Fleming Polymer Ltd

Fleming Polymer Testing & Consultancy is an independent test-house offering the outsourcing of specialised analytical polymer testing facilities to the polymer industry. The business is dedicated to solving polymer problems through sophisticated testing, high level consultancy and process simulation. Our customers, most of whom are household names, are of course the cornerstone of the business, and to this end we appreciate the need to provide rapid solutions.

We deliver value added benefits, which serve both to protect and increase profitability and operate to ISO 9001:2008. The company has been operating for over 15 years, has won a DTI Smart award and been granted a patent for rheometry design.

The company has worked with industry leaders such as; GlaxoSmithKline, BD, Exxon, Uponor, Malvern Instruments, Tyco, TIAutomotive, NPL, Moldflow and Victrex to name but a few. Test Specialisms include;

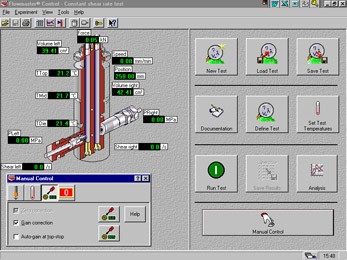

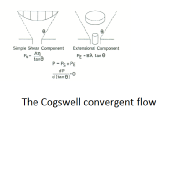

- Capillary Rheometry

- FTIR

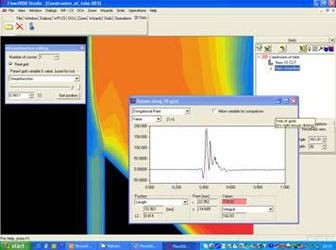

- Extrusion Flow Simulation

- MFR/MVR

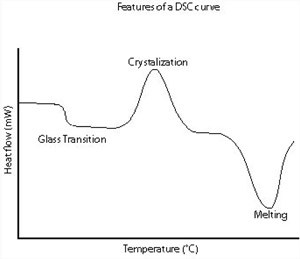

- DSC

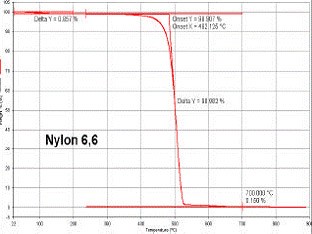

- TGA

- Instrumented Impact

- Elongational Viscosity

- Compuplast VEL distributor

Filter products and services

-

Instrumented Impact Testing

Impact testing today constitutes an important end product and fit for purpose test. Following manufacture many products will experience some form of service impact specific to their environment, it is the aim of the impact tester to replicate these service impacts in order to assess their fitness for purpose. The system can be used for:

- Polymers

- Polymer composites

- Metals

- Ceramics

Our Rosand IFW413 instrumented falling weight impact tester has features including:

- Tower Height: 1.3m

- Maximum available impact velocity: 5m/s

- Energy Range: 0.05 to 200J

- Force range: 10 to 50,000N

- Data acquisition: 12bit resolution, 670ksamples/s, 4000 data points

- Temperature controlled environment

For more information, please see our video.

Request a Quote Supplied by Fleming Polymer Ltd -

Polymer Impact Testing

Impact testing today constitutes an important end product and fit for purpose test. Following manufacture, many products will experience some form of service impact specific to their environment, it is the aim of the impact tester to replicate these service impacts in order to assess their fitness for purpose. Impact testing is generally governed by standards which cater for a wide range of materials. One of the most well known standards is ISO6603-part 2 which covers instrumented impact, our area of expertise. Non-standard testing can also be accomodated for sub-assemblies provided the requisite jigs are used.Request a Quote Supplied by Fleming Polymer Ltd