Fleming Polymer Ltd

Fleming Polymer Testing & Consultancy is an independent test-house offering the outsourcing of specialised analytical polymer testing facilities to the polymer industry. The business is dedicated to solving polymer problems through sophisticated testing, high level consultancy and process simulation. Our customers, most of whom are household names, are of course the cornerstone of the business, and to this end we appreciate the need to provide rapid solutions.

We deliver value added benefits, which serve both to protect and increase profitability and operate to ISO 9001:2008. The company has been operating for over 15 years, has won a DTI Smart award and been granted a patent for rheometry design.

The company has worked with industry leaders such as; GlaxoSmithKline, BD, Exxon, Uponor, Malvern Instruments, Tyco, TIAutomotive, NPL, Moldflow and Victrex to name but a few. Test Specialisms include;

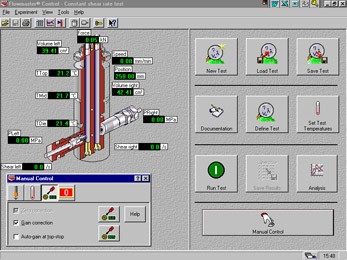

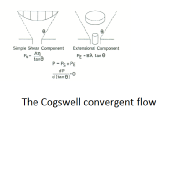

- Capillary Rheometry

- FTIR

- Extrusion Flow Simulation

- MFR/MVR

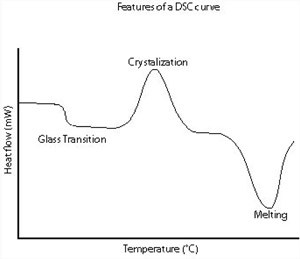

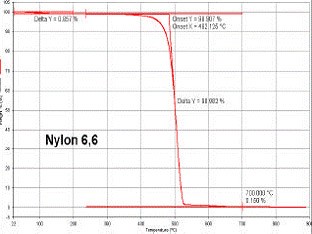

- DSC

- TGA

- Instrumented Impact

- Elongational Viscosity

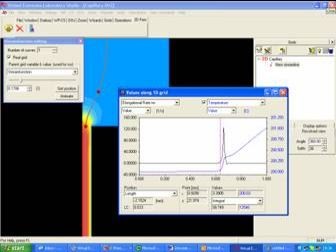

- Compuplast VEL distributor

-

New Germanium crystal ATR enhances identification service

26 April 2016A new GeATR has been added to the FTIR facility. This important addition greatly improves the ability of the spectrometer to investigate materials with a high carbon black content. Clearly, this expands the system capabilities enabling a wide range of rubbers, both natural and synthetic, as well as many filled TPE's to be investigated. The system was purchased in order to overcome the shortcomings of the diamond ATR when dealing with these strongly IR absorbing materials. These types of materials are seeing increased use in extreme environments due to their inherent chemical and physical resistance.

In keeping with ATR analysis, the GeATR is able to inspect very small quantities of sample with little to no preparation. The figure shows part of an unknown material being scrutinized.

The germanium crystal has a different refractive index to that of diamond (essentially the workhorse ATR crystal) and has a shallower surface penetration depth allowing ATR analysis with no band distortion to overcome the often difficult quantitative analysis of strongly infrared absorbing materials such as carbon black filled rubbers and TPE's.

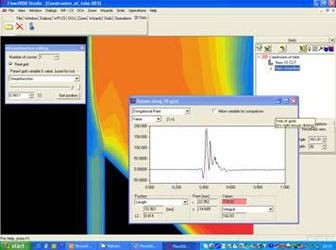

Following their US sister company, Zip-Pak UK recently purchased the Compuplast Profile Die module for the optimisation of their profile dies. Don Fleming is seen during the training advising on the balancing of a die. Most profile dies behave poorly because of cross flows. Cross flows occur when visco-elastic polymers move laterally inside a die and then relax in an unpredictable manner. The usual way out of this problem is to manually tune the latter plate/s via machining, but it is time consuming and the resulting dies often only work over a limited processing window and are machine and polymer specific. The Compuplast software enables the designer to avoid these flows and thus produce balanced dies in less time and with less manual tuning.