, rivers and oceans. One of the key elements is education and, organisations, like the United Nations and Greenpeace, and TV documentaries are essential in highlighting and publicizing the damage caused to the natural environment by the various types of pollution. This, in turn, generates important discussions in government, industry, and the general public about how to tackle these issues. We have to recognise that plastics should not be thrown away but should instead be properly reused.