FTL Technology Ltd

FTL Technology delivers custom engineered solutions for critical applications.

Across a wide range of industries, from oil and gas through to food and pharmaceuticals, our experienced team of engineers will optimise the efficiency of your business by resolving problems based around leakage, friction and wear.

From single components to complete sealing systems, FTL Technology focuses on the needs of the customer as well as the application. This allows us to deliver excellence as standard across every project we undertake. Whatever your sealing challenge, our team has the experience and hte expertise to deliver a precision engineered solution.

Filter products and services

-

Bearings (carbon)

Carbon/Graphite bearings are an excellent solution in demanding applications. FTL Technology's range of materials are able to offer operation at high temperatures and are completely self-lubricating. This specialist bearing material allows operation in aggressive chemicals and when compared to conventional bushing materials is able to offer extended life, full dry run capability and superior dimensional stability. The material is available in numerous different grades to suit the application conditions. The backbone of each grade is a self-lubricating matrix of Carbon and Graphite, contained within this matrix are metal fillers, which provides strength and additional mechanical properties to the material.Request a Quote Supplied by FTL Technology Ltd -

Bearings (composite)

FTL Technology offers a range of composite bearings manufactured from thermosetting resins reinforced with synthetic fibres. They include a solid lubricant for applications that are either dry running or have only marginal levels of system lubrication. Bearings contain either graphite, PTFE or molybdenum disulphide, dispersed evenly throughout the material so that surface wear continually releases additional lubrication. FTL's composite bearings are highly recommended for use where traditional types of lubricant are not permitted, or are intermittent.

Bearings from FTL Technology offer a good level of chemical resistance, compatible with many process liquors and solvents to be used as lubricants. Light or heavy mineral oils, vegetable oils, soluble oils and greases are satisfactory as lubrication media. The surface texture of a resin bonded composite material helps to retain lubricant and as a consequence, maintains a continuous lubrication film on the working surface.

Request a Quote Supplied by FTL Technology Ltd -

Bearings (Glycodur)

Glycodur® dry sliding bearings are a cost effective, press fit bearing system that are suitable for a wide range of applications across multiple industries. They offer an excellent combination of low friction and high load bearing capacity which give them universal appeal to designers and system specifiers.

Request a Quote Supplied by FTL Technology Ltd -

Bearings (plain)

FTL Technology offers a range of plain bearings that are predominantly used in reciprocating applications but can also be used as a rotary or swivel bearing solution. In most cases, plain bearings are able to operate without additional lubrication and so offer a high degree of design flexibility to the designer. Being able to operate in temperatures ranging from -250°C/-418°F to +400°C/752°F makes plain bearings a perfect solution in high temperature or cryogenic applications. Static loads up to 250N/mm² can be achieved along with low friction of dynamic and break away friction.

Request a Quote Supplied by FTL Technology Ltd -

Bearings (polyester)

Polyester bearings are suitable for reciprocating and some rotating applications with the advantage of being non galling and sacrificial. The bearing wears rather than the mating shaft or cylinder, saving costly replacement of the mating parts. Polyester bearings are easier and cheaper to change when worn and can be supplied in a split form for reciprocating applications such as hydraulic cylinders.

Polyester bearing are typically more heavy duty than PTFE bearings.

Request a Quote Supplied by FTL Technology Ltd -

Bearings (PTFE)

PTFE bearings are ideally suited to applications where low friction and dry running are important. PTFE bearings provide a wide operational temperature range (-260?C to +260?C) and are commonly used in a wide variety of lubricated applications and because of their excellent chemical resistance.

PTFE bearings exhibit very low levels of dynamic friction and virtually zero stick slip characteristics combined with excellent mechanical properties, good dimensional stability and very low water absorption.

PTFE bearings can be manufactured with various fillers, and combinations of fillers, added to the base material which allows FTL to offer solutions which are tailored to the application parameters and manufacturing volumes in question.

Request a Quote Supplied by FTL Technology Ltd -

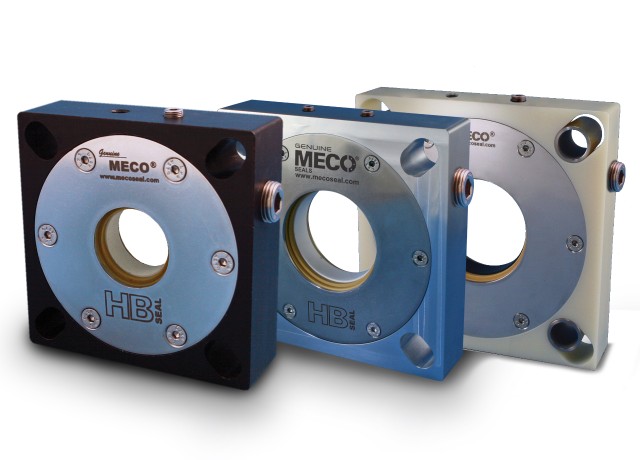

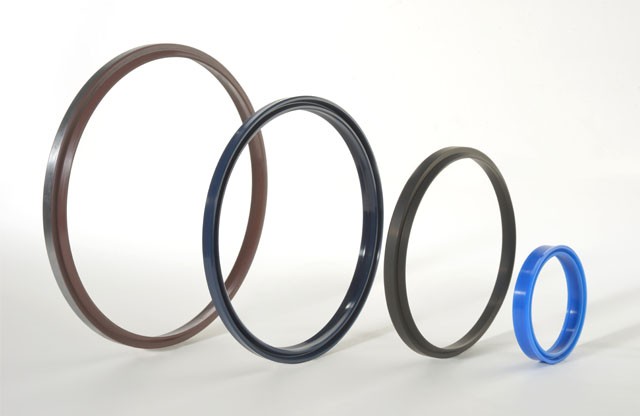

CTI Seals

FTL Technology's CTI seals push the performance barriers of efficiency and reliability to new limits, which allow our products to be experienced by a worldwide customer base. Efficient and reliable rotary seals are at the heart of successful CTI systems. FTL manufacture a range of seal designs for hub reduction and through-drive systems. Each seal can operate dynamically with system pressures up to 10 Bar. High sealing efficiency and excellent oil/air separation give CTI seals from FTL Technology class leading performance.Request a Quote Supplied by FTL Technology Ltd -

CTI Sleeves

Seals are only reliable if the surrounding interface permits them to be so. Providing the ideal tribological and topographical surface conditions is a pre-requisite for a reliable rotary seal system. FTL Technology has developed a solution which not only provides the ideal running surface for the seal, but also gives outstanding corrosion resistance. CTI sleeves in military vehicles are vulnerable to surface corrosion if the air passage becomes contaminated with moisture or water.Request a Quote Supplied by FTL Technology Ltd -

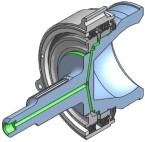

CTI System

FTL Technology's central tire inflation system is an automated pressure control device that enables the user to make rapid adjustments to tire pressures from within the cab whilst the vehicle in is motion.Request a Quote Supplied by FTL Technology Ltd -

Customised Sealing Solutions

FTL Technology has experience of sealing markets that spans over 30 years. During this time, it has built an enviable reputation for creative and innovative seal solutions that add value to products by utilising the latest technologies and materials. Designing custom seal systems which are perfectly aligned to the requirements of an end product is a key component to ensure maximum performance and reliabilityRequest a Quote Supplied by FTL Technology Ltd