FTL Technology Ltd

FTL Technology delivers custom engineered solutions for critical applications.

Across a wide range of industries, from oil and gas through to food and pharmaceuticals, our experienced team of engineers will optimise the efficiency of your business by resolving problems based around leakage, friction and wear.

From single components to complete sealing systems, FTL Technology focuses on the needs of the customer as well as the application. This allows us to deliver excellence as standard across every project we undertake. Whatever your sealing challenge, our team has the experience and hte expertise to deliver a precision engineered solution.

Filter products and services

-

Cylinder Hydraulic Seal Kits

FTL Technology has a distinguished pedigree as a sealing and engineered solutions provider. For over 30 years, FTL Technology has been working closely with their strategic partners bringing advanced sealing technology into factories and offices around the world. Our reputation is built on our unique ability of being able to offer standard solutions from stock as well as a consultative service for more complex and demanding applications. This gives FTL Technology a platform to help more businesses from a greater range of industrial backgrounds. Our sealing solutions help customers manufacture more reliable products or operate their equipment with greater productivity and efficiency.Request a Quote Supplied by FTL Technology Ltd -

Elastomer Mouldings

FTL Technology offers specialist precision moldings in a wide range of high performance elastomers, including organic and inorganic elastomers such as silicone, fluorosilicone and liquid silicone. In addition, FTL Technology can offer rubber to metal composite solutions typically used in bump stops and vibration control. Competitive tooling and piece prices in conjunction with our molding expertize, allow us to provide the most cost effective solutions without compromising performance. Applications vary from standard and non-standard O rings operating in extreme temperatures and chemically aggressive environments, to bespoke custom-designed technical moldings in high specification materials.Request a Quote Supplied by FTL Technology Ltd -

Freundenberg Sealing Technologies

FTL Technology has worked closely with Freudenberg Sealing Technologies for over 30 years. As a leading supplier of sealing and vibration control technology, Freudenberg Sealing Technologies helps FTL provide Sealing Solutions to a wide range of industrial applications. This partnership was endorsed in 2009 when FTL was awarded Preferred Distributor status to reflect their success in providing customers with outstanding service and product support. The partnership was further strengthened when FTL became an exclusive Heavy Industry Partner to acknowledge FTL's expertise and knowledge of heavy duty sealing applicationsRequest a Quote Supplied by FTL Technology Ltd -

Heavy Duty Rotary Seals

FTL Technology has long been a supplier of heavy duty rotary seals into the steel, marine, paper and power industries. Our knowledge and experience of these sectors coupled with our appetite for solving sealing problems, makes FTL Technology an ideal partner to work with. Our product solutions are specified as original equipment for reliability and performance or into the MRO market in response to customers wishing to improve the reliability of their equipment. Seals are manufactured in NBR, HNBR and FPM compounds to suit all operational and ambient conditions. Seal geometries are available which can withstand pressures up to 5 Bar (72 PSI) and peripheral speeds up to 40m/sRequest a Quote Supplied by FTL Technology Ltd -

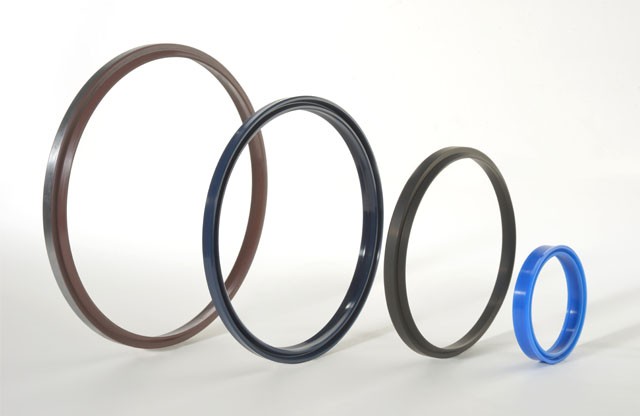

Hydraulic Seals

FTL Technology supplies hydraulic sealing solutions for light, medium and heavy duty industrial applications; manufactured from NBR, FKM, PUR and filled PTFE materials for use with standard mineral based hydraulic oils.

FTL Technology has decades of hydraulic seal experience across several industrial markets. Our product know-how and understanding of the market allows us to specify the correct material and implementation for the needs of any application.

Request a Quote Supplied by FTL Technology Ltd -

Industrial Rubber Seals

FTL Technology's high quality products and materials are designed to meet all critical requirements necessary for use in various industrial applications. FTL provides sealing components for food manufacturing and processing equipment, pharmaceutical handling equipment, bio-medical and analytical equipment, industrial machinery, pumps and valves.Request a Quote Supplied by FTL Technology Ltd -

Laminar Rings

FTL Technology is a sealing specialist providing a complete design, development and manufacturing service across all industry sectors. FTL's fully engineered sealing solutions, combined with responsive service and technical expertize, add value to your product or process by optimizing operational performanceRequest a Quote Supplied by FTL Technology Ltd -

Large Size Seals

FTL Technology is a leading authority when it comes to providing engineered solutions using PTFE. Our range of materials and design capability allow us to provide innovative products to operate reliably in the most demanding of applications.Request a Quote Supplied by FTL Technology Ltd -

Magnetic Flow Filters

FTL Technology Magnetic Flow Filters are the most effective means of removing problem ferrous particles in advanced fluid conditioning. Using magnetic field effect technology, Magnetic Flow Filters reduce operating costs and simultaneously benefit the environment. FTL Technology know that oil filtration in automotive and industrial machinery is essential to achieving optimum performance, reliability and longevity. Through its unique patented design, Magnetic Flow Filters remove ferrous contaminant particles of less than one micron from a variety of fluids. This includes the smallest and most abrasive particles that are responsible for the destructive chain reaction of wear in many processes.Request a Quote Supplied by FTL Technology Ltd -

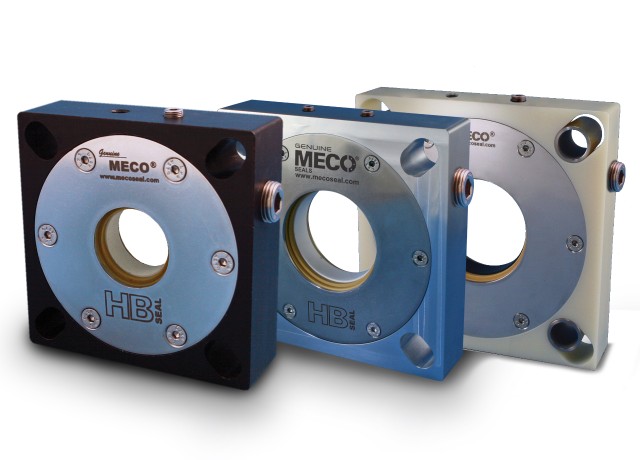

Mechanical Face Seals

Mechanical face seals are synonymous with heavy duty rotary sealing applications. They are specifically designed to operate in environments where there is a high level of external contamination such as mud, sand, dirt and water. Their robust simple design can be packaged neatly into a wide variety of equipment where reliability and a long service life are imperative to ensure end user satisfaction.Request a Quote Supplied by FTL Technology Ltd