Euroby

Euroby Limited is the leading UK environmental waste equipment provider and well-regarded processing company based in Worthing, Sussex with a workshops/factory in the Midlands. Formed in 1996 to provide consultancy services to the power industry, the level of the group’s technical expertise swiftly led them to diversify into the water and other Industrial sectors including food and beverage, oil and minerals.

Euroby's services have enabled many companies and utilities to improve efficiency, reduce costs and increase the effectiveness of their waste management programmes and food and beverage production.

Our ethic is to fulfil the needs and exceed the expectations of our customers. This is achieved with our “State of the art” products and practices and a high standard of service delivered by skilled employees and suppliers. We see ourselves as a forward-thinking company constantly striving to improve the environment whilst seeking opportunities for further growth through the separation of any solids from liquid(s).

Sludge Dewatering

Euroby Limited is one of the UK's leading environmental waste processing organisations and supplier of products and services to the Water, Power and other Industrial Markets

The company prides itself as being recognised by its clients and suppliers as "the specialists in sludge treatment, dewatering, stabilisation and drying"

In addition to marketing and sales staff, Euroby employs an experienced team of mechanical, electrical, process and project engineers

Centrifuges & Separators

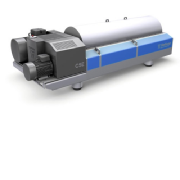

Euroby is the UK Agent for Flottweg SE, supplying the company’s comprehensive range of dewatering and thickening centrifuges and separators for all applications and types of materials.

Flottweg centrifuges are used by industries Worldwide to produce metals, chemicals, pulp and paper, food, power and petroleum products and by municipalities to purify drinking water and treat wastewater.

For more than 60 years our supplier, Flottweg, has been developing and producing extremely powerful and reliable decanter centrifuges, separators, belt presses and systems. They handle key functions in the clarification of liquids, separation of liquid mixtures, and concentrating and dewatering.

Filter Press Plates

Euroby is the exclusive Agent in the United Kingdom and Ireland for Klinkau and Envirotech Filter Plates, which are the worlds leading manufacturers of polypropylene filter plates.

A range of plate types are available with standard recessed or membrane inflation and can be supplied with cloth wash and cake discharge systems.These plates are supplied to all of the leading filter press manufacturers for inclusion in their presses and can be retrofitted into all makes of press, including those currently fitted with rubber steel plates.

Euroby also provide plates as replacement and upgrades on existing presses to end users.

Filter Presses

As part of Euroby’s specialist sludge dewatering portfolio, Euroby supplies, installs and maintains filter press units to meet customer’s individual needs.

Euroby Filter press units manufactured by TEFSA are available in a range of sizes to suit customer’s specific requirement from small manually operated 500mm units to large fully automated 2mtr x 2mtr systems.

Filter press units are available in side bar and overhead designs with a range of plate types and materials to suit all applications.

Belt Filter Presses

The Tefsa range of machines encompasses over 30 years of development and sales in a vast field of dewatering applications – over 2000 units have now been sold world-wide.

The low energy bills and frugal polymer consumption of belt dewatering systems appeals to the cost conscious, without compromising on performance or reliability. This, combined with very low operator input requirements make them ideal for today’s streamlined processes.

Flottweg belt presses are used for the continuous separation of liquid from different solid-liquid mixtures and are specifically designed and constructed from materials – entirely of food grade stainless steel, thereby providing high hygienic standards and long term durability.

Submerged Air Filtration Systems

Our Submerged Air Filtration Systems offer effective reduction of B.O.D, both in municipal and industrial applications.

The I-SAF and SAF cover applications for PE’s of between 50 and 3000 and Euroby can also supply turnkey hire equipment for applications up to 1000PE.

Belt Conveyor Systems

Euroby offer a belt conveyor system which although particularly suitable for the Water Industry will also convey most granular materials and types of cake.

Euroby is an Appointed Distributor of the renowned Easikit range of modular trough and roller belt conveyors – uniquely designed having the benefit of 20 years of research and hands on experience in the conveyor industry. Conveyors are supplied in various lengths to suit nearly all applications – horizontal, inclined, permanent or mobile; fixed discharge or slewing and/or elevating.

Lime stabilisation

Lime stabilisation systems are manufactured in house by Euroby.

The equipment is supplied either as compact, self-contained units with integrated silo and mixer, or as individual components, depending on site constraints.

Each system utilises weighing facilities to accurately measure the amount of burnt lime to be mixed with the incoming sludge cake.

Lime dosing is controlled automatically, enabling the correct dosing levels to be maintained despite fluctuating levels of sludge cake.

The systems are sufficiently adaptable to allow them to be retrofitted into areas with limited space, or where planning restrictions prevent the installation of full height silos.

Sludge Drying

Euroby Ltd provides stand-alone equipment through to turnkey plant delivery including design, finance, construction, build, installation, start up and contract operation.

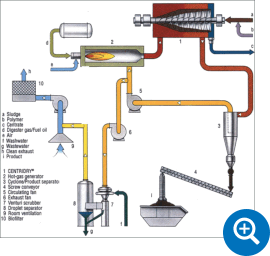

The belt dryer was developed to dry various sludges in a simple, energy efficient and dust free way to d.s contents of 65% to 95%. The mechanically dewatered sludge is extruded on to the perforated belt where it is conveyed slowly through the drying zone and discharged at the end of the conveyor. The retention time can be adjusted very accurately such that homogeneous drying is achieved.

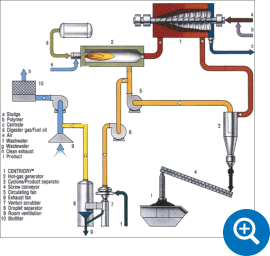

The CENTRIDRY® enhanced dewatering process offers a unique single stage process combining mechanical dewatering and thermal drying in a single compact machine with a small footprint.

Mobile Dewatering

Euroby operates a large fleet of mobile and semi-mobile dewatering and thickening decanter centrifuge, filter press and belt press units with throughputs of between 5m3 and 120m3/hr. The range enables the company’s experienced operators to successfully process the most difficult of materials and liquid wastes from a variety of sources including but not restricted to the water, municipal (sewage), food, soil, dairy, pharmaceutical, petrochemical, brewing, animal feeds, tannery, biofuels and quarrying industries.

Effluent Treatment

For more information on industrial effluent treatment please contact Euroby or visit our website Euroby.com