Flair Electronic Systems Limited

The Flair team has experience in all aspects of cable assembly and cable looms including solder (leaded/lead free), IDC and crimp for all terminations and housings. We work to IPC 620 administered by our in house trainer.

We are able to be as flexible as you need so cables can range from a few millimetres to 20m long and can be built entirely to your specifcation of cable and markings, one off up to thousands. We can produce drawings/loom boards for you or we can work to your designs.

Wires are automatically cut to length and crimped with JST, AMP, FCI and MOLEX crimps on our crimp machines.

RF and COAX cables can be made cost efficiently with our programmable coaxial cable preparation machine giving us particular RF cable capability.

We have the ability to fit the following connectors:

- MIL5015, MIL38999 from several manufacturers & other circular styles

- Push pull connectors; ODU, Lemo, Fischer

- D types, DIN, Mini DIN, Micro D, Hirose, Jack and other AV connectors

- RJ45, USB, CAT5/6 and other data connectors

- BNC and all standard RF connectors

- Molex KK, ribbon cables, and other crimp Board to cable connectors

- Harting, ILME, IEC320 and other power connectors

- Standard spade, ring terminal and other crimps in various wire sizes.

100% testing with our CIRRIS tester for point to point and insulation strength.

The Total Solution: Manufacturing Solutions

Our manufacturing solutions enable customers to save time and money.

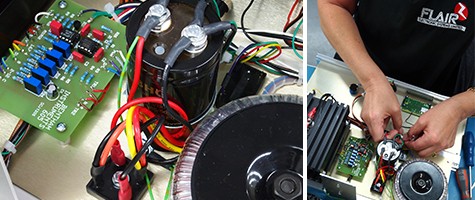

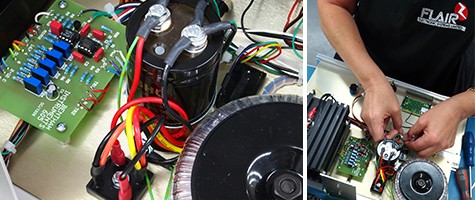

All box build assemblies are bespoke and our highly experienced production engineering team makes sure our customers are up to date with progress at each step. At Flair manufacturing solutions projects are produced in a specially allocated area in our workshop so production is streamlined and highly efficient.

Solutions for specific requirements

We can produce manufacturing solutions to meet very specific requirements including sourcing and manufacturing, sub-assembly or final product assembly, low, medium or high volume – whatever is required.

Our capabilities include:

- Mechanical box build assembly

- Panel assembly

- Wiring and crimping

- Visual inspection

- Product testing and calibration

- Soak testing facilities

- PAT testing services

- Stock holding facilities

- Design and manufacturing

- Sourcing and procurement

- Chassis build and box build

- Sub-assembly and final product assembly

- Enclosure wiring and enclosure assembly

- Electrical control box assembly

Our local sheet metal partner produces panels, chassis and gland plates as well as boxes in standard box forms and in 19” rack and sheet metal work can be in steel, stainless steel, zinctec, galvanised steel, brass, copper, and aluminium with a range of surface finishes.

We work to IPC 620/WHMA-A-620 and ISO9001: 2008 so you can be sure of our quality standards and procedures.

Give us a call to discuss your project.

PCB Assembly

We work closely with a local PCB partner so our customers can rely upon Flair’s management and attention to detail. PCB capabilities include:

- Single, double sided, multilayer boards with various copper thicknesses and plating

- FR4, flexible circuit and IMS (metal clad boards) for various applications

- Boards up to 1600mm x 400mm in size

- Through hole parts or surface mount parts routinely down to 0201

- ISO9001: 2008 and IPC610

- Leaded and Lead free

- Special capability in LED

- AOI (Automatic Optical Inspection) and BGA inspection, extensive test capability.

We are confident that even the most complicated boards can be produced for integration into enclosures and are happy, as part of the total build, to receive your Gerbers, drill files, BOMs and PCB specs to include PCBs into the total project. We can help with the design and manufacture of PCBs too.

CNC Machining

If you need custom turned parts or machined metal plates or assemblies, Flair can help. This is particularly useful if you need a cylindrical sensor probe, a special clamp, a machine mechanism or for making durable test rigs for holding components under test. These services enable us to provide a total solution for test, machinery, aerospace and medical industries.

- From one-off prototypes for test rigs or bespoke machines up to runs of thousands for series production

- In all standard materials, metals and plastics up to aerospace grade

- Turned parts up to 50mm/2” in diameter for CNC bar turning, 300mm/12” diameter for conventional turned parts

- Machined parts up to 600mm x 500mm x 500mm

- Ideal for custom back shells of connectors, box machining, test rig plates and assemblies, optical test beds and automation mechanisms

- Plating and other surface finishes on request.

Give us a call to talk through your total solution requirements.

Design Service

Flair can solve problems and challenges whether you need electronic design, PCBs, PLCs or micro controllers programmed. We can support mechanical design too.

CAD design

We can design in 3D CAD and produce build to print drawings for any products.

Harness and cabinet drawings

Produced and printed to scale from 2D/3D CAD along with wiring diagrams and ladder logic programs.

PCB Information

We are able to design PCBs from supplied circuit diagrams and specifications or if you prefer to supply all the design files we can arrange for the PCBs to be made.

Programming

Devices can be programmed on request, please contact us to discuss your needs.

Design Process

We can support you at any or all of the stages below.

Requirements analysis

The requirements will be agreed and validated with you

Feasibility

Calculations can be performed, ‘Lash ups’ made and investigations carried out, to test whether the project is feasible.

Design

Including circuitry, PCB layouts, BOMs etc. For cabinets and harnesses we create wiring diagrams, loom drawings and with ladder logic.

Prototyping

Built to production standards. Pre-production work can be carried out and long lead time items sourced.

Compliance

EU products need a CE mark, meeting Low Voltage, Machinery, EMC, WEEE and ROHS Directives, by external testing and a technical file. Our experience will ensure your product meets requirements.

Production

Finally production commences. We monitor procurement to handle obsolescence.